Betts ES22PP-AABN Manual

Form Title:

Document #:

INSTALLATION AND MAINTENANCE MANUAL

MM-AD005

(Form: DEF-006A-4)

Revision:

0

Document Title:

Date:

Emergency/Remote Shutdown Air Valves

Oct. 26, 2023

Page:

1 of 10

Betts Industries Inc. ▪814·723·1250 ▪1800 Pennsylvania Ave. West ▪Warren, PA 16365 ▪www.BettsInd.com

Print Date: 11/21/2023 This form is considered uncontrolled 24 hrs. after print date.

PART NUMBERS (Including, but not inclusive)

ES22PP-AABN

Table of Contents:

1.0 General

2.0 Parts List

3.0 Description and Intended Use

4.0 Installation

5.0 Inspection and Testing

6.0 Disassembly and Rebuild Instructions

7.0 Troubleshooting Guide

Form Title:

Document #:

INSTALLATION AND MAINTENANCE MANUAL

MM-AD005

(Form: DEF-006A-4)

Revision:

0

Document Title:

Date:

Emergency/Remote Shutdown Air Valves

Oct. 26, 2023

Page:

2 of 10

Betts Industries Inc. ▪814·723·1250 ▪1800 Pennsylvania Ave. West ▪Warren, PA 16365 ▪www.BettsInd.com

Print Date: 11/21/2023 This form is considered uncontrolled 24 hrs. after print date.

1.0 General Maintenance Manual Guidelines

1.1 It is strongly recommended that this entire manual be read prior to any operation, disassembly, or

assembly of this equipment.

1.2 Betts Industries, Inc. provides this manual as a guideline for reference only and assumes no

responsibility for personal injury or property damage that may occur in conjunction with this manual.

Betts Industries, Inc. cannot be held responsible for incorrect installation, operation or maintenance

ofthis equipment. Useonly genuineBetts replacementparts. Substituteparts will voidall warranties

and could impair the proper function making this equipment unsafe.

1.3 Betts Industries, Inc. recommends all equipment be placed on a regular maintenance schedule that

includes the routine replacement of seals and gaskets and visual inspection for leaks and corrosion.

The end user must make their own determination and set their own schedule based upon use and

environment. In some cases, regulations may dictate the minimum testing frequencyof items. Make

sure operators are aware of all applicable codes.

1.4 Only trained and qualified personnel should perform maintenance on this equipment.

1.5 As with any maintenance work, proper safety gear must be utilized and approved procedures must

be followed at all times. Examples of safety gear may include but are not limited to gloves, safety

goggles, face shields, protective suits and respirators. It is the responsibility of the person/company

working on this equipment to identify the hazardous products that the equipment has been exposed

to and designate specific and appropriate protective gear and safety procedures.

1.6 Safety alert symbols are used to alert operator to potential personal injury hazards. These symbols

are per ANSI Z535.5 and are listed below. Operator MUST obey all instructions that follow a safety

symbol. Alerts will be used to indicate known safety concerns.

A list of hazards may include but are not limited to fall hazards, pressure hazards, loaded springs,

corrosive material, flammable product, pinch points. Additional concerns are possible and should

be identified and avoided by the operator.

1.7 Product Warranty shall be void if equipment is subject to misapplication, misuse, neglect, alteration,

or damage.

1.8 Specific design details described in this document are for reference only and are subject to change

without notice. See Betts Industries, Inc. web page for the most recent revision to this document.

www.bettsind.com

1.9 WARNING: This product can expose you to chemicals including Chromium (hexavalent

compounds), which is known to the State of California to cause cancer and birth defects or other

reproductive harm. For more information go to: www.P65Warnings.ca.gov

1.10 For additional questions or more detailed technical assistance, contact the Betts Industries, Inc.

Customer Service, Sales or Engineering Department at (814) 723-1250.

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also be

used to alert against unsafe practices.

Form Title:

Document #:

INSTALLATION AND MAINTENANCE MANUAL

MM-AD005

(Form: DEF-006A-4)

Revision:

0

Document Title:

Date:

Emergency/Remote Shutdown Air Valves

Oct. 26, 2023

Page:

3 of 10

Betts Industries Inc. ▪814·723·1250 ▪1800 Pennsylvania Ave. West ▪Warren, PA 16365 ▪www.BettsInd.com

Print Date: 11/21/2023 This form is considered uncontrolled 24 hrs. after print date.

