BETTCHER INDUSTRIES Whizard Quantum Q350 Installation guide

Maintenance

Overview

World Headquarters:

6801 State Route 60, Birmingham, OH 44889 USA

quantum@bettcher.com | www.bettcher.com/quantum

Quantum, Whizard, The Pioneer in Trimming and the Bettcher design are trademarks of Bettcher Industries, Inc.

U.S. and international patents. ©2015 Bettcher Industries, Inc. All rights reserved.

Toll-Free: 800-321-8763 | Tel. 440-965-4422 | Fax: 440-328-4535

Offices in Brazil, China, Europe

t h e P i o n e e r i n T r i m m i n g

Rinse & Dry: Rinse and

completely dry all parts.

! Sharp blades may cause cut injury!

! Keep hands away from blades!

! For proper protection of hands, protective cut

resistant gloves should be used when cleaning

equipment and during the handling of the blades.

Clean:

Rinse: Immediately after use.

1. 3.

5.

Clean Handle & Frame:

Remove handle and clean all

surfaces of handle and frame.

4.

Soak: Use 2 oz per gallon of

Extra Cleaner of warm water

... soak for 30 minutes.

2.

Case Part

#184331

WARNING!

Any blade that

passes through

the gauge is worn.

Replace Blade.

With the gear teeth

facing the back,

simply drop a

blade into the

gauge.

Blade Wear Gauge - Simple ‘Go / No Go’ Test

Compressed Air Helps

Case #184331

4 gallons and pump

Gallon #184332

Whizard Cleaning

Tools Kit #184334

4

4

Part # Trimmer Model(s)

163918 Q360/Q350 360M2/350M2 L.P.

163923 Q620/625M2 Low Profile

173577 Q620 Low Profile

163924 Q625 / 620M2 Low Profile

163928 Q1000 / Q1500 / Q1000 / Q1500

173575 Q500/500M2 Low Profile

163920 Q505 / 505M2

163925 Q750 / 7520M2 Low Profile

163926

163927

Q850

Q1850 / 1850M2

Quantum Blade Wear Gauges

Cleaning — Completely Disassemble & Clean

Preventative maintenance program and forms online @ www.bettcher.com/quantum-logs

TRIMMER SYSTEM

Q350/ Q360 Trimmers

Thumb Support

#101021

Knob Assembly

#100649

#100639 – Handle, Small

#100693 – Handle, Medium

#100694 – Handle, Large

Cover Assembly

#183648

Bearing

#100996

Pinion

#183651

Handle Spacer Ring

#

101030 Small

#101130 Med/Large

Grease Ring

#100961

O-Rings (2)

#103388

Frame

Assembly

#101640

Blade Housing

#102075

Blade #

Q350 102076

#

Q360 102077

Poultry Cover

185128

#

Grease Cup Assembly

#101090 Small

#100998 Medium

Inspect Parts

& Re-Assemble

Inspect Parts

& Re-Assemble

Bottom View

Close-Up

Easy to Train, Simple to Use

Top View

Flat Blades

Top View

Straight Blades

EdgeMaster

Steeling Fixture

The EdgeMaster handheld steeling device

quickly restores rolled edges using a fixture that

guarantees the correct angle every time.

E-Z Edge (blue handle) takes just seconds to

sharpens and steels blades at the same time.

E-Z Edge

Sharpens & Steels

Cover Retainer

Screws (2)

#103758

High Performance Grease

#102609 – 13.5 oz / 383 g

#102612 – 35 lb / 15,8 kg

®

HIGH PERFORMANCE GREASE

®

Blade Housing

#102074

Blade #

Q620 102078

#

Q625 102079

Cover Assembly

#101039

Q620

Poultry Cover

#

Asm 101146

Bearing

#100996

Frame

Assembly

#101086

Thumb Support

#101021

Grease Cup Assembly

#101090 Small

#100998 Medium Handle Spacer Ring

#

101030 Small

#101130 Med/Large

Grease Ring

#100961

Pinion

#183365

Cover Screws (2)

