Bioprom AIR PELLET 60 kW User manual

AIR PELLET 60 kW

FLARE PELLET BURNER

Operation Manual

СВ.060.00.00СК

2

Contents

1.

BURNER DESCRIPTION AND OPERATION ................................................................................. 4

1.1.

Purpose ................................................................................................................................... 4

1.2.

Performance Data .................................................................................................................... 5

1.3.

Delivery Set.............................................................................................................................. 6

1.3.1.

Screw Feeder................................................................................................................. 6

1.4.

Operation Concept and Configuration ...................................................................................... 7

1.4.1.

Burner Components ....................................................................................................... 7

1.4.2.

Operation Concept ......................................................................................................... 9

1.4.3.

Marking and Sealing....................................................................................................... 9

1.4.4.

Packaging ...................................................................................................................... 9

2.

INSTALLATION ............................................................................................................................ 10

3.

BURNER OPERATION................................................................................................................. 10

3.1.

Operating Restrictions............................................................................................................ 10

3.2.

Preparation of the Unit for Putting into Operation ................................................................... 11

3.3.

Startup of the Boiler with the Burner....................................................................................... 11

3.4.

Burner Stop............................................................................................................................ 11

3.5.

Actions in Emergency Situations ............................................................................................ 11

4.

TECHNICAL MAINTENANCE....................................................................................................... 12

4.1.

General Instructions ............................................................................................................... 12

4.2.

Safety Measures .................................................................................................................... 12

4.3.

Burner Maintenance Procedure.............................................................................................. 13

4.4.

Current Maintenance.............................................................................................................. 13

4.3.1.

Periodic Technical Maintenance................................................................................... 14

4.5.

Functionality Test................................................................................................................... 15

4.6.

Engineering Certification ........................................................................................................ 15

4.7.

Storage Instructions ............................................................................................................... 15

5.

CURRENT REPAIR ...................................................................................................................... 15

5.1.

General Instructions ............................................................................................................... 15

5.2.

Safety Measures .................................................................................................................... 16

5.3.

Potential Failures and Troubleshooting Practice .................................................................... 16

6.

TRANSPORTATION AND STORAGE .......................................................................................... 17

7.

DISPOSAL.................................................................................................................................... 17

8.

WARRANTY .................................................................................................................................18

Warranty Ticket .................................................................................................................................19

TICKET OF PUTTING INTO OPERATION........................................................................................ 21

3

This Operation Manual contains general information about the technical characteristics, the

unit, the rules for transportation, storage, installation, safe operation, technical maintenance,

current repair and disposal of the pellet burner of «AIR PELLET 60 KW» type (hereinafter

referred to as “the Burner”).

In addition to the present Operation Manual, it is required to follow operating

procedures of plants-manufacturers of the supplied equipment.

Works on the pellet burner installation and putting into operation shall be carried out by

the qualified specialist in strict compliance with the burner passport, installation instructions,

and the Operation Manual.

Individuals authorized to operate and take care of "AIR PELLET 60 kW" burner shall

follow this Operation Manual.

Due to continuous enhancement of the structure (construction) of Air Pellet flare

pellet burners as well as their manufacturing technology, this Operation Manual might

contain some discrepancies in terms of description of the product (unit) and the unit itself,

and such discrepancies do not impact on the unit efficiency, performance data, and

mounting dimensions.

"AIR PELLET 60 kW" pellet burner is manufactured in accordance with Technical

Specifications ТУ У28.2-3026423276-003:2015 and has been certified according to

UkrSEPRO certification system for compliance with requirements of GOST 10617-83, DSTU

7237:2011, GOST 12.1.004-91, GOST 12.2.003-91, DSTU 3075-95(GOST 9817-95), DSTU

CISPR 14-1:2004, DSTU CISPR 14-2:2007.

4

1.

BURNER DESCRIPTION AND OPERATION

1.1.