4.69

CLOSED

5.12

OPEN

1.75

1.00

1.12

.94 Ø.21

1/4" NPT

1/4" NPT

1/4" NPT

1.93

2.65

3/4-16 UNC

2.0 Parts List

No.

Description

Req.

Material

Part No.

1

Control Block

1

Anodized Aluminum

36260AA

2

Piston

1

Stainless Steel

29483SL

3

O-Ring

4

Nitrile (Buna-N)

19467BN

4

Detent O-Ring

1

Polyurethane

19507PY

5

Bushing

1

Brass

76299BR

6

Jam Nut 3/4-16

1

Stainless Steel

9Q9729

7

Flange Nut 5/16-18

1

Stainless Steel

9Q5859

8

Control Knob (Red)

1

Anodized Aluminum

76185AA-RED

9

Sticker - Shutdown

1

Vinyl

AD76276

10

End cap

1

LDPE

76327PE

1

2

5

6

10

3

3

3

3

4

8

9

7

9

Form Title:

Document #:

INSTALLATION AND MAINTENANCE MANUAL

MM-AD005

(Form: DEF-006A-4)

Revision:

0

Document Title:

Date:

Emergency/Remote Shutdown Air Valves

Oct. 26, 2023

Page:

4 of 10

Betts Industries Inc. ▪814·723·1250 ▪1800 Pennsylvania Ave. West ▪Warren, PA 16365 ▪www.BettsInd.com

Print Date: 11/21/2023 This form is considered uncontrolled 24 hrs. after print date.

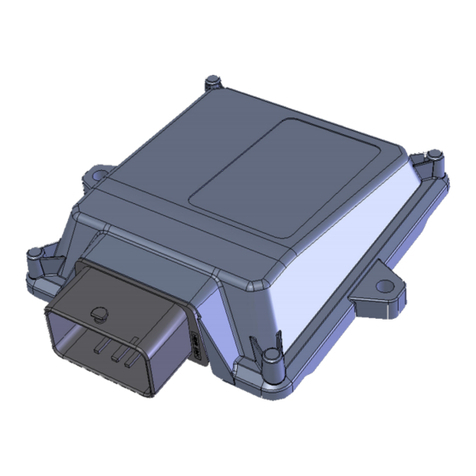

3.0 Description and Intended Use

The Betts’ Emergency/Remote Shutdown Air Valve is a two position push/pull control valve. When plumbed and

mounted correctly, it fulfills the requirements of a remotely actuated means of closure per US DOT 49CFR§178.345-

11(b)(1)(i) and CSA B620-20 clause 5.6.12.3(b), (c), and (f). The Emergency/Remote Shutdown is mounted on the

end of the cargo tank farthest away from the loading/unloading outlet with normal position of the valve in the pulled-

out position and initiates shutdown function when the knob is pushed in. Please note, the Emergency/Remote

Shutdown Valve does not provide provision for thermal activation. If required, fusible plugs should be installed in-

line as needed.

The valve block is lightweight anodized aluminum. The valve includes a detent retention feature for positive click-

in feel during operation. All ports are ¼” NPT. The valve can be mounted via the through holes in the valve body

or through a Ø.81” hole in a panel and secured with the ¾“ hex nut (included).

Simplified plumbing schematics are provided below for the two most common methods of operation. A detailed

plumbing schematic is available upon request. Verify proper shutdown function once valve is installed and test

monthly during active service.

Plumbing Option 1

Emergency Shutdown provides positive air signal

Plumbing Option 2

Emergency Shutdown exhausts air system pressure

Knob pushed-in position: Positive

air signal is sent from port 2 to

compatible Air Panel or Master

Control Valve which shuts down

pneumatic valve system.

Knob pushed-in position: Port

2 exhausts air pressure from

air-lines and shuts down

pneumatic valve system.

Knob pulled-out position: Port 2

exhausts air pressure from Air

Panel or Master Control’s reset

ports and the cargo tank valve

system is now operational.

