BG Systems FlyBox User manual

FLYBOX®

HARDWARE MANUAL

FlyBox Hardware Manual 3

Contents

CHAPTER 1 OVERVIEW ....................................... 5

1.1 WHAT’SNEW ................................................................................................................... 5

1.2 CONVENTIONS USED INTHIS MANUAL ..................................................................................... 6

CHAPTER 2 INSTALLATION ................................... 7

2.1 CONNECTING TOPOWER ..................................................................................................... 7

2.2 CONNECTING TOTHE HOST WORKSTATION ............................................................................... 9

2.3 ADDING ADDITIONAL INPUTS.................................................................................................. 9

CHAPTER 3 HARDWARE..................................... 11

3.1 THE JOYSTICK ................................................................................................................ 11

3.2 LEVERS ........................................................................................................................ 12

3.3 SWITCHES ..................................................................................................................... 12

CHAPTER 4 SOFTWARE .................................... 13

4.1 SOME BASICS ................................................................................................................. 13

4.1.1 Connecting the FlyBox............................................................................................ 13

4.1.2 Theory of Operation............................................................................................... 13

4.2 TUTORIAL FLYBOX_TEST.C.................................................................................................. 14

4.2.1 Setup...................................................................................................................... 14

4.2.2 Opening and Initializing ......................................................................................... 15

4.2.3 The Interval Timer.................................................................................................. 16

4.2.4 Cycling ................................................................................................................... 16

4.3 SOFTWARE MAPPING.......................................................................................................... 17

4.3.1 Optional Digital Inputs ........................................................................................... 17

4.3.2 Testing the Digital Inputs........................................................................................ 17

4

CHAPTER 5 TROUBLESHOOTING ........................... 19

5.1 THE FLYBOX ISNOT RESPONDING ....................................................................................... 19

5.1.1 Serial Cable............................................................................................................ 19

5.1.2 No Power ............................................................................................................... 20

5.1.3 Joystick Problems .................................................................................................. 20

5.1.4 Interference ........................................................................................................... 20

CHAPTER 6 TECHNICAL SPECIFICATIONS ............... 21

FlyBox Hardware Manual 5

CHAPTER 1 OVERVIEW

The FlyBox® is an input device for your computer.

It consists of a three axis joy stick (the third axis is

twist), two levers, and several discrete switches. It

provides inputs to the workstation through an RS-232

serial line, and can be used instead of the mouse or a

dial and button box to move through a terrain

database.

It provides a superior feel for dynamic applications. It

can be used for flight or driving simulation, database

construction, etc. The FlyBox is packaged in an

aluminium case, and has a simple DB-9 or MiniDIN-8

cable connection to the computer.

It provides the following advantages over systems that

use an A/D board:

• You don’t have to rebuild the UNIX kernel to

include a special driver.

• You don’t have to open the computer to

install an Analog to Digital board since the A/D

conversion is handled internally by the box.

• The software interface is extremely simple,

using standard, portable open, and read calls.

• The FlyBox can update as fast as 50Hz, which

is generally faster than inputs can be

generated.

This manual contains instructions for installation of

the FlyBox, some highlights of the software used to

communicate with the FlyBox, and some troubleshoot-

ing hints. This manual should be read in conjunction

with the LV824 Software Manual, which contains

specific details about the software that is used on the

host to communicate with the LV824 circuit board

inside the FlyBox.

The software section of this manual is written in

tutorial style, stepping through some example software.

If you have problems, please consult Chapter 5 of this

manual - Troubleshooting. Most problems in getting

started are related to the workstation configuration.

1.1 WHAT’SNEW

The old FlyBox Owner’s Guide has been split into

this FlyBox Hardware Manual and the companion

LV824 Software Manual. This allows us to update

the software on the LV824 without having to revise all

the hardware manuals for the products that use the

LV824. Reference is made in this manual to software

features that are specific to the FlyBox, but the Software

Manual is intended to be the primary reference.

The FlyBox now uses the JFx joystick which allows a

number of optional switch configurations. These are

discussed in section 3.1.

The page numbers in this manual have been modified

so that links in the “on-line” version are accurate.

(This just means that page 1 is the front cover, and

roman numerals are no longer used for the table of

contents). Documentation can be down-loaded from

the BG Systems web site at any time.

