Bikeservice BS3510 User manual

BS3510

PROFESSIONAL CHAIN REPAIRING MASTER SET

Instructions

Represent.

BS3506

Chain Link Pliers

BS1164

Drive Chain Tension Puller

BS0353

Chain Adjustable C Hook

Wrench

BS3500

Chain Extractor

RELEVANT PRODUCTS OF CHAIN REPAIR SERVICE

Motorcycle Service Tools

APO TOOL INTERNATIONAL LTD.

No.38 Ping An St, Changhua. Taiwan 50055

T: +886 4 7514888 / F: +886 4 7524888

Website : www.bikeservice.com.tw

The BikeService BS3510 Chain Repairing Master Tool is designed to break chains up to chain

size #632 and press the hollow link pins and plates of the Master Link on chains up to #632.

Please read instructions thoroughly prior to use.

The Tool is designed for hand use (tightened by hand ) utilizing the T-Bar or 3/8” Square and 19mm

with 21mm spanner. The use of Power Tools or extension bars for extra leverage may cause damage

to the tool and should be avoided.

Collocating BikeService products BS3506 Chain Link Clip Pliers and BS1164 Drive Chain

Tension Puller, makes it easier and more convenient to remove and install motorcycle chain.

01

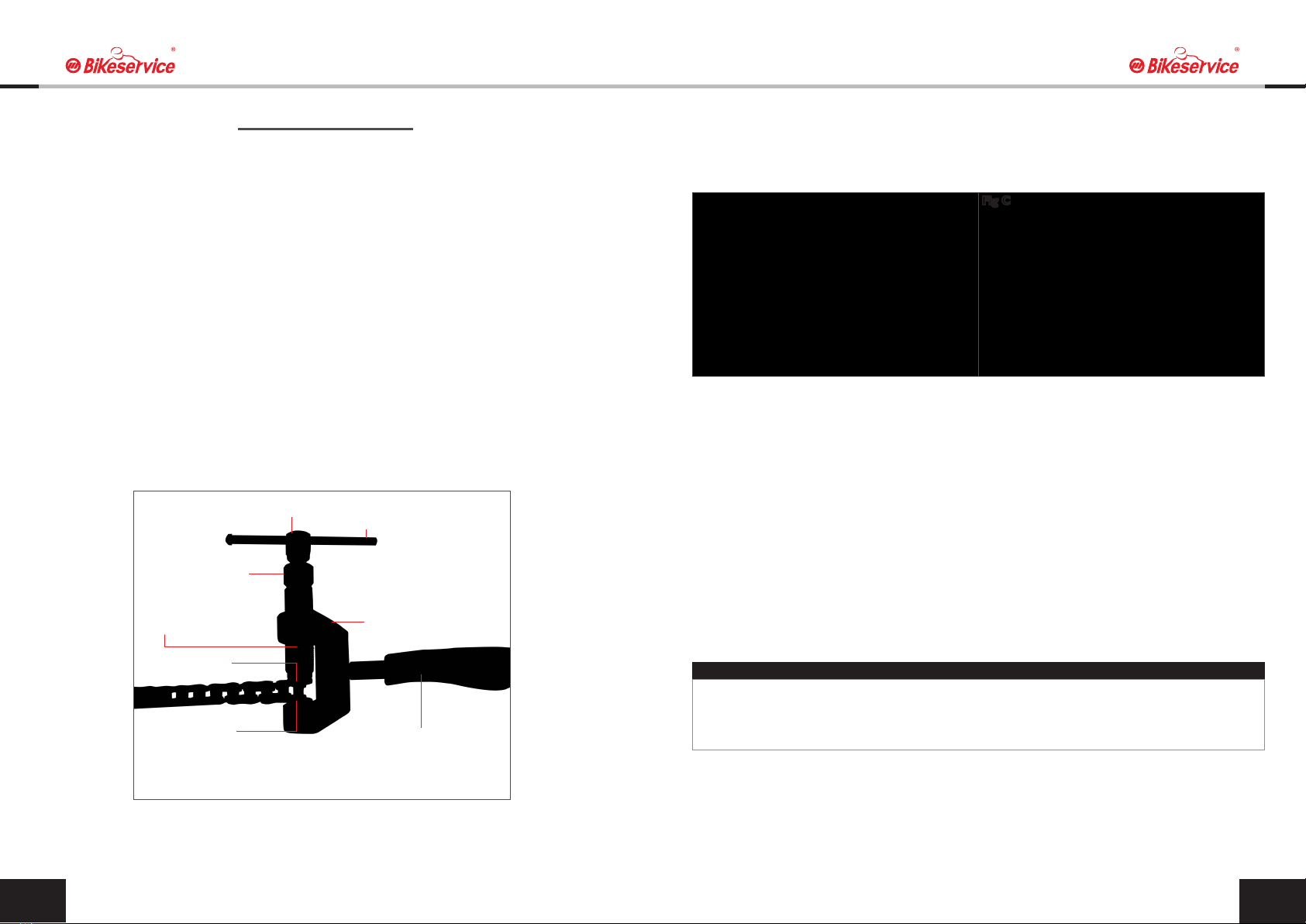

A

B

E

C

D

F1

F2

F3

M

H

L

J

K

G1

K

G2

G3

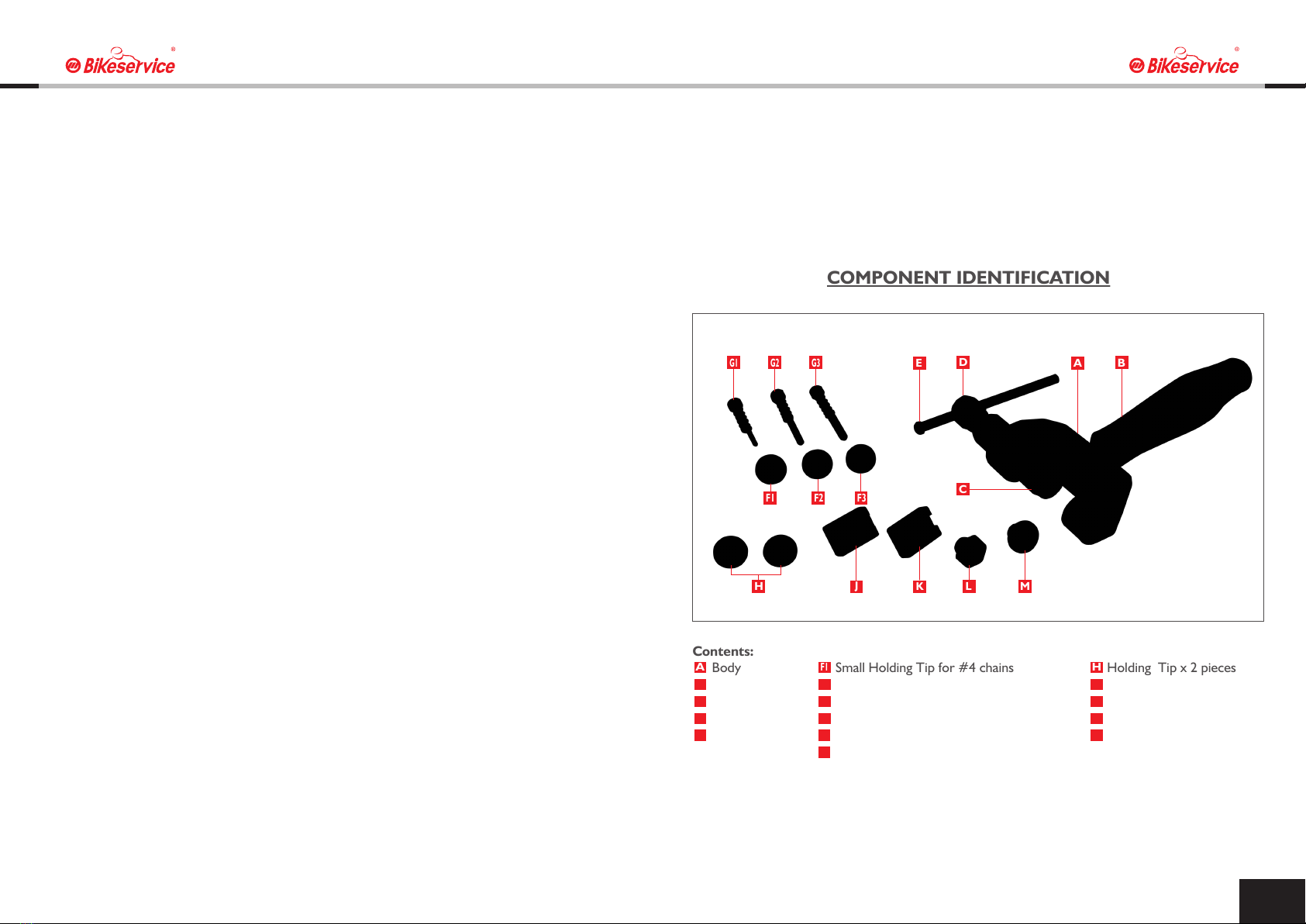

Body

Handle

Center Screw

Forcing Screw

T-Bar

Small Holding Tip for #4 chains

Medium Holding Tip for #5 chains

Large Holding Tip for #6 chains

Small Push Pin w/spring for #4 chains

Medium Push Pin w/spring for #5 chains

Large Push Pin w/spring for #6 chains

Holding Tip x 2 pieces

Shallow Press Block

Deep Press Block

Rivet Tip

Anvil

COMPONENT IDENTIFICATION

Contents:

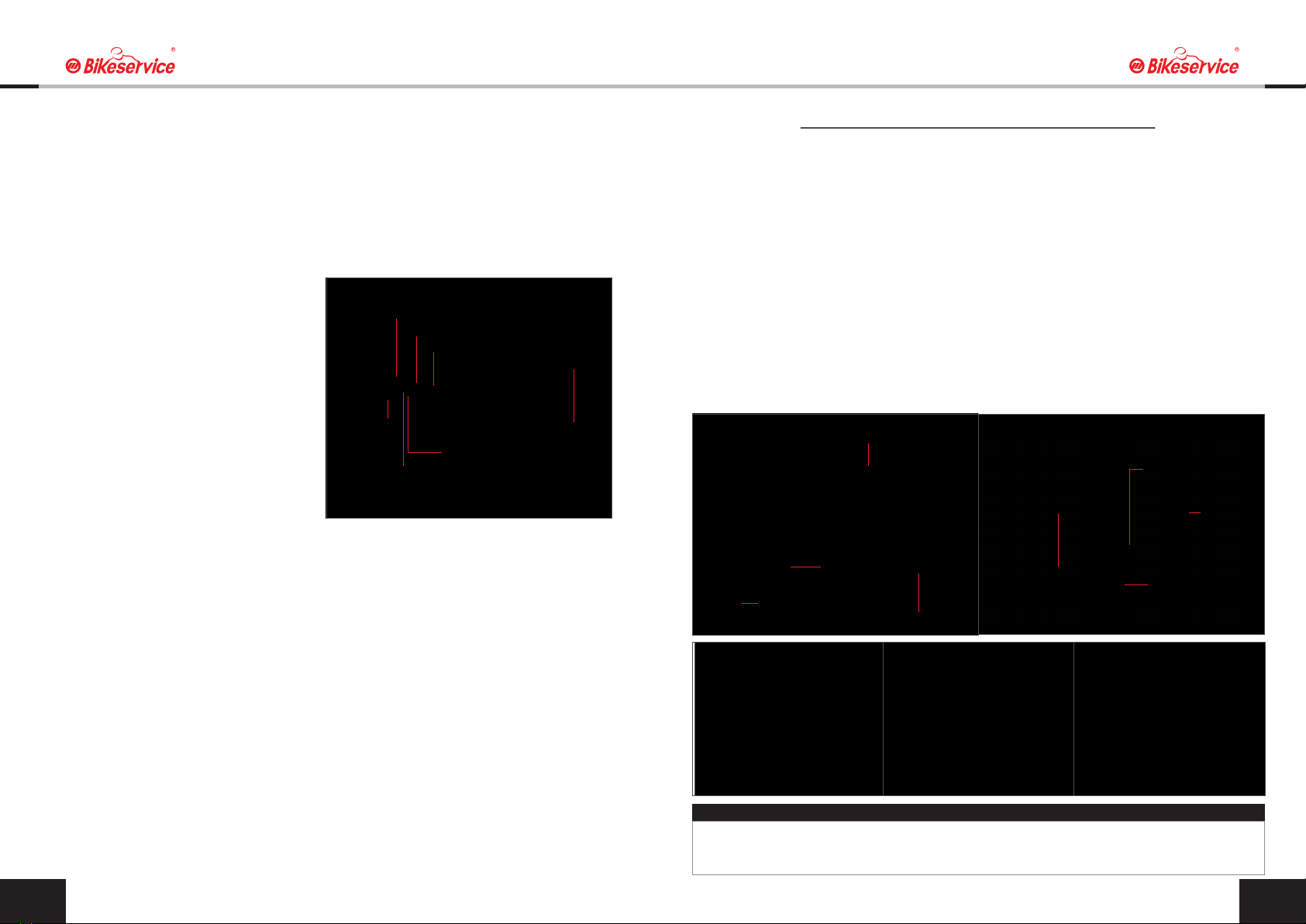

F2

C

D

F1

A

F3

LH JKM

G1

G2

E

G3

B

02 03

PRODUCT FEATURE(PATENT PENDTING)

This special Forcing Screw adopts a multifunctional driving mode (T bar / 19mm & 21mm Hex Wrench

or Socket / 3/8” Square Driver),which makes the removal and installation process more convenient

and easier in any working environment without having tool specification limits.

You can easily find one of the above tools to do the job.

The new type forged Body adopts three lock holes with

different position and angle which allows a nimble

application in varied space and angle when connecting

the Handle.

Right and Left-Handed operation are both

well-considered in this design and application which

brings users the most ergonomically efficiency during

operation.

Two pieces of special Holding Tip hold the chain in position firmly for chain breaking.

When driving the Forcing Screw, this design can easily hold the Chain Pin in the central hole of the

Holding Tip, efficiently locates and fixes the central point of Chain Pin, and accurately makes the

Chain Pin positioned in right vertical angle. This assists the Chain Pin straying from the right angle or

central position during the operation, and also, this design provides the user with more efficiency and

convenience.

This special Ball Tip design Forcing Screw makes the operation more convenient and effective.

This unique application helps to reduce the direct friction with Push Pin, and avoids the rotation of

Push Pin which will make Push Pin misalign from Chain Pin during chain-breaking process.

Use with T Bar to drive. Use with 3/8” Square Driver tool. Use with 19mm & 21mm

Hex Wrench or Sockets.

Forcing Screw (D)

Special Ball Tip

SKD Push Pin w/spring (G)

Holding Tip (F)

Chain

Push Pin

w/Spring (G)

Push Pin

w/Spring (G)

Center Screw (C)Center Screw (C)

Holding Tip (H)Holding Tip (H)

Holding Tip (F)Holding Tip (F)

Handle hole pisitions.

Lift upper +30°

(Easily applied in varied space

and angle.)

Standard 0°

Holding the Chain Pin in central

Right below -30°

(Easily applied by left-handed user.)

Lift upper +30°Lift upper +30°

Right below -30°

Right below -30°

Stantart 0°

Stantart 0°

04 06

(Fig B) Details the position of the Chain to pressing the chain link pin out.