Purpose

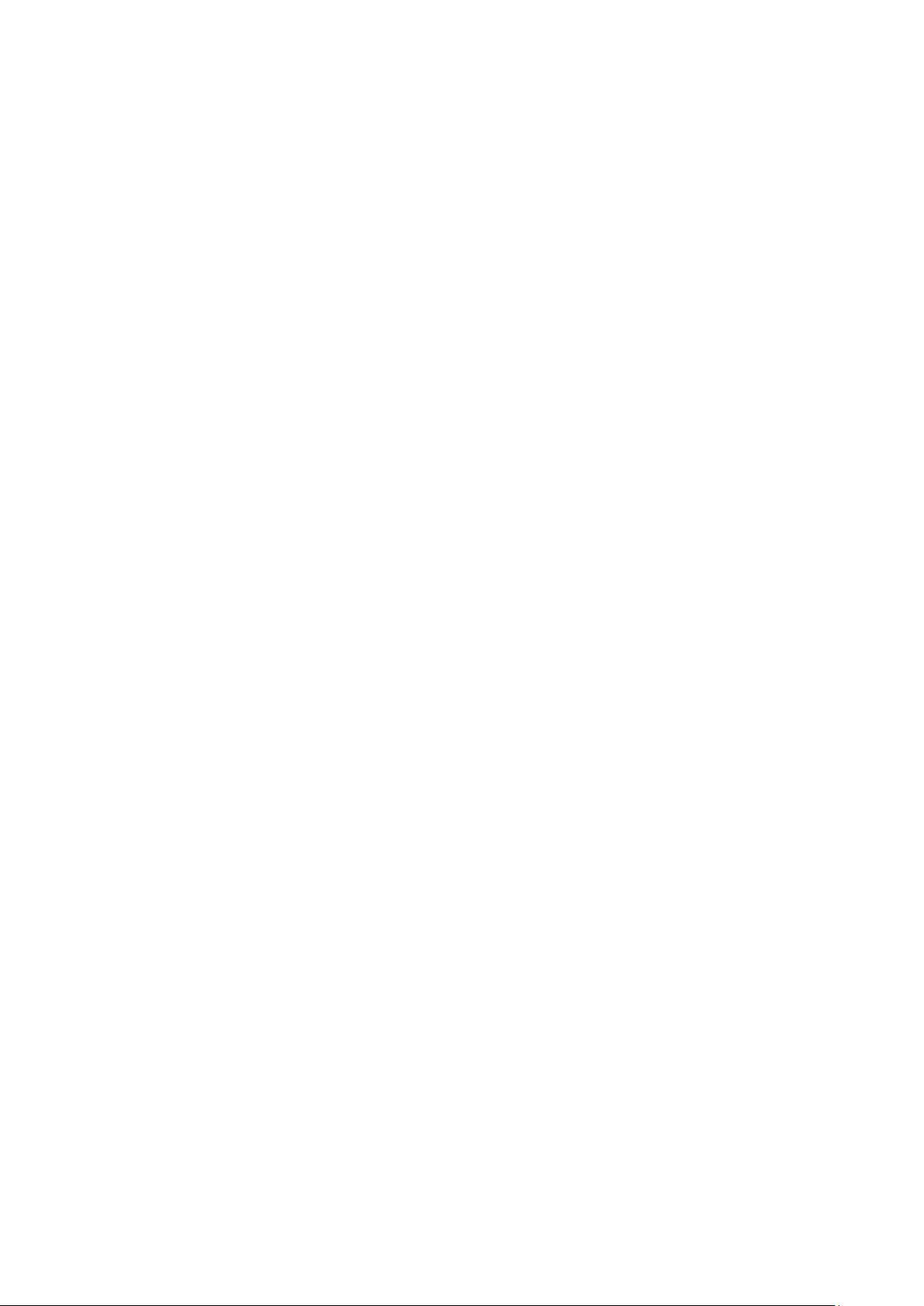

Burners of «AIR PELLET 60 KW» type (Picture 1) are intended for burning wood fuel

pellets in water-heating boilers with a nominal heat output of up to 60 kW.

Picture 1. Overall and mounting dimensions of the burner

5

The design of the boiler on which the burner is installed shall meet the following

requirements:

– the boiler shall be adapted for burning biomass, and its internal flow channels

shall have full capability to exchange heat and exhaust emissions;

– the combustion chamber shall have dimensions allowing to install and remove the

burner;

– the boiler’s door shall have a hole with a size of 260х240 mm, the thickness of

the boiler’s door shall be not more than 100 mm; get a hold of the manufacturing plant for

the boiler and obtain the advice, if required;

– the design of the boiler shall ensure the opening of the boiler’s door with a burner

for ash removal and cleaning. If the boiler’s door is too narrow for opening along with the

burner, the additional hinge straps shall be installed;

– if there is insufficient vacuum in the boiler (less than 5 Pa), it is required to install

the fan exhauster to remove burnt gases;

– the boiler-house where the burner is installed shall correspond with all the acting

local norms and rules;

– the boiler shall be located in such a way to ensure enough room for cleaning the

burner and removing ash from the boiler and the chimney. If the flue gas temperature at the

boiler outlet is less than 120 ° C, there is a risk of condensation of water vapor in the

chimney.

CAUTION! It is prohibited to use the burners for other than the purpose

specified as well as make any design changes of the burner without consent of the

manufacturer.

1.2.

Performance Data

The basic performance data of the burner is described in Table 1

Table 1.

Parameter

Value

Heat power (adjustable), KW

40…60

Fuel Characteristics:

diameter, mm

length

calorific value, KW•h/t

poured density, kg/m3

water content,%

ash content,%

6…8

3…5 of diameter

4700…5100

СА 650…670

kg/m3

8…10

Са 0,5

Power voltage, V

220

Power consumption, KW:

Firing mode

Working mode

not more 2,5

not more 1,5

Burner size LхWхH, m

0,86х0,42х0,34

Burner weight, kg

70

6

1.3.

