BioCare Medical Desert Chamber Pro User manual

www.biocare.net

Desert Chamber Pro™Manual

Turbo-Fan Slide Drying Oven

DRY2008INT

Biocare Medical

Technical Support:

800-799-9499 Option 3

Customer Service:

800-799-9499

Fax:

925-603-8080

Corporate Office:

60 Berry Drive

Pacheco CA 94553

www.biocare.net

Table of Contents

Warranty

The Desert Chamber Pro warranty is for one year from receipt of purchase and covers all parts and labor when performed solely by

Biocare Medical. Warranty is invalidated if equipment is abused, damaged, or improperly maintained by customer. Warranty is not

transferable to any other party should the equipment be resold or transferred by the customer to another party. To the extent permitted

by law, Biocare Medical disclaims any liability for any incidental or consequential damages related to this equipment or for any warranty

related services it performs.

Not for use with flammable solvents or gases

Overview ................................................................................................................................................................................ 1

Specifications ........................................................................................................................................................................ 2

Unit Specifications ................................................................................................................................................................. 2

Unit Construction ................................................................................................................................................................... 2

Contents ................................................................................................................................................................................ 2

Assembling the Oven .............................................................................................................................................................. 3

Electrical Precautions ............................................................................................................................................................. 3

Maintenance .......................................................................................................................................................................... 3

Slide Drying Protocol For Immunohistochemistry ....................................................................................................................... 4

Slide Loading Guidelines......................................................................................................................................................... 4

Manual Operation Instructions ................................................................................................................................................. 5

Preset Program Descriptions .................................................................................................................................................... 6

Preset Program Operation Instructions ...................................................................................................................................... 7

Checking the Sequence........................................................................................................................................................... 8

Changing Between Preset Programs.......................................................................................................................................... 8

Appendix 1: Program Function Map.......................................................................................................................................... 9

Appendix 2: Function Menu................................................................................................................................................... 11

Quick Operation Guide .......................................................................................................................................................... 12

1

Overview

This innovative compact oven from Biocare Medical is extremely efficient and is specially designed for the rapid drying of slides. The

combination of a small footprint, turbo fan, 365-watt element and a digital programmable temperature process controller makes this

oven superior to other conventional drying ovens. This controller will autocalibrate for the amount of mass and volume placed inside

the oven, keeping the inside temperature constant and accurate. The Desert Chamber Pro can be programmed with variable segments,

times, temperatures and alarms.