01. Find out the fixed point of the Chain Link, and use BS3506 Chain Link Pliers for removal of

U clip-type master chain link. (Fig C).

02. Ensure the Chain is positioned straight with the Chain Pin head over the hole in the Body of the

tool. To assist in the pin pressing operation grind flat the mushroomed head of the chain link pin.

Ensure the pressing pin is aligned.

03. Twisting of the Tool or misalignment could cause damage to the tool and the Push Pin.

Place the Chain Pin exactly between the hole of two sides of Holding Tip (F and H in Fig A).

Adjust the Center Screw to fix the Chain Link. The underside of the link pin should

be aligned over the hole in the tool Body to allow the chain link pin to be pressed into the hole.

04. Using the T-Bar or a 19mm spanner, turn the Forcing Screw the Push Pin to push the Chain Pin

out of the chain link.

05. Repeat the Operation 3. to push the other pin out from the Chain Link to complete the chain

breaking.

As chain sizes vary so do the pin sizes depending on the size of the chain links. The Tool breaking pins

in the kit cover sizes to suit the following chain links.

(F1) Small Holding Tip and (G1) Smaill Push Pin w/Spring, suits chains size #415, #420 and #428.

(F2) Medium Holding Tip and (G2) Medium Push Pin w/Spring, suits chains size #520, #525, #530

(#50) and #532.

(F3) Large Holding Tip and (G3) Large Push Pin w/Spring, suits chains size #630 and #632.

(H) Holding Tip for all chains.

(Fig A) Details the correct assembly of the Tool for breaking the Chain Pin.

Assembly of the Tool

01. Screw the Center Screw into the Tool Body.

02. According to the size of chain, choose corresponding Holding Tip (F) for the Center Screw and

Holding Tip (H) for the Body bottom. and lock them on the screw threaded body two sides .

03. Select the correct size Push Pin, with spring according to the chain size and assemble.

Then insert the Push Pin into the centre of the Center Screw.

04. Screw the Forcing Screw or T-Bar into the Center Screw to hold in position.

Make sure the Push Pin is well operated into the centre of the Holding Tip (F) during the

operation. Ensure that the Push Pin is retracted from the nosepiece, prior to preparing the operation.

05

Fig B Fig C

Fig C

Should the chain link pin not press out do not use excessive force as this may damage the tool.

Check the tool for alignment , disassemble the tool if necessary and reassemble , align and

commence the operation as detailed above.

CAUTION

BREAKING CHAINS

T Bar (E)

Forcing Screw (D)

Center Screw (C)

Holding Tip (F)

Body (A)

Handle (B)

Push Pin w/spring (G)

Holding Tip (H)

Fig A

ASSEMBLY CHAIN PRESSING SIDE PLATES

Parts:

(H) Holding Tip x 2 pieces

(J) Shallow Press Block

(K) Deep Press Block

For All motorcycle chain size:

#415, #420, #428, #520, #525,

#530 (#50), #532 and #630, #632.

Assemble the tool as shown in (Fig D) for pressing side plates.

01. Thread the Center Screw into the Body of the tool.

02. 2 pieces Holding Tip (H) of the Center Screw and Body bottom, and lock them on screw

thread at two sides.

03. Refer to (Fig D) as there are 2 pieces Press Block, Shallow (J) and Deep (K), and lock into

the 2 sides Holding Tip (H) hole of the Center Screw and Body bottom.

04. The Shallow Press Block (J) is positioned base plate of the tool (fixed master link side)

and the Deep Press Block (K) on the Center Screw side end of the tool with the Master

link plate underneath.

(The installation direction depends on the chain link, Deep Press Block is distance

of chain pin protrusion.)

05. This tool can be used to quickly remove the chain by conversely assembling the Shallow

Press Block (J) on Center Screw and Deep Press Block (K) on the bottom of Body, and then

repeating the Fig.E-Action.7.

(Different chains may require different operation.)

