5

Table of contents EN

Table of contents............................................................................................................................... 5

1. Safety , warnings and potential hazards...................................................................................... 6

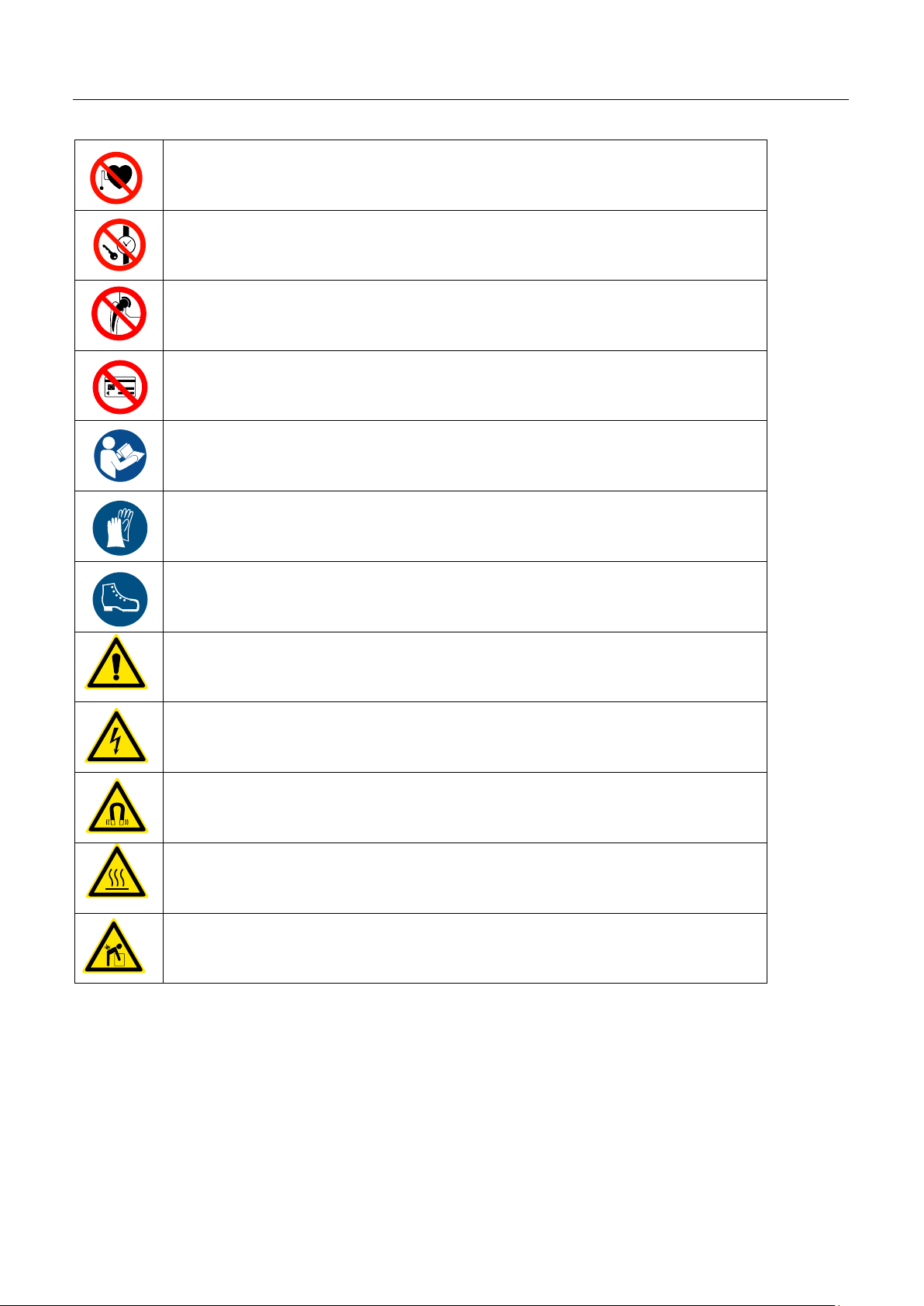

1.1 Explanation of the pictograms ................................................................................................... 6

