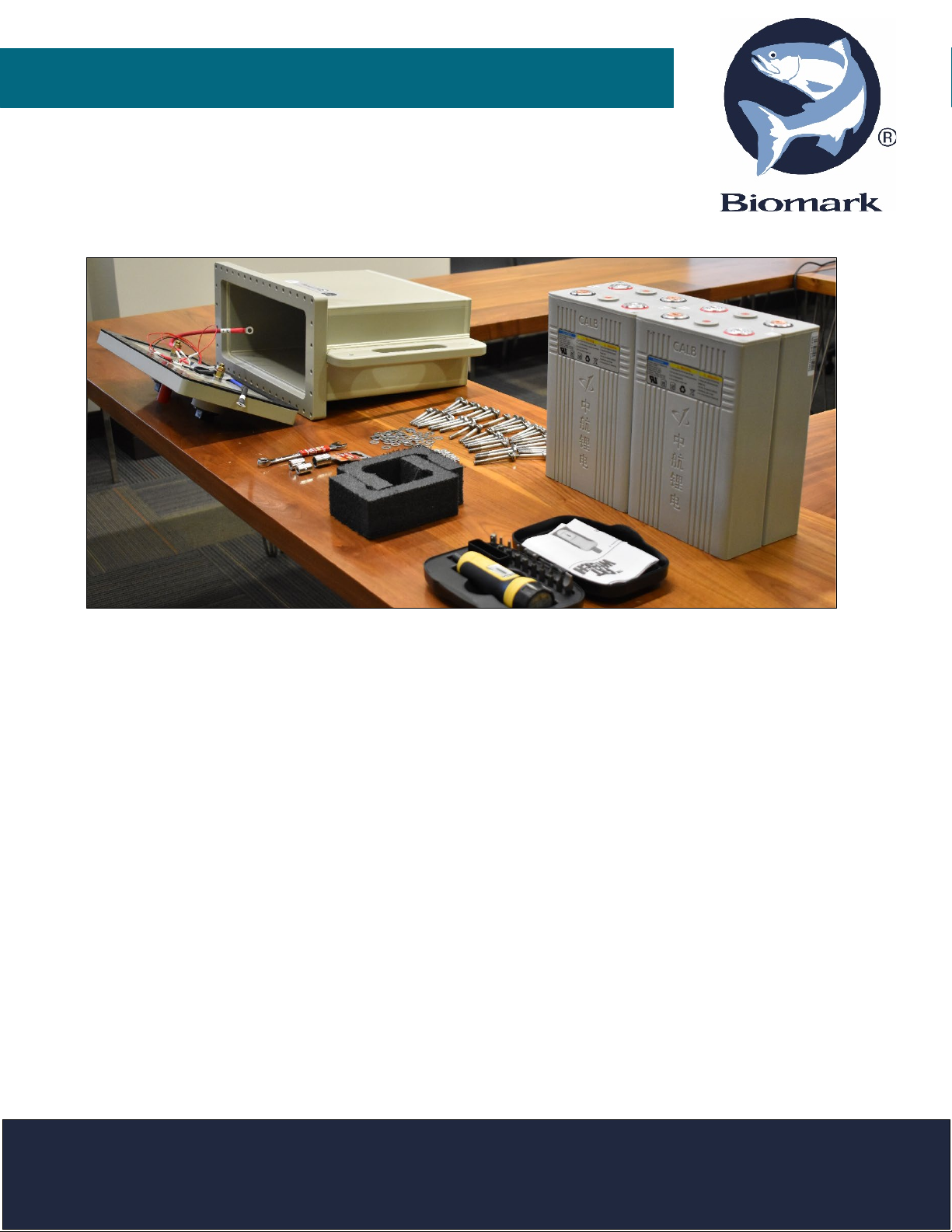

SUBMERSIBLE BATTERY INSTALLATION

QUICK START GUIDE 2

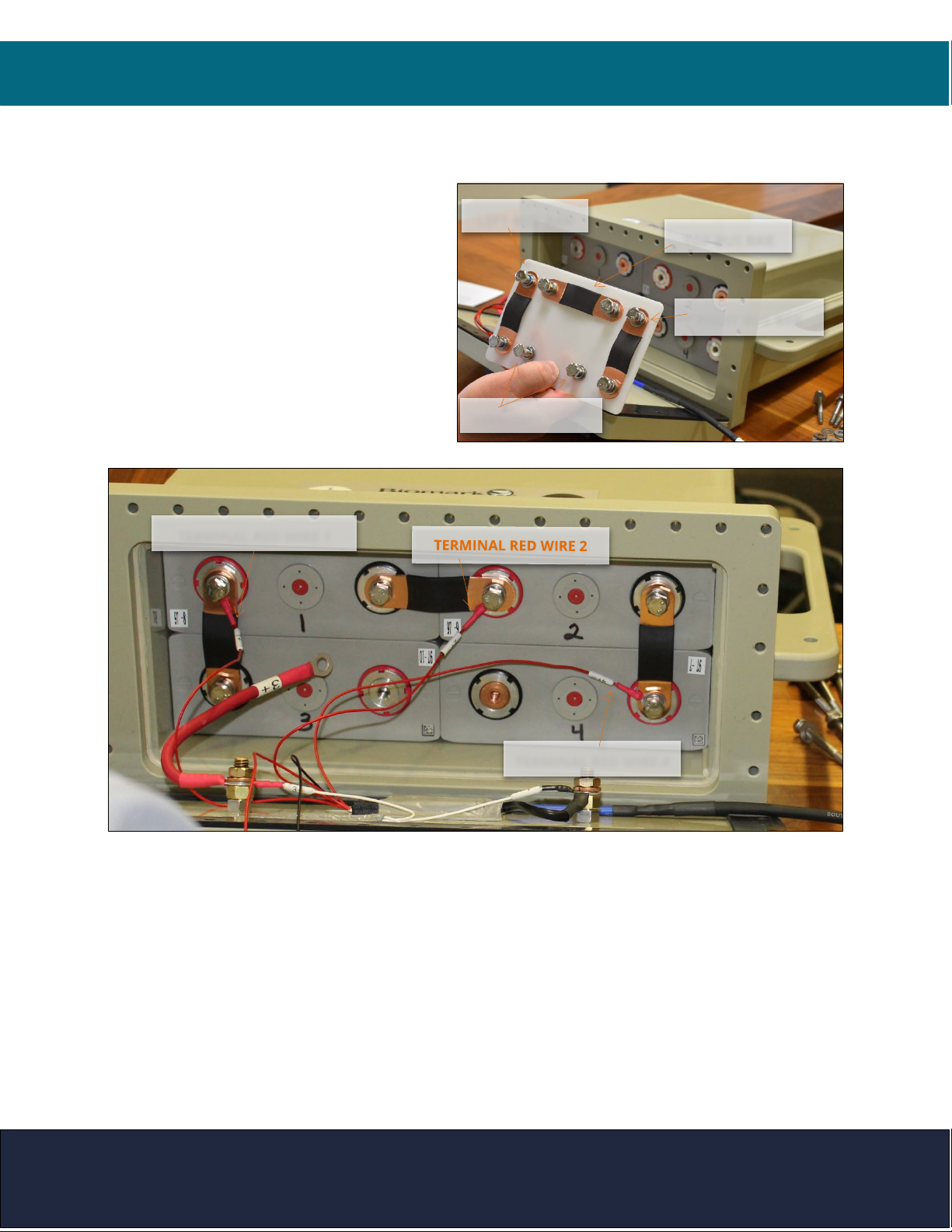

(8) M6 6.4mm ID 11.4mm OD flat washer

(8) M6 6.5mm ID 11.8mm OD split lock washer

o180ah Battery Terminal Hardware

(8) M8 – 1.25 x 15mm full thread hex head screw – 13mm hex size

(8) M8 8.4mm ID 16mm OD flat washer

(8) M8 8.5mm ID 14.8mm OD split lock washer

•Tool Kit:

o(1) Fat Wrench Wheeler Torque Screwdriver Kit – ¼” drive

o(1) 7/16” combination wrench

o(1) 7/16” ¼” drive socket

o(1) 13mm socket (1/4” drive) (180 Ah Battery Cell)

o(1) 10mm socket (1/4” drive) (72 Ah Battery Cell)

