Billi Quadra Sparkling User manual

Install Guide

Quadra Sparkling

Safety

The unit should be isolated from the electricity supply before removal of any covers. Great care must be

employed when working with high pressure carbon dioxide, and in no cases should the maximum operating

pressure of 58 psi (4 bar) be exceeded.

Introduction

This unit has been designed to work in an enclosed, under counter installation without the need for an

additional ventilation kit, as cooling of the fridge system is provided by water from the mains supply

rather than air cooling.

Specification

Dimensions 180mm(W)

360mm(D)

420mm(H)

Compressor Cubigel B38G

Supply 220-240Vac/50Hz This product contains fluorinated greenhouse gas with a GWP

of 1430 in an hermetically sealed system

Rated Input 200W - Cold

2150W - Boiling

Rated Current 1.5A

10A

Refrigerant R134a, 60g

Fuse Rating 5A

13A

Climatic Class N

CO2 Pressure 40-50 PSI (2.7-3.4 bar) Potable water inlet

pressure

Internally regulated at 19

PSI (1.3 bar)

Compliance

Introduction and Specification

Installation and Commissioning

The chilled unit is designed to operate with the Billi™ range of tap/dispensing equipment and should

not be operated in isolation from these units.

•Locate the machine in a suitable enclosure, Quadra Sparkling is designed to work without the

need for additional ventilation, this is achieved by using water to cool the refrigeration system

rather than air.

Note: At this stage do not connect the unit to the electrical supply.

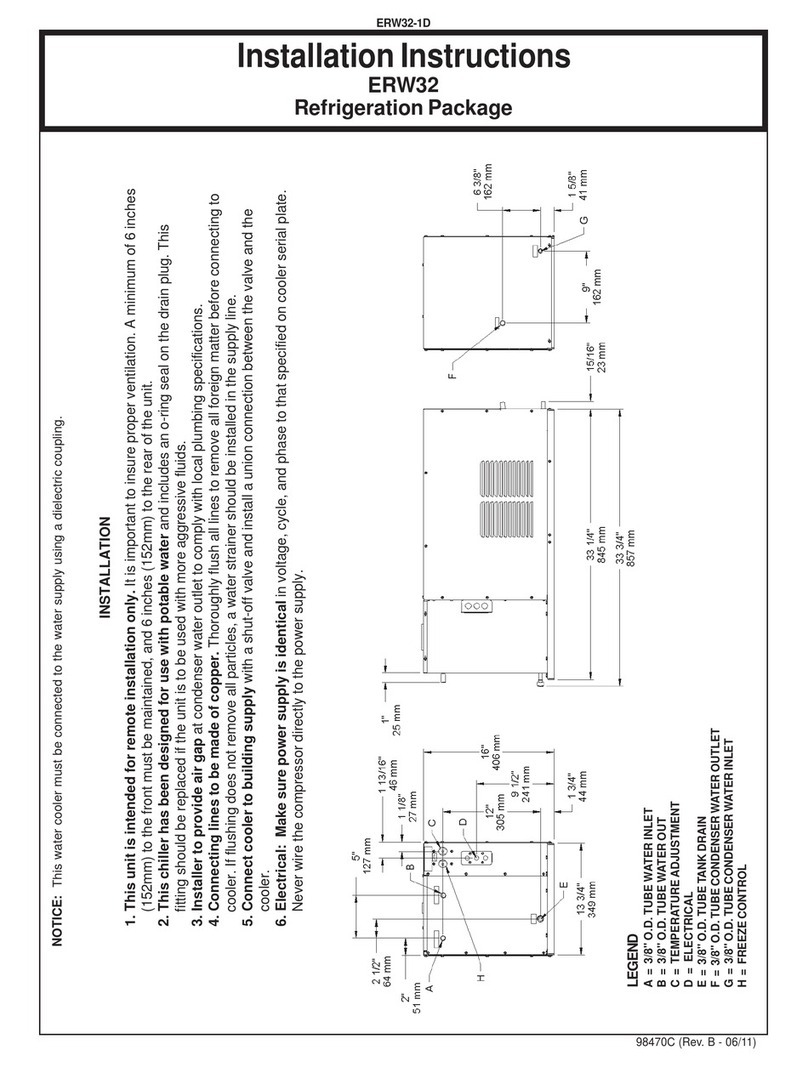

CO2 Gas and Water Connections

Drinking water and gas connections are via 6mm John Guest Speedfit fittings, which are black in

colour.