Delivery Set

The standard delivery set for the burner is described in Table 2

Table 2.

Burner as an assembly

1 ea.

Burner control unit with sensor set and connecting wires

1 set

Flexible heatproof tube for connecting feeder to the burner

2 ea.

Burner case

1 ea.

Operation Manual

1 ea.

1.3.1.

Screw Feeder

The screw feeder is intended for supplying pellets from the bunker to the burner. It

consists of the following elements:

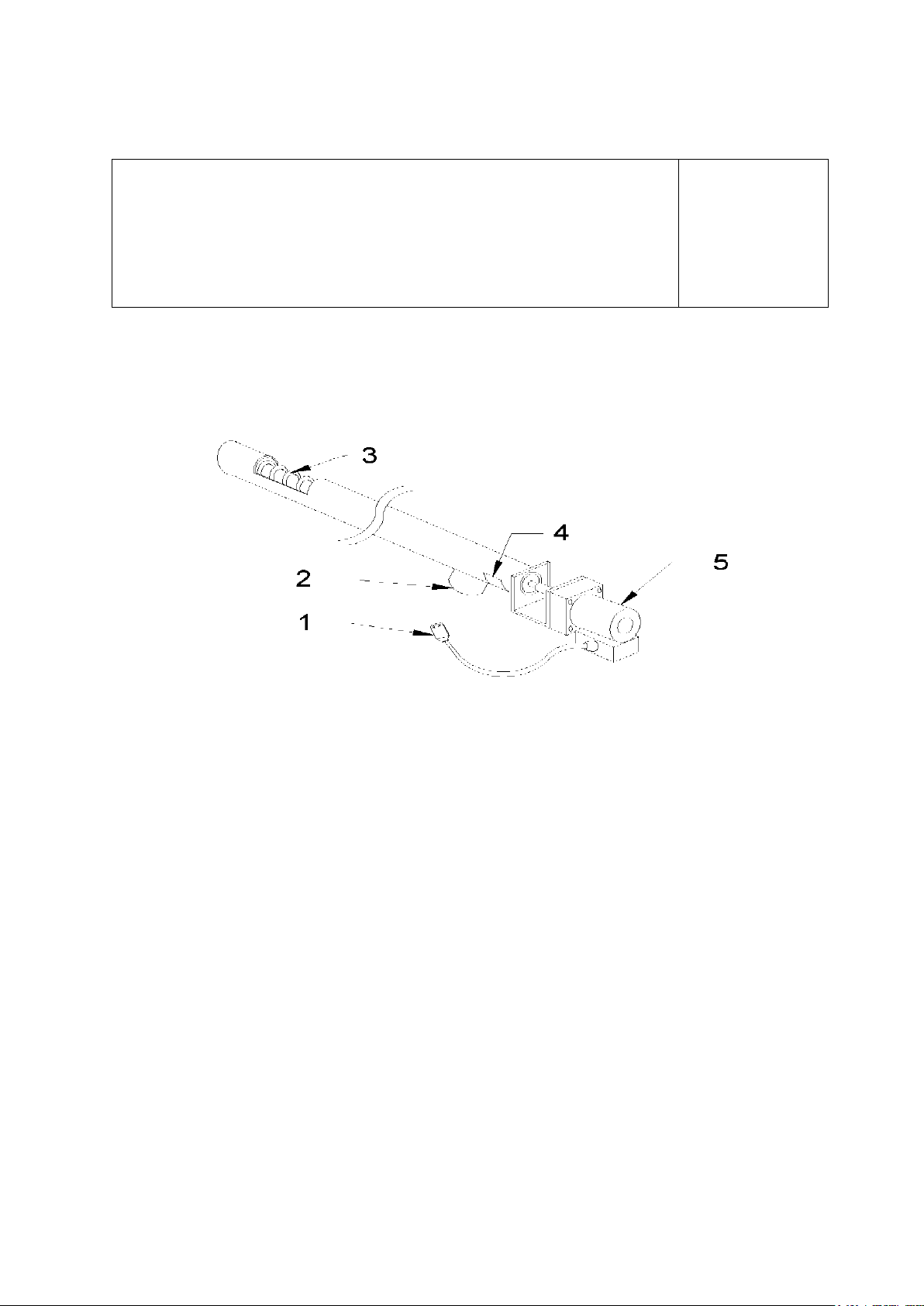

Picture 2. Screw Feeder

1 – power cord; 2 – pellet outflow tube; 3 – pellet intake holes; 4 – safety cutoff; 5 – engine.