#183376

O-Rings (2)

#103388

Inspect Parts

& Re-Assemble

Inspect Parts

& Re-Assemble

Q625 Cover

w/Steeling Device

#101078

Knob Assembly

#100649

#100639 – Handle, Small

#100693 – Handle, Medium

#100694 – Handle, Large

Serrated Blade Q625

#102092

Poultry Cover

#

Q620 101192

#

Q625 101192

Q620 / Q625 Trimmers

Check for rounded or

broken teeth. When re-

placing the pinion also

replace the bearing.

Damaged teeth caused by

worn parts or improper

housing adjustment.

Normal wear pattern.

Replace pinion and bearing.

4Inspect Pinion

TRIMMER SYSTEM

Micro-Break Strap

#103060

Open Depth Gauge

#183076

Closed Depth Guage

#183075

Q1850 / Q1880 Serrated Blade

#101366

Q1850 / Q1880 Blade

#102088

Q850/Q880

Cover Assembly

with Steel

#101437

Bearing

#100996

Frame

Assembly

#101406

Pinion

#183063

Cover Screws (2)

#188017 O-Rings (2)

#103388

Grease Ring

#100961 Handle Spacer Ring

#

101030 Small

#101130 Med/Large

Blade Housing

#102089

Blade #

Q750 102085

#

Q750 101363 Serrated

#

Q850 102087

Grease Cup Assembly

#100998 Medium

#

101316 Large

Knob Assembly

#100649

#100639 – Handle, Small

#100693 – Handle, Medium

#100694 – Handle, Large

Q750

Cover Assembly

#101374

Inspect Parts

& Re-Assemble

Inspect Parts

& Re-Assemble

Q1880 Cover Assembly

#

with Steel 101443

Q750 Poultry Cover

101375

#

Q750/Q850/Q880/Q1880 Trimmers

Check for rounded or

broken teeth. When re-

placing the pinion also

replace the bearing.

Damaged teeth caused by

worn parts or improper

housing adjustment.

Normal wear pattern.

Replace pinion and bearing.

4Inspect Pinion

TRIMMER SYSTEM

#

Q1400 / Q1500 173348

The inner disk can be flipped: metric on

one side and US inches on the other.

Depth Gauge Setting Fixture

Blade #

Standard 100629

#

Serrated 100780

Cover Screws (2)

#101046

Blade Housing

#100628

Cover Assembly

#101031

Cover withOUT

Steeling Device

#101556

Pinion

#183154

Bearing

#100996 Frame Assembly

#100956

Grease Ring

#100961

Knob Assembly

#100649

#100639 – Handle, Small

#100693 – Handle, Medium

#100694 – Handle, Large

Handle Spacer Ring

#

101030 Small

#101130 Med/Large

O-Rings (2)

#103388

Grease Cup Assembly

#100998 Medium

#

101316 Large

Inspect Parts

& Re-Assemble

Inspect Parts

& Re-Assemble

#

Q1400 / Q1500 173348

Closed Depth Gauge

#183160

®

Whizard Trimmers - Q1000/Q1500

Check for rounded or

broken teeth. When re-

placing the pinion also

replace the bearing.

Damaged teeth caused by

worn parts or improper

housing adjustment.

Normal wear pattern.

Replace pinion and bearing.

4Inspect Pinion

TRIMMER SYSTEM

Check for rounded or

broken teeth. When re-

placing the pinion also

replace the bearing.

Damaged teeth caused by

worn parts or improper

housing adjustment.

Normal wear pattern.

Replace pinion and bearing.