Knob pulled-out position: Port

2 supplies air pressure to

pneumatic valve system and

the cargo tank valve system is

now operational

4.0 Installation

4.1 Per US DOT 49CFR§178.345-11(b)(1)(i), the Emergency Shutdown Valve must be “located more

than 10 feet from the loading/unloading outlet where vehicle length allows, or on the end of the

cargo tank furthest away from the loading/unloading outlet.”

4.2 Per §172.328(d) “each on-vehicle manually-activated remote shutoff device for closure of the

internal self-closing stop valve must be identified by marking “Emergency Shutoff” in letters at least

0.75 inches in height, in a color that contrasts with its background, and located in an area

immediately adjacent to the means of closure.”

4.3 The valve can be mounted via the through holes in the valve body or through a Ø.81” hole in a

panel and secured with the ¾“ hex nut (included). See figures 1 and 2.

4.4 The valve should be mounted with exhaust port facing down protected from moisture. If needed,

utilize an elbow and drop tube to route the exhaust to an area free of moisture or debris.

4.5 If airline conditioner/antifreeze is used, it must be compatible with O-ring material.

Pushed

In

Pulled

Out

Pushed

In

Pulled

Out

Form Title:

Document #:

INSTALLATION AND MAINTENANCE MANUAL

MM-AD005

(Form: DEF-006A-4)

Revision:

0

Document Title:

Date:

Emergency/Remote Shutdown Air Valves

Oct. 26, 2023

Page:

5 of 10

Betts Industries Inc. ▪814·723·1250 ▪1800 Pennsylvania Ave. West ▪Warren, PA 16365 ▪www.BettsInd.com

Print Date: 11/21/2023 This form is considered uncontrolled 24 hrs. after print date.

Fig. 1: Secured with Panel Nut, and drop tube to route exhaust

Fig. 2 : Secured with Socket Head Cap Screws through body

5.0 Inspection and Testing

5.1 Bench Test

5.1.1 Inspect all components for corrosion or damage and replace if necessary.

5.1.2 Actuate the valve twice to ensure it is functioning properly with smooth operation.

Ensure that the detent bushing feature is functioning properly with click-in feel in both

open and closed positions.

5.1.3 Check and ensure the end cap is snapped into the back of the valve and ensure that

the vent hole in the cap is not plugged or blocked.

5.1.4 Apply line pressure of 90-125 psi to the ports shown in the table below and inspect for

leaks. See Disassembly and Rebuild section for needed repairs.

Exhaust elbow

drop tube

Exhaust exits at bottom

Form Title:

Document #:

INSTALLATION AND MAINTENANCE MANUAL

MM-AD005

(Form: DEF-006A-4)

Revision:

0

Document Title:

Date:

Emergency/Remote Shutdown Air Valves

Oct. 26, 2023

Page:

6 of 10

Betts Industries Inc. ▪814·723·1250 ▪1800 Pennsylvania Ave. West ▪Warren, PA 16365 ▪www.BettsInd.com

Print Date: 11/21/2023 This form is considered uncontrolled 24 hrs. after print date.

5.2 Field Testing (monthly testing)

5.2.1 Visual inspection:

5.2.1.1 Inspect exterior of valve for corrosion or damage. Pay special

attention to the area where the stem moves in and out of the bushing.

5.2.1.2 Inspect for any air leaking at any of the fittings, at the stem or end cap.

5.2.1.3 Look for leakage of fluid out of exhaust port. This could be an

indication of a seal failure in one of the Emergency Valves or Air

Manifold. Investigate and repair the problematic component.

5.2.1.4 Ensure the end cap is snapped into the back of the valve and ensure

that the vent hole in the end cap is not plugged or blocked.

5.2.1.5 Inspect exhaust port and make sure it is unobstructed and oriented in

an area that is protected from weather, debris or moisture.

Valve

Port

Valve Position

Checks

1

Valve Open

1. Port 1 blocks pressure.

2. No leakage at port 2 or 3.

3. No leakage between the End Cap and the Body or out the

hole in the End Cap.

4. No leakage between the stem and the front of the body.

1

Valve Closed

1. Port 2 expels pressure.

2. No leakage at port 3.

3. No leakage between the End Cap and the Body or out the

hole in the End Cap.