The screw feeder is connected to the burner with using a special hose made of

fusable material what ensures safety factor and prevents from inverted flame. With the help

of the mounting kit the screw feeder is fastened to the wall, bunker or ceiling depending on

installation area conditions. Picture 3shows correct location of the screw feeder towards the

horizon and the burner. It is necessary to meet the following recommendations during

installation and operation process:

– pellet intake hole shall be located upward vertically, and nothing should cover

(overlap) it;

– pellet outflow tube shall be located downward vertically;

– screw feeder shall be located towards horizon at an angle of 30-45°;

– horizontal distance between the pellet outflow tube of the screw feeder and the

burner pellet receiver tube shall be not less than 200 mm, at the same time, the hose for

hooking up the screw feeder and the burner shall not be slacking or having curves of more

than 30°, this will ensure unobstructed supply of pellets.

7

Picture 3 – Screw feeder installation example

CAUTION! Hose for hooking up the screw feeder and the burner shall

correspond with UL 94-HB fire-resistance.

1.4.

Operation Concept and Configuration

1.4.1.

Burner Components

The burner includes the following components:

– burner housing;

– trailing furnace grates;

– fuel firing system;

– burner with ceramic ejector nozzle;

– pellet supply system with driving gear;

– driving gear for furnace grates;

– pressurized air fan;

– electric system.

The burner housing is the basic unit, also serving as the base for the equipment

installed inside, including the trailing furnace grates and the ignition system.

The combustion chamber has the air injection holes inside.Their diameter is selected

in such a way to ensure the open air flow makes possible the optimal air dosing in the volume

required for the optimal burning of pellets.Primary air enters through the pumping holes

located in the trailing elements of the grate.

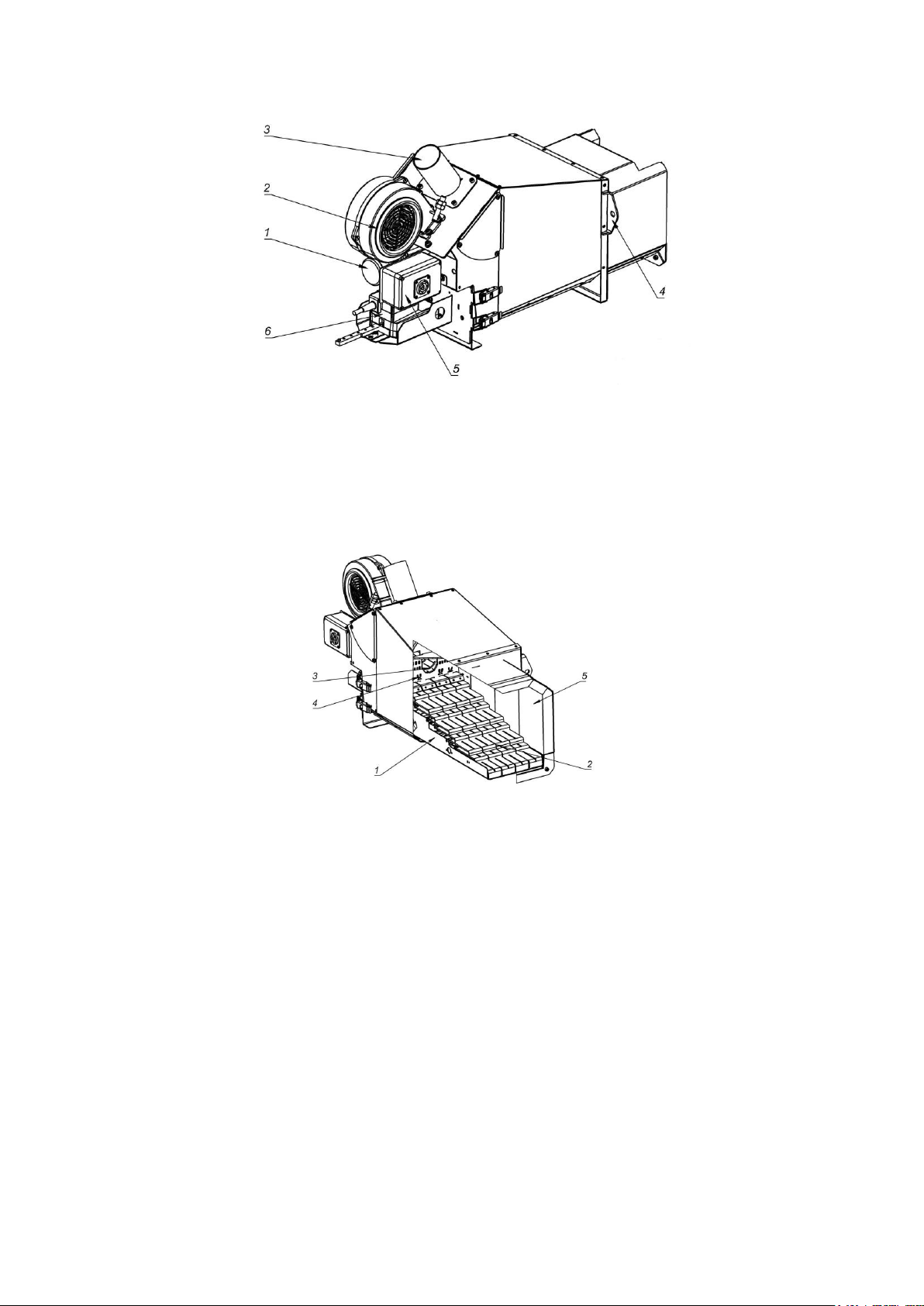

The design of the burner and its basic elements are shown on Pic. 4-5.