6

1.2 CONVENTIONS USED IN

THIS MANUAL

Various typefaces are used in this manual to refer to the

name of something on the computer, to highlight an

important piece of information, etc.

Italics are used in the body of the text to indicate

computer terminology - typically a function or file

name:

open_lv()

A monospace font is used whenever a code fragment is

presented:

tios.c_flag = CS8 | CREAD | CLOCAL;

A monospace font preceded by a % is used for Unix shell

commands:

% cd FlyBox/

When the font is preceded by a #, it means that system

administrator (or root) privileges are required for the

operation

# chmod a+rw /dev/ttyd2

Things that are really important are set apart with a

“hand” pointing to them, and an italic font is used:

FWARNING.

Things that are should be noted, but are not dangerous

if ignored, are set apart with the spectacles:

$NOTE.

FlyBox Hardware Manual 7

CHAPTER 2

INSTALLATION

The first step is to verify that you received all the

necessary parts. As you unpack the box make sure

that everything on the packing list is supplied. If

anything is missing contact BG Systems immediately.

The FlyBox is quite solidly constructed, but you should

ALWAYS carry it by the handles — NEVER pick the

FlyBox up by the joystick, this can cause damage to the

stick, and puts stress on the case.

2.1 CONNECTING TOPOWER

The power switch is located on the right hand side as

you look at the back of the case. The FlyBox is set for

110v when shipped within the U. S. A.. International

shipments are usually set to 220v. Before connecting

the power cord, make sure that the voltage is correctly

set.

If the voltage selector is incorrectly set, or you are

taking your FlyBox to a trade show where the power

requirements are different, the procedure for changing

the input voltage is as follows:

1 Remove the fuse drawer (see figure 1), by

using a screwdriver to push at the drawer

release (see figure 2).

Figure 1 Power Connector

On / Off Switch Fuser Drawer

Voltage Indicator

Screwdriver Notch in fuse drawer

Figure 2 Removal of fuse drawer

8

2 Slide out the voltage selector, the T shaped

board, as shown in figure 3.

3 Turn it through 180°and slide it back in the

channel so that the desired voltage can be

seen through the window.

4 Making sure that the white triangle on the

fuse drawer is aligned with the triangle on

power connector, push the fuse drawer back

into place.

If power is correctly connected, the red LED on the front

of the FlyBox will light up. Also, at the back of the

FlyBox next to the serial connector there are two LEDs.

The green LED comes on with power to the LV824 inside

the FlyBox, and the yellow LED shows status for the

LV824. On power up the yellow LED will blink once.

$If the red LED on the front of the FlyBox

does not come on, it is possible that the fuses

have been blown. Remove the fuse holder as

described above and inspect the fuses. If they

have “blown” there are 2 spare fuses in the

fuse drawer as shown in figure 4. Just push

out the two rectangular boxes underneath the

fuses.

FThe power cord that comes with the

FlyBox has a THREE pin connector. DO NOT

CUT OFF THE THIRD PIN. This provides

ground for the system. If you do not have a

grounded circuit, contact an electrician.

Damage to the FlyBox and the workstation

can result from an ungrounded system.

FIf the FlyBox is being used in a foreign

country where the voltage is 220v, it is not

uncommon for users to forget to switch the

voltage until AFTER they have blown the fuse.

Please use the spare 500mAmp SloBlo fuse

(figure 4) rather than putting in a 2 amp

fuse. Damage to the power supply will result

if connected to 220v while set to 110v.

FIf the FlyBox is set to 220v and con-

nected to 110v, it may appear to work for a

while, but when you push one of the illumi-

nated switches it stops communicating. This

is because the voltage to the LV824 drops

below 5 vDC. Changing the voltage selector

back to 110v will fix this problem.

