Ecolawn Eco 50 User manual

Operator's Manual

www.ecolawnapplicator.com

Model Eco 50

Tow-Behind

Self-Propelled Broadcast Top Dresser

REGISTER YOUR ECOLAWN

www.ecolawnapplicator.com

SERIAL NUMBER:

P a g e 2 | 16 Turf Pros #1 Top dresser www.ecolawnapplicator.com

THANK YOU for purchasing an Ecolawn Top Dresser. Your new machine has been carefully designed and

manufactured to provide years of reliable and productive service. This manual will provide you with safety

instructions and general maintenance tips that will help to keep your machine in top running order. Please

read this manual and assembly part/list carefully before assembling, operating, or servicing your

equipment.

Here are 5 Ecolawn Basic Rules of Operations:

1. Use quality screened material or compost;

2. Use appropriate load size and weight;

3. Load hopper gently to prevent loading compaction;

4. Plan the application before spreading it;

5. Test the spreader by first running it empty. A good application means preparing ahead of time.

Make small adjustments in the field and eliminate major repairs.

Please visit our website or call with any questions.

Website: www.ecolawnapplicator.com

Tel: 1-866-326-5296

A good application means preparing ahead of time!

www.ecolawnapplicator.com Turf Pros #1 Top dresser P a g e 3 | 16

TABLE OF CONTENTS

WARRANTY 4

SAFETY INSTRUCTIONS 5

1. GENERAL

2. GUARDS

3. HOPPER

4. DECALS

OPERATING INSTRUCTIONS 6

1. PROPER TOPDRESSING

2. OPTIMAL OPERATION

3. MAIN USES

USING THE ECOLAWN FOR THE FIRST TIME 7

OPERATING THE ECOLAWN APPLICATOR 8

CHOOSING AN APPROPRIATE SUBSTANCE 11

1. QUALITY AND CHARACTERISTICS

2. FRIABILITY

3. MOISTURE CONTENT

TROUBLESHOOTING AND ADJUSTMENTS 12

GENERAL MAINTANCE 15

1. SHAFT BEARING

2. V-BELTS

SAND DEFLECTOR 16

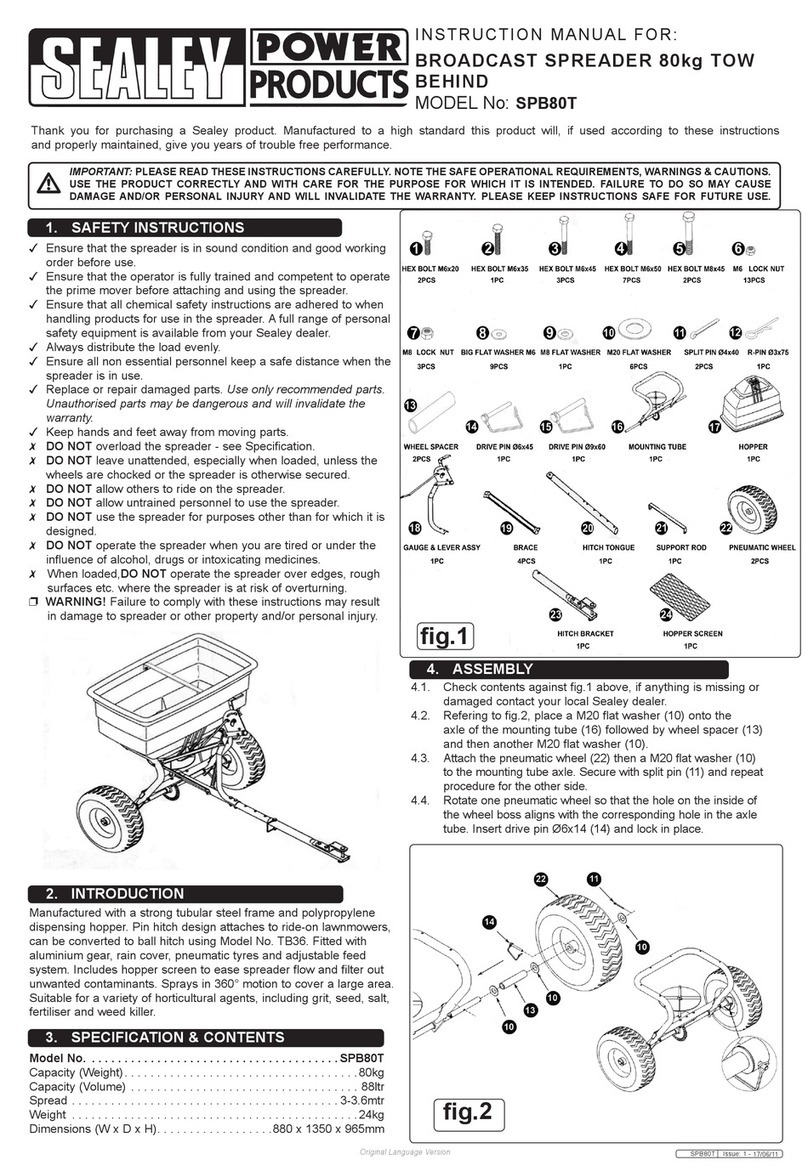

ASSEMBLY STEPS 17

P a g e 4 | 16 Turf Pros #1 Top dresser www.ecolawnapplicator.com

Ecolawn Applicator® One Year Limited Warranty

Terms: Ecolawn Applicators are guaranteed to be free of defects in materials or workmanship for one year

