BioLife ThawSTAR CFT2 User manual

1. ThawSTAR Automated Cell Thawing System Function and Description

ThawSTAR®Automated Cell Thawing System (Item No. AST-601) is designed to rapidly thaw live biological contents of 1.8-2.0 mL cryogenic

vials taken directly from liquid nitrogen (LN2) storage, a -80°C freezer or vials equilibrated and held at dry ice temperature (-78.5°C) in a

container such as the ThawSTAR®CFT2 Transporter (Item No. AST-602). Utilizing patent-pending STAR™adaptive sensing technology, each

vial receives a customized thaw cycle based upon multiple built-in detection parameters. The intended result is a thermal prole equivalent

to a water bath thaw, but without the water, and comparable post-thaw cell recovery and viability.

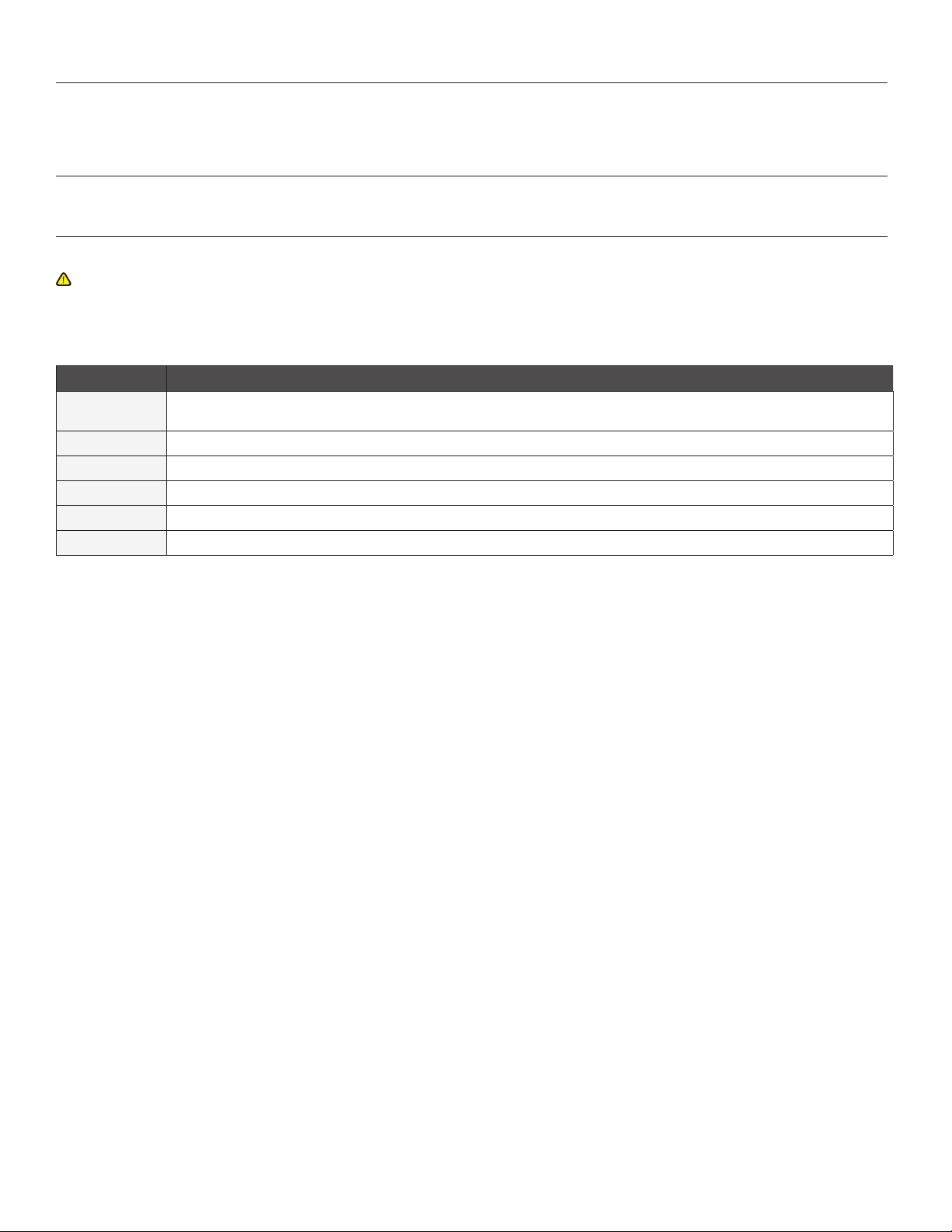

LEDs

Base light

Unit

opening

On/Off

switch

Mini USB port (to be

used only by authorized

service personnel)

Speaker

Power

connection

1.1 General Safety

ThawSTAR Automated Cell Thawing System is intended for the exclusive use by trained and experienced laboratory personnel.

