Betz RIG HD User manual

betz-tools.com

RIG

HD

Manual

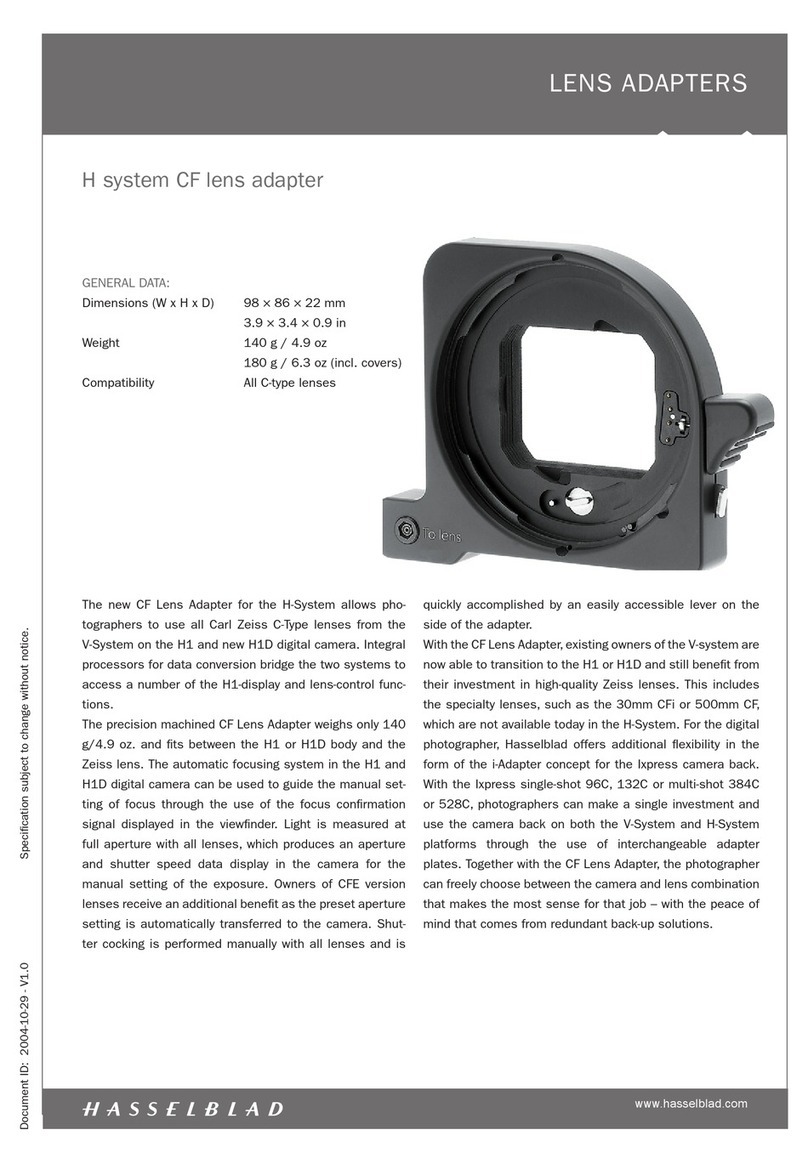

”STAGE”

Fore/aft and side-to-side camera balance can be adjusted

via the marked knurled knobs on both side.

The stage guides run on precision-machined rods in special

non-metalic bearings. These bearings should not be oiled or

greased.

The forward-facing 15 mm rods are for attachment of a

lens-control receiver or additional accessories, and can be

unscrewed for transport.

On the stage rear is a mechanical bubble level which

serves as zero reference to adjust the built-in electronic

bubble level in the „Junction-Box“, which is displayed

in the monitor. Please be shure that the monitor will display

bubble level.

Attach camera with mounted dovetail plate from above.

Make sure that the clamp lever on the stage faces to the rear

(A) so that the clamping is open.

After the camera snaps in, the clamp lever comes into a

middle position and the safety pin (B) springs up.

The camera is now protected against sliding out.

By pulling the clamp lever towards stage rear, approximate

fore/aft balance can now be achieved by sliding of the

camera in the stage.

The clamping lever should lock the camera even before

being pressed to the nal stop! In case the camera can still

be moved even though the lever is pressed until stop,

a spacer of approx. 0,1 mm has to be put under

the compensation track (C) under the cover plate.

To remove the camera, the dovetail clamp must be opened by

pulling the clamp lever fully to stage rear. In order to do this,

you will have to press down the safety pin (A).