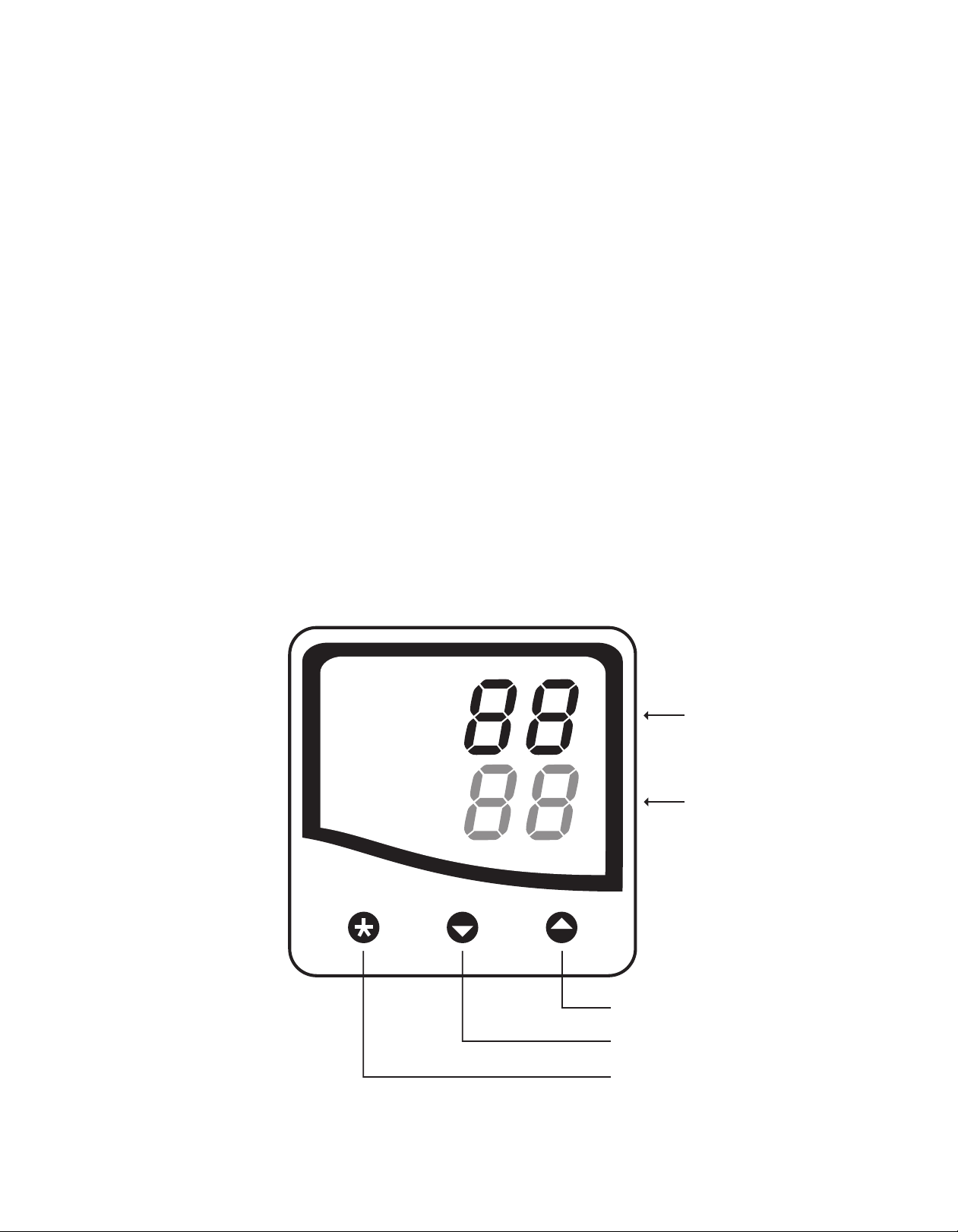

On / Off SwitchTemperature Up

Temperature Down

Main Control Button

Controller

(Program & Temperature)

DRY2008INT

2

Specifications

Interior Dimensions: 10.5 (W) x 9.5 (H) x 11.5 (D) inches / 26.7 (W) x 24.1 (H) 29.2 (D) centimeters

Exterior Dimensions: 13 (W) x 16 (H) x 13.5 (D) inches / 33.3 (W) x 40.6 (H) x 34.3 (D) centimeters

Weight: 27 pounds, 12.2 kilograms

Cubic Foot Capacity: 0.7 cubic feet

Standard Electrical: 115 volts / 365 watts (DRY2008US), 230 volts / 365 watts (DRY2008INTL)

Temperature Range: Ambient - 100 °C

Unit Specifications

Operating Environment:

Indoor use. Installation Category II, Polution Degree 2, ambient temperature

10 °C - 35 °C (50 °F - 95 °F); 80% maximum relative humidity.

Storage Temperature: -10 °C - 70 °C (14 °F - 158 °F); 70% maximum relative humidity.

Approvals: Underwriter's Laboratory Listed, Laboratory Equipment, C/UL

United States / Canadian. E212550 (115 VAC models only)

Compliance: UL Standard 61010-1, IEC 61010-1, 2nd Edition

Unit Construction

Exterior: Powder-coated steel

Insulation: Fiberglass

Thermo-control: PID microprocessor

Interior: Aluminum

Door: Steel insulated

Heater: Resistive-tubular Incoloy

Contents

Inspect the packaging and immediately report any damage to Biocare Medical.

1. Oven with Digital Programmable Temperature Process Controller

2. Adjustable Shelves

3. Wire Shelf Brackets

4. Removable Drip Tray

3

Assembling the Oven

1. Position the unit in its ultimate operating location, keeping a minimum of two inches of space around the

unit and ten inches of space above the unit.

2. Place the removable drip tray on the bottom of the oven. (Figure 1)

3. Push the ends of the wire shelf brackets into the holes until the first bend is against the wall.

Then rotate the bracket down. (Figure 2)

4. Place the adjustable shelves on top of the brackets. (Figure 3)

5. Plug the Desert Chamber into a properly grounded receptacle

(either 115 volt or 230 volt, depending upon the model).

Electrical Precautions

Basic safety precautions should always be followed when using electrical equipment.

• Do not immerse cord or plug in water.

