Berthoud VEGA 120 User manual

1

Duster VEGA 120

377.563-A ENGLISH

to be read attentively

and kept for further reference

© BERTHOUD Agricole 06/2008

2

See pages

- GENERAL AND SAFETY

.Warning----------------------------------------------------------------------- 4

.Technical specifications -------------------------------------------------- 5

.Dimensions and weight --------------------------------------------------- 5

.Position of the safety stickers and the descriptive plate----------- 6

.Meaning of the safety stickers------------------------------------------- 7/8

. Acceptable use of the duster -------------------------------------------- 9

.General safety instructions----------------------------------------------- 10

. Hitching ----------------------------------------------------------------------- 10

.Hydraulic circuit ------------------------------------------------------------- 10

.Maintenance ----------------------------------------------------------------- 10

- STARTING-UP THE DUSTER

.Hitching the duster to the tractor ---------------------------------------- 12

.Filling the hopper ----------------------------------------------------------- 12

-OPERATION

.Outputadjustment----------------------------------------------------------- 14

.Selecting the produt output direction----------------------------------- 14

.Clogging in the product feed venturi nozzle -------------------------- 15

.Flowbalancing -------------------------------------------------------------- 15

.Torquelimiter----------------------------------------------------------------- 15

- DETERMINATION OF THE FLOW RATE

.Table of flow rates ---------------------------------------------------------- 18

- MAINTENANCE

.Drive maintenance --------------------------------------------------------- 20

.Maintenance during periods of use ------------------------------------ 20

.Maintenance when not in use-------------------------------------------- 20

contents

3

GENERAL

AND

SAFETY

4

- Successful treatment depends on correct operation of your duster.

- Correct operation depends on precise calibration of the equipment, and

this requires careful checking.

- When this checking has been undertaken, the duster must be

commissioned correctly, this also being necessary for correct spraying

and operation.

- Finally, to be certain that your duster can give you the performance you

expect, for a long time, make sure that you undertake the maintenance

operations required.

CHECKING, STARTING-UP,

OPERATION, MAINTENANCE

are therefore essential operations, and you have every reason to carefully

read the details in this booklet.

"This duster has been manufactered using materials which withstand most

plantprotection chemicalscurrently availableon themarket. Nevertheless,

BERTHOUD cannot assume responsibility for any damage resulting from

anincompatibilittyof the crop protection chemicals or productmixtures with

theplastic materials (polyethylene, polyvinylchloride, polypropylene, Vitton,

nitrile polyamide,ABS)."

CLEANING THE DUSTER

- Only BERTHOUD is qualified to assist you concerning the maintenance of

the duster and the choice of cleaning products.

- Care should be taken with products containing solvents. Such products

may attack and damage plastic and rubber elements and paint. Berthoud

cannotbe held responsibleincases where inappropriatecleaners are used.

We recommend the ALL CLEAR cleaner.

IMPORTANT

- According to the terms of article R 149 of the Highway Code, any

towed agricultural machine with a GVWR over 1.5 tonnes must be

fitted with a braking mechanism for driving on the public highway.

Because of our policy of constant product improvement,

we reserve the right to modify product specifications or design without prior notice.

WARNING

5

Duster VEGA 120

- Fan speed : 3,490 rpm

- Air flow per outlet : 880 m3/h

- Absorbed power : 4.5HP

- CHASSIS

- Steel profile and plate.

- HOPPER

- Sheet plate.

- Capacity : 120 litres.

- Wide filling orifice.

-Discharge hole.

- MECHANISM

- Speed-increasing gear to V-belts.

- MIXER

- Finger agitator to prevent bridging,

fitted with a torque limiter.

- FEEDING

- By endless screw.

- This system ensures the powder

flowsevenly.

- Length : 1.040 m.

-Width : 0.760 m.

- Height : 0.980 m.

- Weight : 93 kg.

- As the powder does not go through the rotor, micro-granules can be used.

-FAN

- Aluminium.

- Rotationspeed: 3,490rpm.

- ADJUSTMENT

- 8-positionnotched lever.

- Flow of 4 to 88 kg/ha.

- DISTRIBUTION

- Throughdoubleswivelling blades.

- Powder equalising device to ensure perfectly even left-right balance.

- MAINTENANCE

- All greasers located on the right-hand side with grease ducts.

TECHNICAL SPECIFICATIONS

DIMENSIONS AND WEIGHT

6

It is very important to keep the safety stickers in

location and in good condition as they draw your

attention to possible dangers and refer to the

operator's manual.