Condenser water connections are via ¼” John Guest Speedfit fittings, which are grey in colour. NOTE:

6mm tubing must not be used with ¼” fittings as this may lead to water leaks.

•Connect “WATER IN” to the water supply from the parent boiler. After all connections are made

the boiler unit should be on and ready to supply water to the cold unit. Water pressure in the

chiller is internally regulated at 19 PSI (1.3 BAR).

•Connect the “CO2 GAS IN” to the regulator, ensuring the pressure is set to 40 PSI (2.7 bar), and

turn on the supply.

•Connect “TO TAP” to the water dispense tap.

•Connect “CONDENSER WATER IN” to mains water and open the supply of water.

NOTE: This water supply to the “CONDENSER WATER IN” port must have a minimum

pressure of 1.3Bar.

•Connect “CONDENSER WATER OUT” to drain.

•Connect the flying lead from the parent boiler to the socket labelled “TO BOILER”.

•With the boiler ready to supply water plug in and turn on the chiller unit.

•The compressor will start, and the water pump will operate for approximately 20-30 seconds to

fill the carbonator vessel. Verify that water is flowing from the “CONDENSER WATER OUT” to

drain. The flow rate has been factory set to 5ml/s at 1.3 bar, so a low flow rate is expected to

drain, however, this expected to be a constant flow and should not be dripping.

•Once the water pump has switched off dispense still water until all air is expelled from the tap

and a smooth flow of water is established.

•Now dispense at least 1 ltr of soda water to help purge the system of any remaining air.

•After approximately 10 minutes, the compressor will stop as the chiller has reached its normal

operating temperature.

Installation and Commissioning

Note: The time taken for the chiller to reach operating temperature will vary depending on ambient

temperature, humidity and the temperature of the incoming water supply.

The Soda flow rate is factory set to dispense at 30 ml per second at a gas pressure of 40psi (2.7

bar). However, if an alternative flow rate is required follow the steps below:

1. Locate the flow adjuster screw on the side of the unit (Fig 1.).

2. To increase the flow rate turn the screw anti-clockwise.

3. To reduce flow rate turn the screw clockwise.

4. Adjustments can be made with either a large flat head screw driver or with a 6mm Alan key.

5. It is recommended to make incremental changes of no more than a quarter turn at a time until

desired flow rate is achieved.

Fig 1.

Adjust

Electrical Circuit

Water Circuit

PRESSURE REGULATOR.

FIXED AT 1.3 BAR (19 PSI). CARBONATOR CAN

FILL PUMP.

WATER COIL

CHECK VALVE

CARBONATOR

FLOW CONTROL

PRESSURE

RELIEF VALVE

CARBONATOR CAN

CHECK VALVE

TO DISPENSE

TAP.

PRESSURE REGULATOR.

WATER IN.

CO2 GAS IN.

CHECK VALVE SODA

SOLENOID

VALVE

STILL

SOLENOID

VALVE

5A

5A

HEAT EXCHANGER

SOLENOID VALVE

COMPRESSOR

CARBONATOR

CAN

TEMPERATURE

PROBES

POWER INLET.

220-240VAC, 50Hz.

GN/YE

WH

GN/YE YE

BU

BN

WH

BU

BU

BN

1

2

3

4

5

6

7

8

9

10

11

12

13

1

2

3

4

5

6

7

8

9

1

2

3

4

GN/YE

CAN FILL PUMP

GN/YE

WH

BK

WH

BK

HIGH SIDE

PROTECTION

CHILLER

PROBE

PROBE ID

Installation and Commissioning

Prior to any fault finding, please ensure all water connections to the chiller are sound and that the

incoming water supply is turned on. Also ensure that all electrical connections to the chiller and in the

chiller are secure and in good condition, the power is on and that the chiller has had adequate time to

reach operating temperature.

NOTE: When checking electrical connections ensure mains power is switched off.

Symptom Possible Cause Corrective Action

No Water

Dispensing

Water pressure

regulator

Check water can flow through the regulator.

Replace if

necessary.

Frozen chiller block Ensure temperature probe is fully inserted into

the dry block. If necessary replace probe.

Faulty dispense valve Check valve can open on demand. Replace valve

block if necessary.

Flying lead from

boiler not connected.

Connect flying lead from boiler to the chiller unit.

Faulty dispense

control board

Check and replace if necessary.

Pump not running

during still water

dispense.

Check for pump timeout, cycle power off & on.

Check supply to water pump (230V AC), if

voltage present & pump inoperative - replace

pump.

If voltage not present & pump is not timed out,

check main control board fuses. If necessary

replace control board.