1.1.1. Review instructions before installing, using or cleaning the unit.

1.1.2. DANGER: To prevent risk of severe or fatal electrical shock, use only the supplied AC power supply with cables for

the US, UK and EU packaged with the unit.

1.1.3. WARNING: Do not place near ammable materials. This unit is not designed to be explosion-proof or spark-proof.

1.1.4. WARNING: Avoid prolonged exposure to ultraviolet light such as sunlight or germicidal lamps unless covered by

light resistant plastic bag or a large piece of unbroken aluminum foil placed over the unit when not in use.

1.1.5. WARNING: Do not clean unit with ketone solvents; use recommended cleaning protocol in section 5.

1.1.6. CAUTION: Do not place near or immerse in water or other liquids.

1.1.7. WARNING: Removal of shell without authorization will void your limited warranty. Do not remove exterior shell of

the unit unless instructed to do so by an authorized BioLife representative.

1.1.8. WARNING: Unit has a covered mini-USB port on the bottom; do not insert any USB plug into this port or attempt to connect unit

with any other device, (eg. a computer), unless instructed to do so by an authorized BioLife representative.

1.1.9. WARNING: Do not use ag labels or labels that have a tab extending beyond the vial body or with folds or ridges with the

unit as these features may interfere with heat transfer or cause vial to become lodged in the unit.

1.1.10. CAUTION: The unit is designed for stationary indoor laboratory bench top use; outdoor “eld” use or use on a

laboratory bench subject to strong vibrations such as near a centrifuge, shaker, or vortex mixer is not advised.

1.1.11. Ensure the unit is placed securely on a level surface during operation.

1.1.12. Recommended for use with standard 1.8 to 2.0 mL cryogenic vials containing cryopreserved cells; the ThawSTAR

system is optimized for 1.o mL volume of aqueous solution at a starting temperature of <- 70°C.

1.1.12.1. Ensure vials were frozen in an upright and vertical position and that frozen contents are at the bottom of the vial.

1.1.12.2. Vials should be gently inserted into the top opening of the unit; CAUTION: NO other objects (e.g. forceps)

should be inserted into the unit at any time.

1.1.13. CAUTION: Keep liquids out of the unit; ensure cryogenic vials have clean exteriors and are tightly capped to prevent leaks.

1.1.14. CAUTION: Do not touch the vial with hands or any other object until the thawing process is nished (after

cryogenic vial is inserted into the opening of the unit and the thawing process has been initiated).

1.1.15. Thawing time is typically 2-3 minutes from the time of vial insertion. Laboratory personnel are advised to be in close

proximity to the unit while in use so that vials may be immediately retrieved upon thaw completion.

1.1.16. Before moving the unit, ensure that any cryogenic vial has been removed from unit opening.

1.1.17. Keep unit opening covered while not in use.

1.1.18. HOT SURFACE WARNING: The heating elements inside the vial opening are heated while the unit is turned on. Avoid

inserting body parts such as ngers or any object except a 1.8 to 2.0 mL cryogenic vial into the vial opening at any time.

1.1.19. Ensure the power cord can be easily disconnected from the power supply when placing the unit on a laboratory bench.

ThawSTAR®CFT2

Automated Cell Thawing System

Instructions for Use

1.2 Use As Intended

If the ThawSTAR® Automated Cell Thawing System is used in a manner not specied by BioLife in these Instructions for Use, operators are

regarded as proceeding under their own risk and warranty terms and conditions may be voided.

1.3 Packing Components

The ThawSTAR®Automated Cell Thawing System contains the following components:

Item Quantity Photo

ThawSTAR®Automated Cell Thawing System 1

AC power supply with cable for US, UK, EU 1 power supply

3 power cables

ThawSTAR® Conrmation Vials 2 vials

Quick Start Guide 1

Instructions For Use 1

Limited Product Warranty 1

1.4 Unpacking

Remove plastic tie inserted into unit opening and associated tape/padding completely before using. If you are missing any

components, please contact BioLife. See customer service contact information in Section 8.