4Inspect Pinion

Cover Screws (2)

#101046

Blade Housing

#100628

Cover Assembly

#101032

Cover withOUT

Steeling Device

#101556

Pinion

#183154

Bearing

#100996 Frame Assembly

#100956

Grease Ring

#100961

Knob Assembly

#100649

#100639 – Handle, Small

#100693 – Handle, Medium

#100694 – Handle, Large

Handle Spacer Ring

#

101030 Small

#101130 Med/Large

O-Rings (2)

#103388

Grease Cup Assembly

#100998 Medium

#

101316 Large

Post Handle Kit

#101280

Inspect Parts

& Re-Assemble

Inspect Parts

& Re-Assemble

Open Depth Gauge

#183159

Blade #

Standard 100630

#

Serrated 100781

®

Whizard Trimmers - Q1300/Q1400

TRIMMER SYSTEM

High Performance Grease

#102609 – 13.5 oz / 383 g

#102612 – 35 lb / 15,8 kg

®

HIGH PERFORMANCE GREASE

®

Bearing Removal Kit

#

Part 184983

Push Rod

Bearing

Remover

The correct blade housing adjustment is critical for proper

trimmer operation. If the housing is too tight the trimmer may

overheat. The motor-driven flex shaft and casing may be dam-

aged, and parts life will be reduced. If the housing is adjusted

too loose, it may cause rough operation and gear damage.

Here's a procedure to help you get it right:

Tighten Blade Housing:

Begin by threading both screws in the pinion cover. Then tighten

the right cover screw. Next, secure the left cover screw— then

loosen the left screw a half turn to allow for blade and housing

adjustment.

Blade Adjustment:

Gently pry the housing open (see Image 1) until the blade has a

slight amount of side clearance in the housing in the direction of

the arrow shown in Image 2 and the blade rotates freely. A slight

amount of clearance is all that is needed. Finally, tighten both

cover screws to the recommended torque and recheck the blade

clearance and rotation.

Recommended Torque: 30 - 35 lb. in. (3,4 - 4,0 N-m)

Important:

Make sure the blade is free to move in the housing. If the blade

does not move freely, it may cause the trimmer to perform

poorly or overheat.

With the left screw loosened, gently

pry the housing open if the blade is

not moving freely.

The blade should turn freely with a slight

amount of clearance in the direction

shown by the arrow.

Right

Left

Image 1.

Loosen Blade

Housing

Image 2.

Check blade for clearance and rotation.

Q1000~Q1500

#183154

Q620A

#183367

Angled Head

Trimmer

Q620/Q625

#183365

Q750/Q850

Q880/Q1880

#183063

Q350/Q360

Q440

#183651

Quantum Pinions

4

Proper Housing Adjustments

TRIMMER SYSTEM

Begin by making sure the cover is tightened securely … that is,

the cover retaining screws are tightened properly (very tight).

The “best practice” to secure the pinon cover and housing is to

use a torque limiting T-handle tool (Bettcher Part #183898) to

secure the housing quickly and properly.

Using a straight-blade screwdriver, slowly apply pressure to the

housing. If the housing moves easily without much pressure, the

cover is worn. It should be replaced, as it can no longer secure the

blade and housing and may become a safety issue in addition to

running rough.

If the blade housing does not move easily unless a lot of pressure is

applied, then the cover is still good and has useful life.

That's all there is to it! By using this simple test, you should

improve Trimmer performance and lower maintenance costs.

You may also view a video clip demonstrating these test procedures.

To view the video go to:

Torque Limiting T-Handle

4

Begin with a properly

tightened cover using the

Bettcher Torque Limiter

30 - 35 lb. in (3,4 - 4,0 N-m)

Apply gentle pressure, if the

housing moves, the cover is worn.

The cost of a T-handle torque limiter is

about the same as a new pinion cover, so it

makes sense to invest in this tool to ensure

all Trimmer parts are properly assembled for

maximum life and performance.

Additionally, many maintenance pros find

that using the T-handle torque limiter is

faster, easier and more precise than using a

straight blade screwdriver.