Torque Specifications

Battery Terminal Hardware (72 Ah Pack)

30-inch pounds (in/lbs.)*

Battery Terminal Hardware (180 Ah Pack)

Entry Plate Hardware (40-sealing bolts)

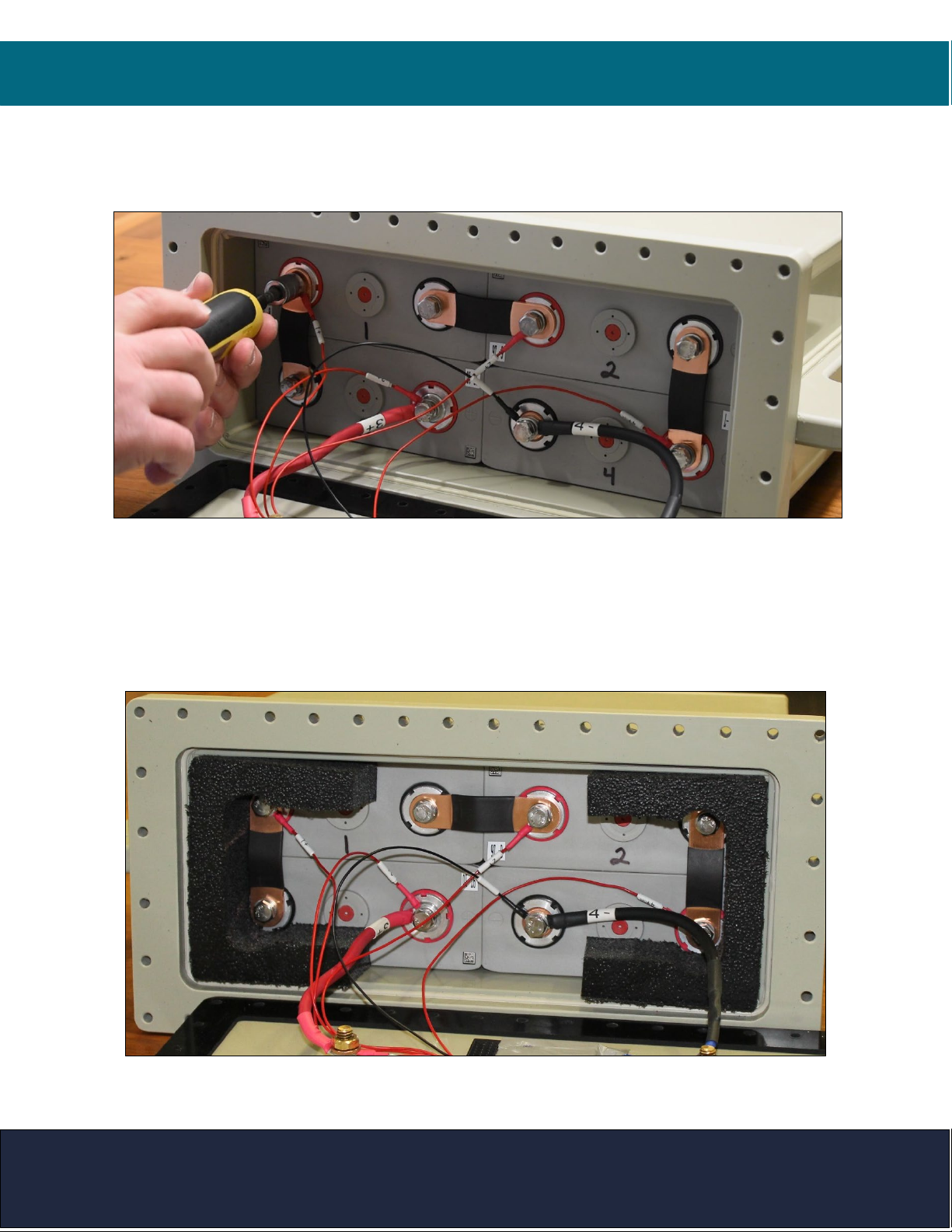

*Use a minimum of 30-inch pounds of torque until you hear an audible click, or until the split

washer is fully compressed and the bolt is firmly secure.