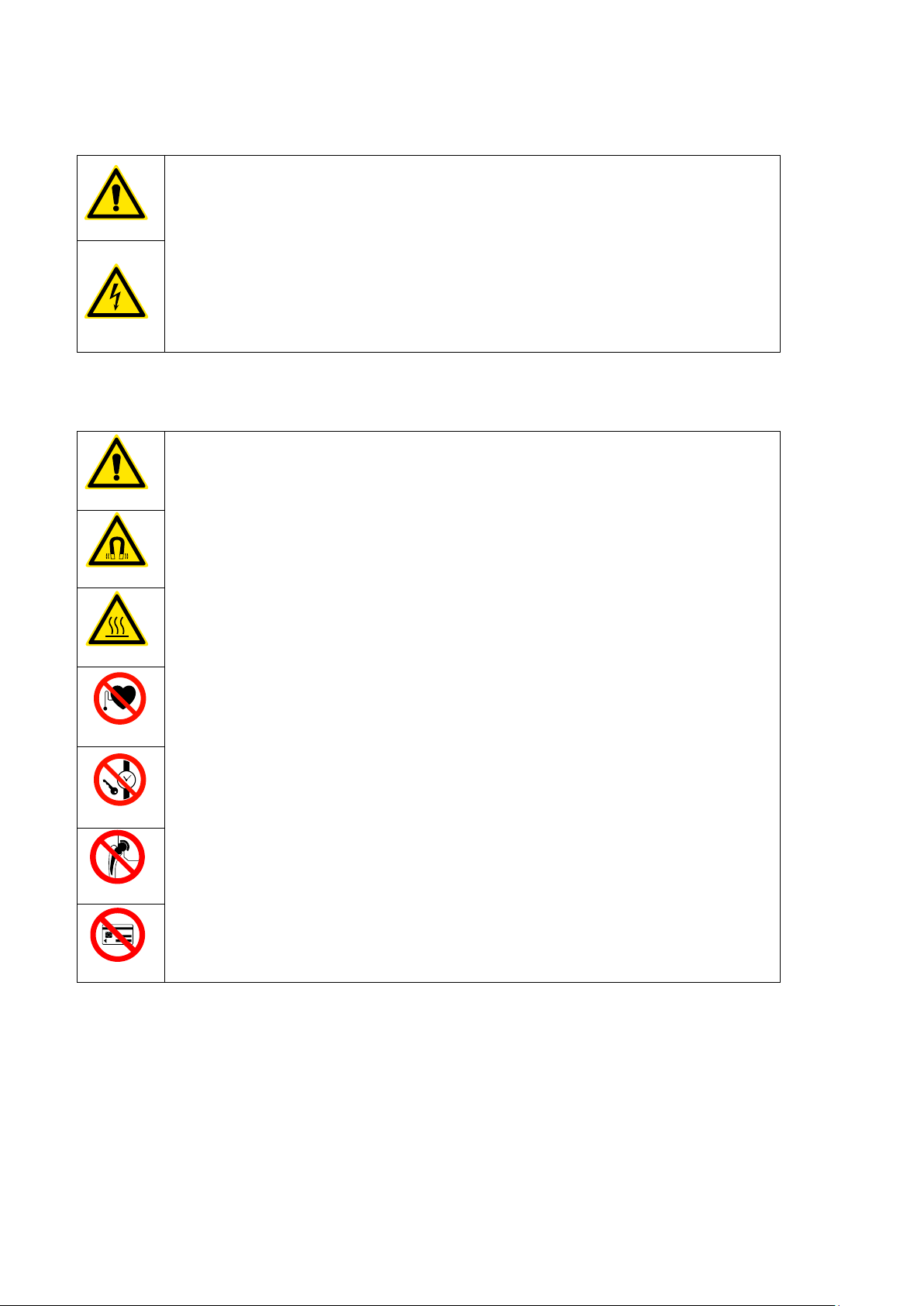

1.2 Description of potential hazards................................................................................................. 7

1.3 Safety measures to be taken ..................................................................................................... 9

1.4 Safety provisions ....................................................................................................................... 9

2. Introduction ................................................................................................................................. 10