Torque Wrench Kit

#

Part 183900

Damage occurs when the housing is

pried without first loosening the

cover screw (red arrow).

Loosen

First

Loosen

First

!

www.bettcher.com/pinion-cover

4Preventing Cover Damage

Torque Limiting Kit

4

Part # Description

183900

183898

183899

183901

183902

Kit 183900

Torque Wrench

Socket ¼” 6 pt

Stecknuss 5/16” 6 pt

Extension ¼” x 3” long

Cover Wear Testing

Simple test to determine the time to replace. TRIMMER SYSTEM

Options and Accessories

Post Handle Kit

#101280

#100639 – Handle, Small

#100693 – Handle, Medium

#100694 – Handle, Large

Handle Spacer Ring

#101030 – Small

#101130 – Medium / Large

Knob Assembly

#100649

Micro-Break

Strap

#103060

Sizes:

Thumb Support

#101021

Small

#101090

Medium

#100998

Large

#101316

4

44Drive End Assembly

Driveline Only

#

48” Small Dia. w/Driver 102755

#

60” Small Dia. w/Driver 102756

Replaceable

#

Driver Assembly 100709

Driver Tip

#100305

Not Pictured

#

48” Small Dia. 102367

#

60” Small Dia. 102368

Quick

Disconnect

Quantum Driveline

4

Grease Cups

Micro-Break Strap

Post Handle

Quantum Handle

4

4

4

4

4

4

Non-Disconnect

#

48” Large Dia. w/Driver 101051

#

60” Large Dia. w/Driver 101054

#

84” Large Dia. w/Driver 102671

#

48” Large Dia. 100618

#

60” Large Dia. 100619

#

84” Large Dia. 102551

4

Quick Disconnect

#

48” Small Dia. w/Driver 102758

#

60” Small Dia. w/Driver 102760

#

48” Large Dia. w/Driver 101055

#

60” Large Dia. w/Driver 101056

#

84” Large Dia. w/Driver 102672

TRIMMER SYSTEM

35 lb. Pail

#102612

13.5 oz. Cartridge

#102609

Listed for use in federally inspected

meat and poultry plants for incidental

food contact. Lubricant specially

devel oped for us e on equip ment

requiring extended performance.

Nonfood Compounds

Program Listed (H-1)

(Registration #150331)

®

HIGH PERFORMANCE GREASE

Net Weight 13.5 oz. (383 g)

NLGI No. 2 Grease | Polyalphaolefin (PAO) Based Synthetic Oil (Grease) | Formula Trade Secret

®

HIGH PERFORMANCE GREASE

®

New

Higher Performance

Superior Protection

Latch #

Collar 100711

Washer

#100713 Driver Tip

#100305

Driveline

#

48” 100618

#

60” 100619

Save money by reusing the

driver end assembly.

Drive End

Assembly Complete

#

100709

4

Use an adjustable

wrench to remove

the driver

assembly from the

casing.

4

Remove the Drive-end assembly

Driver Tip

#100305

Place the Drive Shaft Tool over the square-

end of the driver shaft fits into the square

hole of the tool. This is a left-hand thread,

so turn clockwise to loosen.

The Driver can now be replaced.

#

Quantum Drive Shaft Tool Part 101252

DRIVELINE

Driveline Driver Assembly

When replacing a Quantum Driveline, the driver assembly may be

removed and used on the new casing. To remove driver assembly:

nHold the worn casing end in vise.

nUnscrew the drive end assembly, turning counterclockwise, using

the wrench flats on the drive end assembly.

nRemove the washer and latch collar from casing.

nDiscard the old casing, but reuse the driver assembly on the new

casing.

Assembling the Driver Assembly to the Casing

nSlide casing latch collar and washer on to new casing end.

® #

nClean threads of new casing and apply Loctite 242

Threadlocker.

nThread drive end assembly on to the new casing and tighten with

a wrench while holding casing in hand.