1.5 Specications

Instrument

Thawing temperature Equivalent to a 37°C water bath

Thawing time Typically less than 3 minutes

Operating environment temperature 5°C to 35°C; 75% room humidity (maximum)

Storage temperature -20°C to 60°C

Maximum altitude 2,000 m

Power rating 40 W maximum

Input/Output voltage (power adaptor) AC 100 - 240V / DC 12 V, 50 – 60 Hz

Output current 3A

Phase IØ

Electrical plug formats US, UK, EU

Dimensions (Diameter x Height) 10.9 cm x 14.5 cm (4.3 in x 5.7 in)

Weight without power supply 0.7 kg (1.6 lbs)

Weight with power supply 1.2 kg (2.6 lbs)

Compliance CE mark (EMC and Safety), IEC60601, IEC61010, RoHS, WEEE

Cryogenic Vial Compatibility

Vial body external diameter 12.19-12.37 mm (0.480-0.487 in)*Measured 30.4 mm (1.2 in) from bottom of vial

Vial body external height below cap ring (minimum) 26.6 mm (1.05 in)

Overall height of vial with cap (minimum) 44 mm (1.73 in)

Vial cap diameter (maximum) 14.3 mm (0.56 in)

Vial capacity One standard 1.8 to 2.0 mL cryogenic vial

Sample volume Optimized for 1.0 mL

Vial Contents Optimized for cells in cryopreservation medium such as 10% DMSO / 20% FBS /

70% DMEM

Vial label thickness (maximum) 0.1 mm

2. Instrument Assebly

Plug the power supply into the port in the back of the ThawSTAR®Automated Cell Thawing System and attach

the appropriate power cord (US, UK or EU) to the power supply.