See the following pages and check their location

on the duster.

- Duster VEGA 120 -

417.590

418.630417.572 417.579

On the hood in front of the duster

T/min

R/min

U/min

G/min

540

200

417.588

On the hood

in front of the duster

417.583

In front of the

duster

POSITION OF THE SAFETY STICKERS

7

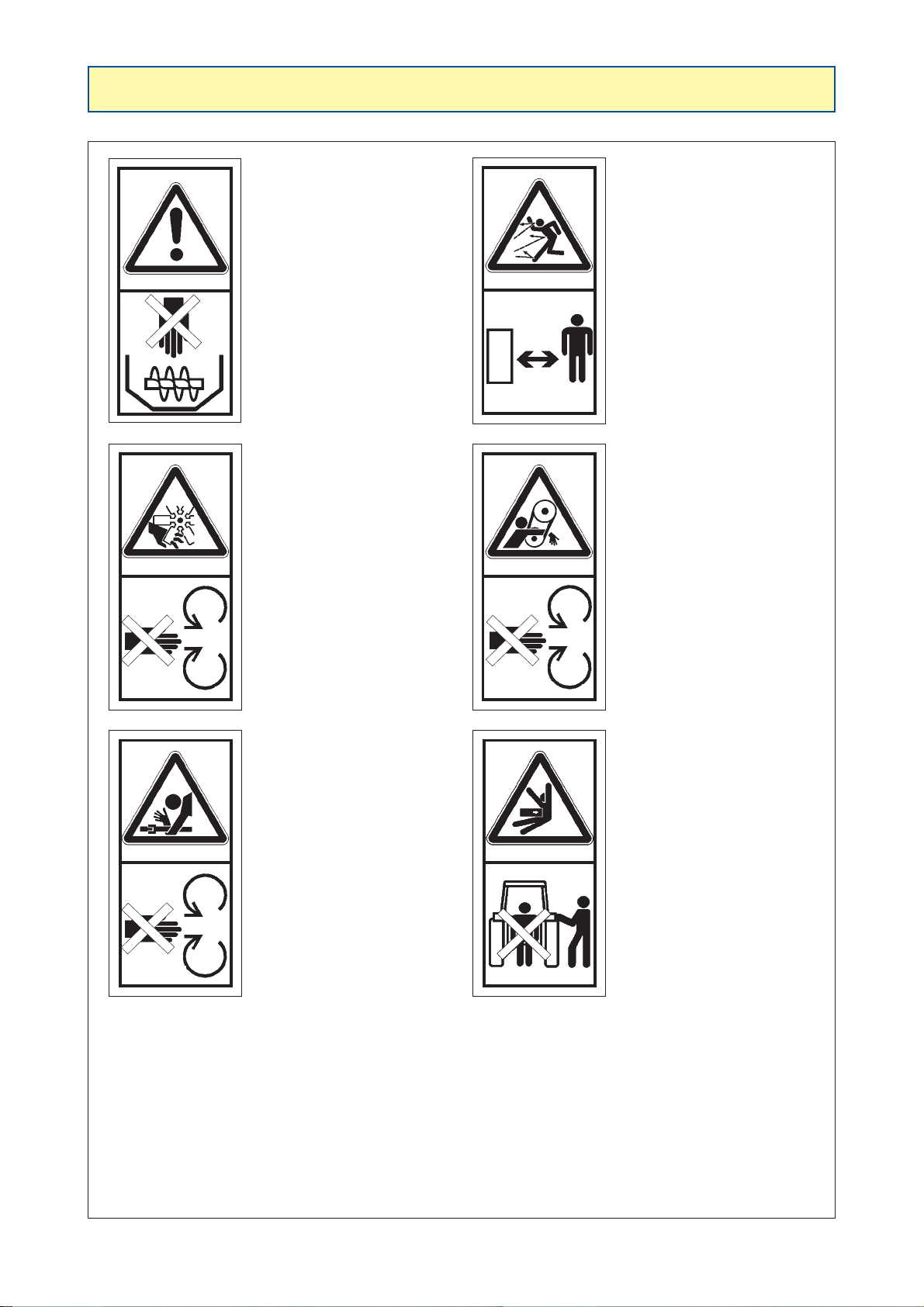

GENERIC WARNING

SYMBOL

READ THE OPERATING

MANUAL BEFORE

ANY OPERATION

SWITCH OFF THE

ENGINE AND REMOVE

THE IGNITION KEY

BEFORE UNDER-TAKING

WITH ANY INSPECTION,

MAINTENANCE OR

REPAIR OPERATION

RISK OFASPHYXIA

DO NOT ENTER

IN THE TANK

RISK OF ELECTRIC

SHOCKAND

ELECTROCUTION

HAND

PROTECTION

OBLIGATORY

FOOT

PROTECTION

OBLIGATORY

AIR PASSAGE

PROTECTION

OBLIGATORY

EYE

PROTECTION

OBLIGATORY

ROTATING SPEED OF

540 REVOLUTIONS

PER MINUTE

RECOMMENDED

HAND PROTECTION

OBLIGATORY FILL WITH CLEAR

WATER

OBLIGATIONTO WASH

YOURHANDS

T/min

R/min

U/min

G/min

540

MEANING OF THE SAFETY STICKERS

8

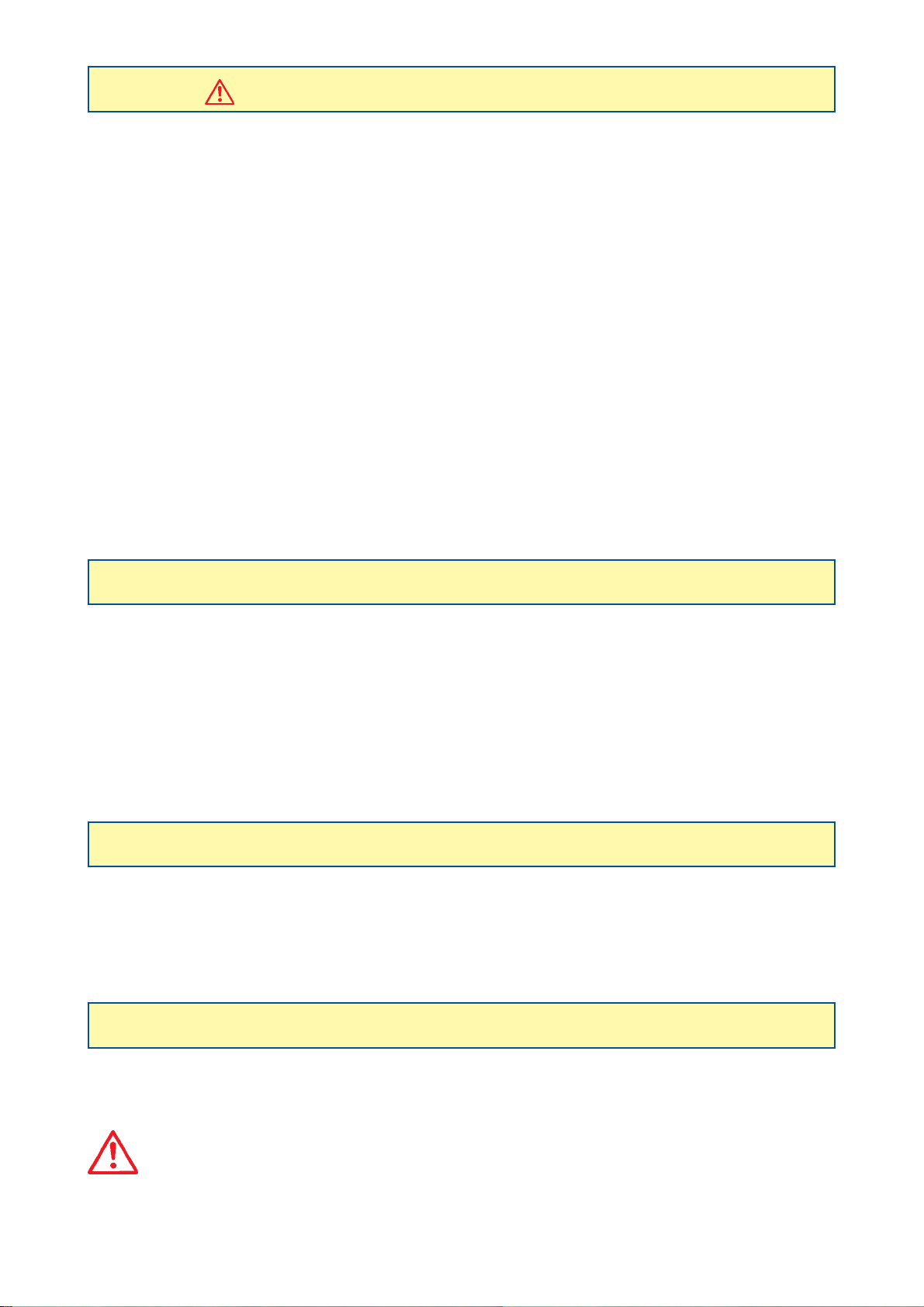

KEEP HANDS AWAY

FROM THE SCREW

WHILE THE TRACTOR

POWER TAKE-OFF

SHAFT IS CONNECTED

AND THE ENGINE IS

RUNNING

RISK OF INJURY

KEEP HANDS AWAY

FROM VENTILATION

FAN WHILE THE

TRACTOR POWER

TAKE-OFF SHAFT IS

ENGAGED AND THE

ENGINE IS RUNNING

RISK OF SNATCHING

DO NOT OPEN OR

REMOVE THE

PROTECTIVE COVERS

WHILE THE TRACTOR

POWER TAKE-OFF

SHAFT IS ENGAGED

AND THE ENGINE IS

RUNNING

RISK OF PROJECTION

STAY ATA SAFE

DISTANCE FROM

THE SPRAYER

RISK OF CRUSHING

KEEPA SAFE DISTANCE

FROM THE SPRAYER

RISK OF SNATCHING

DO NOT OPEN OR

REMOVE THE

PROTECTIVE GUARDS

WHILE THE TRACTOR

POWER TAKE-OFF

SHAFT IS ENGAGED

AND THE ENGINE IS

RUNNING

GENERIC WARNING

SYMBOL

MEANING OF THE SAFETY STICKERS

9

- Do not use your duster out of its function:

- sprayingcrop protection chemicals, spraying of plant protective products.

- Inthe event of any damage related tothe useof the duster outside theframework ofthe applications specified

by the manufacturer, the latter shall not be liable.

- Any extrapolation of the sprayer's original intended use shall be at the user's risk.

- Acceptable use of the duster also implies:

- compliance with the operating, servicing and maintenance instructions laid down by the manufacturer,

- the exclusive use of original spare parts, equipment and accessories or those recommended by the

manufacturer.

- The duster must only be used, serviced and repaired by trained people, familiar with its characteristics and

methods of use.

These people must also be aware of the dangers they may be exposed to.

- The user must comply strictly with existing regulations as regards:

- accident prevention,

- safety at work (Labour Code),

- travellingon the public highway(Highway Code).

- He must strictly observe the warnings affixed on the duster.

- Any change to the duster done by the user himself or any other person, without the manufacturer's prior

written agreement, shall mean that the latter is not liable for any damages which may result.

ACCEPTABLE USE OF THE DUSTER

10

GENERAL SAFETY INSTRUCTIONS

- This duster should be used by a fully trained operator in spray techniques.

- Do not allow anyone to enter the duster's working radius.

- When using hydraulic, electrical or other controls, first ensure that there is no-one within range of the spray.

- The only workpost is the tractor's cab when the duster is in operation.

- In addition to the instructions contained in this manual, comply with the legislation relating to safety and

accident prevention regulations.

- The stickers on the duster indicate safety measures to be complied with to prevent accidents.