Rotate this through 180

°

and slide back in

Figure 3 Detail of voltage selector

Figure 4 Location of spare fuse

FlyBox Hardware Manual 9

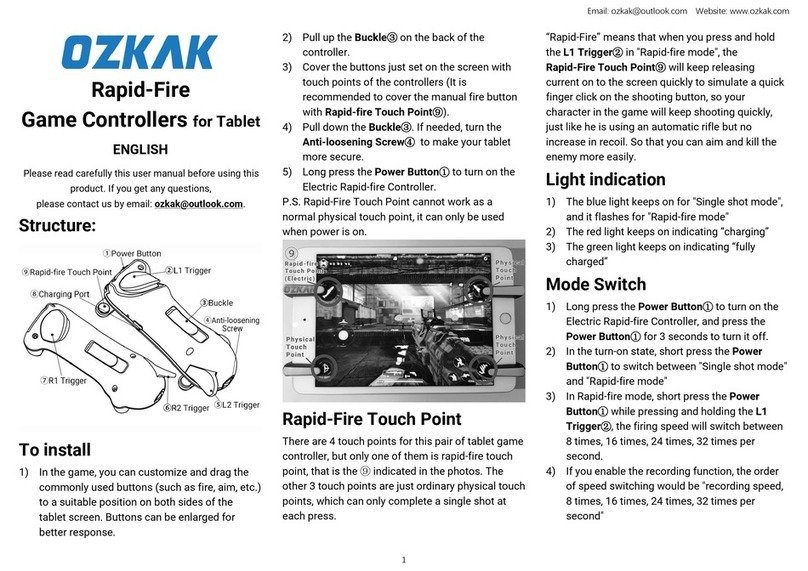

2.2 CONNECTING TOTHE

HOST WORKSTATION

The FlyBox should be set up at a convenient location

near the monitor of the computer. Make sure that the

power switch on the back of the FlyBox is in the off

position, and connect the power cable. Then connect

the RS-232 cable to the FlyBox serial output port (see

figure 5) and the host computer. You can connect the

FlyBox to any available “port” on the back of the host

computer. Note that the female end of the cable

connects to the FlyBox and the male end of the cable

connects to the host. The pins on the DB-9 are: pin 2 -

RX, pin 3 -Tx and pins 5 and 7 - Ground. Pinouts for

the various different serial cables are shown in section

4.1.1.

2.3 ADDING ADDITIONAL

INPUTS

The A/D board inside the FlyBox can handle up to 8

analog and 24 discrete inputs. The standard configura-

tion of the box uses 5 analog and 9 discrete inputs.

Consequently we have provided 4 extra DB-9 ports on

the back of the FlyBox, see figure 5.

Additional discrete inputs can be connected to the port

labelled Discrete Inputs 17-24. A female DB-9

connector should be used, and the pins should be wired

as follows:

Pin Channel

117

218

319

420

521

622

723

824

9 ground

Note that the voltages must be 0v in the off state, and

+5v in the on state. If you have a FlyBox that uses

more than 16 discrete inputs (i.e. with two coolie hat

switches), this input DB-9 will not be connected to the

LV824.

Additional analog inputs can be connected to the DB-9’s

labelled Analog Input 6, 7, and 8. These use a male

DB-9 connector, with pin 1 connected to the input

voltage, and pin 9 connected to ground. The voltage

range must be between 0-5v. Pin 8 provides 5v output

which can be used to power the device that you are

connecting to the FlyBox. Note, however that you

should not try to draw more than 200 mAmps from the

FlyBox.

Reset button

Status LED Power LED

Figure 5 Back panel detail

10

FlyBox Hardware Manual 11

CHAPTER 3 HARDWARE

The FlyBox consists of three major control groups.

The joystick on the right hand side, the levers on

the left hand side, and the pushbuttons in the center.

There are a number of customized versions (e.g. the

Unit Training Device FlyBox) for which some of the

details will differ from those described in this chapter.

The FlyBox is now available with a two axis joystick,

and there are a wide variety of options that can be

added to the JFx joystick.

3.1 THE JOYSTICK

The standard FlyBox (BG-530) has a three axis joystick

with the motion in the following directions: Forward/

Backward (pitch), Left/Right (roll) and Twist (yaw).

There is a trigger on the joystick which is a digital

input. The three axes of the joystick provide a

proportional output between 0-5 volts, which is

converted to a 12 bit analog signal scaled between -1.0

and 1.0.

The FlyBox can also be ordered with a two axis joystick

(BG-520) in which case there is no twist capability. A

proportional thumb rocker can be added to either 2 or 3

axis joystick to provide an additional analog input.

At the head of the joystick it is also possible to mount a

variety of momentary, latching, 2-position and 4-

position switches. Figure 6 shows a common configu-

ration with two momentary switches and a 4-position

switch. See our current price list for the various JFx

options.

The mapping between the physical controls and the

software structure is described in chapter 4.