Important! The screw (B) under the cover plate which xes the

clamping lever must never be unscrewed, this could damage

the mechanism. Should this screw be loosened accidentally, it

should be secured with Loctite 603.

Maintenance: The locking mechanism should be

treated/cleaned occasionally with a resinless oil (e.g. gun oil).

Mounting the Camera ”SAFETY LOCK”

A

B

C

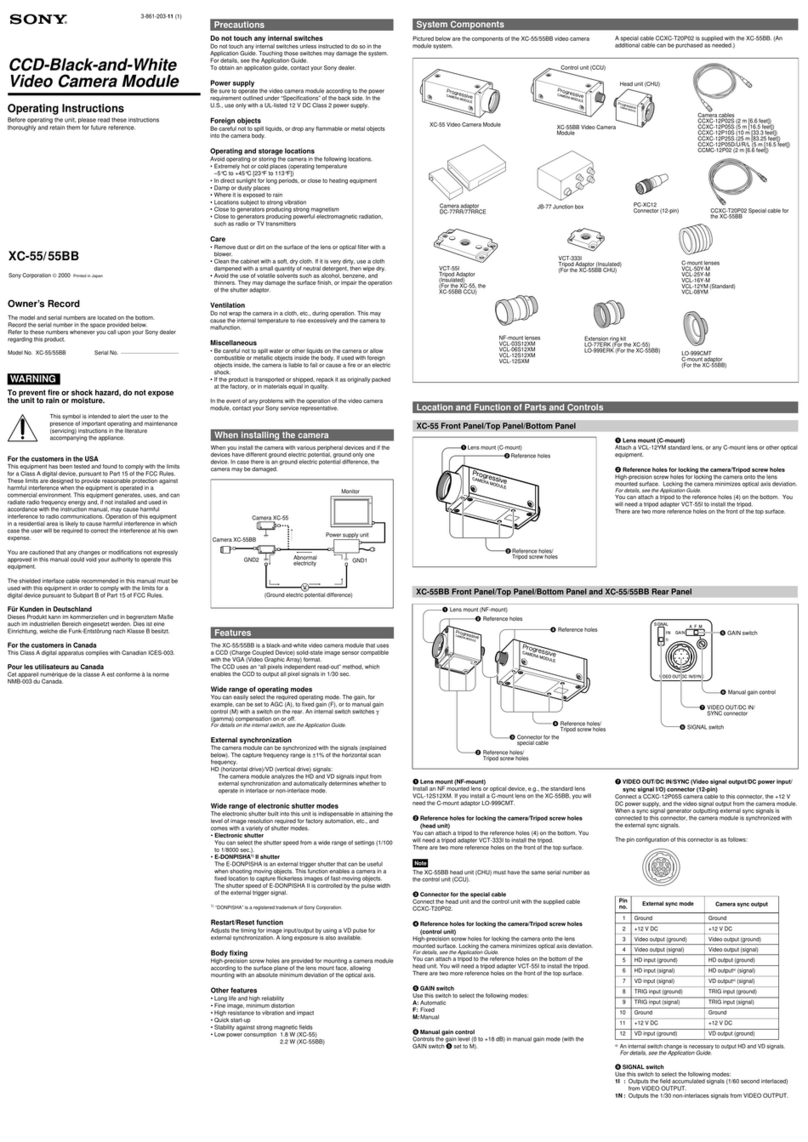

Each sockets supply voltage is indicated with engraved color-

coding. Connector arrangement to battery is shown on the

respective battery conguration layout (RIG-Low) .

Tally on (Camera GND) works only with the battery cong

plug for two batteries !!

Frontside

Rearside

The two HD-SDI Video in/out connectors are wired directly

with the connectors at the lower sled.

The four-pin Lemo and the BNC Video in/output are connected

in one coaxial cable that runs to the lower sled.

Use of the linelaser please see ”Sled Low”.

Junction Box ”J-BOX”

+12V

GND

sold. side connector

Lemo 1B 303

Tally +12V

GND

sold. side connector

Lemo 1B 303

HD-SDI Video

BNC isolated

+12V

GND

sold. side connector

Lemo 1B 303

+24V +12V

GND

sold. side connector

Lemo 1B 303

Video

Analog Video Gnd

BNC isolated sold. side connector

Lemo 0B 304

AnalogVideo Gnd

Analog Video+12V

Gnd 12V

Tally

Electronic Bubble-Level

The bubble-level‘s position sensor and digital electronics are

completely integrated in the “J-Box“. This allows for

uninterrupted direct reference to the camera horizon.