Caution: DO NOT hold the NEW casing in a vise or use pliers as damage

will occur. It is not necessary to over-tighten this joint.

TRIMMER SYSTEM

All trimmers should be disassembled, cleaned, and lubricated after every 8 hour shift.

When these procedures are followed, the estimated parts life, based upon single shift

use is indicated below:

Place a mark in the proper box to indicate when a part was changed

Forms online @ www.bettcher.com/quantum-logs

Whizard Trimmer Maintenance Log

Whizard Trimmer Maintenance Log

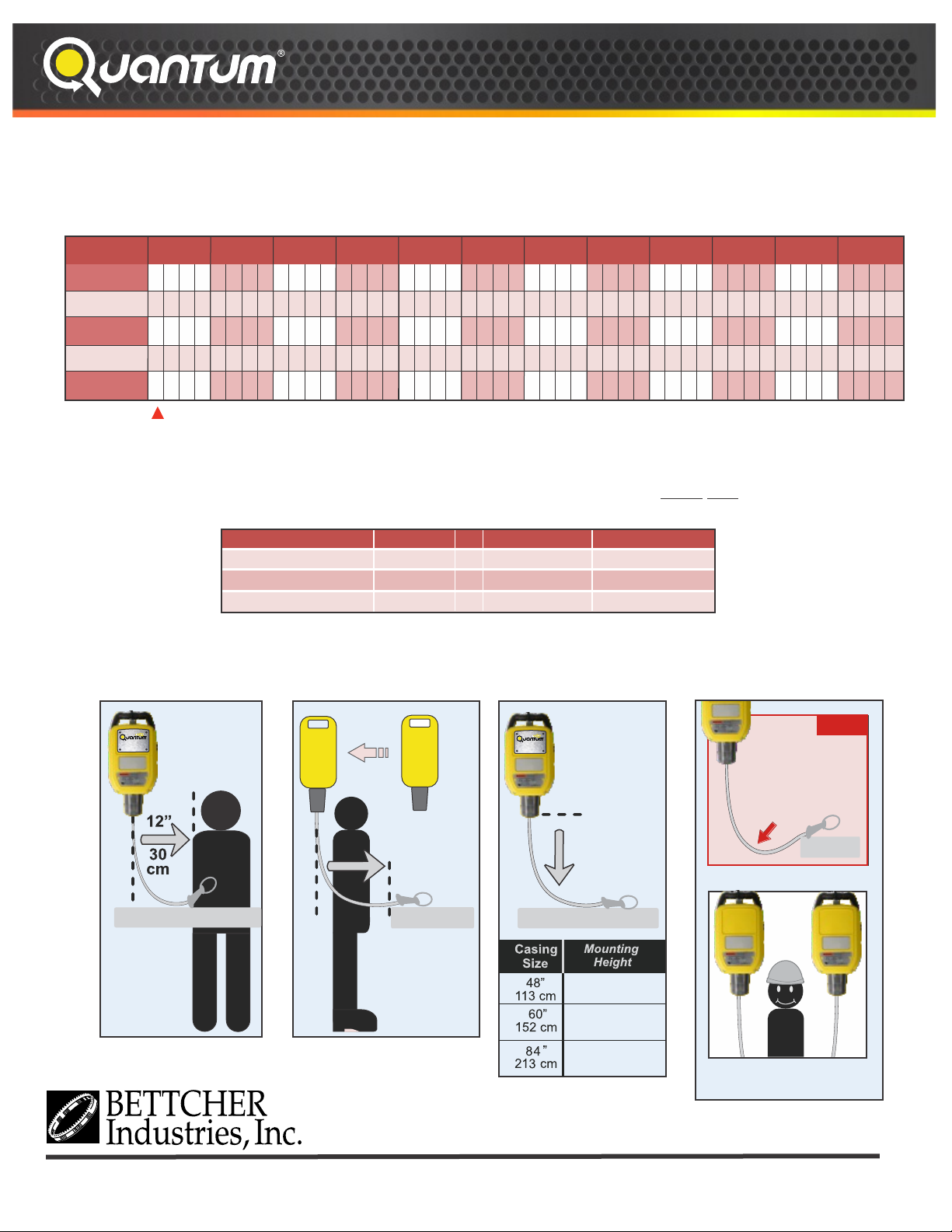

Proper Motor Mounting Height for a Flat Surface

www.bettcher.com

Headquarters: 6801 State Route 60 • Birmingham, OH 44889

Tel: (440)965-4422 • (800)321-8763 • Fax: (440) 328-4535 • E-mail: sales@bettcher.com

Bad

Excessive

curves

accelerate

wear!

Eliminate droopy flex shafts.

Motor position for left- or

right-hand dominance.

P a r t

P a r t Dec.

Dec.

Jan.

Jan. Nov.

Nov.

May

May Jun.

Jun. Jul.

Jul. Aug.

Aug. Sep.

Sep. Oct.

Oct.

Feb

Feb Mar.

Mar. Apr.

Apr.

Pinion

Driveline

Blade

Blade Housing

Bearing

Weeks

Weeks

Blade 4 - 6

Driveline

Small Blade Housing

Large Blade Housing

8 - 10

20 - 24

Pinion Gear 8 - 10

Bearing 10 - 12

Weeks

Weeks

P a r t P a r t

P a r t P a r t

up to 20

© 2015 Order: TS-1014 Rev C. US

Right

Hand

Left

Hand

49 1/2”

125 cm

63 1/2”

161 cm

63 1/2”

161 cm

All

Motors

Mount motors

behind worker.

X

X

All

Motors

TRIMMER SYSTEM

TRIMMER SYSTEM

Long / X-Long

Largo/ X-Largo

15” x 38 cm

Short / Pequeño

12” / 30 cm

TRIMMER SYSTEM

Preventative maintenance program and forms online @ www.bettcher.com/quantum-logs

