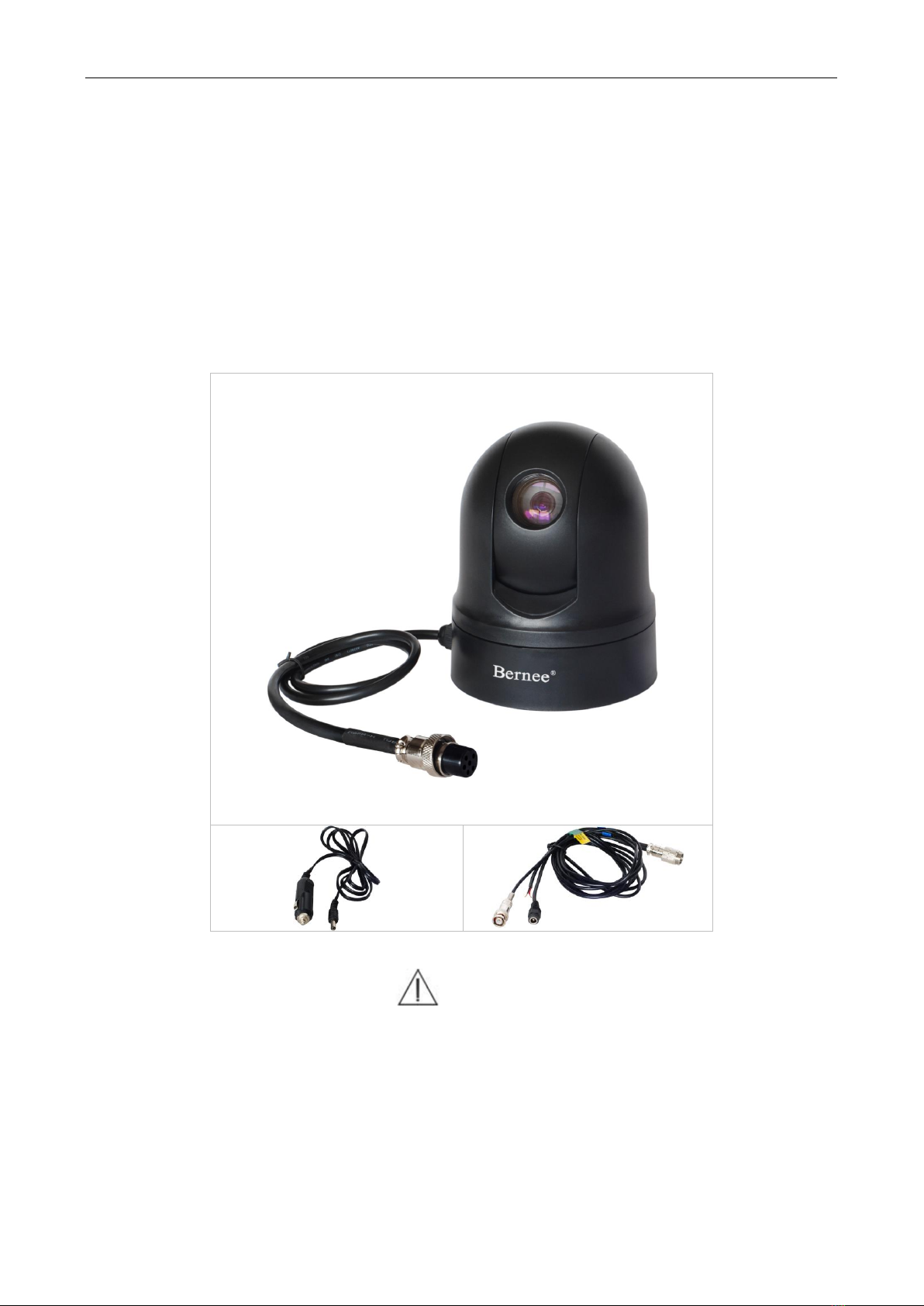

Bernee BN-5606XCAR User manual

Bernee®

1/ 13

Vehicle Speed Dome User Manual

BN-5606XCAR

DC 12V

Berneeproduction

----------------------------------------------------------------------------------------------------------

Please read this User Manual carefully to ensure that you can use the device correctly and safely.

Bernee®

2/ 13

Index

MAIN CAUTIONS..................................................................................................................................................... 3

PRECAUTIONS ....................................................................................................................................................... 3

1. PREFACE......................................................................................................................................................... 4

2. FEATURES....................................................................................................................................................... 4

3. FUNCTION INTRODUCTION ......................................................................................................................... 4

4. INSTALLATION AND CABLE CONNECTION METHOD............................................................................. 6

4.1 DIMENSION......................................................................................................................................................... 6

4.2 BOTTOM PLATE STRUCTURE.............................................................................................................................. 6

4.3 6-PIN AVIATION PLUG &6-PIN CABLE ................................................................................................................. 6

4.4 VIDEO,POWER,CONTROL LINE.......................................................................................................................... 7

4.5 CABLE CONNECTING.......................................................................................................................................... 7

4.6 TWO METHODS FOR DOME INSTALLATION.......................................................................................................... 7

5. DOME SWITCHER SETTING......................................................................................................................... 7

5.1 VEHICLE DOME ADDRESS SETTING .................................................................................................................... 8

5.2 COMMUNICATION PROTOCOL &BAUD RATE SETTING...................................................................................... 10

5.2.1 Communication protocol setting ......................................................................................................... 10

5.2.2 Baud rate setting................................................................................................................................... 10