3. Instrument Start-Up

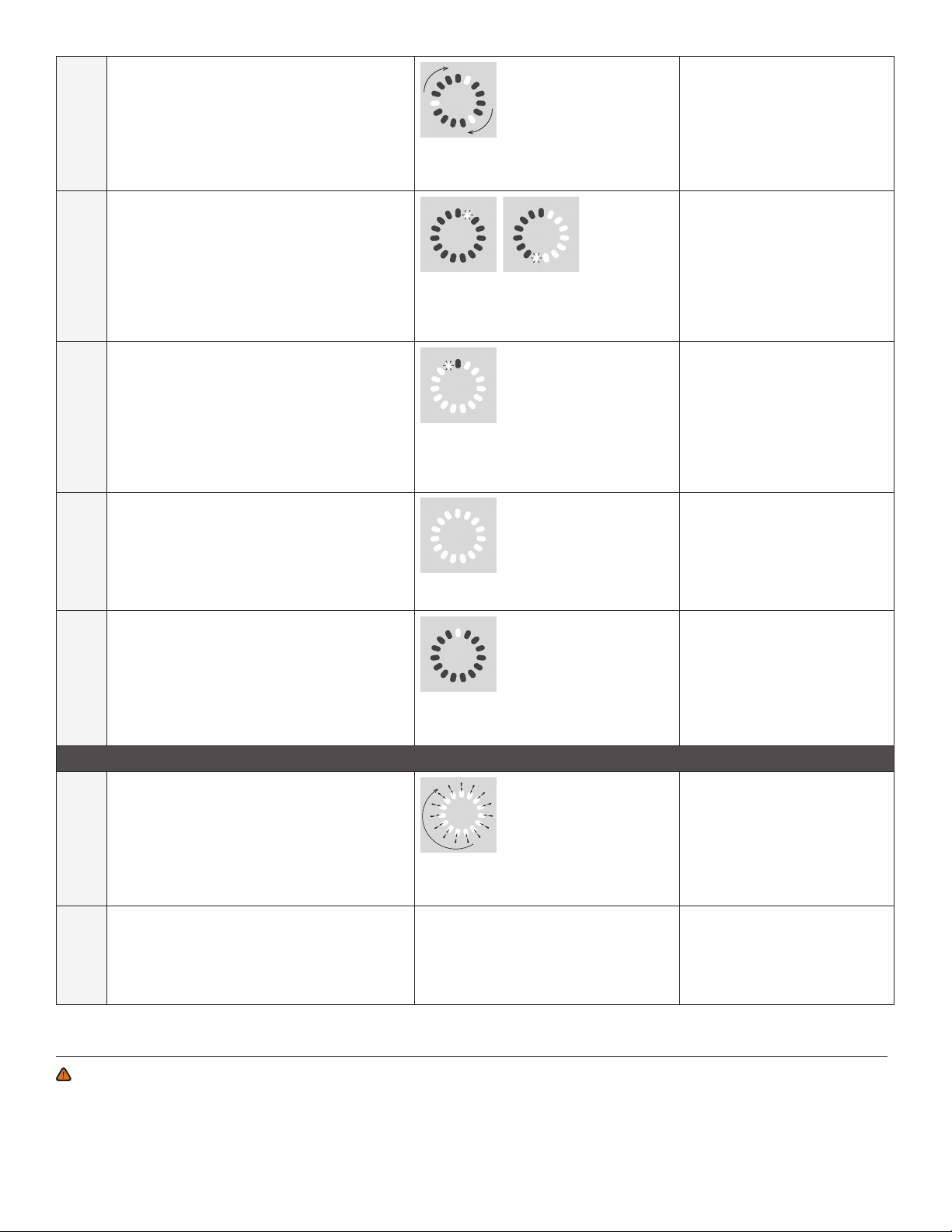

Step Action Light Sequence Sound

3A. Check to ensure that assembled unit is plugged

into an electrical outlet

N/A N/A

3B. Turn on unit using the rocker switch above

the unit’s power source connection port,

ensuring that the side of the switch labeled “I” is

depressed.

Front: Red light ash, then full circle light

chase, one cycle

Two-tone, descending

3C. Allow up to 5 minutes for unit to warm up

Front: Rising symmetric semicircle in red

background

Base: Slow pulsing pattern

N/A

3D. The unit will shift into “ready” state

Front: Top light of light circle will be

illuminated

Base: Not pulsing

Single tone at transition to ready

Note: If unit does not reach a “ready” state within 10 minutes of powering up and the power supply was properly connected to the unit and

plugged into an electrical outlet with a provided cable, please contact BioLife customer service.

4. Operating Instructions

Note: Use of the ThawSTAR®CFT2 Transporter (Item No. AST-602) is recommended to keep samples below -70°C during sample transport

and holding time to ensure sample integrity and provide a standardized starting vial and thaw temperature. Use of a ThawSTAR® Conrmation

Vial, frozen and handled under the same conditions as biospecimens to be thawed, to evaluate and log unit thaw performance at least once

daily before thawing biospecimens, is recommended. Initial time to warm up, thawing time of ThawSTAR Conrmation Vial, vial lot number,

vial expiration date, ambient room temperature, ambient humidity level, unit serial number, evaluation start time and date are data which

could be logged.

Step Action Light Sound

4A. Carefully insert a clean, tightly capped frozen 1.8

- 2.0 mL cryogenic vial (below -70°C) containing

1.0 mL volume into the opening on the top of

the unit and allow vial to drop into place.

Tip: Before freezing, cap cryogenic vial tightly

after lling to avoid leaks and clean exterior

of vial with 70% alcohol wipe or sprayed 70%

alcohol.

Front: Top light of light circle will be

illuminated

Base: Not pulsing

N/A

4B. Push the top of the vial down gently until the unit

emits a deep dual tone. The vial will now remain

in a depressed position.

The unit will begin phase change detection using

STAR™ sensing technology.

Front: Three LED light triangle rotating

clockwise

Base: Pulsing pattern

Two-tone, rising

4C. Beginning of solid to liquid phase change is

detected by unit.

Front: LED circle shows progressive ll-in

sequence clockwise to nish, leading light

always blinking

Base: Pulsing pattern

N/A

4D. Countdown of the last 10 seconds of the thawing

process begins.

Front: Progressive ll-in sequence

continues, leading light continues

blinking

Base: Pulsing pattern

Tone on each one second interval

4E. Upon thaw completion, the vial is raised

approximately 1 cm (0.4 in).

Front: Filled LED circle

Base: Pulsing pattern

Two tone climbing sequence

4F. Remove vial immediately and for a few seconds,

manually agitate the vial gently from side to side

to equilibrate the liquid temperature until no ice

can be seen within the vial. Begin downstream

protocol.

Front: Return to single LED illuminated at

top of the light circle (“ready” state)

Base: Not pulsing

N/A

Post-thaw Alerts

4G. If vial is not removed within 5 seconds of

ejection, unit will signal an alert.