No

Carbonated

Water

No CO2 pressure,

check by operating

pressure relief valve

on carbonator can

Check CO2 bottle, regulator and non-return valve.

Supply pressure should be 40 psi (2.7 bar), adjust

or replace as necessary.

Water pressure

regulator Check water can flow through the regulator.

Replace if necessary.

Frozen chiller block Ensure temperature probe is fully inserted into

the dry block. If necessary replace probe.

Faulty dispense valve Check valve can open on demand. Replace valve

block if necessary.

Flying lead from

boiler not connected.

Connect flying lead from boiler to the chiller unit.

Faulty dispense

control board

Check and replace if necessary.

Carbonator Can

Not Filling

Check carbonator probe for possible short circuit to

ground. Check for pump timeout, cycle power off &

on then purge carbonator. Check supply to water

pump (230V AC), if voltage present & pump

inoperative - replace pump. If voltage not present &

pump is not timed out, check control board fuses. If

necessary replace control board.

Fault Finding

Poor Quality

Carbonation

Incorrect CO2 Pressure Check CO2 bottle, regulator and non- return valve.

Supply pressure should be 40 psi (2.7 bar), adjust

or replace as necessary.

Air in Carbonator Can Isolate water supply and operate the carb water tap

until gas is expelled. Allow gas to expel for 5

seconds. Restore water supply and allow the can to

refill.

Residue in

Carbonator Can

After prolonged use, a surface film can develop

within the carbonator can. This can be removed by

flushing the system using a solution of citric acid.

Carbonator can is

overfilled

If pump runs continuously, check connections to

can level probe, if problem persists replace the

PCB.

Warm Drinks Insufficient water flow

through the fridge

heat exchanger.

Check for water flow from the “FRIDGE WATER OUT”

port whilst the fridge is running. The flow rate should

be a minimum of 5ml/s with a minimum water inlet

pressure of 1.3Bar.

Check supply voltage to the heat exchanger solenoid

valve (230V AC) whilst the fridge is running. Replace

valve if necessary. If supply not present move on to the

compressor. The supply to the solenoid valve and the

compressor are linked.

Compressor not

running Fridge overheat. Switch off the unit and allow to cool.

Ensure the solenoid valve operates and sufficient

water flow is available through the heat exchanger. If

overheating persists return for repair.

If no overheat is found check voltage to compressor

(230V AC).

If voltage not present check the temperature probes

and replace if required.

If voltage not present check control board fuses. If

necessary replace control board.

Control board not

operating. Check control board and main plug fuses. If

necessary replace control board.

Fridge failure If compressor is running & sufficient water is

flowing through the heat exchanger and there is

no cooling, return for repair.

Fridge Condenser Care & Maintenance

After a period of operation it is possible that, especially in hard water areas, scale deposits may

build up inside the fridge heat exchanger. To help reduce this it is recommended that the water

supply to the “CONDENSER WATER IN” is fitted with a chemical or magnet water conditioning unit.

These units work to reduce the possibility of calcium particles be deposited in the heat exchanger.

If the water supply does not contain a conditioning system calcium build-up may reduce water flow

and potentially lead to a blockage. To prevent this, periodic cleaning of the heat exchanger may

be required using a descaling solution. The frequency of this will be dependent on the hardness

of the water and the demand on the chiller.

Fault Finding

Symptom Possible Cause Corrective Action

Removal, Transportation and Disposal

Important: Before removal from the installation, ensure all electrical, product

and gas connections are disconnected.

Disposal of Scrap Units

It is illegal to simply scrap a refrigeration unit. Before a unit can be scrapped it must first

have the gas removed by a specialist using special equipment. Please contact Billi

UK, who will be happy to provide a quotation for disposal.

Transportation

Important: This unit must be transported in an upright position

As with all refrigeration systems, irreparable damage can be caused by laying the unit on its

side or even transporting upside down. Where the unit is transported by a carrier, the carton

should always be marked in a conspicuous manner, the correct upright position in which it

must be handled.

If a unit has been transported incorrectly it should be placed in the correct upright position and

left for 24 hours before attempting to run the system.

Failure to observe the above precautions could seriously damage the system, and would void any

warranty.

Unpacking your Billi Quadra Sparking Unit

Before commencing installation, carefully

check for any damage to outer carton, inner

liner, appliance metalwork, pipework fittings

and electrical power cord. If damage is found,

please photograph and record details for use

if a claim is to be made.

WARNINGS relating to this appliance must be

read before commencing installation. Refer

to page 8.