Figure 6 JF3-1-MP-CH-MP option

12

3.2 LEVERS

Two levers are mounted on the left side of the FlyBox.

In the standard FlyBox configuration these are in a

friction hold mode. The levers can be ordered with a

spring centering mechanism if required.

They produce a voltage which is fed to an amplifier

circuit board which is calibrated to ensure that the

output voltage covers the full 0.0 to 5.0 volt range. This

voltage is then converted to an digital value by the

LV824 circuit board, and the software values run from

-1.0 to 1.0.

3.3 SWITCHES

There are 6 discrete switches (red covers) mounted on

the FlyBox, nearest the top. These switches produce a

discrete (on/off) reading. They are on when pushed in,

and when on they are lit. The discrete switches are

spring loaded and stay down until pressed again.

There are two momentary switches (orange covers)

mounted at the bottom of the cover. These are on ONLY

when pressed, and off when released.

$This is the standard switch configura-

tion. If you need more momentary switches,

you can order FlyBoxes with your specifica-

tions for switch combinations.

FlyBox Hardware Manual 13

CHAPTER 4 SOFTWARE

This chapter describes the software interface to

FlyBox. This chapter should be read in conjunc-

tion with the more detailed descriptions in the LV824

Software Manual. The primary purpose of this

chapter is to indicate the relationship between the

physical aspects of the FlyBox and the software data

structure.

To get the most out of our products a good understand-

ing of your application is also required, since the

demands of real-time simulation, low frequency data

acquisition and model viewing are so different.

We provide source code for an example program that

interface to the FlyBox, which you should be able to

modify to suit your needs.

$The software provided may be copied

and used as needed. The library functions

should be changed with caution. The

examples are intended to act as templates for

your own software applications.

In fact you may be able to get away without in depth

knowledge, but if you do encounter problems, please

read this chapter thoroughly.

Section 4.1 reviews the basics of connecting the FlyBox

to the host computer. Section 4.2 is a tutorial which

studies an application that communicates with the

FlyBox.

4.1 SOME BASICS

4.1.1 Connecting the

FlyBox

Once you have connected the FlyBox to the host with an

appropriate serial cable and connected power, you are

ready to test the connection to see if you can communi-

cate with the FlyBox. However, there are some

parameters that you need to be aware of on the host in

order to get started. (Note that this is covered in full in

section 2.2 of the LV824 Software Manual.)

The first thing to do is decide which serial port to

connect the FlyBox. The serial ports are typically

numbered 1-n, with 1 typically reserved for use as an

alternate console. Therefore we recommend that you

choose port 2 or higher.

Once you have selected a serial port, we recommend

that you use the Unix environment variable feature:

% setenv FBPORT /dev/ttyd2

When the BG software tries to open the serial port, the

first thing that it looks for is this environment variable,

and once things are working, you should add this line

to your .cshrc file so that it is set every time you log in.

4.1.2 Theory of Operation

It is also useful to understand the basic sequence of

events that are required to use the FlyBox. Since the

FlyBox is an input device, we assume that the host

needs to collect the inputs at some regular interval.

Some applications will need updated information faster

than others, but it is important to understand that the

data transfer is being made via RS-232 serial protocol,

and there are finite amounts of time involved. The

steps required are:

1. Send character to FlyBox requesting data

2. Wait for data to arrive

3. Read data from the port

Typically you would use the time waiting in step 2 to

perform whatever processing is required based on the

14

last set of data received. It is important that you wait

long enough for the data to arrive and this will be

determined by the baud rate and the number of

channels that you are sampling. It may well be that the

processing takes longer than the time required to wait,

but if you don’t have much processing to do, then you

will have to include some sort of timed wait in order to

avoid looking for data that hasn’t arrived.

4.2 TUTORIAL

FLYBOX_TEST.C

Perhaps the easiest way to understand how to use the

software is to study an example. In the bg/FlyBox

directory, the source code in flybox_test.c is a fairly

simple program that samples the FlyBox and prints the

values to the terminal.

There is a Makefile in the directory, and you should be

able to type:

% make flybox

to compile and link the executable flybox.

4.2.1 Setup

As you go through this example, look at the file

flybox_test.c and make sure that it matches this

document.

The low level library routines use a data structure,

defined as bglv, that is defined in lv3.h. (Note that this

file is in the bg directory.) This data structure must be

declared in the main file.