• Unplug the instrument when not in use and before cleaning.

• Do not operate the instrument with a damaged cord or plug.

• Do not let the cord hang over the edge of a table or counter or touch hot surfaces.

Important Note

The oven temperature has been calibrated at the factory and should not be adjusted by the end-user.

If any problems arise with the oven, call Biocare Medical for technical service at 800-799-9499.

Maintenance

The Desert Chamber Pro oven is designed to be virtually maintenance-free. However, the oven does require periodic cleaning and

chamber temperature accuracy verification in order to maintain operational and safety standards. Periodically check the rear air intake

vents for dirt or dust build-up. Keep the intake and exit ports clear of obstruction and free of dust and dirt. Once a year, check the

actual oven chamber temperature against a known accurate temperature measurement device. To clean exterior and interior surfaces,

use a damp cloth with an all-purpose cleaner. Avoid commercially available oven cleaners.

1 2 3

4

Slide Drying Protocol For Immunohistochemistry

Drying slides correctly for immunohistochemistry (IHC) is essential to achieving optimal staining. Tissue sections will not adhere to the

slide if all the water is not removed prior to deparaffinization and Heat Induced Epitope Retrieval (HIER). Tissues with a high collagen

content such as skin or a high fat content such as breast can be especially problematic.

Slide Drying Protocol

Use distilled water only in the Water Bath. Do not use any organic or inorganic adhesion products such as gelatin. The water bath

temperature should be 10 - 12 °C lower than the paraffin melting point - usually 40 - 45 °C.

Use Biocare Medical Kling-On Slides or other positively charged slides for optimal tissue adhesion. Shake the slides with a snapping

action of the wrist to remove excess water that may be trapped between the tissue section and the glass slide. Drain slides in a vertical

position for 5 - 10 minutes.

Place slides in a slide rack and tap on the counter to remove residual water. Position slide rack in oven. Close oven door. Dry slides using

one of the Preset Programs. All the water should be evaporated from beneath the tissue section and the glass slide, and the paraffin

should be melted prior to deparaffinization and HIER.

Note: the times may vary according to the number of slides placed in the oven.

Technical Notes:

Under-fixed tissue is less likely to adhere to the slide properly. Ideally, the tissue should be grossed at 3mm, placed in 20X volume

of formalin and fixed for 16-24 hours to allow adequate infiltration prior to processing.

Do not dry slides for immunohistochemistry at temperatures higher than 60 - 70 °C, or for longer than one hour. Longer drying times

or higher temperatures may compromise the antigen of interest (e.g., Estrogen and Progesterone Receptors).

Slide Loading Guidelines

Load the oven so that air circulation within the oven is not impeded.

• Stagger slide racks on the shelves.

• Do not overload; leave a space between racks being processed.

• For the best processing performance for a single item, place it in the center of the oven.

• Do not use acids or corrosive reagents inside the oven.

5

Manual Operation Instructions

Operation Instructions

1. Turn on the oven by pushing the On/Off button. The button will light red when the unit is on.

2. The Temperature Controller is pre-set at 25 °C (red LED, bottom right corner). To change the target

temperature, press and hold the main temperature control (asterisk) button and at the same time, press the

up or down arrow buttons to increase or decrease the temperature readout.

The green LED is the actual temperature inside the oven. The red LED is the target temperature.

Stopping a Manual Run

1. Push the up and down arrows simultaneously, then push and release the up arrow twice and finally

push the asterisk button and down arrow simultaneously.

2. Do not end a programmed run prematurely by turning off the using the On/Off button. Make sure the LED display

shows the temperatures before stopping a manual run using the On/Off button. Run Off will be displayed until

the LED displays the temperatures. This may take several minutes.

3. To turn off the oven, push the On/Off button.

Note: Attempting to stop a manual run using the toggle switch will result in the oven retaining the current run settings.

If the program controls become jammed due to an electrical power surge or power outage, unplug the unit's power cord, wait a few

seconds and plug it back in to reset.