4. No leakage between the stem and the front of the body.

3

Valve Closed

1. Port 3 blocks pressure.

2. No leakage at port 1 or 2.

3. No leakage between the End Cap and the Body or out the

hole in the End Cap.

4. No leakage between the stem and the front of the body.

3

Valve Open

1. Port 2 expels pressure.

2. No leakage at port 1.

3. No leakage between the End Cap and the Body or out the

hole in the End Cap.

4. No leakage between the stem and the front of the body.

2

3

1

Air In

2

3

1

Air In

2

3

1

Air In

2

3

1

Air In

Form Title:

Document #:

INSTALLATION AND MAINTENANCE MANUAL

MM-AD005

(Form: DEF-006A-4)

Revision:

0

Document Title:

Date:

Emergency/Remote Shutdown Air Valves

Oct. 26, 2023

Page:

7 of 10

Betts Industries Inc. ▪814·723·1250 ▪1800 Pennsylvania Ave. West ▪Warren, PA 16365 ▪www.BettsInd.com

Print Date: 11/21/2023 This form is considered uncontrolled 24 hrs. after print date.

5.2.2 Operation:

5.2.2.1 Open and close the valve several times.

5.2.2.2 Feel for smooth operation with a positive “click-in” feel in both the

open and closed position.

5.2.3 Functional:

5.2.3.1 Prior to testing the function of the Emergency/Remote Shutdown

Valve make sure the cargo tank is safe to simulate a shut down.

Cargo tank and piping should be empty and all end of piping stop

valves and caps should be closed and in place.

5.2.3.2 With Emergency Valves or Air Manifold Valves open, actuate the

Emergency/Remote Shutdown Valve.

5.2.3.3 To satisfy 49CFR§178.345-11(b)(1), inspect Emergency Valves and

Air Manifold Valves to ensure they completely closed within 30

seconds of actuating the Emergency/Remote Shutdown Valve.

5.2.4 Repair or replace the Emergency/Remote Shutdown Valve if it does not meet any

of the monthly field testing requirements.

6.0 Disassembly and Rebuild Instructions

Pressure Hazard –Cargo tank or piping may contain

residual pressure and failure to safely relieve could result in

sudden loss of pressure causing death or serious injury.

Flammable Product –Cargo tank or piping may contain

product that could present risk of fire, explosion, asphyxiation

or other hazards resulting in death or serious injury.

Tools

Use

½” open ended wrench

Qty 2

Removing the control knob (8) and Flange Nut 5/16-18 (7).

O-ring Pick

Removing O-rings (3)

Small flat head screwdriver

Pop off end cap (this may not be needed)

7/32”Allen Wrench

Prevent piston from spinning to remove (7) (this may not be

needed)

Low temperature silicone

lubricant

Lubricate O-rings (3)

Arbor Press (optional)

Only needed to remove the pressed-in bushing (5)

.495 Dia X 4” Pin (optional)

Only needed to remove the pressed-in bushing (5)

Thread lock compound

Threaded connections

Form Title:

Document #:

INSTALLATION AND MAINTENANCE MANUAL

MM-AD005

(Form: DEF-006A-4)

Revision:

0

Document Title:

Date:

Emergency/Remote Shutdown Air Valves

Oct. 26, 2023

Page:

8 of 10

Betts Industries Inc. ▪814·723·1250 ▪1800 Pennsylvania Ave. West ▪Warren, PA 16365 ▪www.BettsInd.com

Print Date: 11/21/2023 This form is considered uncontrolled 24 hrs. after print date.

6.1 Disassembly

6.1.1 Use the two ½” open ended wrenches to remove the Control Knob (8) and the

Flange Nut (7) from the piston (2). If the flange nut (7) is spinning with the piston, use

a small screwdriver to pop off the end cap (10). Insert a 7/32”Allen wrench into the

end of the piston to prevent it from spinning to remove the Flange Nut (7).

6.1.2 Push the piston (2) through the back of the valve. If the end cap (10) is still on, apply

enough force to pop the end cap and piston out through the back of the valve.

6.1.3 Remove the O-rings (3) from the piston. Using your fingers, squeeze the O-rings (3)

up to be able to slide a plastic O-ring pick under the O-ring and pull it off the piston.