When unpacking your appliance, ensure you

have identified the following components:

1. Boiling water module

2. Chilled water module

3. CO2 cylinder

CO2 regulator

4. Dispenser

5. Tube spring clamps x 2

6. Natural and 2 x black Ø6 mm PE tubes

with stem elbows fitted

7. 600mm flexible braided hose

8. Filter cartridge (installed)

9. User guide

10. Warranty registration card

11. Warning label

Determine Unit Location

Plan the installation carefully, taking into

consideration dispenser tube lengths,

position of power and water outlets,

ventilation airspace requirements and access

for service. Refer to diagrams 1, 2, 3a, 3b and

4. Diagram 4 shows minimum clearances

required around the units for ventilation

Water Supply

A single cold water supply point with a ½” BSP

stop tap is required. Stop tap is to be installed

in an easily accessible position, within 600 mm

of the inlet to the boiling water module.

Sparkling chilled water module is supplied from

an outlet fitting on the Boiling water module.

Dynamic supply pressure: Min. 250 kPa, max,

1000 kPa

NOTE: Quadra Plus models require an

additional ½” BSP stop tap water supply tap.

Refer to instructions on Page 6.

Supply temp: Min. 5°C, max. 30°C

Do not install with water that is

microbiologically unsafe or with water of

unknown quality without adequate disinfection

before or after the system. Systems certified for

cyst reduction may be used on disinfected

water that may contain filterable cysts.

Power Requirements

Quadra Sparkling models 460 and Plus 9

require 2 x 13 amp sockets, installed in an

accessible position. Refer to Diagram 1.

Quadra Sparkling models 4100 and Plus 15

boiling module require a separate 20amp

double pole with a dedicated circuit. Power

circuits must be fitted with an earth leakage

protection device (RCD). Both boiling and

chilled water module are supplied with flex

cord and plug.

Installation requirements.

XL

Diagram 1

Stop Tap

(Installed by Plumber)

Max 600mm from Unit

Tubing

removed

for clarity

205mm

175mm

20mm

bench

thickness

1mm-48mm

Diagram 2

10mm

130mm

35mm 70mm

Tubing

removed

for clarity

Installation requirements.

XL

1. Install Dispenser Assembly

Determine position of dispenser mounting

hole in sink top or bench top. Dispenser base

template (Diagram 5) may be cut out and

used to assist in correct positioning. Refer to

Diagram 2 for clearances allowed. Hole size

required is ø32mm.

The Billi XL dispenser is supplied with base

assembly preassembled into dispenser

upper and this must be first removed prior to

starting installation. Using allen key supplied

in installation kit, remove chrome plated

M4 screw from rear of housing. Twist base

casting around 60º and then slide assembly

out of upper housing. Carefully pull tubing

and electrical cable and plug through base

assembly.

—Stainless Steel Sinktop

A suitable 32mm hole punch (Part no:

857901) is available as an accessory from

Billi Pty Ltd. If possible, cut hole with die

mounted below the sinktop surface so that

burr is pulled downwards. Alternatively,

remove burr and radius edge of hole with

fine file. This allows barbed dispenser mount

to slide smoothly into mounting hole.

—Timber/Laminate Benchtop

Maximum benchtop thickness is 50mm.

Cut 32mm hole in appropriate position.

When drilling through a particle board

bench top, take care to avoid substrate

chipping and breaking away as drill breaks

through underside surface. We recommend

drilling a small pilot hole through benchtop,

partially drilling the 32mm hole from

underneath and then completing drilling the

hole from above. The large 30mm washer

supplied may be used to secure barb where

bench top substrate has chipped away.

—Granite/Marble Benchtop

For granite or marble bench tops

we recommend that you use a certified

stone mason to pre-drill the hole.

2. Activate Dispenser Swivel Feature

The XL dispenser can be installed either as

locked into straight position or able to swivel

45º in either direction. To activate the swivel

feature of your dispenser, remove the locking

piece from the dispenser base. Simply push

out the piece as show in Diagram 6. This will

allow the tap to swivel to the left and right.

3. Fit Dispenser Base

a. Cut a 32mm hole in sinktop or benchtop.

Remove burr if protruding upwards.

b. Push barbed mounting shaft through

mount hole.

c. Insert barb locking bush as shown in

Diagram 7. Finger tighten nut.

d. Ensure barb is centred in mount hole

before tightening. Check position of base

ring and gasket.

e. Moderately tighten locking nut using

multigrips or spanner. Take care to avoid

overtightening nut which may break the

plastic threaded shaft.

f. Place large D washer over thread as

shown in Diagram 7.

g. Cut off excess threaded shaft with a

hacksaw, using washer as a cutting guide.