Temperature Down

Green LED

Red LED

Temperature Down

Main Temperature Controller

6

Preset Program Descriptions

Level P = 1

Program 1: Standard Program

Segment 1 - 37 °C for 30 minutes

Segment 2 - 60 °C for 30 minutes

Level P = 2

Program 2: Fast Dry Program

Segment 1 - 45 °C for 20 minutes

Segment 2 - 70 °C for 10 minutes*

Level P = 3

Program 3: Bulk Program

Segment 1 - 45 °C for 30 minutes

Segment 2 - 70 °C for 30 minutes*

Level P = 4

Program 4: Overnight Program

Segment 1 - 37 °C for 60 minutes

Segment 2 - 60 °C for 60 minutes

Level P = 5

Program 5: Delayed Program

Segment 1 - 25 °C for 720 minutes

Segment 2 - 37 °C for 60 minutes

Segment 3 - 60 °C for 60 minutes

Note: All programs can be customized to user-defined specification.

*Temperatures over 60 - 70 °C are not recommended for IHC

7

Preset Program Operation Instructions

Starting a Program (Run On):

1. Press the power button to activate the oven - a red light will indicate that the oven is in the “on” position, and the

screen will display the actual temperature.

2. Press and hold the up and down arrow buttons until the screen displays "Level P".

3. Press the up arrow button and immediately release. The screen will display "Program 1".

4. Press and hold the asterisk button and use the up arrow buttons to select the desired program number

(Programs 2-5). Omit this step if desired program is currently displayed.

5. Press the up arrow button once and immediately release. The screen display will read Run Off.

6. Press and hold the asterisk button down, and then press the up arrow button. Immediately release. The screen display

will read Run On.

7. Press and hold the up and down arrow buttons until the screen displays the current temperature as well as the set

temperature. The program will start immediately; however, it may take several minutes to display.

8. At the start of a run the display will read "SPr" in green with the target temperature in red. When the set temperature is

reached the display will read "SoAK" in green, alternating with the actual temperature.

Stopping a Program (Run Off):

1. To stop a program, similar steps to starting a program are repeated.

2. Press the up and down arrow buttons and hold until the screen displays "Level P".

3. Press the up arrow button and immediately release. The screen will display Program (1-5).

4. Press the up arrow button once and immediately release. The screen display will read Run On.

5. Press and hold the asterisk button down, and then press the down arrow button and immediately release.

The screen display will read Run Off.

6. Press and hold the up and down arrow buttons and hold down until screen displays current and set temperatures.

The oven can now be powered off.

7. To turn the power to the oven off, press the red power button. The red indicator light will turn off.

Note: It is important not to prematurely power down the Desert Chamber Pro before stopping a run that is in progress.

8

Checking the Sequence

Program

To check the program number which is currently selected:

1. Press and hold the asterisk button.

2. Release the asterisk button to return to the original display.

Segment

To check the segment information for the program:

1. Press and hold the asterisk button and press the up arrow button.

2. Release the asterisk and up arrow buttons to return to the original display.

Time Remaining

To display the time remaining (in minutes) for a Program:

1. Press and hold the asterisk button and press the up arrow button.

2. Continue to press and hold the asterisk button and press the up arrow button again.

3. Release both the asterisk and up arrow buttons to return to the original display.

Changing Between Preset Programs

1. Press and hold the up and down arrow buttons until the screen displays Level P.

2. Press the up arrow button and immediately release. The screen will display Program 1-5.

3. Press the up arrow button once and immediately release. The screen will display Run On.

4. Press and hold the asterisk button, and press the down arrow once, immediately release.

The screen will read Run Off.

5. Press and hold the up and down arrow buttons until the screen displays the temperature.

6. Press and hold the up and down arrows buttons and hold until the screen displays Level P.

7. Press the up arrow button and immediately release. The screen will display Program 1-5.

8. Press and hold the asterisk button, and press the up or down arrow button to the desired

program number (Programs 2-5).

9. Press and hold the asterisk button, press the up arrow button once, and immediately release.

The screen will display Run Off.