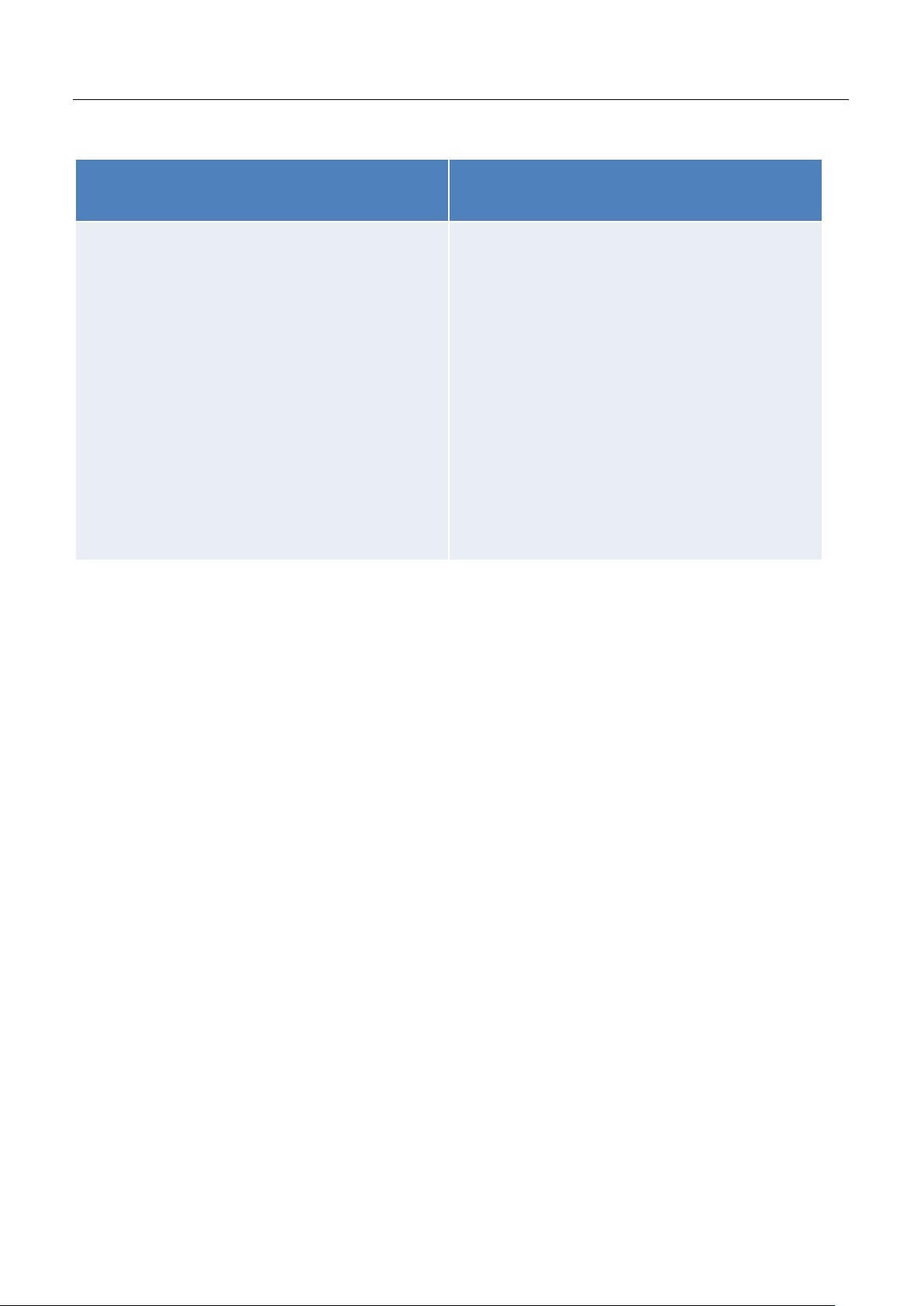

2.1 Application............................................................................................................................... 10

2.2 Operating conditions................................................................................................................ 10

2.3 Principle of operation............................................................................................................... 10

3. Installation ....................................................................................................................................11

4. Explanation of display and keys ............................................................................................... 12

5. The magnetic temperature sensor ............................................................................................. 12

6. Method of operation.................................................................................................................... 13

6.1 Heating a hanging workpiece .................................................................................................. 13

6.2 Heating a horizontal workpiece................................................................................................ 14

6.3 Maximum weights for swivel arm models................................................................................. 15

7. Operation..................................................................................................................................... 16