(Fig E) Chain assembly and riveting or mushrooming the head of hollow link pins. Riveting process is

not required on solid link pin style master links with elongated U clip retainers.

01. Check the chain manufacturer’s instruction or workshop manual for installation.

02. Install the new chain over the pulley’s sprockets and swing arm.

03. Use BS1164 Drive Chain Tension Puller to fix the distance of Master Link

04. Using the new Master link grease the O-Rings and place these on the master link pins.

05. Join the chain using the master link from the back of the chain with the pins facing outwards.

The rear sprocket will provide a position for the links to be joined easily.

06. Grease the Master link pins and install the O-Rings onto the hollow pins and then position the

Master link backing plate. Greasing the backing plate will hold the plate in position prior to

riveting. Note Ensure that the O-Rings are on the underside of the backing plate.

07. Using the Forcing Screw or 21mm spanner tighten the Center Screw checking that the link is

correctly aligned.

08. Compress the chain link until the chain Master link pins protrude above the Master link backing

plate.

09. Ensure that the link is evenly compressed on both sides. This measurement can be easily

checked with a vernier caliper. Refer to the chain manufacturers specification of recommended

protrusion as this may vary depending on the brand of chain.

10. For Master Link U Clip design attach the U clip ensuring, Using BS3506 Chain Link Pliers to

install that the U clip locks the backing plate firmly in position. (Fig F)

06 07

BS1164

Drive Chain

Tension Puller

BS1164

Drive Chain

Tension Puller

Shallow Press Block (J)

Deep Press Block (K)

Center Screw (C)

Center Screw (C)

21mm Wrench

Fig F

Fig E

Center Screw (C)

Body (A)

Holding Tip (H)

Holding Tip (H)

Shallow Press Block (J)

Deep Press Block (K)

Fig D

Solid Pin U-Clip Master

Link

Solid Pin U-Clip Master

Link Assembled

Hollow Pin Rivet Master

Link

Hollow Pin Rivet Master

Link Assembled

Master Link Identification

Chain assembly and riveting or mushrooming the head of hollow link pins. Riveting process is not

required on solid link pin style master links with elongated U clip retainers.

Please pay attention that if the chain pin and side link are positioned correctly when repeat using

Master Chain Link. If they are in the wrong position, please repeat the Breaking Chain Operation 4.

using Push Pin to fix the chain pin at the point of side link. Please check the figure.

(Fig H) Refer to the chain manufacturer's specifications for distance of chain pin protrusion, and

direction and installation of master link clips.

All chains are different, and BikeService cannot provide the exact specification for your chain.

Holding Tip (H)

Holding Tip (F)

Chain Side

Link Push Pin w/spring (G)

Center Screw (C)

Forcing Screw (D)

Chain Pin

Fig H

Fig J

08 09

Assembly of the Tool

01. Reassemble the tool to rivet or mushroom the hollow pins. (Fig L)

02. Thread the Center Screw into the Body of the tool.

03. Assemble the Rivet Tip into the Center Screw end thread and the Anvil in the thread of the tool.

04. Using a 21mm spanner firstly tighten the Center Screw checking that the link is correctly aligned.

05. Tighten the Forcing Screw either via the T-bar or 21mm spanner ensuring the tool Rivet is

centered on the Master Link Pin. (Fig J)

06. Remove and repeat this procedure on the second Master Link Pin.

07. Check that the Master link Pins are correctly Riveted as per the chain manufacturers

recommendation. (Fig K)

08. Do not over tighten as this can cause damage to the Master Link hollow pin or the Tool riveting

pin.

RIVETING MASTER LINK HOLLOW PINS

Center Screw (C)

21mm wrench

Rivet Tip (L)

Anvil (M)

Riveting chain pin

Anvil (M)

Rivet Tip (L)

Center Screw (C)

Check the line of sight to ensure that the chain is aligned straight.Tension the chain and align the

wheel to the manufacturers specification.

IMPORTANT

Fig K

Fig L

Table of contents