#include “lv3.h”

bglv bgdata;

// Main BG data structure

$Note the use of C++ style comments //

which are not in the actual code, but are

used here to help readability.

Only the following members need to be set.

int analog_in;

// Analog input selector

int dig_in;

// Digital input selector

int baud;

// Baud rate selected

$The remaining members of the structure

are computed in open_lv() and init_lv().

The bglv structure is passed to most of the library

functions in the call sequence. In order to collect data

from the FlyBox, the serial port needs to be opened by

FlyBox Hardware Manual 15

your program, and the appropriate configuration sent

to the FlyBox. The function setup_lv() in the example

performs this task.

bgdata.analog_in = 0;

bgdata.analog_in = AIC1 | AIC2 | AIC3

| AIC4 | AIC5;

The analog_in member of the bgdata structure sets

any combination of the 8 available analog inputs. In

the example above, channels 1, 2, 3, 4, and 5 have been

requested by “or-ing” the predefined values AIC1 - AIC5.

If you have connected an additional analog input to the

DB-9 at the back of the FlyBox, you could add it to the

list:

bgdata.analog_in |= AIC8;

// Analog input 8

If you examine the definitions in lv3.h, you can of

course use the shorthand hex representation to set these

parameters.

$Note that we use the logical (not C

based) counting system that assigns AIC1 to

pin 1 on the connector. Of course in C this

corresponds to the zero element in the array.

Next we select the digital (discrete) channels:

bgdata.dig_in = 0;

bgdata.dig_in = DIC1 | DIC2;

In the example above, we have selected digital inputs 1-

16. These are selected according to the following table:

DIC1 0x10 Channels 1-8

DIC2 0x20 Channels 9-16

DIC3 0x40 Channels 17-24

These can be combined in any desired way. For

example:

bgdata.dig_in = DIC1 | DIC3;

// channels 1-8 and 17-24.

4.2.2 Opening and

Initializing

First we set the baud rate in for the bgdata structure:

bgdata.baud = BAUD192;

The next step is to open the serial device on the host

with the open_lv() function. The call takes three

arguments: the first is the address of the BG data

structure the second specifies the /dev/tty that you are

connected to; and the third specifies whether the read

will be blocking or non-blocking.

st = open_lv(&bgdata, “/dev/ttyd2”,

FB_NOBLOCK);

In general for SGI workstations, setting the baud to

19200 as shown above should work well, and the

default on power up for the FlyBox is 19200. This is

important when you try to send initialization data to

the FlyBox, since if your serial port is configured for a

different baud rate, nothing will get through ! The

open_lv() function sets the baud rate to 19200 to begin

with, and the init_lv() function sets the baud rate to

the desired operational rate.

$Note that when you push the reset button

or cycle power, the LV824 reverts to 19200

baud.

$Details of the open_lv() function can be

found in the LV824 Software Manual

During the open_lv() call, the software sends a

character to the FlyBox to retrieve the EPROM version.

This is stored in the bgdata.Rev structure:

bgdata.Rev.year

// Year the EPROM s/w was written

bgdata.Rev.major

// Major release (currently 3)

bgdata.Rev.minor

// Minor release (currently 0)

bgdata.Rev.bug

// Bug release (currently 6)

bgdata.Rev.alpha

// EPROM version e, f, or g.

This data is available for checking by your application,

and is used in the init_lv() routine to make sure that

the requested setup matches the hardware.

The information from the revision and the channel

setup is used in the call to initialize the FlyBox:

16

$See also section 3.3 and 4.1 of the LV824

Software Manual for a more detailed

discussion of sampling rates.

4.2.4 Cycling

The normal cycle looks something like this:

st = w_lv(bgdata.sp_fd, “o”);

// request data

sigpause(SIGALRM);

// wait for the alarm

st = r_lv(&bgdata);

// get the data

After reading the data, we choose to print it to the

terminal in this example. This is of course where you

would choose to do something interesting with the data.

The input values are computed within the r_lv() call,

and stored in the bgdata.ain[] array and the

bgdata.din[] array. The analog values are scaled

between -1.0 and 1.0 for convenience. The digital

values are packed into the integers in the array, so you

need to mask (as in the example) to determine which

bits (channels) are set.