- The user must train himself in the operation of this duster before doing any work.

- Protect yourself from spray drift during spraying.

- No passengers should be carried on the duster.

- Take care when hitching or unhitching the duster.

- Before hitching the duster, make sure that there is sufficient ballast on the tractor's front axle.

- All the remote controls must be placed so that they cannot cause a dangerous situation.

- Before doing anything on the duster, disconnect the power take-off, switch off the engine, remove the ignition

key and wait until the sprayer has stopped completely.

- Make sure that all the safety covers are in place.

- Carry out the adjustments and a water spray test before preparing the spray mixture.

- Dispose of chemical cans in accordance with the instructions given by the manufacturer.

HITCHING

- Beware of crush risks in the 3-point lifting area.

- Disconnect the power take-off, switch off the engine and remove the tractor's ignition key while the duster's

drive shafts are being connected.

- Use only EC-approved drive shafts. Fit them and service them in accordance with their manufacturer's

instructions. Replace their protectors as soon as they are damaged.

- The protective covers must always be in place and properly secured.

- Rest the drive shafts on their supports as soon as they are disconnected.

HYDRAULIC CIRCUIT

- Before connecting a hose to the tractor’s hydraulic system, make sure that the tractor and sprayer-side

circuits are not pressurized.

- Check that the hydraulic hoses are in good condition and replace them if they are damaged.

MAINTENANCE

- For all maintenance work, the PTO has to be disconnected, the tractor engine must be switched off, the

ignition key removed.