Do not use a sharp pick which may scratch or damage the O-ring grooves on the

piston. The polyurethane detent O-ring (4) is a split O-ring and can easily be pulled

off the piston. Discard the used O-rings.

6.1.4 Clean and inspect the piston (2). Replace if there is any wear or damage.

6.1.5 Clean and inspect the control block (1) bore. Replace if there is any wear, corrosion,

or damage.

6.1.6 Inspect the bushing (5) for corrosion or damage. If it needs replaced, use the .495

diameter pin and push out the bushing (5) using an arbor press.

6.2 Rebuild

6.2.1 If the Bushing (5) was removed, it must be pressed into the Control Block (1) using

an arbor press. Retaining compound is recommended but do not get compound in

the bore of the bushing (5) and clean off all excess compound after assembly.

Ensure that the bushing (5) starts straight and presses flush with the thread face of

the control block (1).

6.2.2 The Detent O-ring (4) is a white polyurethane O-ring. Use a razor blade and cut the

O-ring in one spot. The cut location is not critical.

6.2.3 Install the split Detent O-ring (4) onto the Piston (2) in

the location as shown in Fig. 3.

6.2.4 Install the other O-rings (4) onto the Piston (2) in the

locations as shown in Fig. 3.

6.2.5 Lubricate all O-rings (3) using low temperature silicone

lubricant. Ensure that O-rings are compatible with any

airline conditioner/antifreeze.

6.2.6 Insert the piston (2) with all O-rings into the Control

Block (1). Be careful when inserting the piston to

prevent any O-ring damage.

6.2.7 If attaching to a panel, insert the Control Block into the panel and thread on the panel

Jam Nut (6). Apply thread lock compound to the threads to prevent vibration from

loosening the nut.

6.2.8 Apply thread lock compound to the piston threads and thread on the Flange nut (7)

until it bottoms out on the piston (2). Thread the control knob (8) down to the flange

Fig. 3

Form Title:

Document #:

INSTALLATION AND MAINTENANCE MANUAL

MM-AD005

(Form: DEF-006A-4)

Revision:

0

Document Title:

Date:

Emergency/Remote Shutdown Air Valves

Oct. 26, 2023

Page:

9 of 10

Betts Industries Inc. ▪814·723·1250 ▪1800 Pennsylvania Ave. West ▪Warren, PA 16365 ▪www.BettsInd.com

Print Date: 11/21/2023 This form is considered uncontrolled 24 hrs. after print date.

nut. Using two 1/2” open ended wrenches, tighten the flange nut (7) into the control

knob (8).

6.2.9 Insert the end cap (10) into the Control Block (1).

6.2.10 Test the rebuilt Emergency/Remote Shutdown Valve for proper function per 5.1

Bench Test Procedure prior to installation. Verify proper shutdown function once

installed.

7.0 Troubleshooting Guide

Use to help diagnose potential issues that could be encountered. The list is not all inclusive and other solutions might be needed.

Problem

Potential Cause

Potential Solution

When actuated, the

Emergency/Remote

Shutdown Valve does

not shutdown the

loading/unloading

outlets (emergency

valves).

Emergency/Remote Shutdown Valve is not

plumbed correctly.

Verify the plumbing is correct depending on how

the air system on the cargo tank is designed.

See schematic in section 3.0.

Exhaust port of Emergency/Remote Shutdown

Valve is plugged.

Clear exhaust port.

Airline to Emergency/Remote Shutdown Valve

is not getting air pressure.

Resolve air feed issue.

Airline from Emergency/Remote Shutdown

Valve is damaged, plugged or pinched.

Replace damaged airline.

Master Control Valve on Air Panel is not

operating properly.

Resolve Master Control Valve or Air Panel issue.

Emergency/Remote Shutdown Valve is not

operating properly.

Review entirety of troubleshooting guide and

replace or rebuild Emergency/Remote Shutdown

Valve as necessary.

Valve stuck open or

closed. Hard to

actuate.

Corroded bushing (5) or control block (1).

Investigate reason for corrosion. Harsh cleaning

solutions or incompatible airline additives should

not be used. Remove and replace bushing (5).

If the bore of the control block (1) is corroded it

is recommended to replace the entire valve.