8

Picture 4 – Burner Design

1 – screw feeder driving gears; 2 – air supply fan; 3– hole for pellets supply from the bunker;

4 – flange for attaching the burner; 5 – housing for mounting electrical part; 6 – driving gear system of

movable grate bars;

Picture 5 – Burner combustion chamber design

1 – removable grate module, 2 – movable grate bars,3 – screw feeder of pellet supply, 4 –

heating elements of the ignition system, 5 – refractory lining.

CAUTION! The manufacturer reserves the right to incorporate changes into the

design, configuration, and software of the burner. Due to frequent upgrade of the

product some of presented below examples may insignificantly vary from the reality,

and this fact, however, does not impact on safety factor as well as proper operation

of the boiler and the burner.

9

1.4.2.

Operation Concept

The fuel located in the bunker is supplied by screw feeders to the burner and further to

the grate system, where it ignites as a result of contact with the elements of the ignition

system.

The air pumped by the fans goes further through the ejector openings of the grate

directly to the supplied fuel, as a result of which a flame rises and is directed horizontally to

the combustion chamber of the boiler.

The fuel remnants burn out in the ceramic pipe in the burner outlet tube. Hot air from

the burner goes further through channels of the boiler’s heat exchanger heating the water

that is the main heat carrier. Air is supplied exclusively in a volume required for clean

combustion, and its flow is monitored by the controller.

The electronic controller is monitoring the proper progress of the fuel supply and

combustion process. It controls the working cycle of the boiler: regulates supply of air to the

burner; regulates speed of fuel supply by screw feeders; controls water temperature and

exhaust emissions to the chimney; controls pumps operation and maintains the temperature

preset on the boiler. The burner is operating based on measurements coming from sensors:

gas temperature in the chimney, as well as water temperature in the boiler. Once the boiler

reaches the preset temperature the controller will automatically switch off the burner. In

addition, the controller plays a very important informational role displaying boiler operation

parameters as well as some emergency situations. Servicing of the boiler and the burner is

quite power-operated, but, however, it does not mean that the user is free from monitoring

the instructions and directions displayed on the controller.

CAUTION! The burner is able to work only with software of ТМ AIR automatic

equipment. Replacement of the controller with another one might result in failure of

the boiler and the burner as well as will result in loss of warranty. The way of

servicing the controller, its installation and hookup is described in detail in the

operation manual for ТМ AIR automatic equipment.

1.4.3.

Marking and Sealing

Each burner is accompanied with a manufacturer’s plate that contains the following

minimum information:

– full name and location of the manufacturer, and, if required, his authorized

representative;

– the unit’s purpose;

– marking with the national mark of conformity in accordance with Item 24 of the

Technical Regulations for the Safety of Machinery and Equipment;

– designation of the series or type;

– serial number (if available);

– year of manufacture (the year when the manufacturing process was completed).

1.4.4.

Packaging

Products are shipped in closed packaging, and the elements themselves are protected

with air-bubble film.

10

The technical documentation of the burner is always inside the box, and a bill of

lading is on the outer side. Products should be transported only in the original packaging,

thus eliminating the possibility to damage the units.

2.