(Diagram 8)

IMPORTANT: Remove burrs and check internal

bore is completely smooth.

4. Fit Dispenser Head Assembly

a. Feed dispenser tubing and loom through

center hole in the following order:

i. Dispenser power cord

ii. Silicone tubes

iii. Blue PE tube.

b. Gently pull hoses from under the bench

top. Do not attempt to force tubing through

with a pointed object as silicone tube is

easily punctured. Check tubing is not

kinked or twisted. Refer to Diagram 9.

c. Turn dispenser head assembly to

approximately 60° from the straight ahead

position of dispenser base. Slide head

assembly onto base assembly whilst

gently pulling tubing downwards from

underneath to prevent tubing bunching and

kinking. Head retaining lugs will pass nut

and slide down the 3 grooves on the swivel

bearing.

d. Once fully down, turn dispenser to

straight ahead position. Fit chrome

plated M4 retaining screw to lower rear

threaded hole and tighten using the allen

key supplied. If swivel feature is activated,

check dispenser now swivels smoothly 45°

in each direction.

Installing the dispenser.

XL

IMPORTANT: This Billi appliance is to be installed by a licensed trades person in accordance with

AS/NZS 3500.1 and AS/NZ 3500.2 and in compliance with applicable state regulatory requirements.

For correct operation of this appliance, it is essential to observe the manufacturer’s instructions.

3

dispenser base

template

Diagram 5

Diagram 6

Silicone

tubing

Diagram 9

Diagram 7

Swivel

Bearing

Gasket

D Washer

required

Barb locking bush in position

Barbed

Mounting

Shaft

Ensure burr

is removed

& edge has

a radius

Base Casting

Locking Nut

Diagram 8

Cut o

excess

thread

Remove burrs after cutting and

ensure internal bore is smooth

Alloy locking

bush

D washer

CHECK EACH OF THE FOLLOWING ITEMS:

Filter packing foam removed

from under filter cannister.

Dispenser mounted securely – M4

chrome retaining screw fitted.

Dispenser swivels 45º in each direction

(if activated) - locking piece is removed.

Tubing is cut to correct lengths and

not kinked or sagging. Red and grey

silicone tubes have a continual fall.

Tubing secured correctly – nuts and

spring clips fitted.

Water main flushed before connection to

unit.

Unit connected to COLD water supply.

Correct air clearances around unit.

Power circuit fitted with an RCD

– earth leakage protection device.

Sawdust cleaned out of cupboard area.

Door vents and spacer pads fitted

correctly

Initial program settings correctly set

for dispenser tube length.

Unit heating and cooling (after initial fill).

Red and blue dispenser icons flashing

(or on continually when reached correct

temperature).

Boiling and chilled water flow correct.

Commissioning

Checklist WARNINGS.

For continued safety of this appliance it must be installed, operated and maintained in

accordance with the manufacturer’s instructions. For correct operation of this appliance,

it is essential to observe the instructions as outlined in this booklet.

—Your appliance should be installed by a suitably qualified tradesperson.

—For correct operation of this appliance it is essential to observe the instructions as

outlined in this booklet.

—Do not use this appliance with water that is microbiologically unsafe or with water of

unknown quality without adequate disinfection before or after the system. Systems

certified for cyst reduction may be used on disinfected water that may contain filterable

cysts.

—Filter replacement must be performed at intervals of not more than 12 months.

—Use this appliance only as directed in these instructions and relevant Billi User Guide and

only for its designed purpose.

—Do not install unit if power cord is damaged.

—This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning use of the appliance by a

person responsible for their safety.

—Always activate boiling water safety lock switch where children or mentally disabled

persons could access the appliance.

—This appliance is designed for indoor installation only and must not be exposed to

direct sunlight, rain and excessive heat, cold, damp or dust.

—Do not store solvents or corrosive chemicals or other flammable items on or around

this appliance

—DANGER: High Voltages. Power supply must be disconnected before cleaning or

removing and outer covers form the appliance. Any service or unit repairs must be

performed by a trained and suitably qualified technician.

—Children should be supervised to ensure that they do not play with the appliance.

—DANGER: The operation of the thermal cut-out indicates a possibly dangerous situation.

Do not reset the thermal cut-out until the water heater has been serviced by a qualified

person.