IMPORTANT: Formanually or hydraulically operated equipmentwith lifting, folding or extension gear,

etc. and prior to all maintenance work, even of minor importance, mechanical parts must be at the

limit of their travel, jack pressure off, arms on their supports and sliding or swinging frames locked

into position.

- Only use recommended spare parts by BERTHOUD.

11

STARTING-UP

THE DUSTER

12

- Attach the tractor’s lifting arms to the two pins on the drawbar.

- Mountthe cardan drive shaft.If necessary, cut the tube tothe required length and removeany burrs. Lubricate

thetubes.

- Attach the top link to the duster mounting pin.

- Lift the device to the required height using the lifting arms so that the drive shaft angle is as flat as possible.

The drive shaft angle must not be greater than 15° in relation to the PTO.

- PTO operating speed: 540 rpm.

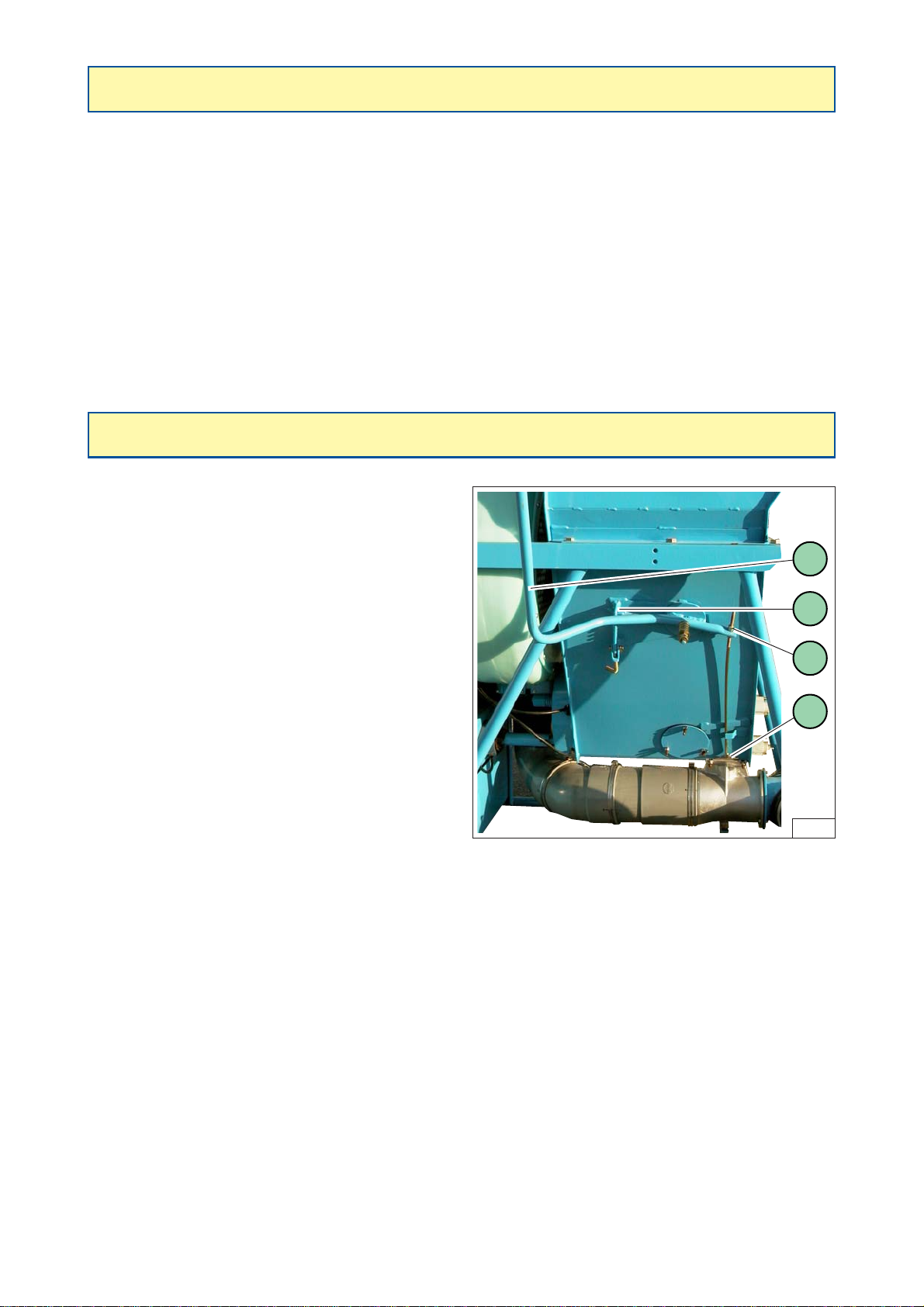

- Rest the bag of powder on the rear edge of the

hopper.