If you want to run this as a single process, you would

usually put the intensive processing just before the

sigpause(). The sigpause() suspends your process

until the signal is caught, so you should do your

processing before you are suspended.

st = init_lv(&bgdata);

This call simply sends a string to the FlyBox that tells it

what baud rate to run at, and which channels to

sample.

$Note that the FlyBox starts out assuming

communication at 19200 baud. If you want

to operate at a different baud rate, you can

set this when you init_lv() with bgdata.baud

set to BAUD9600 for example. However, be

aware that if you don’t close_lv(), the FlyBox

will stay at 9600 baud, and the next time you

initialize, the changes will not be received.

You need to either push the reset button or

turn power off and on to reset the FlyBox to

19200.

The init_lv() routine performs some compatibility

checks. For example, if you have selected:

bgdata.dig_out = 0x70;

then the init_lv() call will fail because you cannot use

the digital output feature on an LV824-E.

4.2.3 The Interval Timer

Next we call the function init_timer() which sets up

the interval timer, to trigger an alarm every 50,000

microseconds (50 ms).

itv.it_interval.tv_sec = 0;

itv.it_interval.tv_usec = 50000;

itv.it_value = itv.it_interval;

setitimer(ITIMER_REAL, &itv, (struct

itimerval *)0 );

Next we set up to catch the alarm signal sent by the

interval timer. (The routine that we call does nothing.)

sigset(SIGALRM, catcher);

Using the interval timers is simply a method that we

have found to be reliable. On high end Silicon

Graphics machines with multiple processors, you may

be able to get more accurate or fine grained timing by

using the graphics subsystem clock. You might look

into the Performer software system calls to see how to

get a more accurate clock.

FlyBox Hardware Manual 17

4.3 SOFTWARE MAPPING

The physical controls on the FlyBox are mapped into

the bglv data structure according to the following

tables.

The analog values are stored as floats between -1.0 and

1.0 and each analog channel is represented as a

separate member of the data structure. The buttons,

switches and trigger are all digital inputs, which are

packed together in groups of 8.

Table 1 Analog Inputs

bgdata Function Negative Positive Note

ain[0] JFx lateral Left Right

ain[1] JFx longitudinal Back Forward

ain[2] JFx twist Left Right Not on JF2

ain[3] Left Lever Back Forward

ain[4] Right Lever Back Forward

ain[5] Thumb Rocker Left Right Optional

Table 2 Digital Inputs

bgdata Function Bit Shift Note

din[0] Top Left 0x01 0 Latching

din[0] Top Right 0x02 1 Latching

din[0] Mid Top Left 0x04 2 Latching

din[0] Mid Top Right 0x08 3 Latching

din[0] Mid Low Left 0x10 4 Latching

din[0] Mid Low Right 0x20 5 Latching

din[0] Low Left 0x40 6 Momentary

din[0] Low Right 0x80 7 Momentary

din[1] Trigger (1) 0x01 0

4.3.1 Optional Digital

Inputs

The following table presents the mapping for the

optional switches. Of course there are some combina-

tions that are not available, and also some of the

mappings occur more than once.

Table 3 Optional Digital Inputs

bgdata Function Or with Shift Note

din[1] 4-pos left 0x02 1 “Coolie Hat”

din[1] 4-pos right 0x04 2

din[1] 4-pos down 0x08 3

din[1] 4-pos up 0x10 4

din[1] Left button 0x20 5

din[1] Right button 0x40 6

din[1] Trigger (2) 0x80 7 2-pos trigger

din[1] 2-pos left 0x02 1

din[1] 2-pos right 0x04 2

din[1] 2-pos down 0x02 1

din[1] 2-pos up 0x04 2

Note that the two position switch can either be a left/

right or an up/down.

4.3.2 Testing the Digital

Inputs

To determine the state of a given digital input you need

to mask it with the appropriate bit or shift and mask

with 0x01. For example, the trigger is always digital

input number 9, which is mapped as the first bit of the

second member of bgdata.din[]. So to see if the trigger

is on:

if ( (bgdata.din[1] >> 0) & 0x01 )

printf(“trigger on\n”);

Note that we shift the value to the right by the physical

number of the switch minus one. So, to test the state of

the top right latching pushbutton, number 2 of input

block 1:

if ( (bgdata.din[0] >> 1) & 0x01 )

printf(“top right on\n”);

Alternatively we can test directly with the appropriate bit

if ( bgdata.din[0] & 0x02 )

printf(“top right on\n”);

but this doesn’t work as well when we put this code

fragment into a loop.