10. Press and hold the asterisk button and press the up arrow button once. The screen will read Run On.

11. Press and hold the up and down arrow buttons, until screen displays the selected temperature.

12. Press the asterisk button to verify the selected program.

9

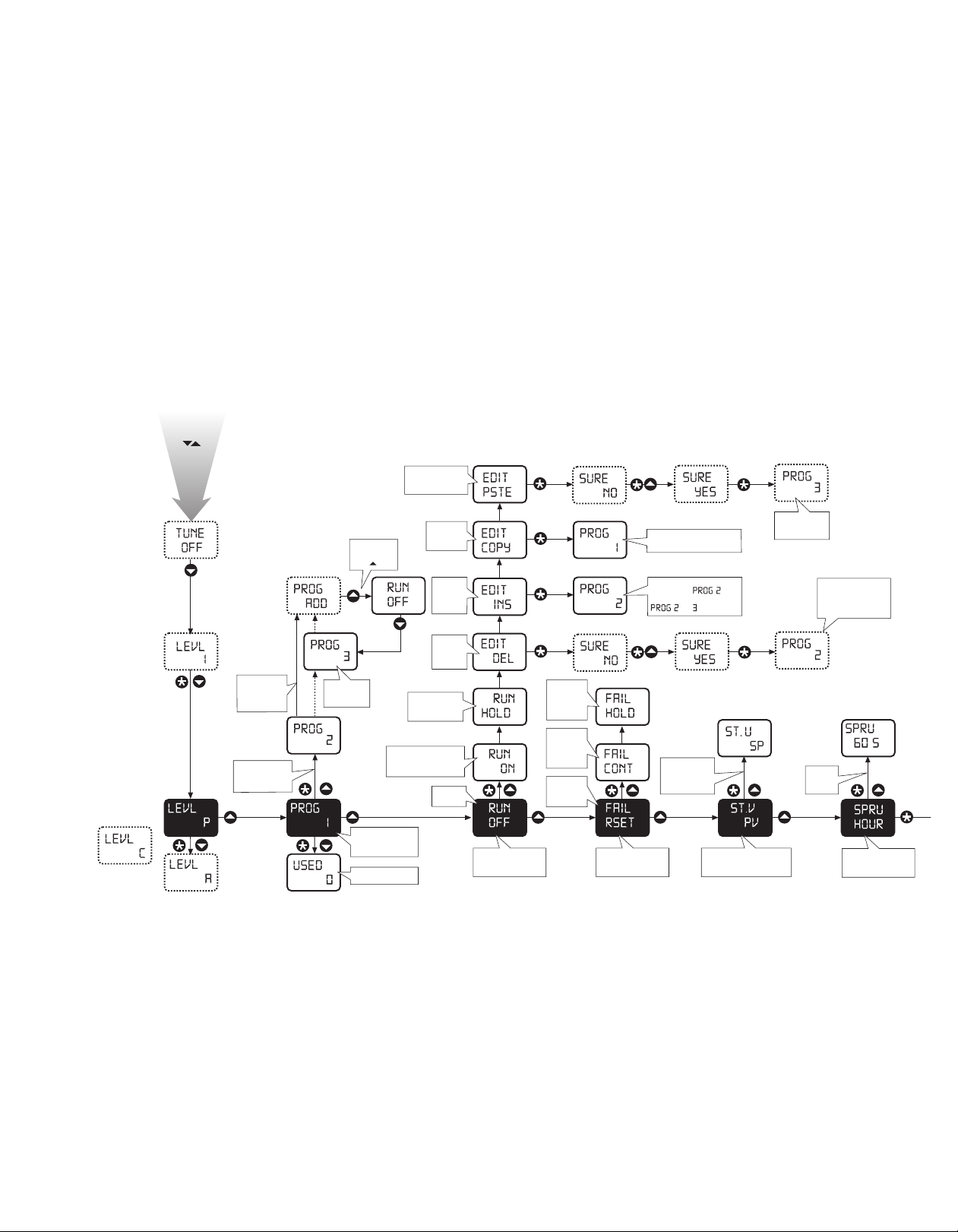

START HERE

Press and hold

for 3 seconds

ENTER

PROGRAM

If COMMS option

tted, LEVEL C

appears between

LEVEL P and LEVEL A

Hold the

program at

the point it

stopped

Continue the

program

from where

it stopped

Reset the

program at

beginning

Program

‘o’ state

Program 3

now appears

in list

Start program when ‘on’

selected. This locks

other options out

Hold the

program at

current position

Program

editing

functions.

Insert

Program

editing

functions.

Delete

Copies the

selected

program

Paste only appears

after a program is

copied

To add new

program,

press once

Add new

programs at

top of existing

menu

Select the required

program number.

Default: 1

Memory used (%)

Select program mode

of operation

Default: o

Power failure recovery

position

Default: reset

Select the starting point of

program after power up

Default: PV

Ramp rate time units

adjustment

Default: hour

Options: start

program at main

SP or process

variable

Options:

hours

minutes

3 secs 3 secs

3 secs

3 secs

3 secs 3 secs

Another program has been

inserted into

re-numbering existing

to

A copy of program 1 can be

pasted into another program

Program 1 has

been copied to

program 3

To view existing

programs 1 to 31

or full?