While pouring it in, check that there are no foreign

bodies (pieces of bag or other) in the powder.

- Before filling the hopper, check that the opening

lever (1) is in the closed position, i.e. with the lever

in the top position, notch No. 1 (figure 1, ref. c1).

- Check that the gate (4) is fully blocking the powder

outlet aperture in the closed position (notch No. 1).

Use the nuts and locknuts (e) to adjust the position

(figure 1).

HITCHING THE DUSTER TO THE TRACTOR

FILLING THE HOPPER

1

1

c1

e

4

13

OPERATION

14

- Adjust the flow rate with the device powered by the

tractor PTO (540 rpm), going from:

notch No. 1 (c1) = closed position, to notch No. 8

(c8) = maximum opening.

Select the opening notch position from the flow rate

chart (see page 18).

CAUTION:

To avoid overheating and to prevent the

sulphur from solidifying we advise you:

1 - Not to use the VEGA with notch No. 1 (c1).

2 - To count 4 rows treated at a time. This

performance corresponds to the device’s

power.

3 - To drive at a normal working speed (between

4 and 6 km/h).

4 - Not to allow the VEGA run with the lever (1) in

the closed position.

With certain mixtures or sulphurs and when

theheadlandmakesitnecessaryto manœuvre,

disengage the PTO at the end of the rows.

- The product output direction lever is located on the

rightside of themachine, on theproduct feed venturi

nozzle (black knob).

a - central position:

evenflow through both product outlet vanes.

b - right position:

flow through right vane only.

c - leftposition:

flowthrough leftvane only.

OUTPUT ADJUSTMENT (figure 2)

2

1

c8

c1

SELECTING THE PRODUCT OUTPUT DIRECTION (figure 3)