The bubble level is displayed in the monitor screen (only in use

with Sunbird / Pro monitors or Transvideo HD monitors with

special software). The Bubble-Level keeps its settings even

without power and remains valid for both „high“ and “low

mode“ operation. When switching between“high“ and “low

mode“, it is only necessary to re-zero by pressing “zero“.

Display Zero Position

Position the RIG to zero with the help of the built-in mechanical

bubble level on the backside of the stage. Now press “Zero“ (A)

for approx. 2 seconds. If the bubble don‘t cover the center mark

adjust as follows. Press “Zero“ (A) for approx. 10 seconds then

push “+“ or “-“ to cover the marks. Push “ “ (D) to get back

in the working mode. Attention PRO monitor user!

Set always level “zero“ on the monitor by pressing “offset“!

If the bubble don‘t cover the center mark after setting,

you have to adjust rst the level in the monitor menu:

select “Level“ go to “set ref. position“ adjust to zero.

go to “level gain“ adjust to max. -4

Display Direction Reversal

Press “direction“ (B) for 2 seconds, after releasing the

button the display direction is reversed.

A B C D

Level Sensitivity

Sensitivity can be adjusted in 5 steps. After pressing “Speed“ (C)

the monitor display mark goes to the presently adjusted level.

Left Nearly no damping

Middle Maximum damping

Additional pressing of the keys “+“ or “-“ adjusts the damping,

the selected value will be displayed and stored after release of

the respective button.

Display Angle

The display`s horizon-inclination range can be adjusted in ve

steps. After pressing “ “ (D) the monitor display mark goes to

the presently adjusted angle.

Left +/- 3° full scale

+/- 6° full scale

+/- 11° full scale

+/- 23° full scale

Middle +/- 90° full scale

Additional pressing of the keys “+“ or “-“ adjusts the angle, the

selected value will be displayed and stored after release

of the respective button.

Electronic Bubble-Level

BCD

Removing ”STAGE /J-BOX”

Position the stage so that all four screws (A) can be loosened

from above, remove stage.

Loosen the screw (D) from the docking ring

using a 3-mm allen wrench.

Loosen the 4 socket head cap screws (B) with a 4-mm

allen wrench, remove (unplug) the J-Box upwards.

When attaching the J-Box, make sure that the pin of the plug

(C) ts into the socket to avoid damage to the connector.

A

B

C

D

”Gimbal”

The gimbal is absolutely maintenance-free and has no

friction on any of the three axes. However, if the stainless steel

gimbal bearings become contaminated, they should be cleaned

and oiled.

Caution ! The gimbal bearings should only be oiled with one

drop of the special “RIG Gimbaloil“ otherwise, there may be

friction in the rolling elements. Maintenance of the gimbal

requires it to be removed from the post.

The clearance hole in the handle allows for use of a

ball-lock-quick-release pin when in “Low Mode“

Never dock the RIG with the gimbal directly on the

docking bracket. The bearing races will be damaged.

Always use the upper or lower “Docking ring“.

Post

The telescopic post can be extended in four increments.

Each post segment is marked to show the maximum

extension limit.

“CAUTION LIMIT“ The mark shows the maximum safe

extension limit; past this mark, the post tubes may slide out

(or slip), even while clamped.

For “Low mode“ operation an additional lock has to be

attached to the camera.

Caution!

When adjusting the post (extension or retraction of post

segments), hold both adjusted post segments rmly with both

hands; the spiral cable in the post could exert tension and pull

the segments together unexpectedly, causing injury.

Release the post segments only when the respective clamp has

been locked. It can occur, that the post cannot be pushed back

to its minimum length. This is due to turning the post segments

against each other too often. In order to solve the problem,

simply open the clamp and twist the upper segment clockwise

as many times as necessary until the segment can be pushed

back completely again.

Adjustment of Post Clamps

Adjust the allen screws with a 2 mm allen wrench (A);

after adjusting one, adjust the other (B) until the lever

is aligned with the ring.

Check the clamping force by opening and closing the clamp.

Caution:

Adjustment should only be performed with the clamping in

“locked“ position. Do not overclamp the clamp insert (C)

could be damaged.

If the allen screws become loose, they should be xed with

Loctite 243 (this number differs by country; it is the Loctite

blue threadlocker).