INSTALLATION

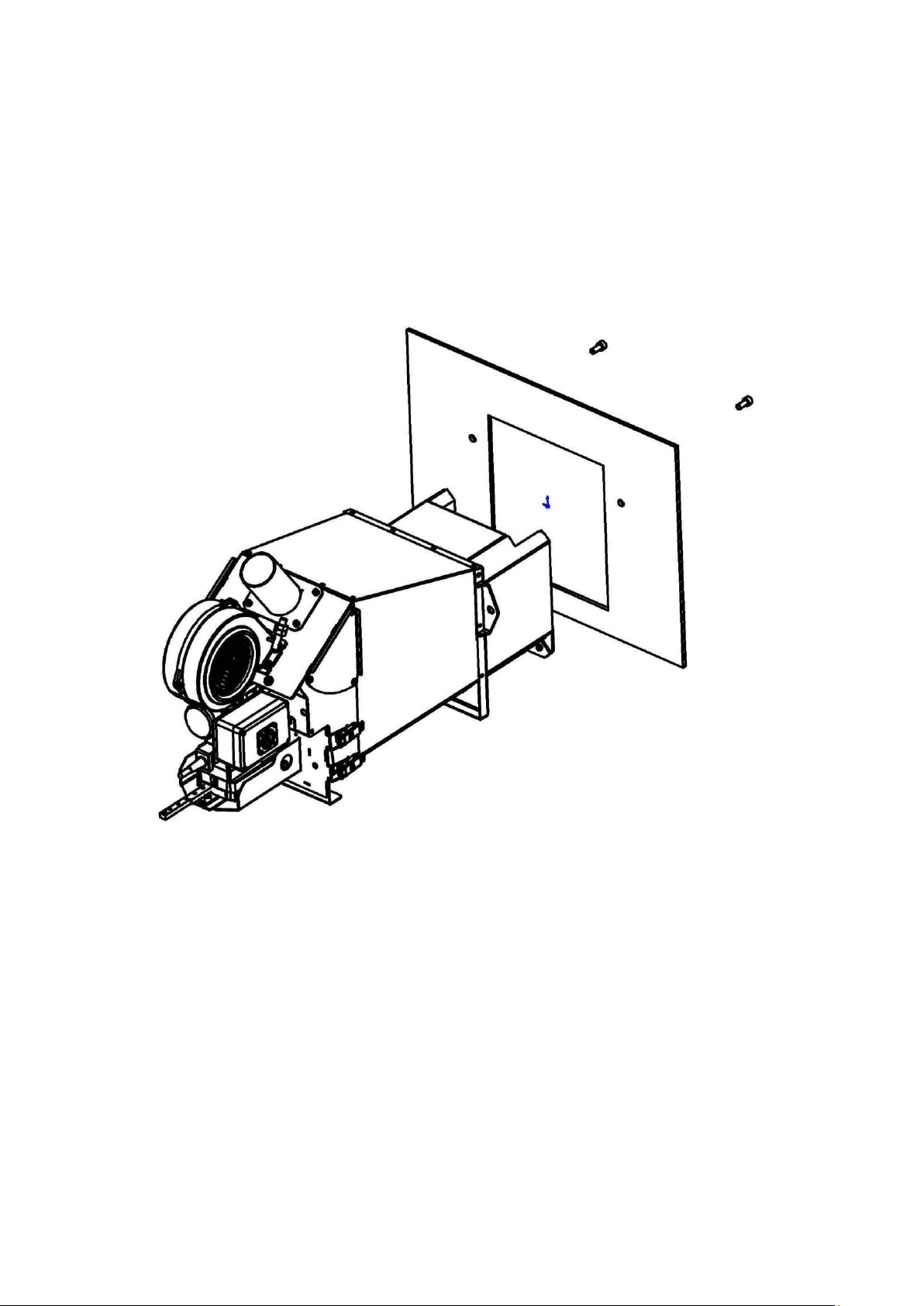

The burner is mounted in such a way to have the furnace in the combustion chamber

and the burner is fastened with bolts using mounting holes located on the burner (Picture

6). If required, installation can be carried out using adapter flange as well as with use of

noncombustible, sealant material.

Picture 6 – Burner Installation

CAUTION! If there is a mounting seat stipulated by the manufacturing plant,

then the burner is installed on it in accordance with the documents delivered along

with equipment.

3.

BURNER OPERATION

3.1.

Operating Restrictions

The boiler room in which the burner is installed shall be equipped with exhaust

ventilation ensuring air flow at least 5 volumes of air in the boiler room for one hour.

11

3.2.

Preparation of the Unit for Putting into Operation

Prior to the first commissioning of the burner it is required to:

– verify proper installation and fastening of: the boiler, fuel tank, screw feeder and the

burner;

– check measuring devices for accurate installation;

– connect all electric cables and sensors to the controller, and connect the controller

to the in-house electrical network;

– check “idle” operation of all functions of the controller and the equipment installed;

– fill the bunker with pellets;

– check operation of the screw feeder.

3.3.

Startup of the Boiler with the Burner

The first commissioning of the boiler with the installed burner is always done by the

technician in the presence of a user. User’s presence is necessary to get familiar with

proper and safe service of the boiler as well as for correct setting up the corresponding

operation parameters on the boiler.

In order to start the boiler along with the burner it is required to take the following

steps:

– put all valves installed on the equipment in working position;

– set the required temperature on valves and radiator thermostats;

– close all boiler’s doors and covers of fuel tanks;

– switch on power supply for the burner and the controller;

– the further sequence of startup operation depends on the control system modification

and is described in detail in the Instruction for the control system.

CAUTION! The method of programming the controller and its service is

described in the Instruction for the control system.

If there is a necessity to change parameters set up on the controller it is required to

follow the procedure described in the Instruction for the control system.

3.4.

Burner Stop

The sequence of the burner stop depends on the control system modification and is

described in detail in the Instruction for the control system. It is not recommended to switch

off the power supply of the controller.

3.5.