from the registered purchase date. To qualify, the applicator must be registered online at

www.ecolawnapplicator.com (under the product tab). This one-year warranty is extended only to the

original, registered purchaser of the Ecolawn Applicator.

Starting from the registered purchase date, Ecolawn will replace, free of charge, any part(s) on the machine

that Ecolawn or its approved agent deems to be defective in material and/or workmanship upon

examination.

The warranty is limited to the Ecolawn Applicator itself. Ecolawn Applicator® is not responsible for any

other equipment used with the Applicator.

www.ecolawnapplicator.com Turf Pros #1 Top dresser P a g e 5 | 16

Safety Instructions

This manual describes the operation of the ECO 50 Ecolawn Applicator spreader only.

1. General

•Never allow children to operate power equipment.

•Do not use the Ecolawn Applicator on any slope that is greater than 10 to 15 degrees.

•Do not modify the Ecolawn Applicator. Any alterations to the machine will void the warranty.

•Use the Ecolawn Applicator ONLY for its intended purpose.

•Keep hands and objects out of the hopper and away from the agitator/mixer while the motor is running.

•Use only original Ecolawn parts to repair the Ecolawn Applicator.

2. Guards

Do not run the engine or operate the machine when any of the guards have been removed. This may result

in severe injury and/or damage to the unit.

3. Hopper

The hopper's maximum load is 440 lbs (200 kg). Never exceed the maximum load capacity; this may

damage the spreader.

4. Decals

Replacement safety decals are available at no cost from Ecolawn.

P a g e 6 | 16 Turf Pros #1 Top dresser www.ecolawnapplicator.com

Operating Instructions

1. Proper Topdressing

When topdressing, follow the same pattern you would use when mowing. Start with the sections of lawn

that are farthest away from the supply source to avoid repeated traffic over the areas that have already

been top-dressed.

Type of Spreading Material:

•Screened compost

2. Optimal Operation

Never exceed the maximum load capacity of the hopper (440lbs/200 kg). Some substrates (such as sand

or soil) are much denser than others, so it is not possible to judge load size visually. The same volume of

sand or soil can weigh significantly more than compost. Overloading the hopper may damage the spreader.

Comparative: Materials and Weights

Material Volume Weight

Compost (60% humidity) 10 cubic feet: 300 lbs

Mix Blend: 50% compost, 50% sand 10 cubic feet: 550 lbs

Sand 10 cubic feet: 800 lbs

3. Main Uses

The Eco 50 Tow-Behind Broadcast Compost Spreader is designed to spread compost, peat moss, soil

amends and seeds for lawn restoration and renovation. To learn more about compost topdressing, please

visit our website at www.ecolawnapplicator.com.

www.ecolawnapplicator.com Turf Pros #1 Top dresser P a g e 7 | 16

Using the Ecolawn Applicator for the First Time

Before using the spreader for the first time, make sure the tow bar is extended out far enough to operate

the activation lever. While the spreader has been factory adjusted for immediate use, some minor

adjustments may be necessary. We recommend the following startup procedure to ensure that the machine

is properly adjusted before use.

Step 1. The spreader's belts are new, so they may not adhere perfectly to the pulleys; they may slip a little

when the machine is used for the first time. Before loading the spreader with substrate, run it around empty

for about 10 minutes to allow the belts to become seated properly on the pulleys.

Step 2. Fill the hopper to 1/3 capacity (see Page 8, Step 1), then run the spreader until empty and refill to

this level for the first 3 or 4 loads.

Step 3. Fill the hopper to its maximum capacity (440lbs/200 kg) and begin using the spreader normally.

Step 4. After one hour of use, visually inspect the spreader. Vibrations combined with a heavy load may

occasionally cause nuts and bolts to loosen. Tighten these when necessary.

Step 5. After 8 hours of use, inspect the nuts and bolts again and tighten if necessary.

If some pulleys do not run correctly after these trials, please refer to Ecolawn Application: Troubleshooting

and Adjustments.

P a g e 8 | 16 Turf Pros #1 Top dresser www.ecolawnapplicator.com

Operating the Ecolawn Applicator

Step 1. Filling the Hopper

Before filling the hopper, first ensure that the Feed Flap (Figure 1) is properly closed by pushing the Feed

Flap Lever all the way down (Figure 2).

