Fein MSfv 649 User manual

Other Fein Grinder manuals

Fein

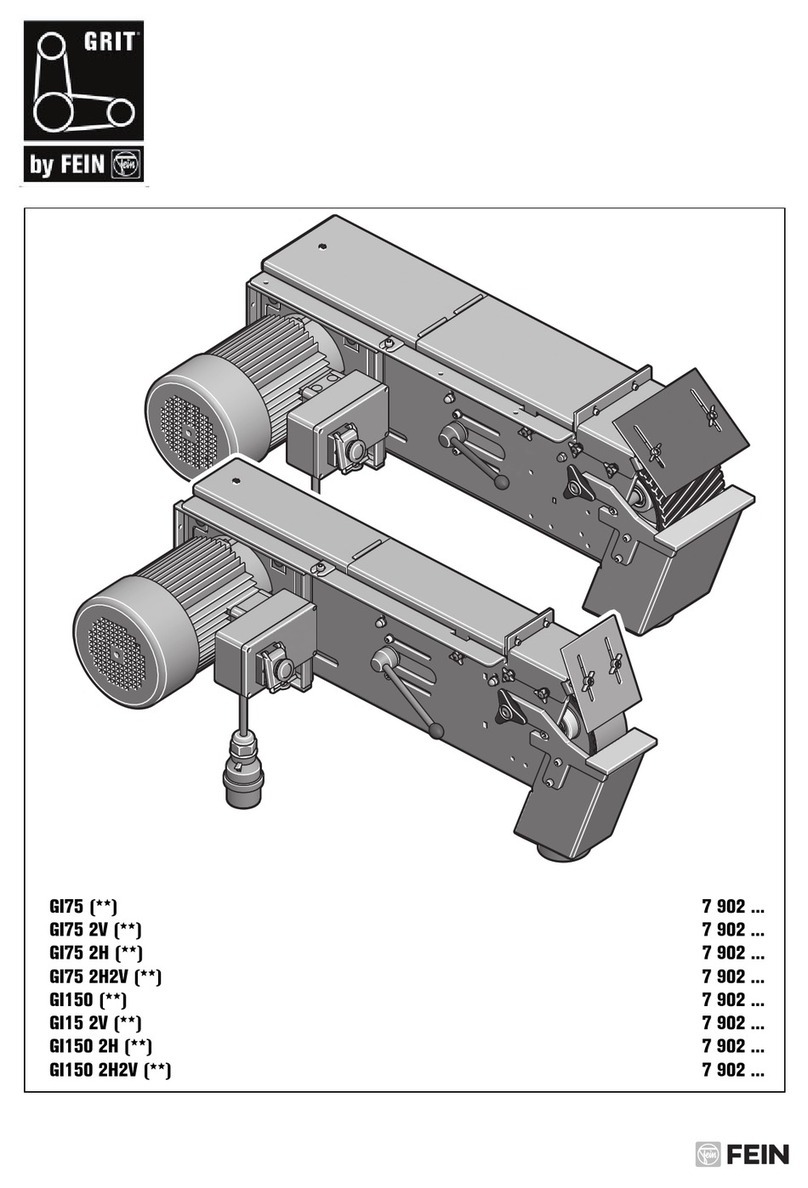

Fein GRIT GKS75-1,5KW User manual

Fein

Fein AGSZ18-280BL User manual

Fein

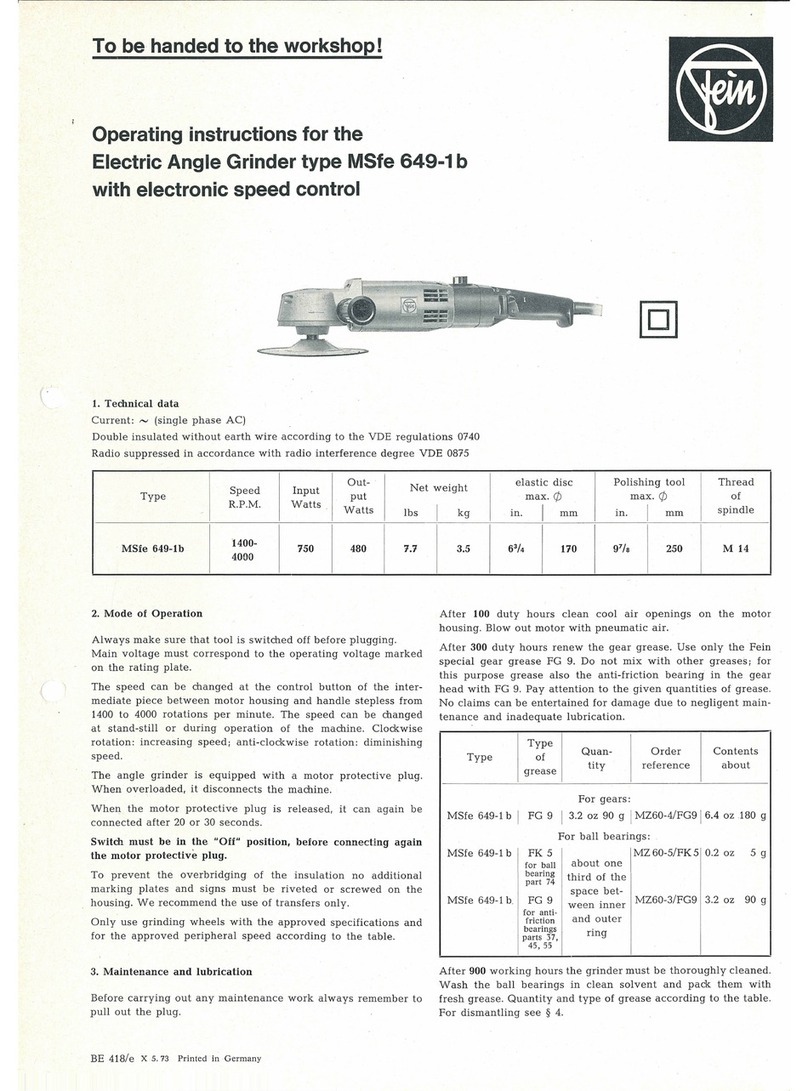

Fein MSfv649-1 User manual

Fein