Actions in Emergency Situations

In case of a burner failure it is required to take the following steps:

– switch off the power supply of all boiler units;

– turn off the power to the controller on the burner;

– disconnect the flexible pipe connecting the burner with the screw feeder (if required);

– unscrew the bolts fastening the burner with the boiler, move the burner away and

clean the boiler inside off the operational contamination;

12

– mark the boiler with the plate "FAULTY – DO NOT SWITCH ON";

– report to the management of the enterprise about the failure;

– ascertain the reason of the failure;

– if it is the simple failure, it can be eliminated on your own using technical services or

technical department of the enterprise. This Operation Manual includes the list of such

failures.

CAUTION! Intervention in such systems as: electrical, electronic and

mechanical is unallowable.

– If it is the serious breakdown, contact an authorized service center or use the

damage claim and contact the burner manufacturer.

4.

TECHNICAL MAINTENANCE

4.1.

General Instructions

Throughout the entire lifecycle of the boiler and the burner the user shall perform

routine cleaning as well as periodic inspections, and preservation of all units. They also

include periodic annual checks of chimneys.

4.2.

Safety Measures

Basic principles and recommendations to follow while operating the boiler with the

burner «AIR PELLET 60 KW»:

– Individuals who got familiar with the Operation Manuals for the boiler, the burner,

and the controller as well as with all possible threats can be allowed to operate this system.

CAUTION! Requirements as to hookup and operation of the boiler are

described in the technical documentation.

– It is prohibited to use the burner with a faulty seal of the mounting plate. In case of

smelling carbon monoxide from the outside of the boiler it is required to immediately turn off

the burner and restore the tightness of the seal.

– If it is necessary to carry out work inside the boiler, always turn off the burner and

wait for about 20 minutes to ventilate and cool off the combustion chamber.

– While performing a control (visual) test of the burner operation that might require

even a brief inspection of the combustion chamber, when opening the door one shall always

stand on the side of the door so as not to get a burn of the face and body with hot air. Do not

open the furnace doors with the burner installed!

– Do not touch the burner during its operation. Touching hot elements of the burner

with bare hands might result in the burn!

– When cleaning, always use protective gloves. Caution! To perform this work one

should not use the tools that could damage the equipment installed in the ejector tube of the

burner (grates, ignition system, etc.).

CAUTION! During the boiler and the burner operation, it is strictly forbidden to

drop hands into the elements of the screw feeder and the bunker with the fuel. This

might result in severe damage to the hands.

– Do not touch electrical wires or live electrical equipment. In case of such necessity,

it is always required to switch off the power supply to the whole system (boiler-burner-screw

13

feeder).

– The electrical system of the whole complex of the boiler with the screw feeder and

the burner shall have an effective protection system ("grounding / zero"). Sockets of all used

electrical connections must have a "zero" contact.

– It is prohibited to store flammable and explosive materials and liquids in the

immediate vicinity from the operating burner.

– Always follow the controller’s instructions correctly and properly. Especially in case

of "emergency situation" appearance and alarm.In such a case the procedure for

extinguishing the boiler (the burner) should be immediately applied, and the switched off

boiler shall be marked with the plate "FAULTY – DO NOT SWITCH ON".

CAUTION! Methods of behavior in emergency situations were described in a

separate section of this Manual.

– Protection against flame ingress into the screw feeder and the bunker is an elastic

polyurethane pipe provided by the manufacturer of the burner. Having overheated the pipe

melts what results in displacement of the hole and the cut-off of the pellet feed into the

burner. This is an effective form of protection against fires in fuel. It is forbidden to use

substitutes of the above mentioned pipe.

– It is strictly forbidden to use a defective burner or the burner with faulty equipment.

Re-commissioning of the burner is allowed after troubleshooting.

– Information and warning signs are placed on the whole system of the boiler with the

burner.

– During the operation of the boiler with the burner, always follow the principle of

“limited confidence” and carefully monitor the readings of the installed measuring-and-

recording equipment.

CAUTION! The information that is displayed on the controller is very much

important.

– All technical devices that are part of the boiler and the burner system shall undergo

a systematic technical inspection to the extent required by the acting normative documents.

This requirement is a guarantee for the safe use of these devices.

– In each emergency situation, immediately turn off the burner and the boiler, and

mark with the plate "FAULTY – DO NOT SWITCH ON".

– Each such a situation shall be reported to the relevant services of the enterprise

that are obliged to respond to the situation.

4.3.

Burner Maintenance Procedure

The burner maintenance procedure includes two main phases:

– current maintenance;

– periodic technical maintenance.

4.4.

Current Maintenance

The current maintenance includes the system of the following measures and actions:

– to keep the complex of the boiler – the burner – the screw feeder – the bunker, as

well as the installed equipment properly clean;

– current removal of contaminants in the burner nozzle;

14

– current elimination of minor operational problems on all the installed units (for

instance, replacement of a safety fuse in the controller, cleanup of the screw feeder, fixing of

a seal "burner – boiler", cleaning of the holes forcing the air into the burner);

– carrying out of all the current activities associated with maintaining the proper

operation of the burner;

– ongoing monitoring of the controller operation as well as operation of the

measuring-and-recording equipment.