18

FlyBox Hardware Manual 19

CHAPTER 5

TROUBLESHOOTING

Every FlyBox is tested prior to shipping, and we have

confidence that when you connect a FlyBox it will

work. However, since we have two pieces of hardware

(host and FlyBox), three pieces of software (host,

FlyBox, and the operating system), and a cable, we

realize that there will be occasions when you connect a

FlyBox it will appear that nothing is happening.

Chapter 7 of the LV824 Software Manual also contains

trouble shooting advice, and should be checked for

information regarding host setup.

5.1 THE FLYBOX ISNOT

RESPONDING

You have plugged everything in, and you try to run a

test program (eprom or flybox), and the program exits.

Check the following:

1. Is the red power LED on the front of the

FlyBox on ? If not check the fuses and power

connection.

2 Is the green LED at the back of the FlyBox on?

If not check your power supply. If the red

LED is on, and the green LED is not, contact

BG Systems.

3 Does the yellow LED blink when you turn on

power? If not then the FlyBox is not working.

Call BG Systems for help.

4 If the yellow LED blinks when you apply

power, it should also blink when you run a

test program. If it does not, then the

character from the Unix host has not made it

to the FlyBox. Check your cables and the host

configuration.

5 Did the test program print any helpful text on

the screen? If you do not have permission to

write to the serial port, the software should

tell you. In this case contact your system

administrator for help.

A common software problem is that the host is

configured with the requested serial port as a terminal

running at 9600 baud. The FlyBox software may run

for a short period (with the baud at 19200), but Unix

will come along and reset the baud rate to 9600 - at

which point the FlyBox will stop responding.

5.1.1 Serial Cable

The most common hardware problem is when there is a

problem with the serial cable. This problem is

compounded by the fact that SGI uses three different

types of serial connector (although it appears they have

finally settled on the PC DB-9). We make every effort to

20

ship the correct serial cable with the products, but if you

move the FlyBox to a new workstation for which you do

not have a BG serial cable proceed with caution. The

tables below list the functions on the pins for the

various connectors:

Signal SG-DB-9 MiniDIN-8 PC-DB-9

Rx332

Tx253

Gnd 7 4 5

Signal LV824

Rx 2

Tx 3

Gnd 5 and 7

FMake sure to connect Rx on the LV824 to Tx

on the serial cable !

If the LV824 stops responding when you connect to a

new SGI workstation, please consider the serial cable as

a likely problem. The quickest test of the BG hardware

is to reconnect it to the last known working machine. If

it works with one computer, but not with another, then

the BG hardware is OK, and you should double check

the serial cable.

5.1.2 No Power

As described in section 2.1 there are circumstances

under which the FlyBox will stop operating due to

blown fuses or incorrect voltage selection. One of the

more interesting problems occurs when the voltage

selector is set to 220v and the power provided is only

110v. Under this condition, the FlyBox will often work

for a while, but when a load is placed on the power

supply (i.e. when a light bulb is turned on), the DC

voltage to the LV824 drops below 5, and it stops

functioning. This gives the appearance of a FlyBox that

is acting “flakey”. Please double check the voltage

selector.

5.1.3 Joystick Problems

The new JFx joysticks are built from machined

aluminium and stainless steel and use sealed ball

bearings on the gimbals for high precision operation.

As with all mechanical assemblies, it is impossible to

completely eliminate the dead band at the joystick

center position. The JFx is built such that this

deadband should be within +/- 0.01 on the xlv test

program. This represents a 1% tolerance. Older

FlyBoxes used a joystick with a 3% tolerance.

5.1.4 Interference

The FlyBox will not electromagnetically interfere with

the operation of the host computer. However, there are

some peripheral devices which will either cause

interference with the FlyBox, or which will not operate

in close proximity to the FlyBox.

Since the FlyBox contains a power supply, some

magnetic sensors will be affected when they are in close

proximity to the FlyBox. This can occur with certain

tracking devices. The sensors on the JFx joystick are

Hall Effect magnetic sensors, and so operating the

FlyBox in close proximity to a strong electromagnetic

producer will cause problems.

We do not recommend using the FlyBox in such

circumstances. If you have a requirement to use a

FlyBox under these conditions, please contact BG

Systems for advice.

This manual suits for next models

1

Table of contents