7.1 Heating in temperature mode (start position of the heater) ...................................................... 16

7.2 Heating in time mode............................................................................................................... 16

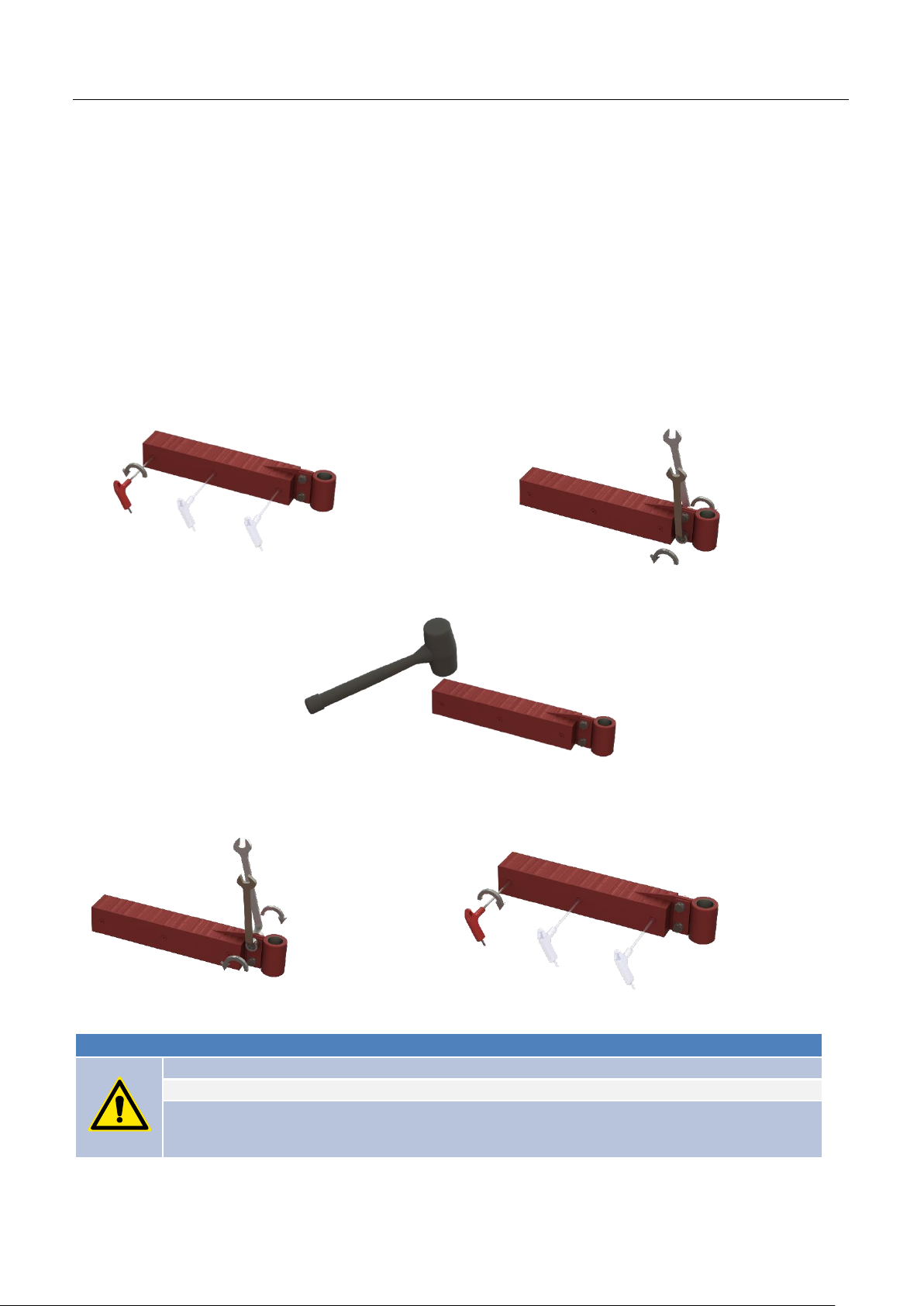

7.3 Workpiece installation.............................................................................................................. 17

7.4 Error message......................................................................................................................... 17

7.5 Switching between Celsius and Fahrenheit ............................................................................. 17

8. Cleaning, maintenance and troubleshooting ............................................................................ 18