Fill the hopper with the substrate to be spread. Note: Never exceed the hopper's maximum load capacity

(440 lbs/200 kg); this can damage the machine.

Figure 1

Figure 2

www.ecolawnapplicator.com Turf Pros #1 Top dresser P a g e 9 | 16

Step 2. Starting to spread

Before pulling the Eco 50, make sure the conveyor system is not engaged. Be sure that the Conveyor

Action Lever (Figure 3) is disengaged and the Feed Flap is properly closed.

Figure 3

Step 3: Topdressing with a Substrate

After loading the machine, transport to the desired location to start spreading. Before moving forward, open

the Feed Flap with the lever shown in Figure 2. Pull the Conveyor Activation Lever toward you (Figure 4) to

move the spreader forward and spread the substrate.

Note: The ground speed determines the width of spread.

Figure 4

P a g e 10 | 16 Turf Pros #1 Top dresser www.ecolawnapplicator.com

Step 4. Stopping the Spreader

When the hopper is empty, release the Conveyor activation Lever to disengage the conveyor belt and close

the feed flap. If filling the hopper again, tow the unit to the substrate source and then refill the hopper.

www.ecolawnapplicator.com Turf Pros #1 Top dresser P a g e 11 | 16

Choosing an Appropriate Substrate

1. Quality and Characteristics

It is very important to choose a high-quality topdressing substrate. For greatest cost efficiency,

Ecolawn recommends using a bulk substrate which is friable, has a moisture content lower than

65%, and contains no inorganic matter (plastic, glass, or concrete, etc.) or raw organic matter (such as

pieces of wood, raw manure).

2. Friability

A friable material is one that crumbles easily into small fragments. A substrate that is not very friable

appears to be composed of numerous, compact pieces which do not readily break down. Screening a

substrate makes it much more friable. Additionally, a substrate containing 10% sand is more friable and will

flow more smoothly and efficiently through the applicator.

3. Moisture Content

A substrate with a moisture content greater than 65% will tend to stick to the inside walls of the hopper and

other parts of the spreader. When working with a substrate with a high moisture content, coat the insides of

the hopper, as well as the spreading disk, with a lubricant.

To help the substrate flow freely from the hopper, stop the machine and loosen with shovel. This will loosen

the substrate so that it can flow freely from the hopper.

P a g e 12 | 16 Turf Pros #1 Top dresser www.ecolawnapplicator.com

Troubleshooting and Adjustments

Important: Most adjustments are remedied in the field with just a few procedures

The most frequent problems encountered involve the conveyor, but these can easily be resolved with a few

simple solutions. Check the following issues for your particular problem, and make the corresponding

adjustments as needed.