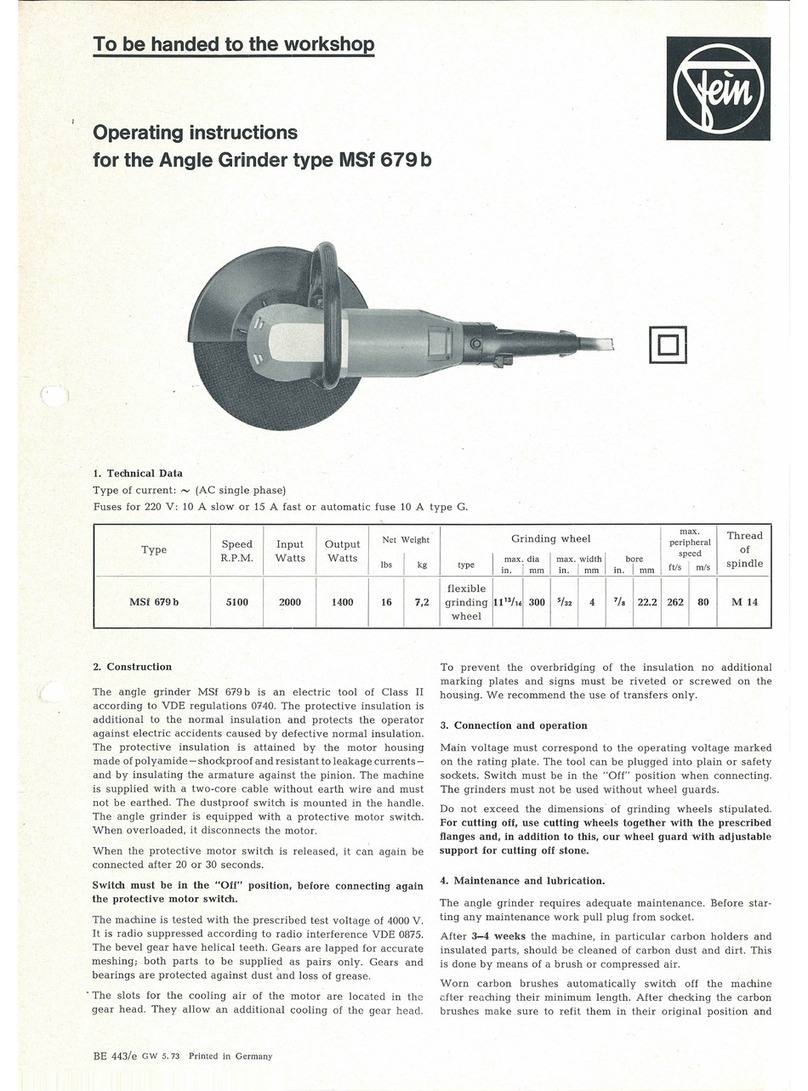

Fein MSf 679 b User manual

Fein

Fein 7 820 86 User manual

Fein

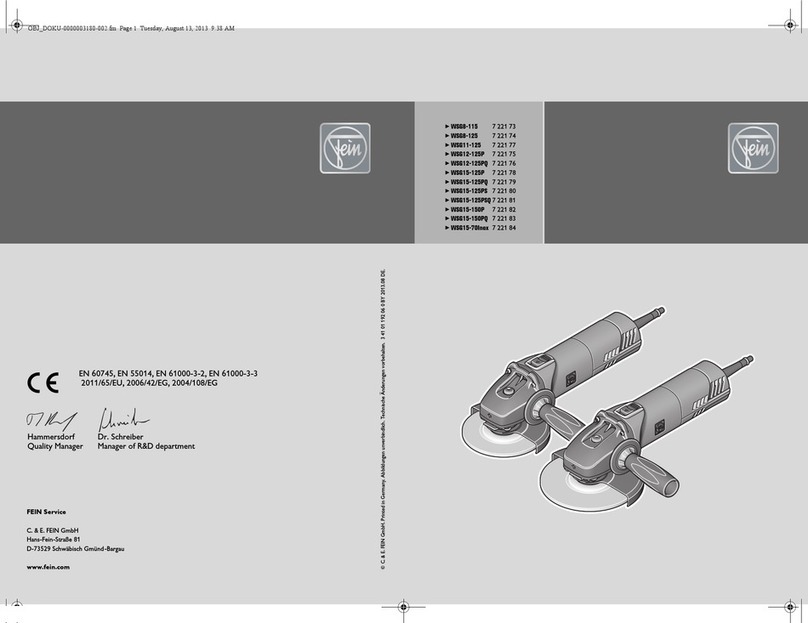

Fein WSG8-115 User manual

Fein

Fein WSG14-125 User manual

Fein

Fein GRIT GHB 15-50 User manual

Fein