3

c a b

15

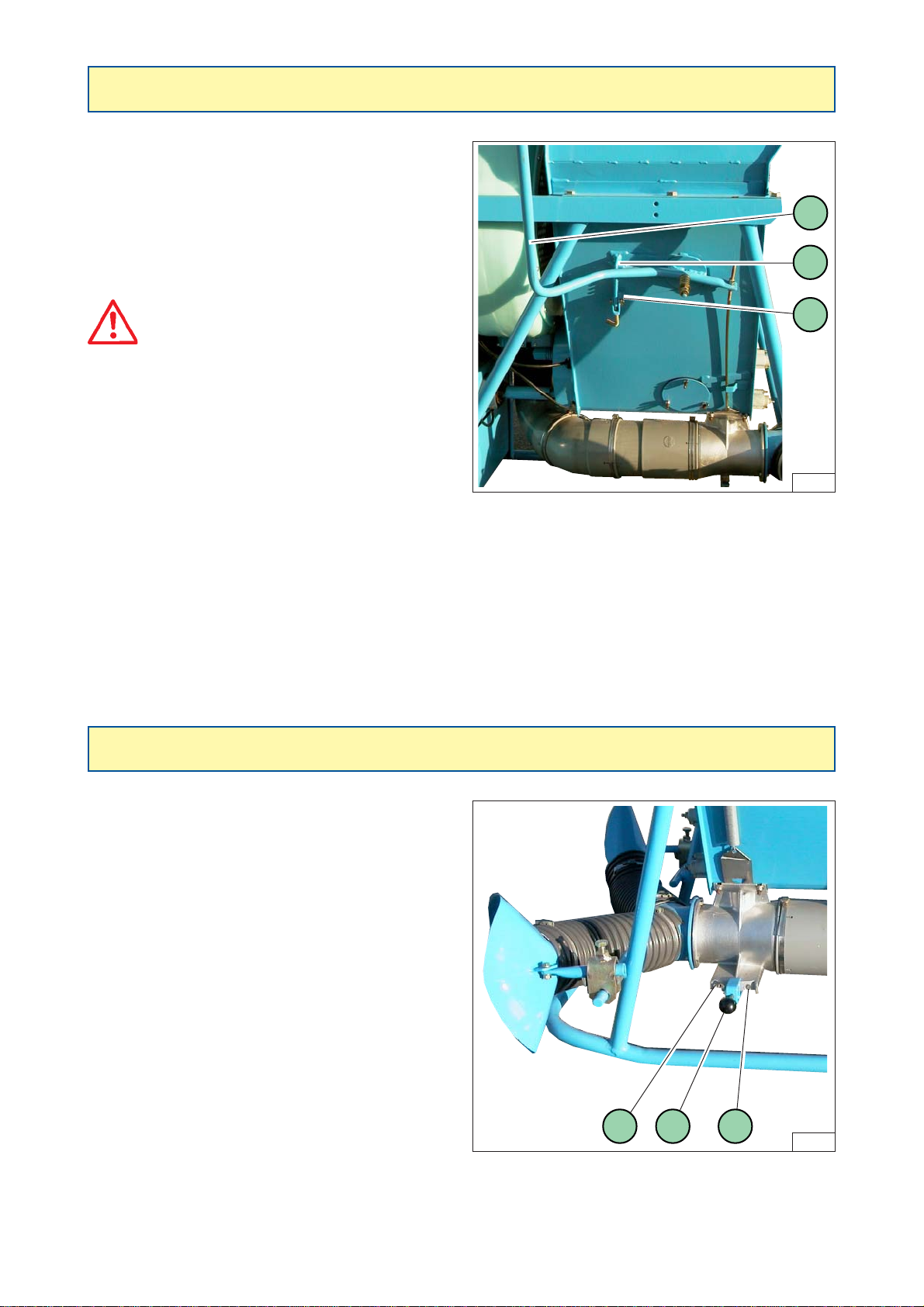

- The feed pipe to the swivelling venturi nozzle is

blocked by powder adhering to the walls due to

humidity.

- Disassemble the fixed venturi by removing the

4 nuts (2) attaching it to the hopper.

- Loosen the connecting collar (3) on the

ventilationpipe.

- Clean the powder feed pipe so that the walls

arecompletely smooth.

- Before reassembling, check that the flow rate

control gate is working properly (4).

- To balance flow at the outlets:

- with the machine running:

- put the product output direction lever in the

centralposition,

- loosen the nuts (e),

- use a screwdriver to adjust the balancing

screw (v).

- Theagitator must notdisengage if thereisno foreign

body.

- To increase or decrease torque, turn the screw (v).

CLOGGING IN THE PRODUCT FEED VENTURI NOZZLE (figure 4)

FLOW BALANCING (figure 5)

TORQUE LIMITER (figure 6)

4

4

2

3

6

v

5

e

v

16

17

DETERMINATION OF THE FLOW RATE

18

7

5

4

13.5

10

8

25

19

15

33

25

20

41.5

31

25

55

41

33

58

44

35

- These flow rates have been determined using fluid sulphur (fluidosoufre). They are therefore indicative and

significant differences may arise with powders which are more or less fluid.

- To obtain flow rates corresponding to different treatment widths, apply the following coefficients.

example:

- width 3 m: double the 6 m indications,

- width 12 m: divide the 6 m indications by 2.