Program 3 has been

deleted. Display

shows next program

down from top of list

Appendix 1: Program Function Map

10

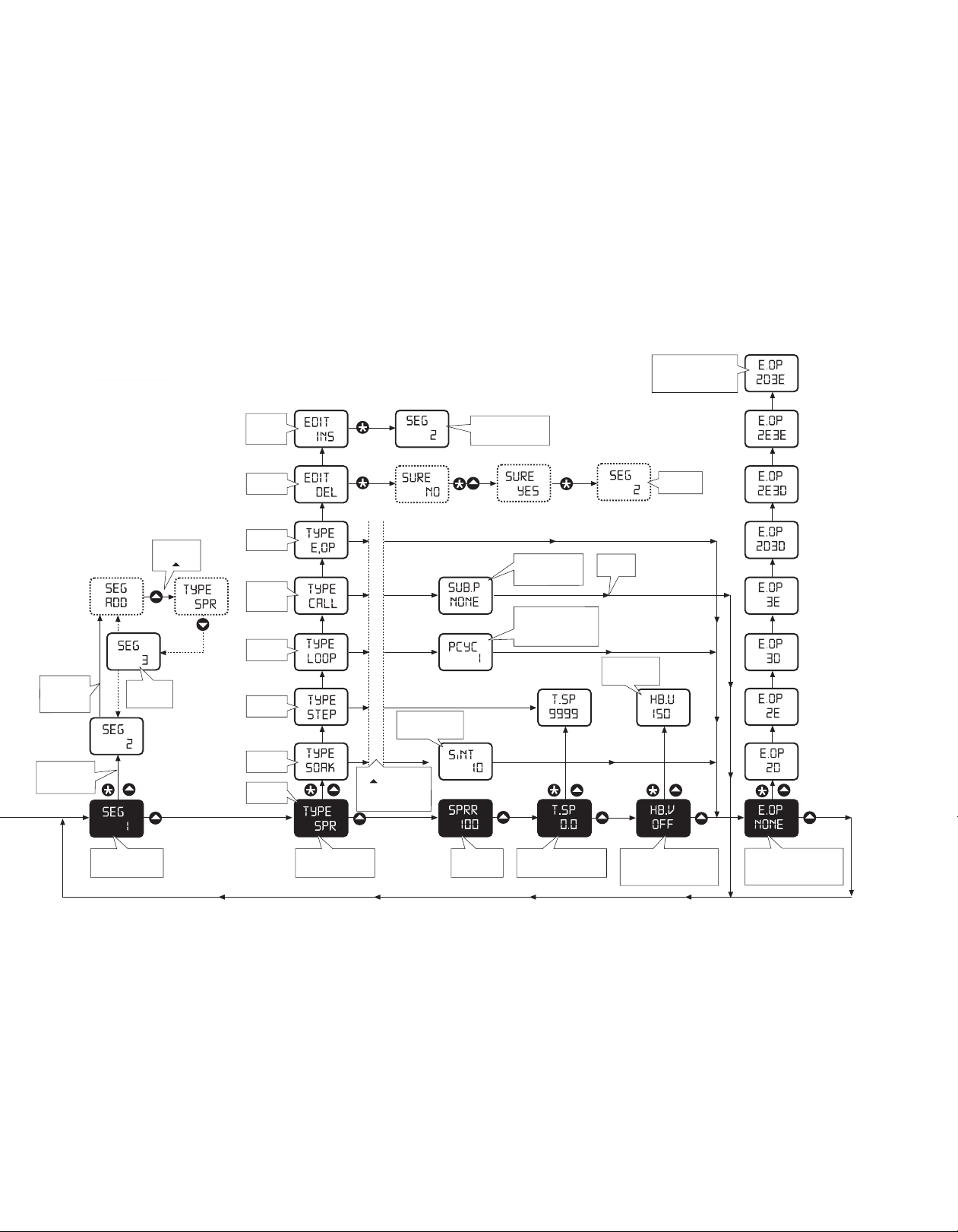

Insert new

segment in

the menu

Delete a

segment

Event

output

Call up

another

program

Program

re-cycles

Step

Soak

Ramp

Segment 3

now appears

in menu

To add new

segments

press once

Add new

segments at

top of existing

list

To view existing

segments 1 to 126

or full?