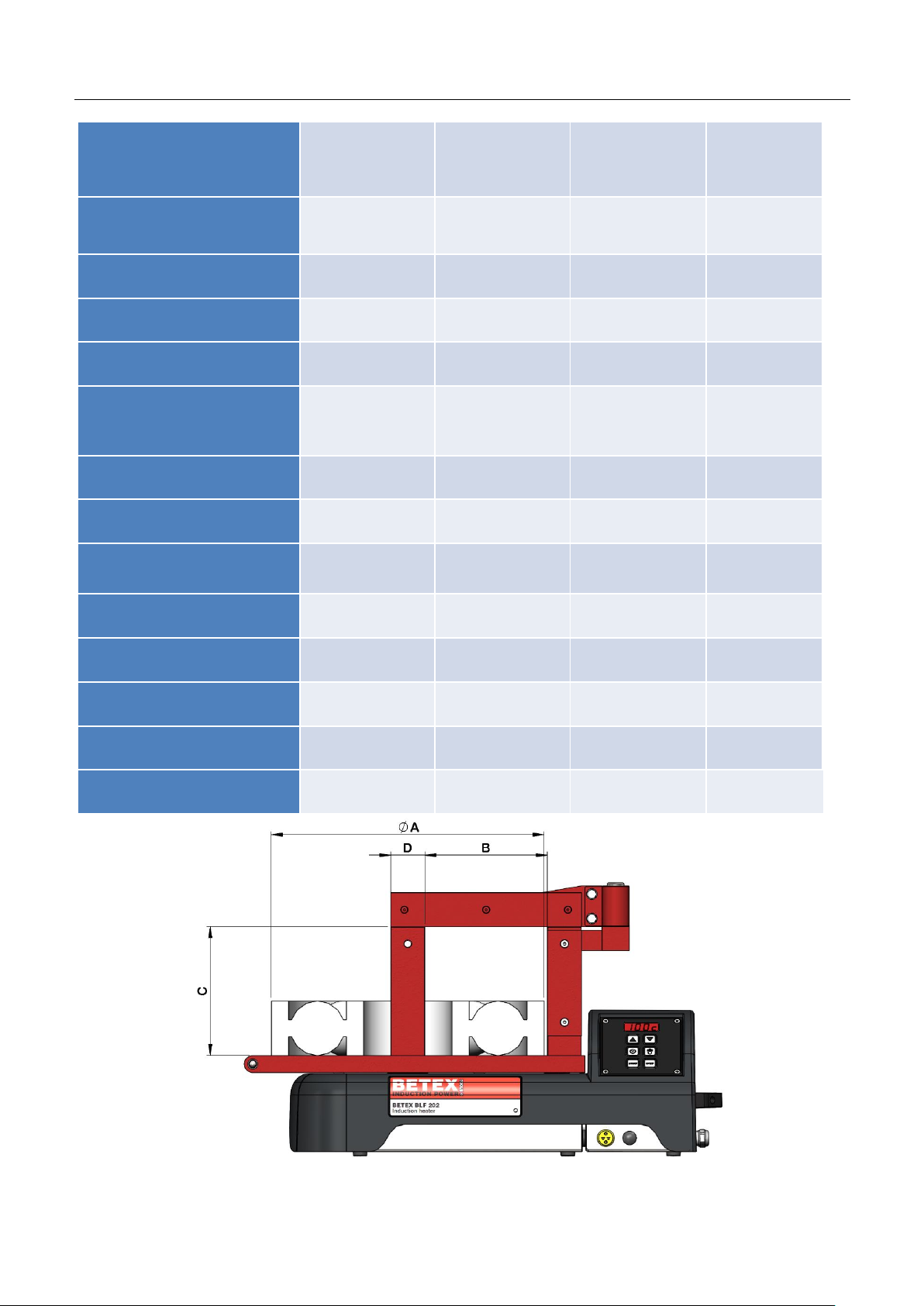

9. Technical specifications ............................................................................................................. 19

10. Miscellaneous............................................................................................................................ 20

10.1 Warranty conditions............................................................................................................... 20

10.2 Disclaimer.............................................................................................................................. 20

10.3 Waste disposal ...................................................................................................................... 20

11. Certificate of conformity ........................................................................................................... 21

Annex 1. Electrical diagrams.......................................................................................................... 22