Flow rates in kg/hectare according

to the forward speed

4 km/h 5 km/h 6 km/h

Selecting the

notch No. Flow rates /

minute Width

treated

6 m

8 m

10 m

6 m

8 m

10 m

6 m

8 m

10 m

6 m

8 m

10 m

6 m

8 m

10 m

6 m

8 m

10 m

6 m

8 m

10 m

2

3

4

5

6

7

8

0.4 kg

0.8 kg

1.5 kg

2.0 kg

2.5 kg

3.3 kg

3.5 kg

10

7.5

6

20

15

12

37.5

28

22.5

50

37.5

30

62.5

47

37.5

82.5

62

49.5

87.5

65.5

52.5

8

6

5

16

12

10

30

22.5

18

40

30

24

50

37.5

30

66

49.5

39.5

70

52.5

42

TABLE OF FLOW RATES

19

MAINTENANCE

20

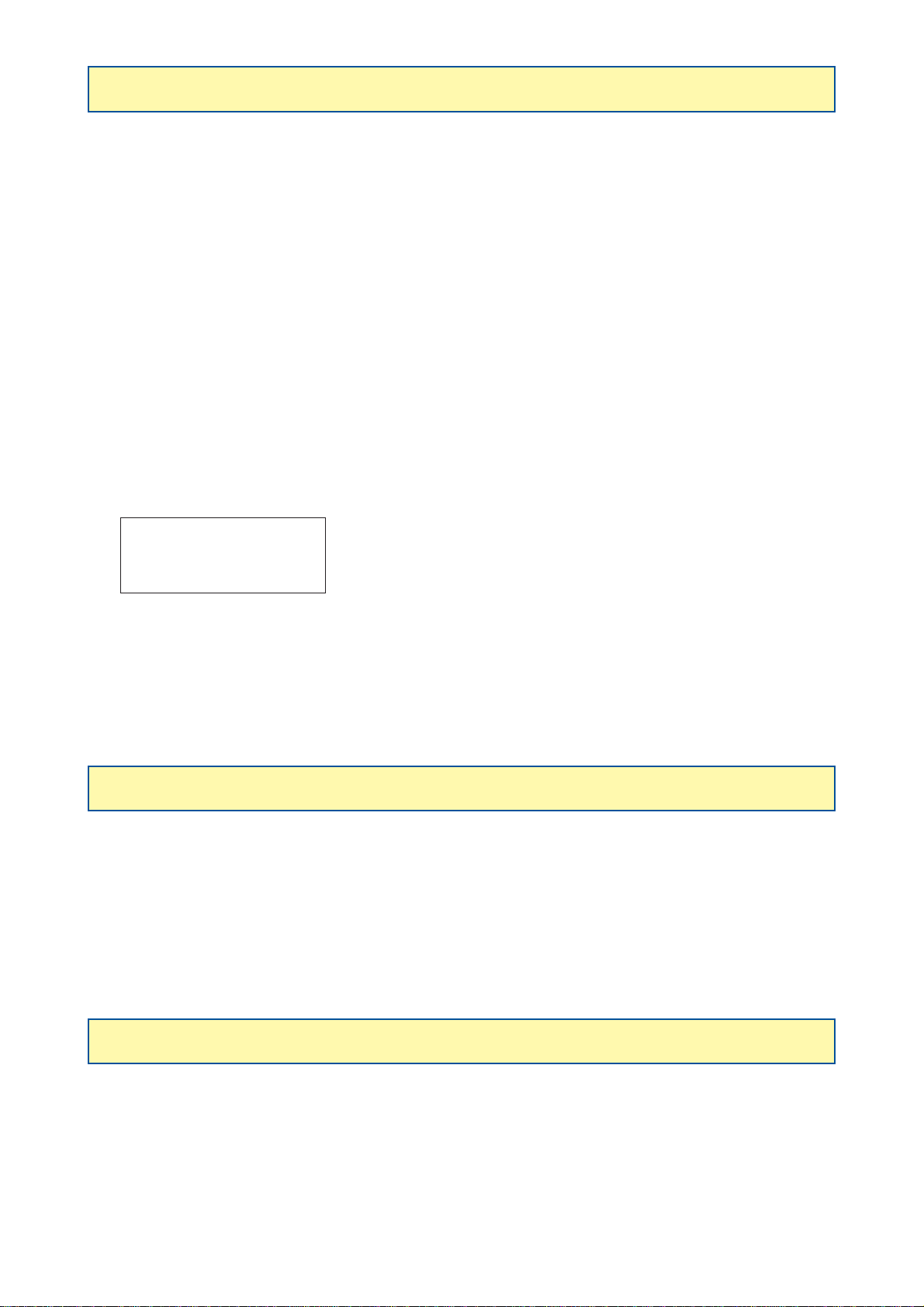

- During the first hours of use, retighten the belts frequently.

- Remove the front cover (5) by unscrewing the nuts (6) (figure 7).

- Loosen the collar on the fan outlet tube elbow (7) (figure 7).

- Loosen the 4 screws (8) on the crosspiece (9) (figure 8).

- Unscrew the 2 nuts (10) (figure 8).

- Tighten the belts using the two tension screws (11) located under the crosspiece (figure 8).

- Retighten the nuts (10) and screws (8) (figure 8), and remount the cover (5) (figure 7).

- Lubricating the bearings: approximately every 100 hours.

- 8 greasers:

- 6 are centrally placed on the right side of the vertical support (12) (figure 9).

- 2 on the bearings (13) (figure 10).

- Use a brush to apply grease to the agitator shaft movement transmission pinions.

- Runningwithout lubricationwill resultin prematurewear.

- Recommended greases:

- After each day’s work: empty the hopper.

- Aftercleaning:openandclosetheflow regulation gate several times andleaveintheopenposition:notch No. 8.

- Carefully clean the hopper.

- Loosenthe belts.

- Unhook the return spring from the flow regulation gate which is open at its maximum position.

DRIVE MAINTENANCE

MOBILUX: Grease 2 or 3

SHELL: Alvania 2 or 3

ESSO: Beacon EP 2

MAINTENANCE DURING PERIODS OF USE

MAINTENANCE WHEN NOT IN USE

Table of contents