A

B

C

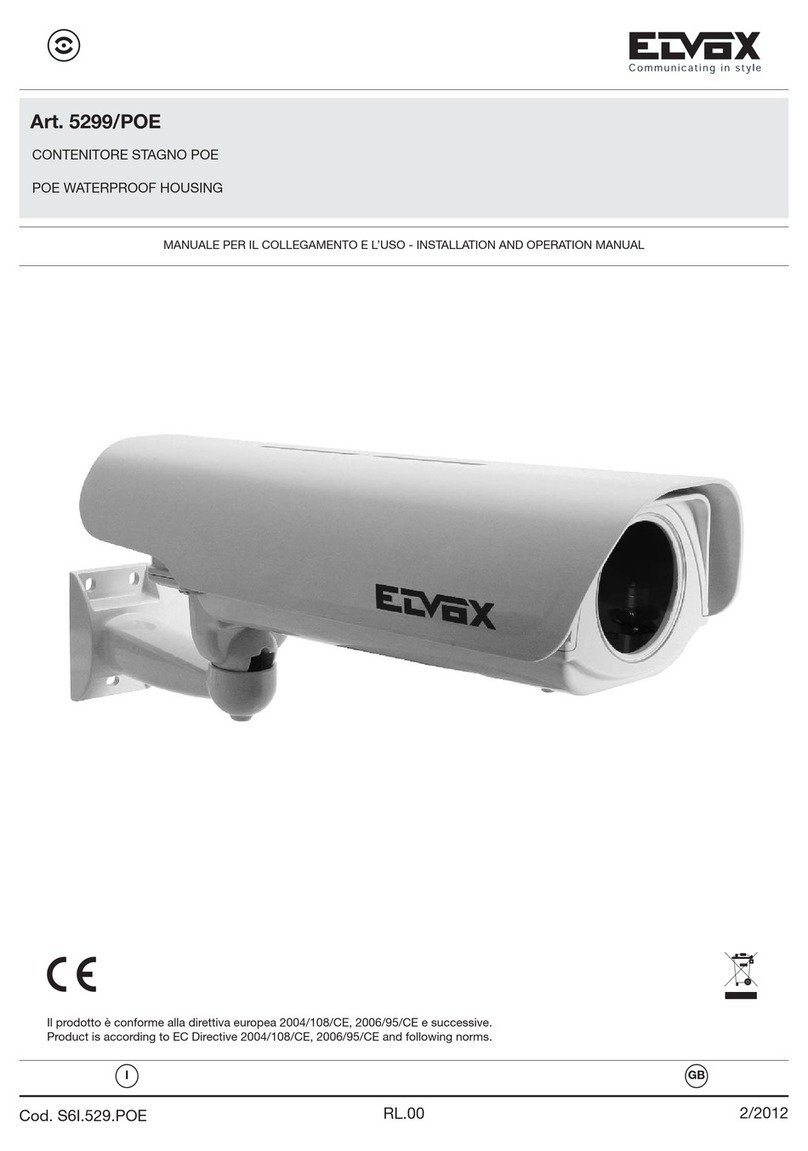

Sled Low ”RIG LOW/BASE”

For extra bottom clearance, the battery mounts can be

turned upside down.

To remove the battery mounts from the rods, proceed

as follows:

Left index nger on left push button,

right index nger on right push button.

Push the buttons simultaneously

and take off the mount by exerting a counter pressure

to the rods with your thumbs.

Turn around battery mount, press buttons and push battery-

mount back on the rods. The single battery mount in front

is attached upside down to the small rods which contain

the 3pin respectively the 8pin connectors.

The engraving battery A/B for the power switches is now

reversed (see engraving battery mounts).

The front battery mount can be removed completely,

according to use of the battery conguration plug.

Power switches - Fuses

The lower part of the RIG “base“ serves as camera

counter-balance as well as a power distributor

for the system.

The three circuit breakers (B) serve as a main switch for battery

voltages A/B or C, and also as fusing . (10 Amp.)

If the breaker trips in case of short-circuit or overcurrent,

it can be pushed back in for reset.

Dynamic balance (shift during rotational moves) can be

adjusted motorised via switch (C) or manualy via the knobs (A)

which adjust battery mount position on the lower rods.

A

B

c

3 Batteries 12/24 Volt (Standard)

2 Batteries 12/24 Volt (Opt.)

Battery-Congurations

A

B

The battery conguration plug (A) in combination with

the 12-24V switch (B) enable a most varied interconnection

of the batteries.

The system can be operated with two, three or even only

one battery.