Front: Progressive ll-in sequence

clockwise, one LED per second up to 15

seconds with double ash

Two beeps every half-second for

up to 10 seconds

4H. If vial is not removed within 15 seconds of

ejection, unit will switch into “abandoned vial”

(error code 7) mode.

See Section 5, Trouble Shooting, for “abandoned

vial” (error code 7) recovery.

Front: Display red light and error code 7. Four tone sequence for 5

seconds, then two tone sequence

every 15 seconds for 5 minutes

5. Care and Cleaning

WARNING: Do not attempt to clean internal components. Do not insert any cleaning objects or solution past the green guide chute on

the top opening of the unit. Clean exterior only with a soft, non-abrasive laboratory wipe moistened with 70% alcohol before and after each

use period. Condensation from frozen vials should not present an issue, as it will evaporate during the thawing process or stand-by interval.

6. Troubleshooting

Refer to steps in Section 3 (Instrument Start-up) and Section 4 (Operating Instructions).

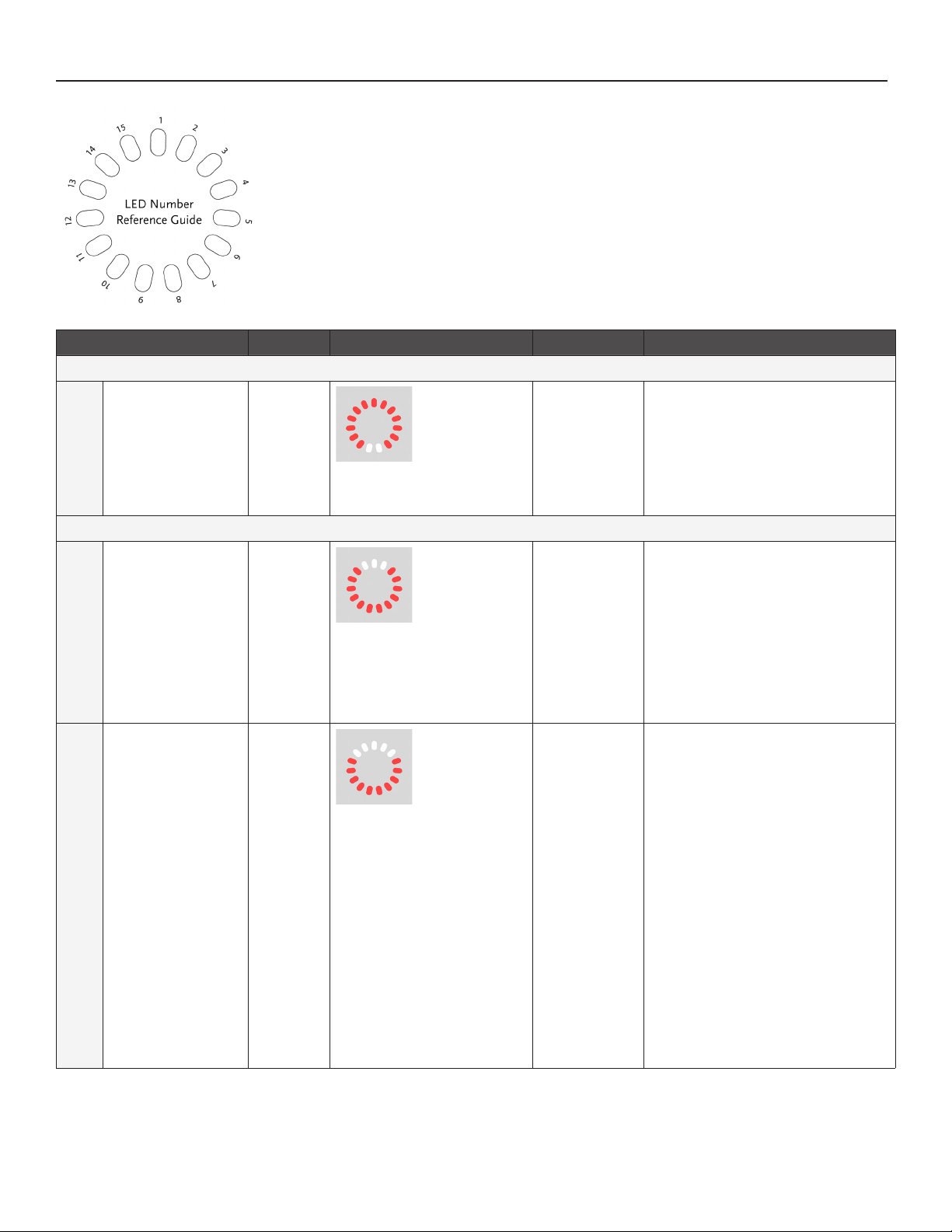

Situation Error Code Light Sound Instruction

Instrument start-up (Refer to Section 3)