Set the segment to be

adjusted

Default: 1

3 secs 3 secs

Segment 3

deleted

3 secs

New segment now

inserted into 2. Old

segment 2 becomes 3

To select operational

mode of each segment

Default: Ramp

Important note

Up button must be

used after selecting the

segment type to

conrm it’s selection

Adjusts ramp

rate

Default: 100

Soak time in minutes

or continue

Default: 10

Dene the program

number called

Default: none

Set Numbers of

re-cycles 1 to 999 unless

full. Or continuous

Default: 1

Returns to

SEG

Target set point adjustable

over the unit’s range

Default: Current main SP

‘Hold back’ this function only

appears for ramp operational

once a value is set

Default: o

Event output – options only

appear when SP2A or SP3A

modes set to E.OP

Default: de-energise

Event output options

energise and de-energise

for all combinations of

SP2 & SP3.

‘Hold back band

size adjustable

0.1 to 150 units

Appendix 1: Program Function Map (continued)

11

Call sub-program number

nonE ; 1 to number

of programs

Soak time interval

Cont ; 0.1 to 1400

(10) min

Program re-cycle count

Cont; 1 to 999

Derivative sensitivity

0.1 to 1.0 x dEr.t ( 0.5 )

Display averaging

dir ; 1 to 32 (6)

Disable -AL- alarm

display ; on

Disable program auto-exit

Auto ; StAY

Security lock

nonE; LEV 3; LEV 2; ALL

Change program entry point

O ; on

USER-PROTECTEDSETTINGS

SP2 output device

none; SSd; rly; (read only)

Sensor burn-out

uP.SC ; dn.SC; 1u.2d; 1d.2u

Zero adjustment

0.0 to 25% sensor

full scale

Set Monitor

O ; on

Read Monitor

VAr; hi; lo deg

Read Tune Data

CtA; Ctb; Ct1; Ct2; Ct3; Ct4;

oS1; uS; oS2

Software version

Consult unit

RESET

nonE; ALL

SP1 output device

none; rly; SSd; AnLG

Reverse outputs

1r.2d ; 1d.2d; 1r.2r; 1d.2r

Reverse O/P LEDs

1n.2n ; 1i.2n; 1n.2i; 1i.2i

Span adjustment

0.0 to 25% sensor

full scale

CONFIGURE OUTPUT SAFETY SETTINGS CALIBRATION PERFORMANCE DATA

Read SP1 output %

0 to 100% read only

SP1 manual output %

0 to100% proportional

mode only

Limit SP1 output %

100 to 0%

Limit SP2 output %

100 to 0%

Main SP2 mode

nonE ; dV.hi; dV.Lo; bAnd;

FS.hi; FS.Lo; Cool; EoP

Second SP2 mode

nonE; LtCH; hold; Lt.ho;

nLin

Display resolution

1or 0.1 degree

Set scale maximum

0.0 Sensor max to sensor

full scale

Set scale minimum

0.0 Sensor min to sensor

full scale

Select input sensor

nonE

Select display units

nonE;°C; °F; bAr;

PSi; Ph; rH; SEt

\\

MANUAL ADJUSTMENTS SP2 MODES CONFIGURE INPUT

RANGING

SP1 SETTINGSSP2 SETTINGS

Autotune or Park

O ; on; ParK; At.SP

SP1 Prop band (gain)/

hyst 0.1 deg to 100%

sensor f/s ( 10°C/18°F)

Integral time (reset)

O; 0.1 to 60 min

(5 min)

Derivative time (rate)

O; 1 to 200 sec

(25 sec )

Derivative approach

0.5 to 5.0 x bAnd

(1.5 )

Cycle time or on/o

On.o; 0.1 to 81 sec

( 20 sec )

Oset (manual reset)

0 to 50% x bAnd

( In.t = o )

Setpoint lock (SP1)

O ; on

Adjust SP2 setpoint

+/– sensor full scale or

full scale

SP2 prop band/Gain/

Hyst 0.1 deg to 100%

sensor f/s (2°C/3.6°F)

SP2 Cycle on/o

On.o ; 0.1 to 81 sec

Program number

1to 31

Run program

oFF; on; hoLd; dEL

inS; CoPY; PStE

Power failure

recovery mode

rSEt ; Cont; hoLd

Program start value

PV; SP

Setpoint ramp time units

hour ; 60s

Holdback value

oFF; 0.1 to 150

Event output (SP2A or SP3A)

nonE; 2d; 2E; 3d; 3E; 2d.3d;

2E.3d; 2d.3E; 2E.3E

PROGRAMMER SETTINGS

S

egment number

1to 126 max.