Assembly & Installation Instructions

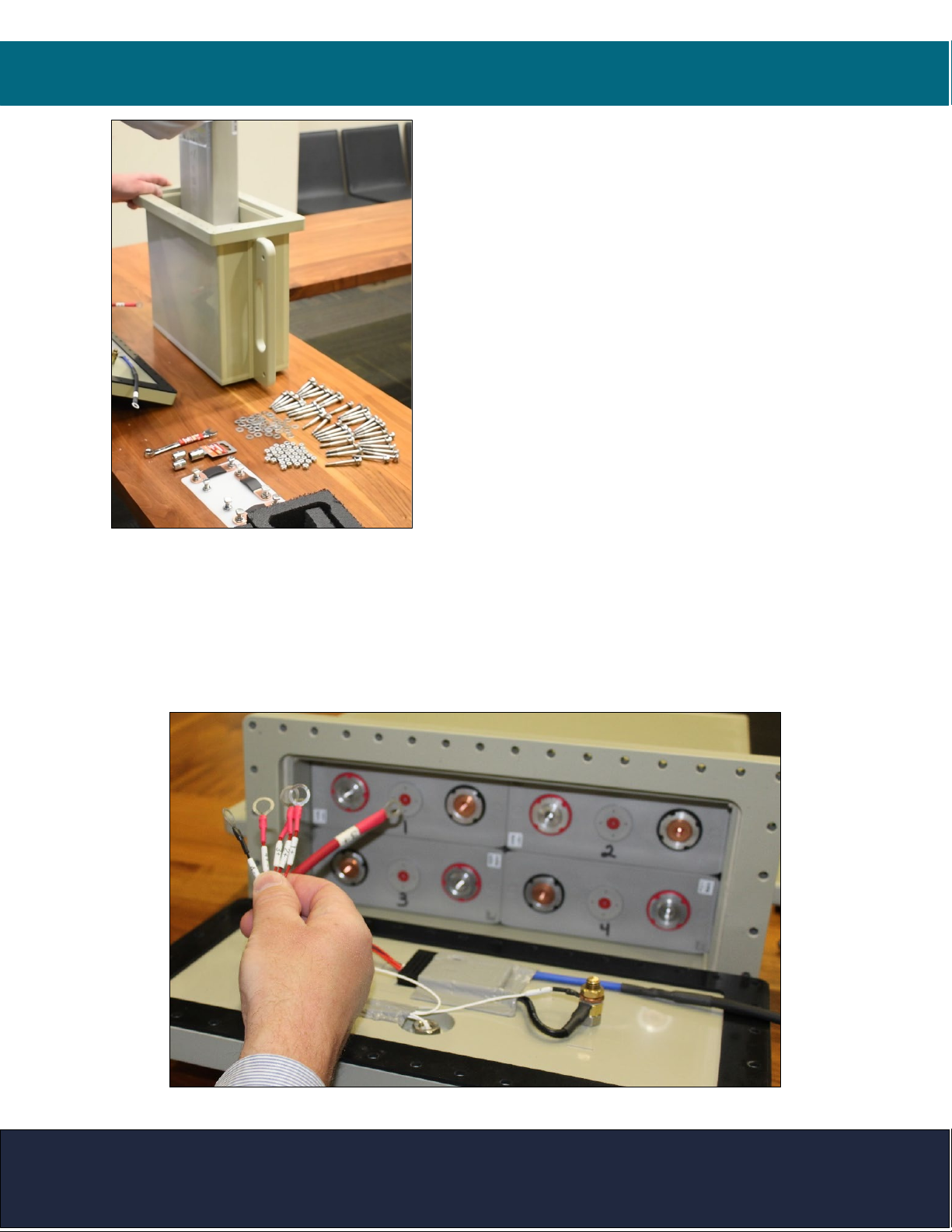

Assembly and installation of the submersible battery pack must be performed in a clean

environment to ensure proper seal of waterproof enclosure, and on a large flat surface, free of

contaminants or obstructions.

