Bernard Controls AQ Series User guide

Other manuals for AQ Series

1

This manual suits for next models

3

Table of contents

Languages:

Other Bernard Controls Switch manuals

Popular Switch manuals by other brands

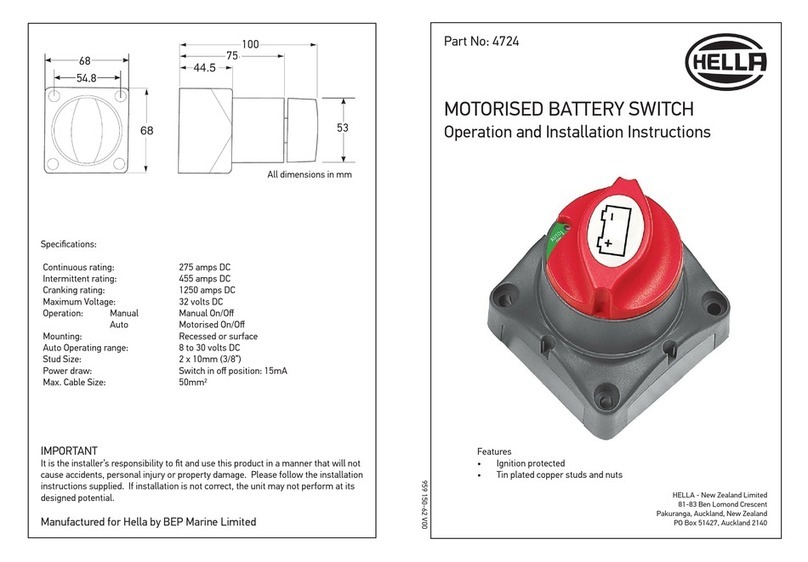

Hella

Hella 4724 Operation and installation instructions

schmersal

schmersal AZM201Z-CC-T-1P2PW-2719-1 Operation and assembly instructions

ZyXEL Communications

ZyXEL Communications PRESTIGE 128MH user manual

EMC

EMC Connectrix B Series Hardware reference manual