Fein WSG10-115T User manual

Fein

Fein MSfe 649-1 b User manual

Fein

Fein CCG18-115 BL User manual

Fein

Fein MShy 664 User manual

Fein

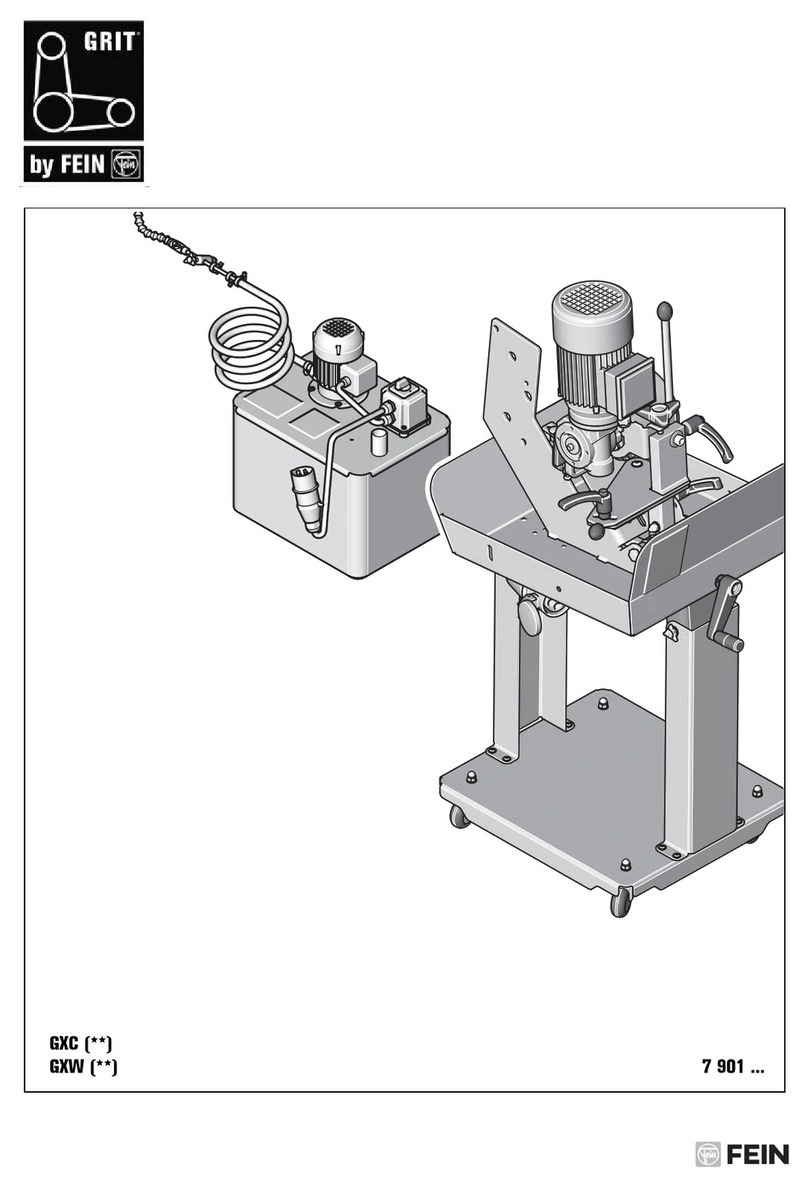

Fein GRIT GXC Series User manual

Fein

Fein CCG 18-115 BL Setup guide