—WARNING: Do not connect any restrictor or pressure relief device to the vent pipe of this

water heater if installed.

—If the supply cord is damaged, it must be replaced by the manufacturer, its service agent

or similarly qualified persons in order to avoid a hazard.

—New hose-sets supplied with the appliance are to be used and old hose-sets should not

be re-used.

—Packaging material including plastic bags must be kept out of reach of children and

disposed of according to local regulations.

—If the appliance has been turned upside down during transport and handling, wait for

at least 8 hours before switching appliance on.

As Billi (UK) LLP has a policy of continual improvement,

all details are subject to change without notice. All goods

are sold subject to our published terms and conditions.

Billi is a registered trademark.

© 2019

QSIG0519

Billi (UK) LLP

6b Central Avenue

St Andrew's Business Park

Norwich

NR7 0HR

020 7456 6789

www.billi-uk.com

London Showroom:

Synergy London

15 Dufferin Street

London

EC1Y 8PD

If any problems or difficulties arise contact

Billi (UK) LLP on 020 7456 6789. To

validate your warranty refer to the

warranty card or validate online at

www.billi-uk.com.

For information on our filtration

and service contracts please contact

Billi Customer Service on 020 7456 6789 or

Table of contents

Popular Chiller manuals by other brands

Daikin

Daikin EWWD J Series Installation, operation and maintenance manual

Daikin

Daikin AGZ 190D operating & maintenance manual

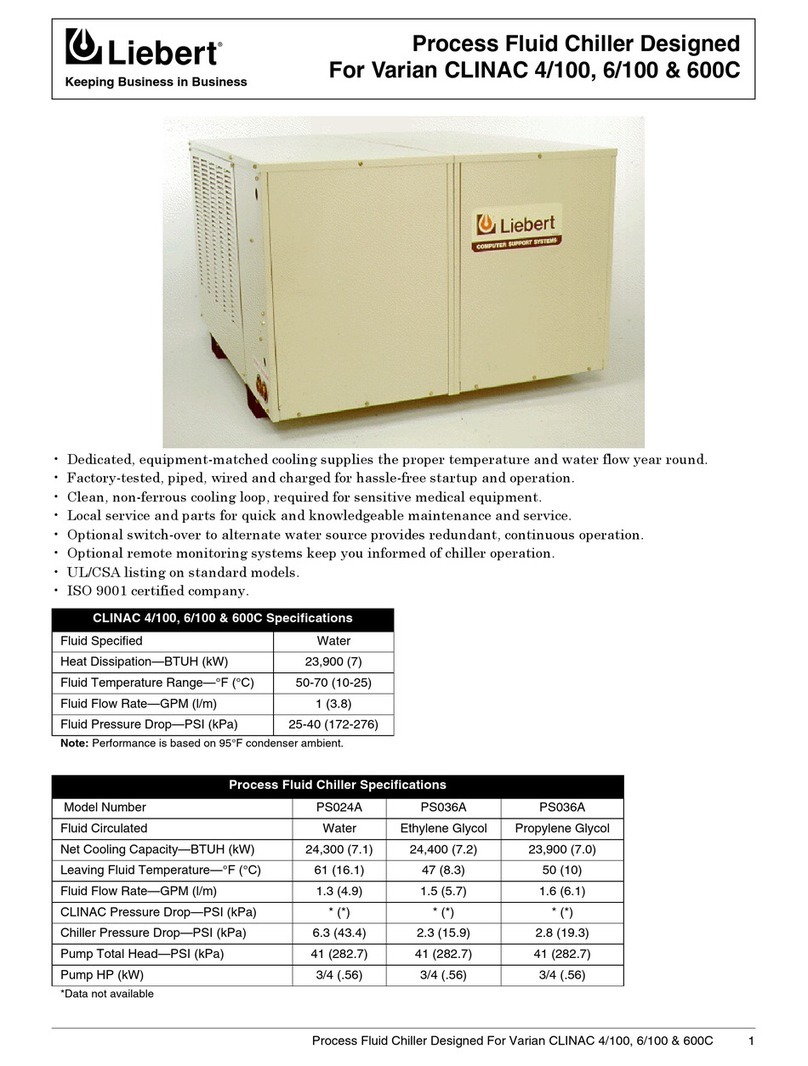

Liebert

Liebert Process Fluid Chiller PS024A Specification sheet

Swegon

Swegon BlueBox Zeta Rev Series Installation, use and maintenance manual

Trane

Trane 4YCY5024A1060A Installer's guide

hailea

hailea HC-100A instruction manual