6. BASIC CONTROL FOR DOME.....................................................................................................................11

6.1 POWER CONNECTION SELF-TEST .................................................................................................................... 11

6.2 PRESET SETTING.............................................................................................................................................. 11

6.3 CALL PRESET ................................................................................................................................................... 11

7. INSTALLATION...............................................................................................................................................12

8. CLEANING ......................................................................................................................................................12

9. SPECIFICATIONS...........................................................................................................................................12

APPENDIX: SIMPLE FAULTS SOLVING.............................................................................................................13

Bernee®

3/ 13

Main Cautions

Please read this manual carefully before installing

Comply with all caution items on device & manual

Comply with all indicated operations as well as manual

Use components recommended by seller avoiding fault

This product should use specified power supply & voltage. If practical power supply & voltage is

unknown, please ask for seller.

Do not disassemble body but contact to seller

With body cleaning do not use strong or grinding detergent.

Use a dry, soft cloth to clean the camera shell when it is dirty. If very dirty, please use neutral

detergent rather than strong detergent in order to taken not to scratch the dome when wiping it. Then

use dry cloth wiping rest detergent.

Happen the following faults, please contact with dealer:

- Power supply and control line destroyed

- Body fell down or shell destroyed

- Device performance works abnormal

- Yet abnormally work after operation according to instruction

With component replacement, please use those components offered by dealer or performed

equally.

Precautions

Do not direct to sunlight with camera

Do not aim to shining objects with camera. Never aim to sunlight or other strong light objects no

matter during operating or not.

Do not long-time aim to strong light or expose in light source

If equivalent light forms facula, part of image will fade caused by CCD filter worsening under camera

face changing.

This product standard voltage is DC 12V

For seldom vehicle power sockets (lighter socket) are DC 24V and improper voltage will

damage camera greatly, please ensure power socket (lighter socket) voltage is DC 12V.

Bernee®

4/ 13

1. Preface

Vehicle speed dome is our advanced monitoring product with optical, mechanical and electronic

integration. It includes dynamic structure, precision actuator, CCD camera, digital decoder, image

processing unit and controller. Machinery structure designs simply and is precise. High precision &

reliability; smart operating, high speed, stable start & stop, easy control; multi-object presetting,

remember and auto tour; random position, true Omni-bearing & non-blind point monitoring; auto adjust

object distance and size to suit ambient brightness, high cost-performance, long-term stable running.

2. Features

Vehicle environmental designment, anti-shake, waterproof, IP66 protection grade

Horizontal 360°continuous running, max speed 100°/s.

Vertical -15°to 90°rotation from which begin to auto flip 180°and continuous monitoring.

64 customized presets

Auto tour function: 0~54 presets orderly switch

Set max running speed and proportional speed-down, fast call preset positions and manually

control precision tracking

RS485-485 bus-control

Built-in memory to store the setting data, which can not be lost after power off

Compatible with various protocols with adjustable baud rate (Pelco-P /Pelco-D/ Kalatel/

Samsun/ AD)

High-strength plastic shell with light weight

In installing, suck dome onto vehicle roof by owned magnet, or use three M5 screws mounting

dome onto vehicle roof

DC 12V power supply

3. Function Introduction

The following will introduce main functions of integrated speed dome, as well as various functions

operation (no operation details).

Set address code, baud rate and control protocol

Each command matches with only one camera address code, baud rate and control protocol, single

camera only reacts to commands matched to own address code, baud rate and control protocol.

Motion control

Customer can use keyboard controller to manage camera rotation, tracking motion object or motion

sight; besides can change view-angle or image size with adjusting focal length. In auto focus state, as

lens moving, camera will according to sight change adjust automatically, getting clear image.

Focal length / running-speed auto matching

In manual state, for long focal length, slight moving of controller will cause so great changes on

image as to data loss. Based on humanity designment, dome according to focal length can auto adjust

horizontal / vertical speed, so as to make manual tracking easier.

Bernee®

5/ 13

Auto flip

If lens is pulled until up to top (vertical 90°), it will auto horizontally turning 180°and then flip

downward, which can directly watch backside sight. This process ensures vertical 180°continuous

monitoring.

Set and call preset position

Preset function means that in present state, pan/tilt angle and focal length data stores into memory

in order to call and place pan/tilt with camera to specified position. Customer can store and call presets

with controller o infrared controller easily. This function supports 64 presets.

Lens control

- Focal length control

Customer can adjust focal length with controller or matrix so as to get full shot or close-up shot.

- Focus control

In auto focusing & zooming state, camera will focus on picture center to keep picture clear; in

special condition, customer can manually focus to get needed effect. Manual focus restores to auto

focus only needs shake joystick.

- Aperture control

Customer can manually adjust aperture size with controller to get needed picture

brightness. It is also operable to restore auto adjustment by calling a preset position.

Auto backlight compensation

When backlight compensation opens, camera can auto compensate brightness for dark sight

among strong light background. Adjusting background lighting prevents such a brightness mass on

careen caused by background brightness as to can not distinguish dark object, so that you can get clear

image.

ATW (auto tracking white)

Automatically adjust according to ambient light changes to reveal true color.

Auto tour

We can beforehand set presets for tour and put them into an ordered queue, a calling command

required only for that all points (domes) operate circularly based on certain interval.

Zone scanning

Only an outer command or power connection is required for that all domes circularly & horizontally

scan within certain scope (55°~63°or specified angle) with a speed.

Table of contents

Other Bernee Security Camera manuals