Biodom 33

Biodom 33Biodom 33

Biodom 33

|

| |

| instructions for use, maintenance and installation | version 1.0 July 2017

3

INDEX

1. PURPOSE OF INSTRUCTIONS FOR USE ...................................................................................... 5

1.1. UPDATES .................................................................................................................................. 5

2. RESPONSIBILITY OF MANUFACTURER ....................................................................................... 5

2.1. BASIC PREVENTIVELY REQUIRED STANDARDS ......................................................................... 5

2.2. TRANSPORTATION AND HANDLING OF PELLET BOILER ........................................................... 6

2.3. RESPONSIBILITY OF INSTALLER ................................................................................................ 6

3. INSTALLATION ..........................................................................................................................

3.1. PLACEMENT ............................................................................................................................. 7

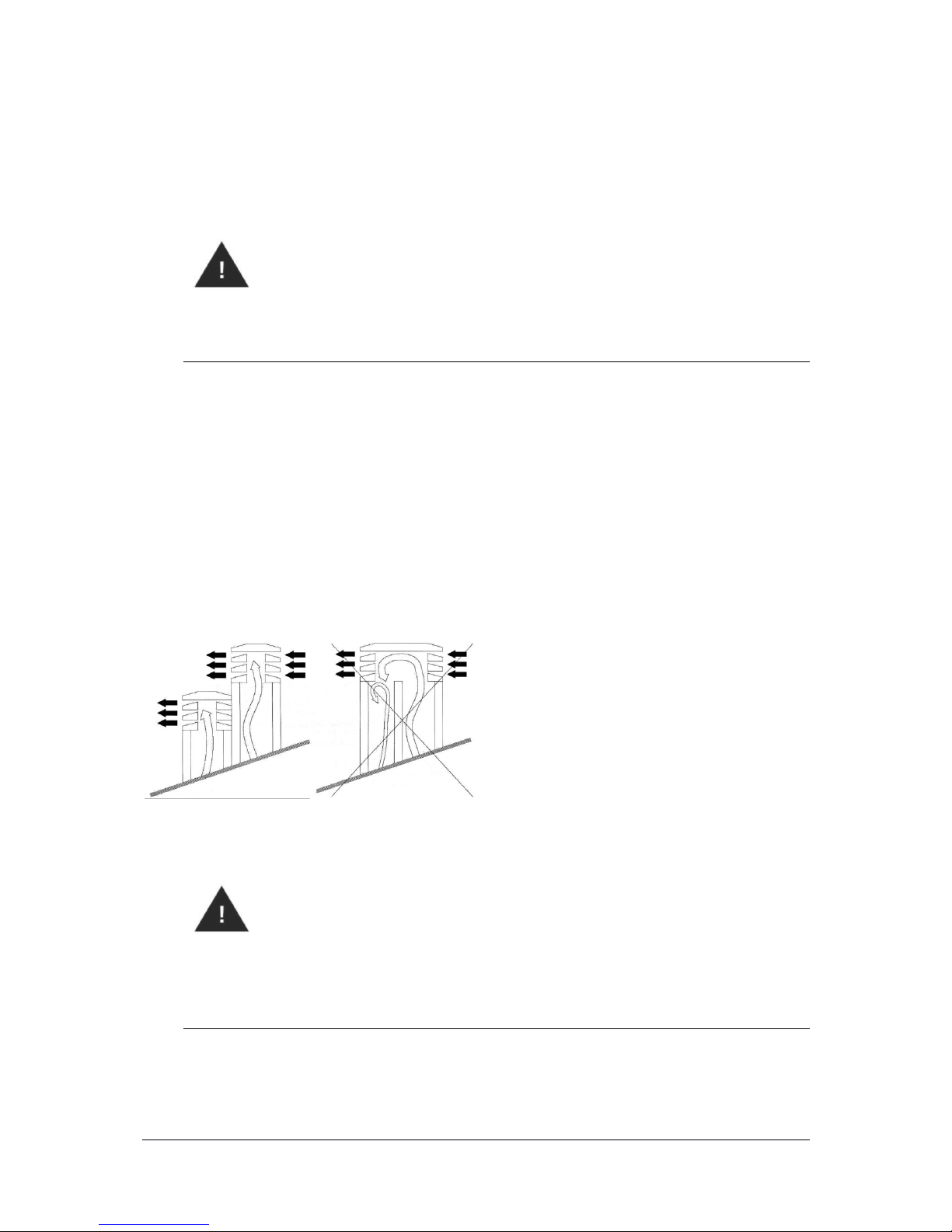

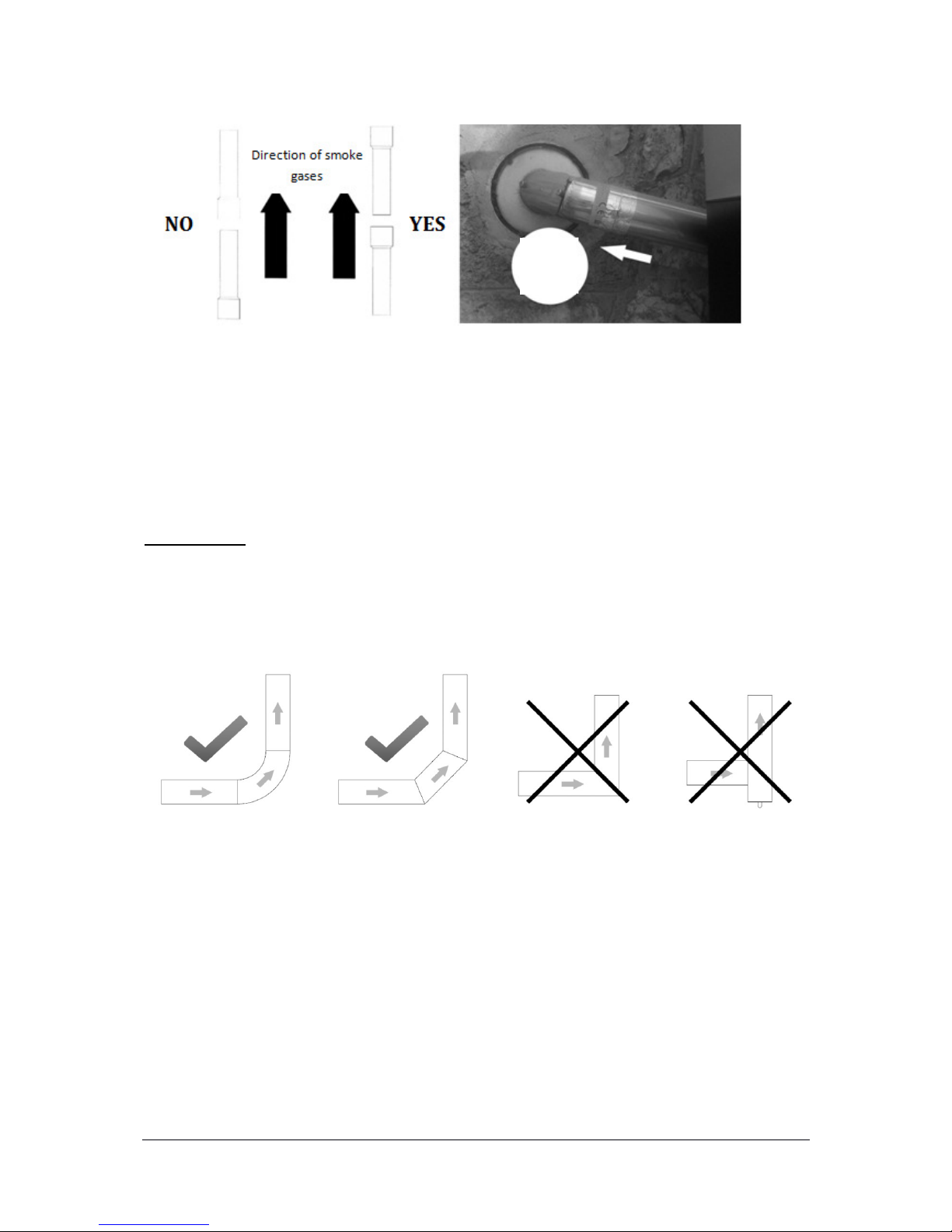

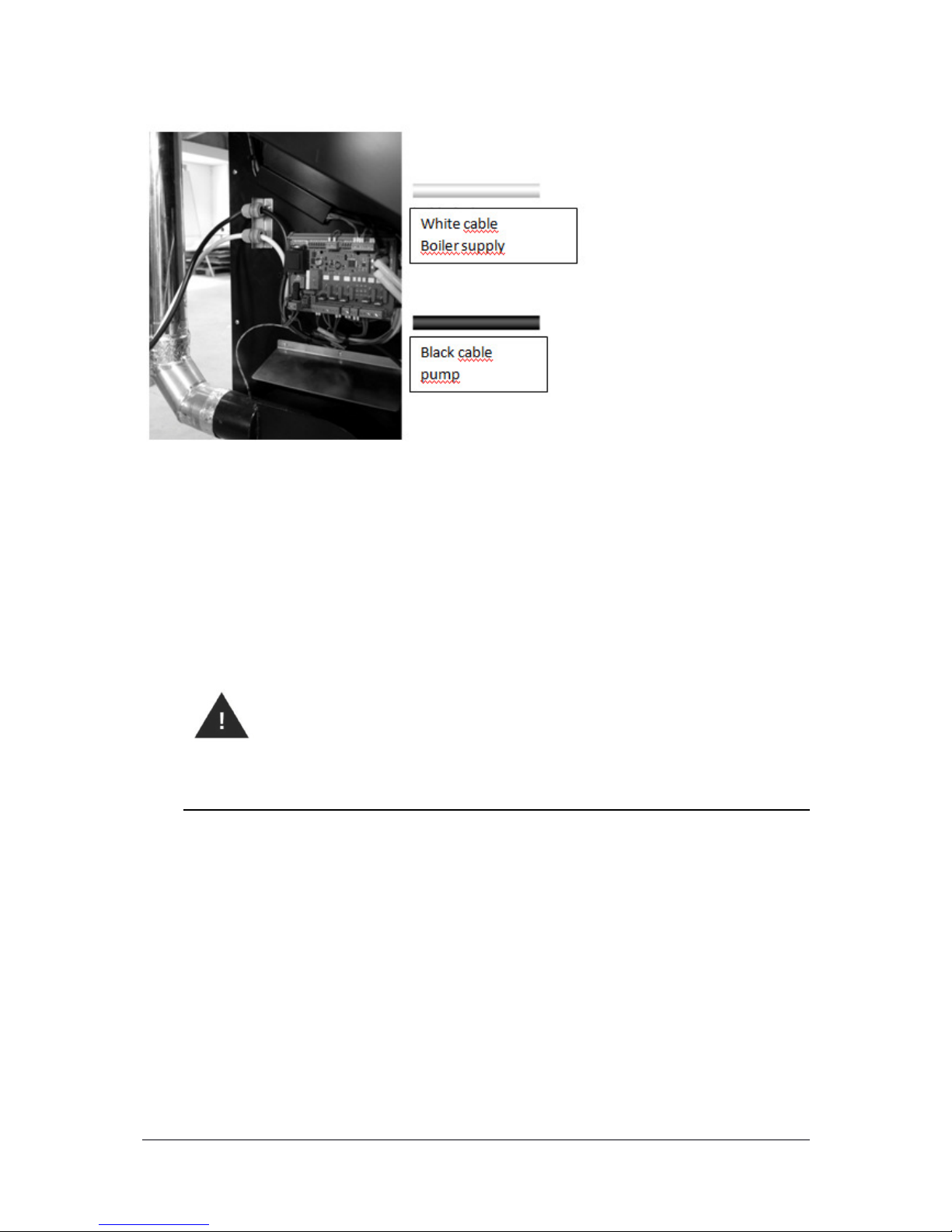

3.2. EXTRACTION OF SMOKE GASES ............................................................................................. 10

3.3. INSULATION AND DIAMETER OF HOLES IN THE ROOF .......................................................... 12

3. . INLET AIR ............................................................................................................................... 12

