7

4Installation

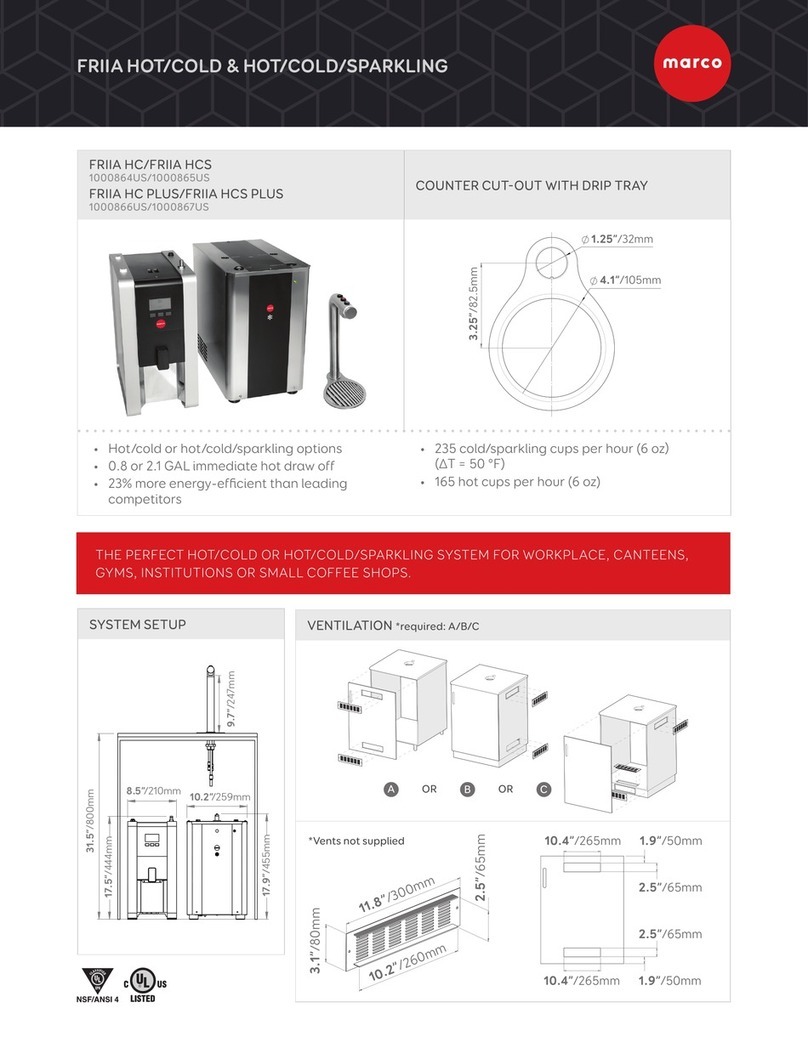

4.1 Positioning

• The equipment must be placed on a surface capable of bearing the weight of the chiller

full of water. Install the equipment following the schematic described in this user guide.

• The chosen position must allow satisfactory ventilation; there must be a gap of at least

10 cm (3.9 in) around the back and top for ventilation.

• The equipment must not be placed close to direct or indirect heat sources (ovens,

stoves, radiators, etc.).

• The electrical connection and water supply points must be close to the equipment must

be located in such a way the power cable and water hose do not form an obstruction.

• The appliance must not be installed where water jets can be generated. Do not spray

water on the device; this could cause electric shock or fires.

• The equipment is not suitable for external use.

• The equipment must be placed so it is protected from rain and water splashes, and in a

location with the temperature appropriate to its climate class (stated in specification);

otherwise, warranty rights are forfeited, and malfunctions may occur.

4.2 Electrical Installation

• When installing the chiller, always observe the local regulations and standards.

• The chiller is supplied with a moulded power cord.

• A suitable mains power supply socket should be available within easy access of the

chiller so that it can be disconnected easily after install.

4.3 Plumbing Installation

• Ensure that the chiller is installed according to local plumbing & water regulations.

• Fit a stop valve on a cold-water line and attach a 3/8” BSP male fitting, (E.g. 3/4” x 1/2”

311 or washing machine type stop valve).

• Connect water supply lines following the installation drawings. As per installation guide

in the User Manual (starting page 8).

• Push the pipe firmly into the fittings until locked into position to avoid leaks. 15mm is

the correct depth of insertion.

• In case filter systems are used verify that they satisfy the requirements of the legislation

in force.

• The chiller has a pressure reducer in case the incoming water exceeds 3 bar.

• Turn on the water to flush any impurities, dust etc. from the inlet hose and water pipe.

• Allow several litres through. Especially for new installations.

4.4 CO2 Installation

There are two CO2 installation options with this chiller, either an inbuilt 360-410gr/60L gas cylinder

or an external CO2 cylinder.

Internal gas cylinder

Open the side door. Install the CO2 cylinder into the machine. A compatible gas cylinder to use is the

Sodastream 60L cylinder https://sodastream.co.uk/pages/co2-gas-cylinders Once the CO2 cylinder is

installed, the yellow CO2 light stops flashing on the font of the machine.