24V

12V switch

24V

12V switch

2 Batt.

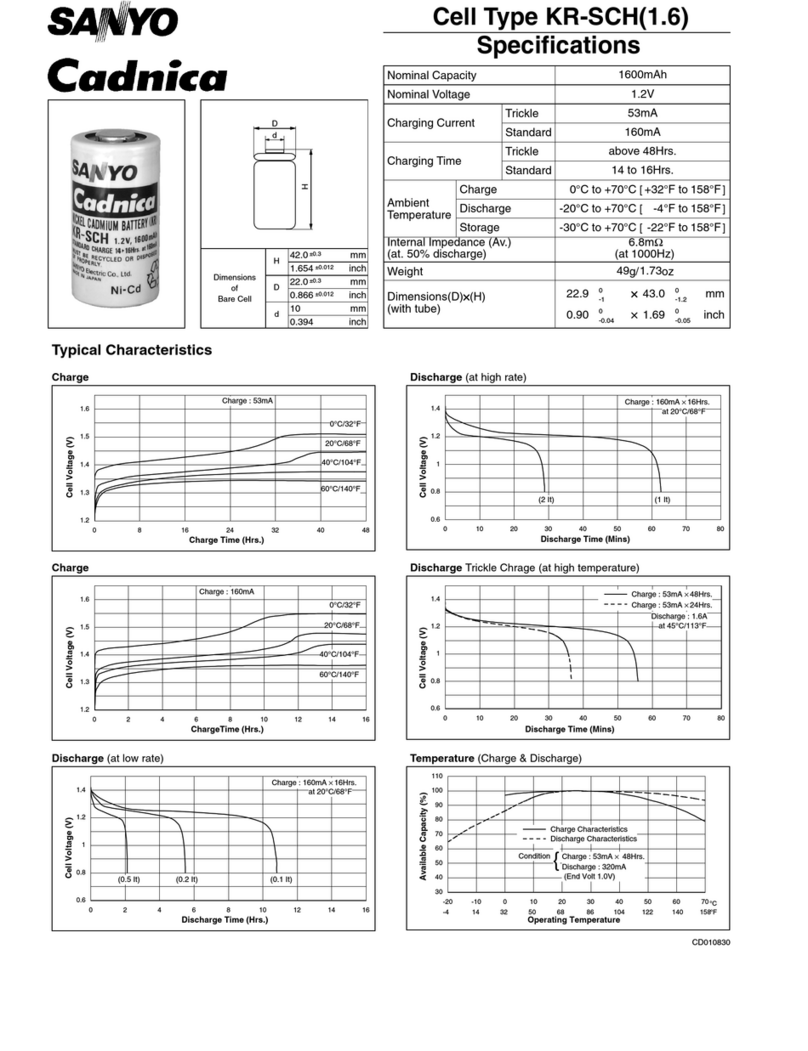

Batterie Display / Linelaser / setup

The battery capacity is displayed in levels of 10%.

Attention:

When using NIMH- or L-ion batteries display can show

wrong datas.

NICAD batteries will display properly with their

characteristic curves.

The integrated switchable linelaser which is built in the

”J-Box” is used for the correct adjustment from the

lower sled part to sled top part. The reference marks next to

the battery display are to line up.

The marks from the linelaser on the oor can be used as

reference marks while shooting.

Referencemarks

Referencemarks

Laserline

Connector pin out

+12V

-12V

-12V

-12V

+12V

+12V

Betz-tools RAK BU 4P

soldering side connector

Betz-tools RAK BU 4P

soldering side connector

Lemo 1B 303

soldering side connector

+12V

+24V

GND

Accessories

Lemo 0B 304

soldering side connector

+12V

GND

Analog Video

Analog Video GND

Video/Acc.

Batteries

Batteries

Lemo 1B 308

soldering side connector

Analog Video GND

Analog Video

Tally

AnalogLevel

+12V

GND

Monitor

Digital Level RX

Digital Level TX

HD-SDI Video

in/out

Motor - sled

for/aft

Accessory Adapters

There are 2 different adapters available at present to attach

accessories to the lower sled.

An adapter with dovetail (A) which can be attached to the rear

of the forward battery mount

A rod bridge (B) which can be attached to the rods behind the

rear battery mount.To attach the accessories both mounts can

be equipped with common 15mm rods;

the adapter for Kenyon gyros RGMB can be directly attached to

the adapter and the bridge.

Other Gyro adapters, light weight support are available

see actual list.

RAMB

RDB

RGMB

B

A

Mounting the Tiltplate

A

C

B

Position the stage so that all four screws (A) can be loosened

from above, remove stage.

Push the“Tiltplate“ in position as shown on the drawing

Fix the “Tiltplate” with the four delivered screws (B)

to the J-box.

Put the stage on top of the “Tiltplate” (C) and x

the stage via the four screws.

Any Question?

Table of contents

Other Betz Camera Accessories manuals