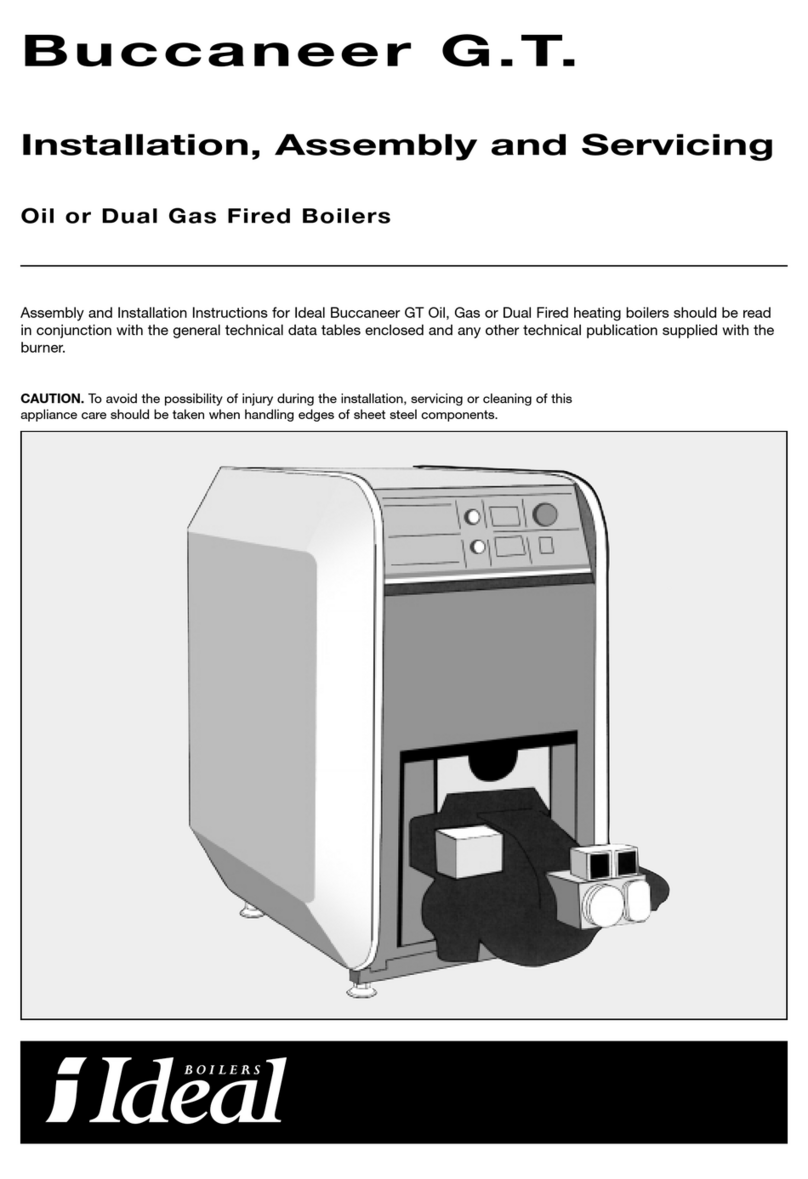

3.5. ELECTRICAL CONNECTION ..................................................................................................... 13

4. BOILER COMMISSIONING ....................................................................................................... 14

5. SAFETY WARNINGS ................................................................................................................ 15

5.1. SAFETY WARNINGS FOR MAINTENANCE STAFF .................................................................... 15

5.2. SAFETY WARNINGS FOR USER ............................................................................................... 15

6. INSTRUCTIONS FOR SAFE IGNITION AND CLEANING OF BOILER ............................................... 1

6.1. REGULAR MAINTENANCE AND CLEANING OF BOILER .......................................................... 17

6.2. CONTROL AND PARTS REQUIRING MAINTENANCE ............................................................... 19

6.3. ADDITIONAL MAINTENANCE ................................................................................................. 20

. IMPORTANT SAFETY INFORMATION ....................................................................................... 20

8. PELLET QUALITY IS VERY IMPORTANT ..................................................................................... 20

8.1. STORING PELLETS .................................................................................................................. 21

9. DESCRIPTION AND OPERATION OF CONTROL DEVICE .............................................................. 22

9.1. BOILER DURING OPERATION ................................................................................................. 26

9.2. BOILER SHUTDOWN .............................................................................................................. 26

9.3. BOILER ACTIVATION ............................................................................................................... 26

9. . TIME PROGRAMME SETTING ................................................................................................ 27

9.5. INDICATIONS AND MESSAGES ON DISPLAY ........................................................................... 29

10. MENU ................................................................................................................................... 31

11. ALARM STATUSES .................................................................................................................. 33