This manual suits for next models

11

Table of contents

Other BETTCHER INDUSTRIES Trimmer manuals

Popular Trimmer manuals by other brands

Stanley

Stanley SXPG42604 operating manual

Ergo tools

Ergo tools Pattfield E-RT 3525 Directions for use

Black & Decker

Black & Decker NST2218 instruction manual

Toro

Toro Flex-Force Power System 51834 Operator's manual

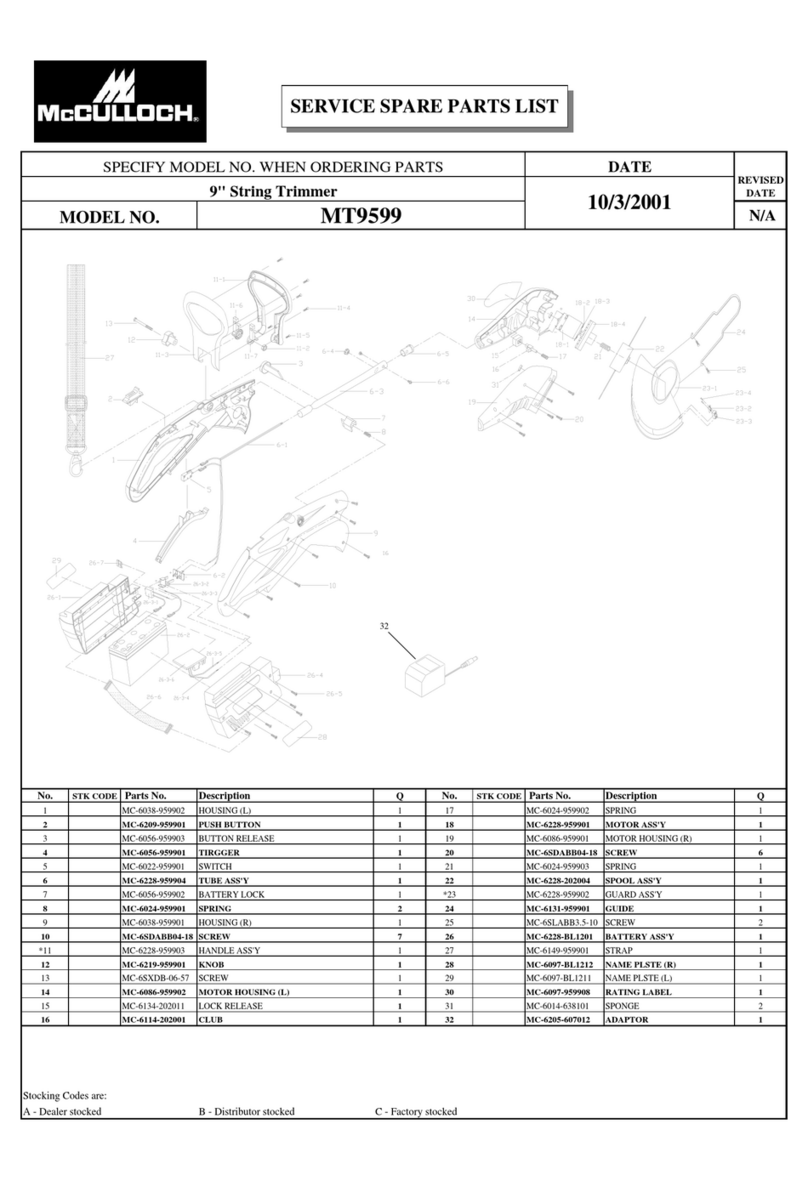

McCulloch

McCulloch MT9599 Service spare parts list

Husqvarna

Husqvarna 227R, 227RD, 232R, 232RD, 235R Operator's manual

Husqvarna

Husqvarna 324L X-series Operator's manual

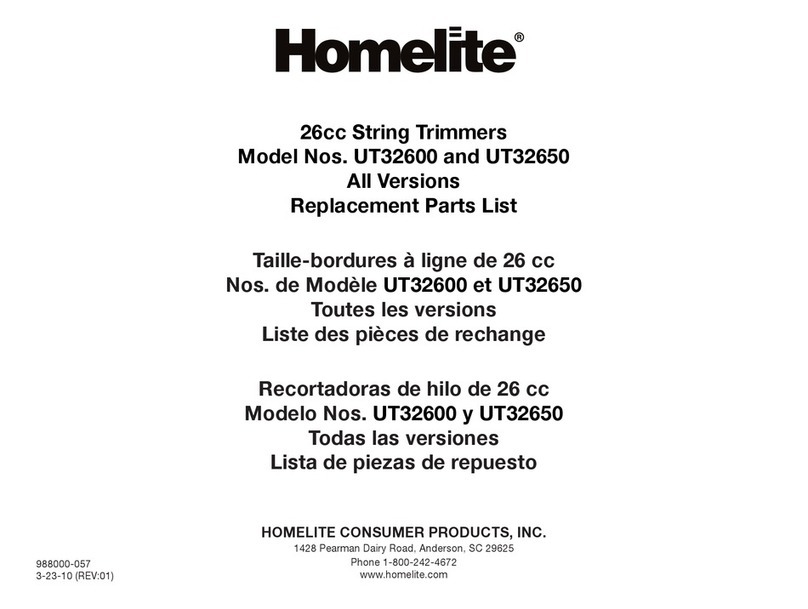

Homelite

Homelite UT32600 Replacement parts list

Troy-Bilt

Troy-Bilt AST TB75SS Operator's manual

Remington

Remington Titanium All-in-one PG6020AU Use & care manual

Echo

Echo GT-200R - 12-08 Operator's manual

Garden Groom

Garden Groom Garden Groom "Midi" GG10 instruction manual