6A. Step 3C

Failure to warm up

properly; or other

mechanical fault in

the heating system

Error Code

2

Front: A red light background

with error code 2 (two LEDs at

the bottom of the circle: 8,9)

Single tone

repeated twice

Check power source connection at

back of unit, cable connection to power

adapter and the plug connection to the

electrical outlet. Turn the unit off and

back on. If the unit displays the same

error code 2, contact BioLife customer

service.

Instrument operation (Refer to Section 4)

6B. Step 4A

Vial too warm and/or

already thawed

Error Code

3

Front: Flash full circle with

red light background once

and then display red light

background with error code

3(three LEDs at the top of the

circle: 15,1,2)

Single tone

repeated twice

Gently remove vial that is too warm.

Unit will display a single light at the top,

indicating that the unit is ready for the

next thaw.

6C. Step 4B

Vial cannot be seated

properly (e.g. too

wide, too short, etc.)

Error Code

5

Front: Flash full circle with

red light background once

and then display red light

background with error code

5 (ve LEDs at the top of the

circle: 14,15,1,2,3)

Single tone

repeated twice

Gently remove the vial. Unit will display

a single light at the top, indicating

that the unit is ready for the next

thaw. (1) Look into opening to see if

there is anything lodged in the heater

grasping mechanism. Invert unit to

gently shake out obstructions, if any.

(2) Ensure that the thermal pads lining

the internal heating blocks are intact

and undamaged. Note: If thermal

pads are not intact and/or damaged,

contact BioLife customer service. (3)

Ensure vial is within specications

outlined in section 1.5. (4) Try to thaw

frozen ThawSTAR® Conrmation Vial. If

situation repeats itself with same error

code 5, hardware issue (latching fault)

may be the root cause; contact BioLife

customer service.