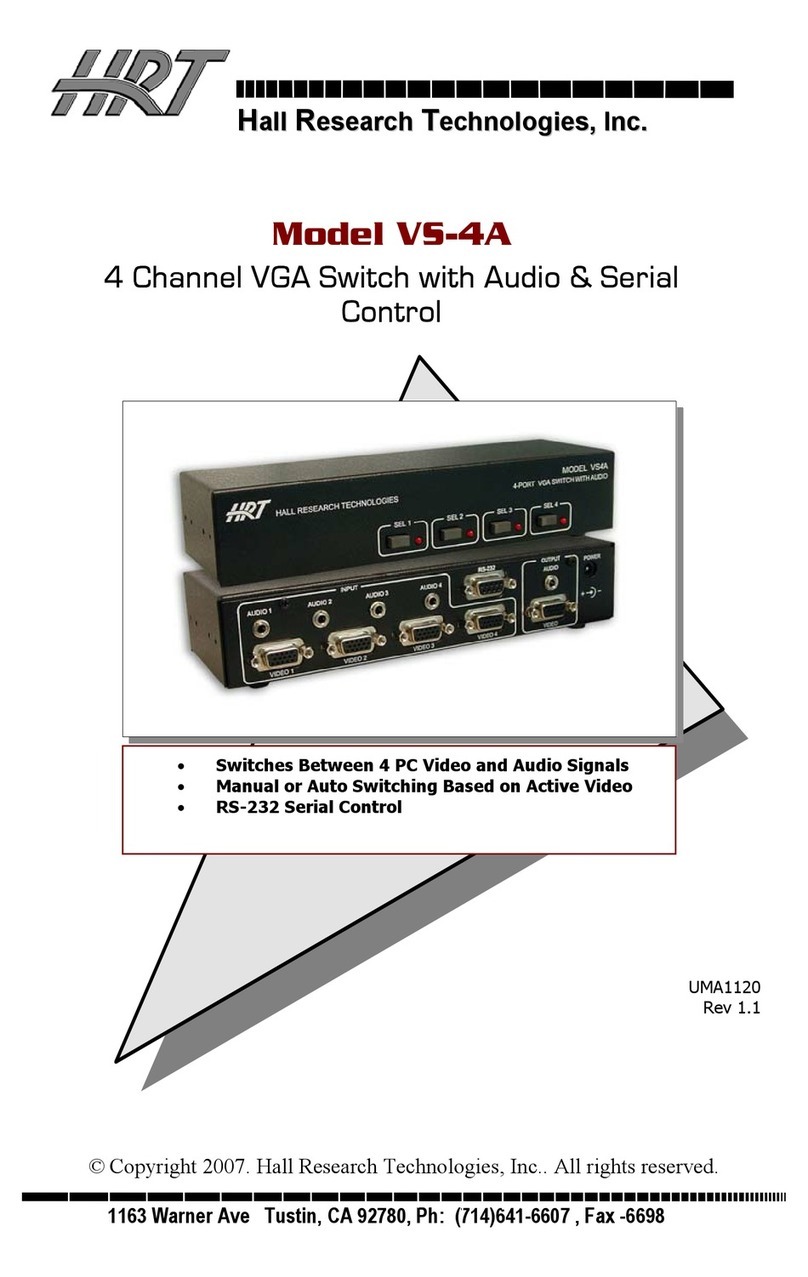

HRT

HRT VS-4A user guide

Extreme Networks

Extreme Networks Summit X150 Series Hardware installation guide

Intermatic

Intermatic ET100 SERIES Programming manual

ITT

ITT NEO-DYN 132T Installation and operation manual

schmersal

schmersal AZ 200 operating instructions

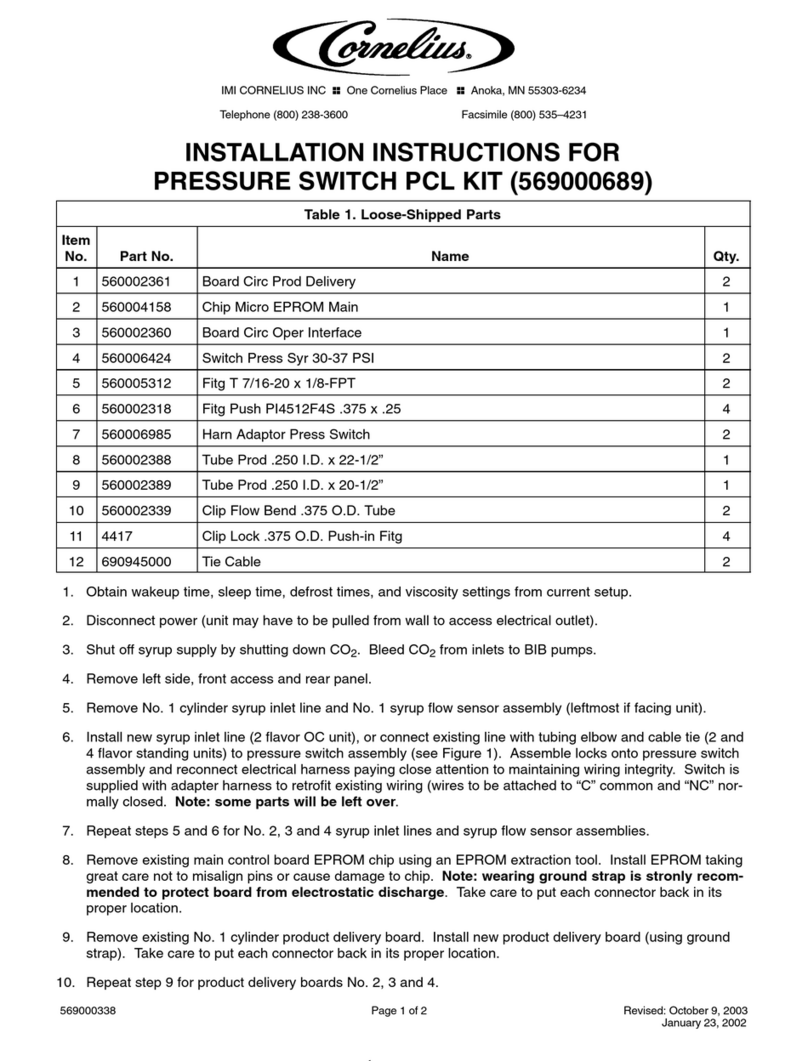

Cornelius

Cornelius 569000689 installation instructions

HP

HP A7500 Series Configuration guide

Safe Living Technologies

Safe Living Technologies NEFA 20-plus F/1 installation guide