Fein

Fein Grit GIC Series User manual

Fein

Fein AGSZ18-280BL User manual

Fein

Fein GSZ8-280P Setup guide

Fein

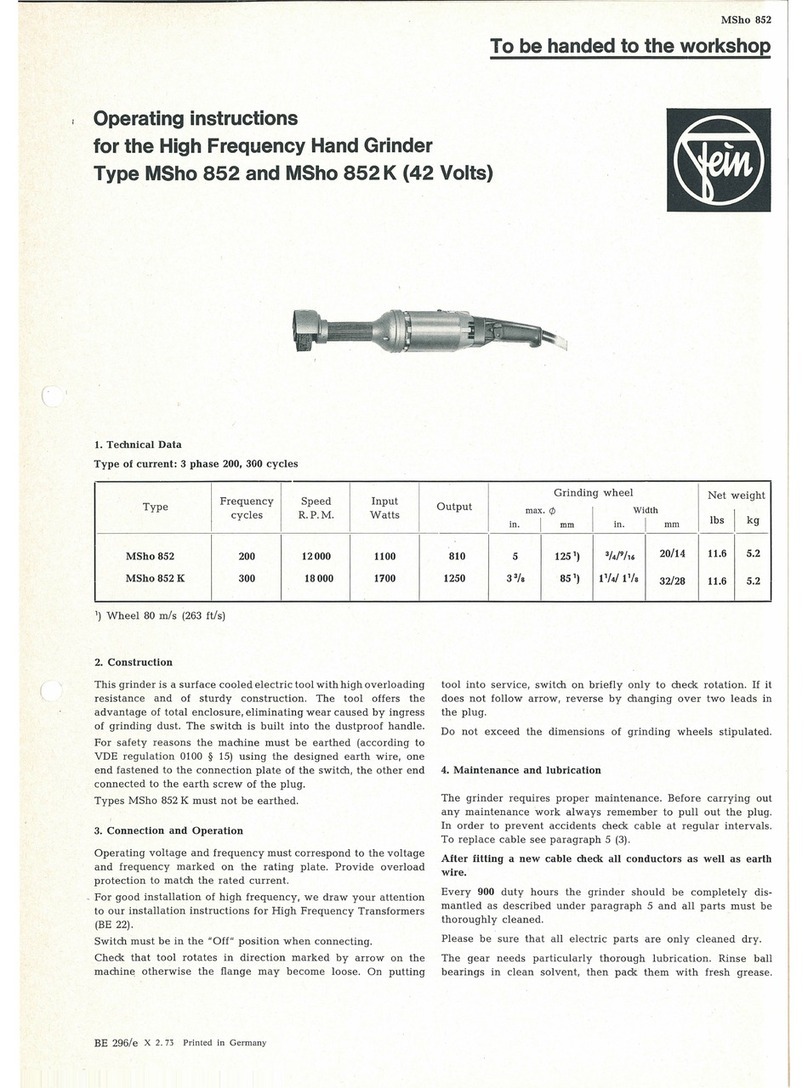

Fein MSho 852 K User manual

Fein

Fein MSho852-1ZV User manual

Fein

Fein GRIT GICS User manual