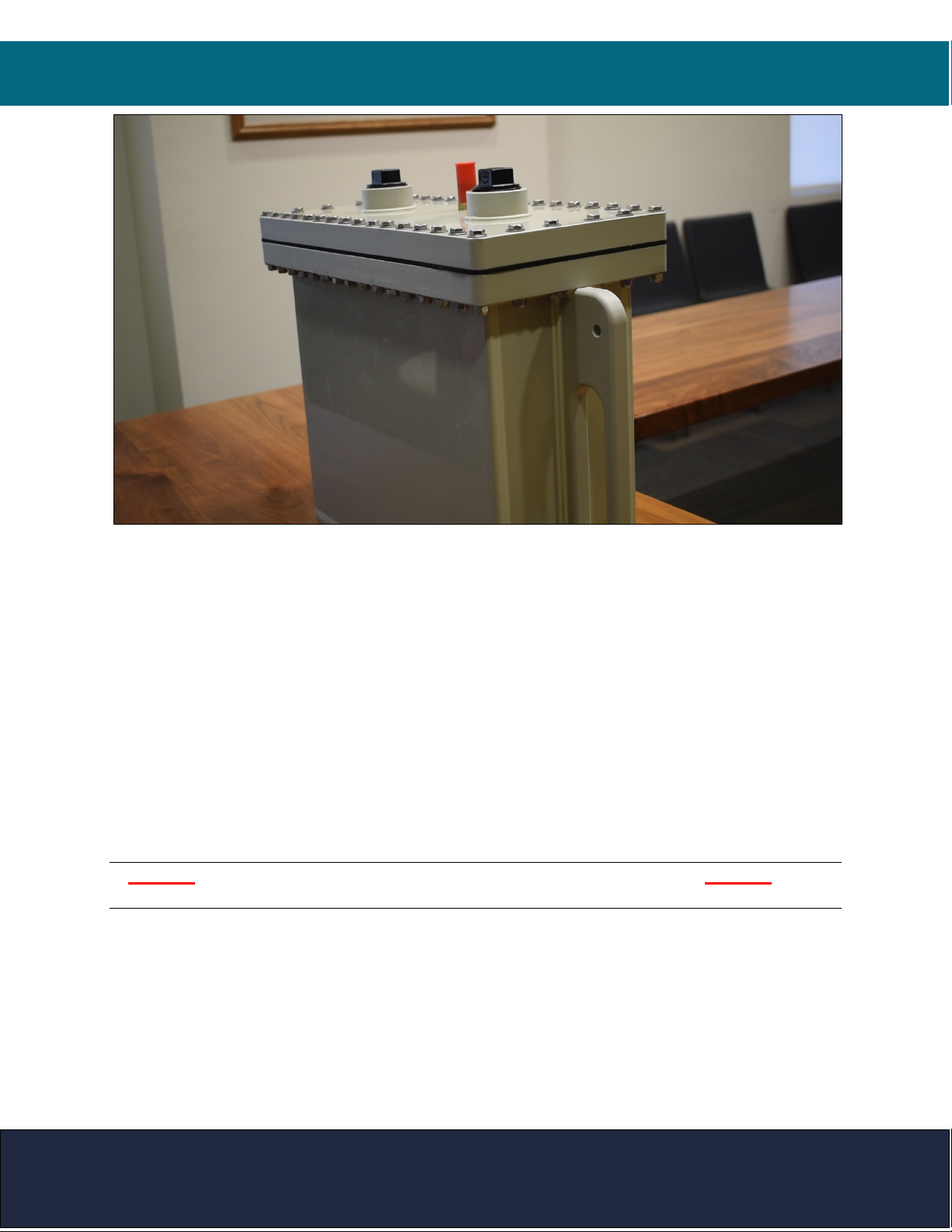

Step 1:Label Batteries

Label the batteries from 1-4 with a permanent marker to ensure proper installation of each

independent cell within the enclosure. Place the four battery pack cells in a 2 by 2

configuration, with cell 1 and 2 on top (orientated from left to right; positive (red) -negative

(black) and positive (red) - negative (black)) and 3 and 4 on the bottom (orientated from left to

right; negative (black) - positive (red), and negative (black) -positive (red)). Obtain proper

battery sequence prior to moving to step 2.