Dene segment type

SPr; SoAK; StEP; LooP;

Call; EoP; dEL; inS

Setpoint ramp rate

1 to 9990 ( 100 )

units/time

Adjust target setpoint

+/– sensor full scale or

full scale

Instrument address

0to 255

Baud rate

1200; 2400; 4800

9600 ; 19k2

Data format

18n1 ; 18E1; 1801

TxRx activity

O ; on

COMMS SETTINGS

High scale 1000

-1999 to 9999

Low scale 0

-1999 to 9999

Input high 50.0

0.1 to 50.0

Input low 10.0

0.0 to 49.9

Decimel 0000

000.0 or 00.00

Burnout SP3 - uPSC

dhSC

R

everse O/P3 3D

3r

SP3 SAFETY SETTINGS

Main mode nonE

dv.hi; dVLo; bAnd; Fshi;

FSLo; EoP

Second mode nonE

LtCh; hoLd; Lt.ho

Set SP3 0

0 to 2500

Hysteresis SP3 20

1–100% sensor

full scale

SP3 ADJUSTMENTSSP3 MODESLINEAR SCALING AND INPUT SETTINGS

INITIAL

SET-UP

ENTRY

PROGRAM ENTRY (DEFAULT)

Level C only visible

when COMMS

Option tted

KEY OR TOGETHER TO CHANGE LEVELS OR OPTIONS

KEY OR TO VIEW FUNCTIONS

Appendix 2: Function Menu

12

Quick Operation Guide

Manual Use

1. Turn the oven on using the On/Off button. The red light should be on.

2. Temperature control is preset at 25 °C. To change the temperature, hold the main temperature control (asterisk) button

down and at the same time, push the up or down arrows to increase or decrease the temperature.

3. When finished, turn off the oven.

Program Instructions

1. Turn the oven on using the On/Off button. The red light should be on.

2. Temperature control is preset at 25 °C.

Selecting a Program

1. Hold the up and down arrow simultaneously for five seconds. "Level P" will be displayed.

2. Push the up arrow and immediately release. "Program 1" will be displayed.

3. Push the asterisk button and up or down arrow for desired program.

Turning On a Program

1. Go through “Selecting a Program” as above.

2. Push the up arrow and release. "Run Off" will be displayed.

3. Push the asterisk button and push the up arrow and immediately release. The screen will read "Run on".

Turning Off a Program

1. Hold the up and down arrows simultaneously for five seconds. "Level P" will be displayed.

2. Push the up arrow and immediately release. "Program 1" will be displayed. Select the desired program.

3. Push the up arrow once and release. "Run On" will be displayed.

4. Push the asterisk button and push the down arrow and immediately release. The screen will read "Run Off".

Changing from One Program to Another Program

1. Hold the up and down arrows simultaneously for five seconds. "Level P" will be displayed.

2. Push the up arrow and immediately release. "Program 1" will be displayed.

3. Push the up arrow once and release. "Run On" will display.

4. Push the asterisk button and push the down arrow and immediately release. The screen will read "Run Off".

5. Push the up and down arrows and hold until the screen displays the temperature.

6. Select another program by holding the up and down arrows for five seconds. "Level P" will be displayed.

7. Push the up arrow and immediately release. "Program 1" will be displayed. Select the desired program by

holding the asterisk key down and pushing the up or down arrows.

800.799.9499

60 Berry Drive

Pacheco CA 94553 www.biocare.net

904-009-071817

Other manuals for Desert Chamber Pro

1

Table of contents

Popular Oven manuals by other brands

Bosch

Bosch HBL43S4.0A instruction manual

Euro Appliances

Euro Appliances EP8060DS instruction manual

Bosch

Bosch HBG7741 1 Series User manual and installation instructions

Fulgor Milano

Fulgor Milano SUPREME Instructions for installation and use

Bakers Pride

Bakers Pride EP series Operation manual

Solt

Solt GGSO605MS user manual