5

PROJECT MANAGEMENT

Follow the installation instructions in this manual

precisely to ensure outstanding speaker performance

and true invisibility. To accomplish this flawlessly

every time requires project management and close

coordination with the drywall and finish trades along

with the General Contractor and sometimes even the

client. Here are some best practices that will prevent

unmet expectations and expensive rework:

• After IS speakers are connected and screwed in but

before any drywall mudding, taping, or finishing

has started, schedule a walk-through with the client

from the screw.

Listening Test

These are key tips for testing the subwoofer.

• Allow construction adhesive to dry before

energizing the subwoofer.

• During listening testing prior to mudding, listen for

buzzes, squeaks, and chung.

• Fix noise problems before drywall mud is applied.

• Let the subwoofer play at a moderate to high

level for 30 minutes to allow possible noises to be

discovered.

Drywall

The stud bays above and below the subwoofer cutout

as well as the stud bays on either side of the subwoofer

cutout should have construction adhesive added to

front and back of studs when attaching drywall. Drywall

can loosen over time and create buzzing and slapping

noises. In addition to the construction adhesive, screws

must be used instead of nails. Screws should be placed

every four inches around the subwoofer opening and

every six inches for the stud bays on either side of the

subwoofer cutout. Do not have a drywall joint at the

IS15W location. Use studs to support any drywall joint

near the IS15W. Place construction adhesive on the

bottom plate as well to prevent air leaks and chung

sounds.

FINISH MATERIALS

Prior to speaker installation, verify that the topping

compound and final finish are flexible materials (slow-

setting drywall mud/topping compound, wallpaper,

acrylic-based Venetian plaster, thin wood veneer) and

will not exceed 1/16” (1.5mm).

Our recommended target for optimal performance

is between 3/64”-1/16” (1.0-1.5mm) of topping

compound. Sound quality and installation durability

will be adversely eected if too much topping

compound is applied. For wood veneer finishes, use

only 20mil (0.5mm) veneer with paper backing.

Do not use hard-setting or sti materials over the

surface of invisible speakers, such as fast-setting

drywall mud (“hot mud”), genuine Venetian plaster,

stucco, metal panels, tile, etc.

(or client’s representative), the General Contractor,

and the finish manager. Listen to every speaker

for a couple minutes. This is the best opportunity

to discover any anomalies or issues with invisible

speaker performance.

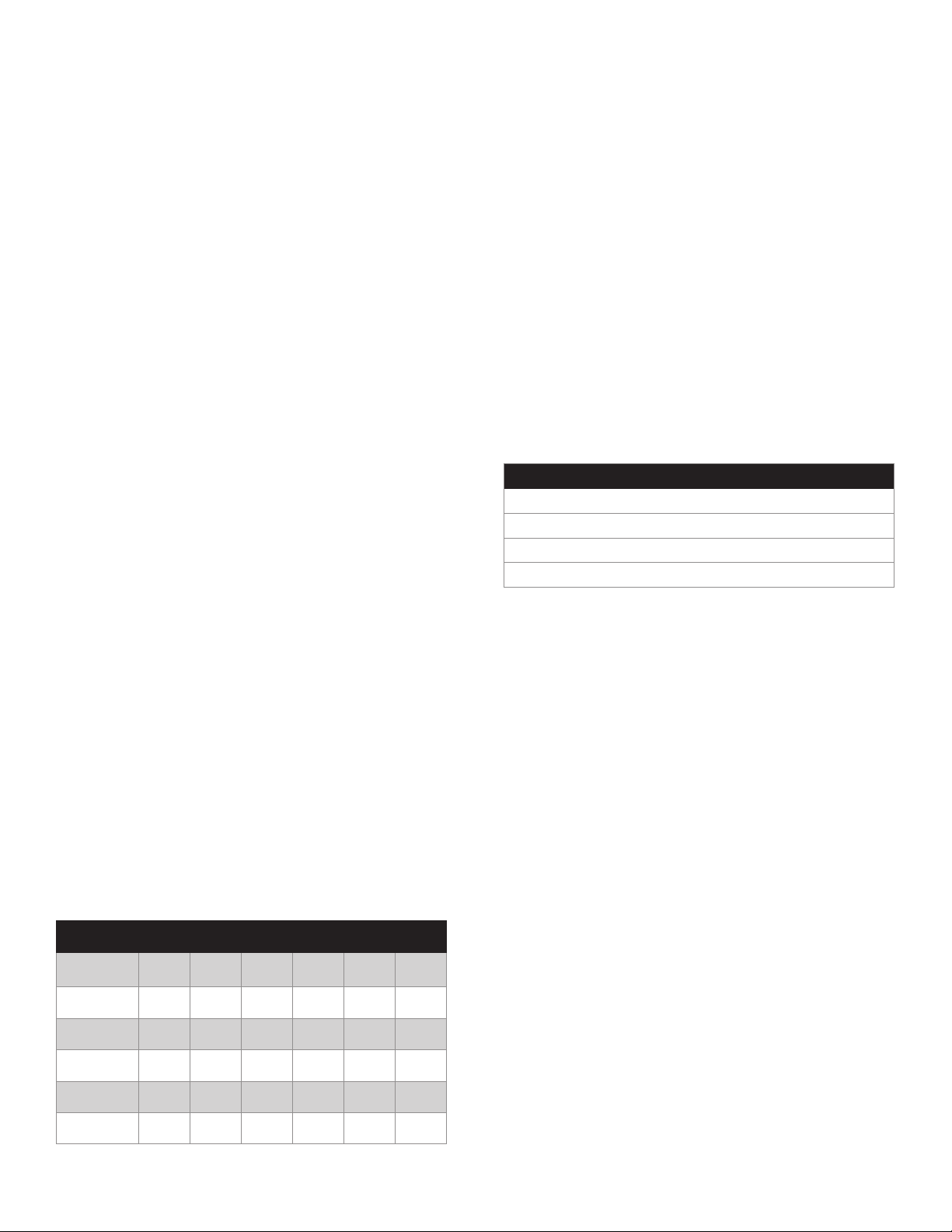

• All in attendance should sign o on audio

performance, speaker-by-speaker and room-by-

room. Prepare a checklist like the example below

and ask all parties to sign and date, acknowledging

that the Sonance IS speakers perform to everyone’s

expectations.

• Review all installation steps and processes with the

finish manager, emphasizing to cover the speakers

with only enough flexible material to make the

speakers disappear and no more. This typically ends

up being our recommended target of 3/64”-1/16”

(1.0-1.5mm). Also emphasize the maximum of 1/6”

(1.5mm) finish thickness. Review our guidelines for

recommended materials on page 4 and 14 with the

finish manager. Construction adhesive must be used

between drywall and studs.

• Use the Sonance DISC system and DG-1 depth

gauge (SKU 93491) to validate the finish thickness.

It is helpful to lend the gauge to the finish manager

so that it can be used during the actual process.

• Once the finish material has completely dried,

perform another room-by-room listening check of

each speaker. If the speakers do not sound similar

to the performance you heard prior to finishing,

it is likely that the finish thickness exceeds the

maximum of 1/16” (1.5mm). Now is the time to

correct this by removing material.

• Remember: once the flooring is installed and the

furniture is in place, it is too late to remove excess

finish material from the Sonance IS speakers

without significant cost, cleanup, and/or complexity.

Eective project management, sign-os, and proactive

communication with the trades will prevent unexpected

results and provide consistent, beautiful installs that

wow the client and end-users.

ADDITIONAL INFORMATION

For CAD files, detailed dimensions, and other technical

information, scan the QR code below or visit

www.sonance.com/in-wall-in-ceiling/invisible-series