Damaged or bent piston (2).

Replace piston (2) but also inspect bore of

bushing (5) and control block (1) to see if they

are also damaged.

O-rings (3) swelled.

Investigate reason for O-Ring swelling.

Incompatible airline additives should not be

used. Product may be leaking into airline from

one of the Emergency Valves or Air Manifold.

See specific problem below: Product of cargo

tank leaking from exhaust port (liquid/fumes).

O-rings (3) damaged.

Investigate reason for O-rings (3) damage.

Burrs or sharp edges inside bore should be

removed without damaging sealing surface prior

to replacing O-rings (3).

Ice or debris behind end cap (10) or in valve.

Remove ice or debris. Replace end cap (10)

with a new cap. Ensure the exhaust port is

facing down protected from moisture.

Continued on next page.

Form Title:

Document #:

INSTALLATION AND MAINTENANCE MANUAL

MM-AD005

(Form: DEF-006A-4)

Revision:

0

Document Title:

Date:

Emergency/Remote Shutdown Air Valves

Oct. 26, 2023

Page:

10 of 10

Betts Industries Inc. ▪814·723·1250 ▪1800 Pennsylvania Ave. West ▪Warren, PA 16365 ▪www.BettsInd.com

Print Date: 11/21/2023 This form is considered uncontrolled 24 hrs. after print date.

Problem

Potential Cause

Potential Solution

Air leak from valve.

O-rings (3) swelled.

Investigate reason for O-Ring swelling.

Incompatible airline additives should not be

used. Product may be leaking into airline from

one of the Emergency Valves or Air Manifold.

See specific problem below: Product of cargo

tank leaking from exhaust port (liquid/fumes).

O-rings (3) damaged.

Investigate reason for O-rings (3) damage.

Burrs or sharp edges inside bore should be

removed without damaging sealing surface prior

to replacing O-rings (3).

Bore of control block (1) damaged or dirty.

Clean and inspect bore of control block (1). If

bore is damaged replace the entire valve.

O-ring grooves on piston (2) scratched or dirty.

Clean and inspect piston (2). If piston (2) is

damaged replace piston (2).

Bushing (5) has partially pulled out.

Remove and discard bushing (5). Replace

bushing following step 6.2.1.

Flange nut (7) is not threaded down to

shoulder of piston.

Apply thread lock compound to the threads of

the piston (2). Remove end cap (10) and hold

piston (2) stationary with Allen wrench. Tighten

flange nut (7) down to the shoulder of the piston

(2). Tighten the Control knob (8) to the flange

nut and lock together.

Product of cargo tank

leaking from exhaust

port. (liquid/fumes)

This could be an indication of a seal failure in

one of the Emergency Valves or Air Manifold.

Investigate and repair the problematic

component of Emergency Valve or Air Manifold.

Flush and dry all airlines.

The Emergency/Remote Shutdown Valve should

be taken apart, cleaned and O-rings (3) replaced

prior to placing back in service.

Detent is not providing

a positive “click-in” feel

in both the open and

closed position.

Detent O-ring (4) is worn.

Replace with new detent O-ring (4). Please

note, this O-ring is a split polyurethane O-ring.

Flammable Product - Cargo tank, piping

or air system may contain product that

could present risk of fire, explosion,

asphyxiation or other hazards resulting in

death or serious injury.

Table of contents

Other Betts Control Unit manuals

Popular Control Unit manuals by other brands

Immergas

Immergas MAGIS PRO ERP Instruction and recommendation booklet

Pentair

Pentair HI-FLOW 261049 Installation and user guide

Rockwell Automation

Rockwell Automation Allen-Bradley Micro800 manual

Madas

Madas XVR-1-3-6 manual

Gi

Gi MP48 DF installation manual

Baldor

Baldor 23H Series Installation & operating manual

XQP

XQP 500 Series manual

Siemens

Siemens SENTRON product manual

vacuubrand

vacuubrand VAC 24seven Instructions for use

Grundfos

Grundfos CIM 1 Series Installation and operating instructions

Zurn Wilkins

Zurn Wilkins 375 Installation, Testing, Maintenance Instructions

Miele

Miele DSM 408 Operating and installation instructions