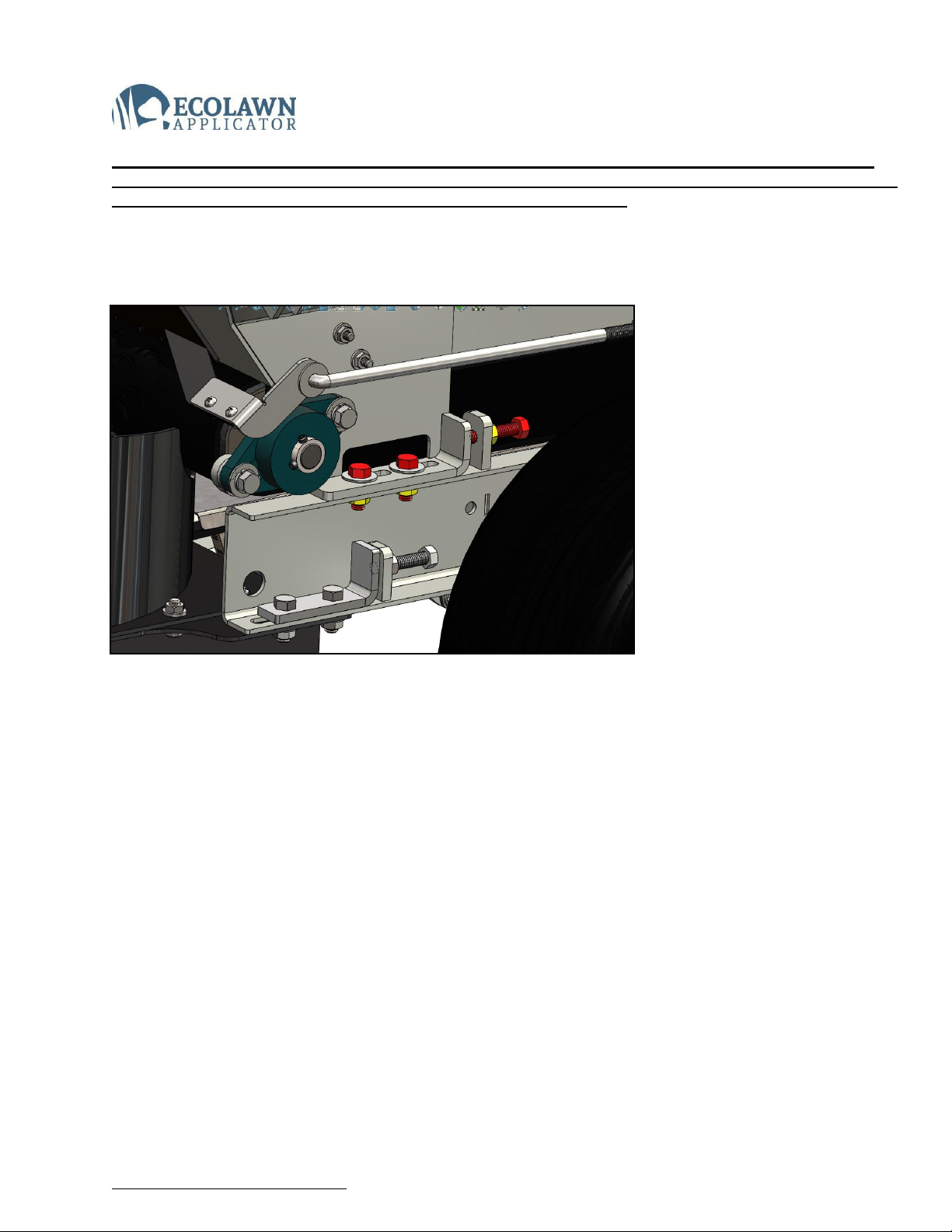

Issue: The V-belts are slipping. The spreader's hopper is full. The conveyor has been activated by

pulling the conveyor activation lever toward you, but the conveyor belt does not work because the

V-belts are slipping.

Solution: The V-belts are not tight enough. First remove the guards from the tensioner and check the

tension of the belts, which may be slipping on the pulleys that power the conveyor belt drive roller. If the

tension is incorrect, adjust it by lengthening the tension rod of the conveyor activation clutch, a few turns at

a time, as follows:

1. Loosen the (Yellow) jam nuts to

adjust the tension of the tensioner

rod.

2. Turn the (green) top tensioner

adjuster to increase tension, or

clockwise to reduce it.

3. Tighten the (yellow) jam nuts to

maintain the tension at the proper

level.

www.ecolawnapplicator.com Turf Pros #1 Top dresser P a g e 13 | 16

Issue: The spreader's hopper is full. The conveyor has been activated by pulling the conveyor

activation lever toward you, but the conveyor belt is not turning even though the tension rod has

been adjusted properly and the conveyor drive roller is turning.

Solution: Adjust the tension bolts of the conveyor belt system on each side, 1/2 turn at a time on both sides

equally, to increase the tension on the conveyor belt. Do as follows:

1. Loosen the 2 vertical (yellow)

nuts on each side of the machine.

2. Loosen the (yellow) jam nut and

tighten the horizontal bolt to push

the conveyor belt roller forward a

1/2 turn at a time.

3. Now tighten down the two vertical

nuts on both sides to hold the front

system in place and tighten the jam

nuts to lock the tension bolts.

4. Test the machine and re-adjust if

necessary.

P a g e 14 | 16 Turf Pros #1 Top dresser www.ecolawnapplicator.com

Issue: The spreader moves forward and the conveyor works, but the spreading disk does not spin.

Solution: To free the disk, turn the machine off, and then turn the spinner disk backward manually to

remove any debris. Visually inspect the pulleys and clean them as needed. If the pulley groove used to turn

the spinner disk has collected substrate, it may cause the belt to come off. Clean out the pulley groove

under the spinner, then re-mount the belt in the pulley groove.

www.ecolawnapplicator.com Turf Pros #1 Top dresser P a g e 15 | 16

General Maintenance

1. Shaft Bearings

Grease the bearings after every 50 hours of operation.

2. V-belts

The proper belt tension is tight enough that the belts will not slip during operation. Occasionally, belt tension

must be readjusted. Do not over-adjust the tension, as this may damage other parts.

Table of contents

Other Ecolawn Spreader manuals

Popular Spreader manuals by other brands

SnowEx

SnowEx Super Maxx SP-9300XH Owner's manual and installation instructions

Egholm

Egholm City Ranger 2250 Operator's manual

Brinly-Hardy

Brinly-Hardy Spyker Spreaders ROS 6 quick start guide

Kubota

Kubota VS220-330 Technical & service manual

Fisher

Fisher Speed-Caster owner's manual

Trynex International

Trynex International TurfEx TS45 owner's manual