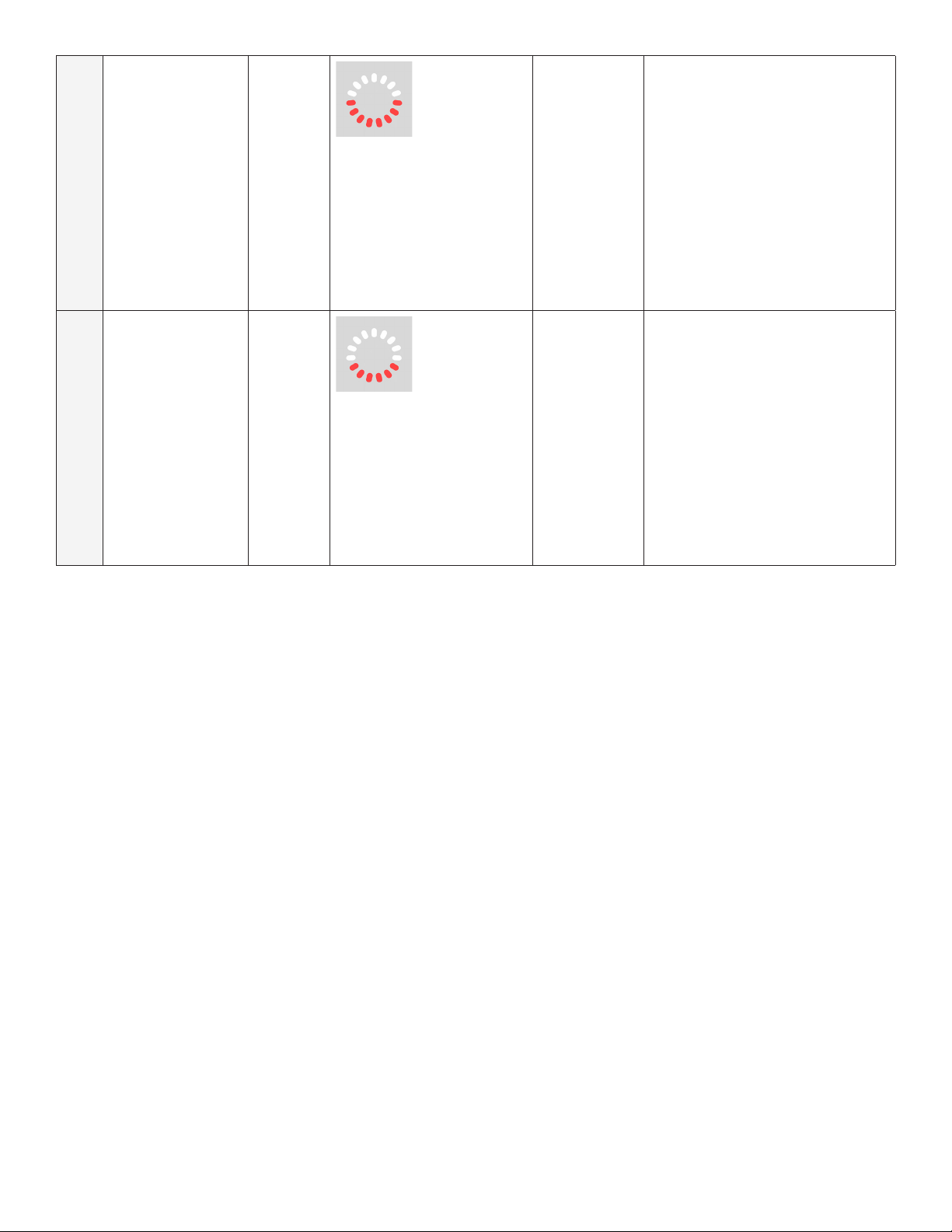

6D. Step 4H

“Abandoned” vial left

in unit more than 15

seconds after thawing

process is completed

Error Code

7

Front: Flash full circle with

red light background once

and then display red light

background with error code 7

(seven LEDs at the top of the

circle: 13,14,15,1,2,3,4)

Four tone

sequence for

5 seconds,

then two tone

sequence every

15 seconds until

vial is removed.

Gently remove vial. Unit will emit a

single tone. Unit will display a single

light at the top, indicating that the unit

is ready for the next thaw.

6E. Step 4E-H

Vial fails to rise after

thaw process is

nished

Error Code

9

Front: Flash full circle with

red light background once

and then display red light

background with error code

9 (nine LEDs at the top of the

circle: 12,13,14,15,1,2,3,4,5)

(If in step 8, error code 7

displayed after 15 seconds)

Four tone

sequence for

5 seconds,

then two tone

sequence every

15 seconds until

vial is removed.

Grasp the vial cap only with ngers or

forceps and rock vial gently to dislodge

and remove from opening, taking care

not to open the cap. Unit will display

a single light at the top, indicating

that the unit is ready for the next thaw.

Ensure that the thermal pads lining the

internal heating blocks are intact and

undamaged. Note: If thermal pads are

not intact and/or damaged, contact

BioLife customer service. Avoid sticking

forceps or other foreign objects into the

opening.

7. Registration

To register please email [email protected] and include your product serial number and contact information. In addition to

documenting your purchase date and other information related to the Limited Product Warranty, you will have the opportunity to be notied

of any other product updates.

8. Customer Service Information

8.1 Technical Service and Repair

CAUTION: If it is necessary to return your ThawSTAR®Automated Cell Thawing System for any reason, it is required that you

decontaminate the unit prior to sending. Contact BioLife technical support or a BioLife authorized representative for decontamination

instructions and a Return Material Authorization (RMA) Number.

8.2 Ordering Information

Item No. Description

AST-600 ThawSTAR®Transport and Automated Cell Thawing System, complete with ThawSTAR®Automated Cell Thawing Instrument

(AST-601) and ThawSTAR CFT2 Transporter (AST-602)

AST-601 ThawSTAR®Automated Cell Thawing Instrument

AST-602 ThawSTAR®CFT2 Transporter

AST-603 ThawSTAR® Conrmation Vials, pack of 20 vials

AST-606 AC Power Adaptor and Cables for US, UK, EU

AST-614 IOP Qualication Packet for ThawSTAR®Automated Cell Thawing System Model CFT2

The ThawSTAR®System is for research or further manufacturing use.

©2019. BioLife Solutions, Inc. All rights reserved. Patents pending.

BioLife, ThawSTAR, STAR designations are trademarks owned by BioLife Solutions, Inc.

IG-AST-19052R01

Table of contents

Other BioLife Freezer manuals