4.3.1.

Periodic Technical Maintenance

In addition to current activity, it is the user’s responsibility to perform all periodic

technical inspections of the boiler, the burner, the screw feeder, the bunker, the installed

units and the chimney.

Inspection of the boiler and the fume extraction plant shall be carried out in

accordance with the schedule presented in the technical documentation for the boiler.

Within the framework of the periodic technical inspections it is required to perform:

– Monthly maintenance. Clean the burner outlet chamber from dirt and clean the air

intake openings. Monitor the controller operation. Check connections of the tank, screw

feeder, and the burner. In case of loose connection, it is required to tighten.

– Quarterly maintenance. Clean the internal space of the blower fans of the burner

with a vacuum cleaner.Check the fastening of the burner to the boiler, and in case of

detecting loose connection, it is required to tighten. Clean the heating elements of the

ignition system. Check, clean, and tighten the sensor connections. Check the fastening of

the screw feeder, clean the feed openings, and evaluate the correct operation of these units.

Check the cooling system of the burner.If leakage is detected at the joints, they shall be

fixed. Clean the controller with a vacuum cleaner, and check the operation of all its working

functions. Eliminate all reported operational problems, and make a list of the required spare

parts for replacement during the annual maintenance.

– Annual maintenance (best at the end of the heating season when the boiler is off).

Perform thorough inspection of the whole complex of the burner, screw feeder, and a fuel

tank.Perform thorough inspection of all control units and elements responsible for the

burner operation. Remove all the sensors and clean thoroughly all the joints. Check the

condition of the electrical installation of the entire burner complex and eliminate all the

identified problems.

Check the drives of the screw feeder and the moving grates. Add oil to the

gearboxes, if required. Clean all air injection holes in the trailing grates with a vacuum

cleaner. Unscrew the fans, clean them inside, and clean with a vacuum cleaner. Check the

mechanical functionality of the burner and confirm the readiness of all control elements.

Paint the cover of the burner complex, if required.Protect all sockets from adverse factors

that might occur in the boiler room.

CAUTION! Immediately prior to start of the heating season, a mechanical test

shall be carried out for all the units. This should be done after completion of the

annual boiler maintenance.

15

4.5.

Functionality Test

Burner functionality is checked with the help of the following sequence of actions:

– visual review in order to make sure there are no any mechanical defects, impurities,

then check fasteners and connecting wires for reliability;

CAUTION! If required, replace damaged parts or send for repair, remove dust,

impurities, screw attaching bolts as well as connecting ports.

– connect the burner to the control unit;

– when in manual mode, check operation of the internal screw, fan, and the heating

element;

– make sure there are no abnormal noises, sounds, etc. the internal screw rotates

anti clockwise, the fan is operated within the full range from 1% to 99%;

– if there are any discrepancies you shall get a hold of the service center and invite

the specialist.

CAUTION! The heating element shall be tested with the fan running only.

4.6.

Engineering Certification

The procedure, scope, and periodicity of the engineering certification of the product

and its components are in accordance with the current normative documents.

4.7.

Storage Instructions

The burner and its components shall be stored indoors or under the shelter excluding

direct atmospheric precipitation. Spare parts shall be stored in the closed premises. The

burner is delivered from the manufacturing plant after the preservation with the duration of

protective coatings of 12 months. At the end of the effective period of preservation of the

manufacturing plant or on long storage (more than 6 months) the burner shall be put into

long-term storage. All unpainted surfaces shall be coated with anti-corrosion grease.

Preservation shall be carried out at a temperature of not lower than +15 °Сand relative

humidity not exceeding 70 %. The units arriving for preservation shall be free of corrosion

damage to the metal and without damage to the paint and varnish coatings. Surfaces that

are subject to preservation shall be cleaned, degreased, and dried. Lubricants required for

preservation shall be consistent with those for the specified shelf life.

Depreservation is carried out by washing off the preservative coating.

5.

CURRENT REPAIR

5.1.

General Instructions

Normal operation of the burner requires only routine maintenance, cleaning, and

implementation of the necessary inspections. However, sometimes there are cases of

irregularities in the proper operation of the boiler and the burner. During the initial

operational period this is mainly caused by inability to properly operate the controller and the

boiler. But there are also problems for technical reasons. Below are the possible failures and

troubleshooting methods.

16

5.2.

Safety Measures

When carrying out repairs follow safety precautions described in Item 4.2 of this

Manual, safety rules, as well as requirements to repair of boilers that also include

requirements for the burner repair.

5.3.

Potential Failures and Troubleshooting Practice

Table 3 includes simple failures the user faces very often and the user is allowed to

fix such failures by his own efforts.

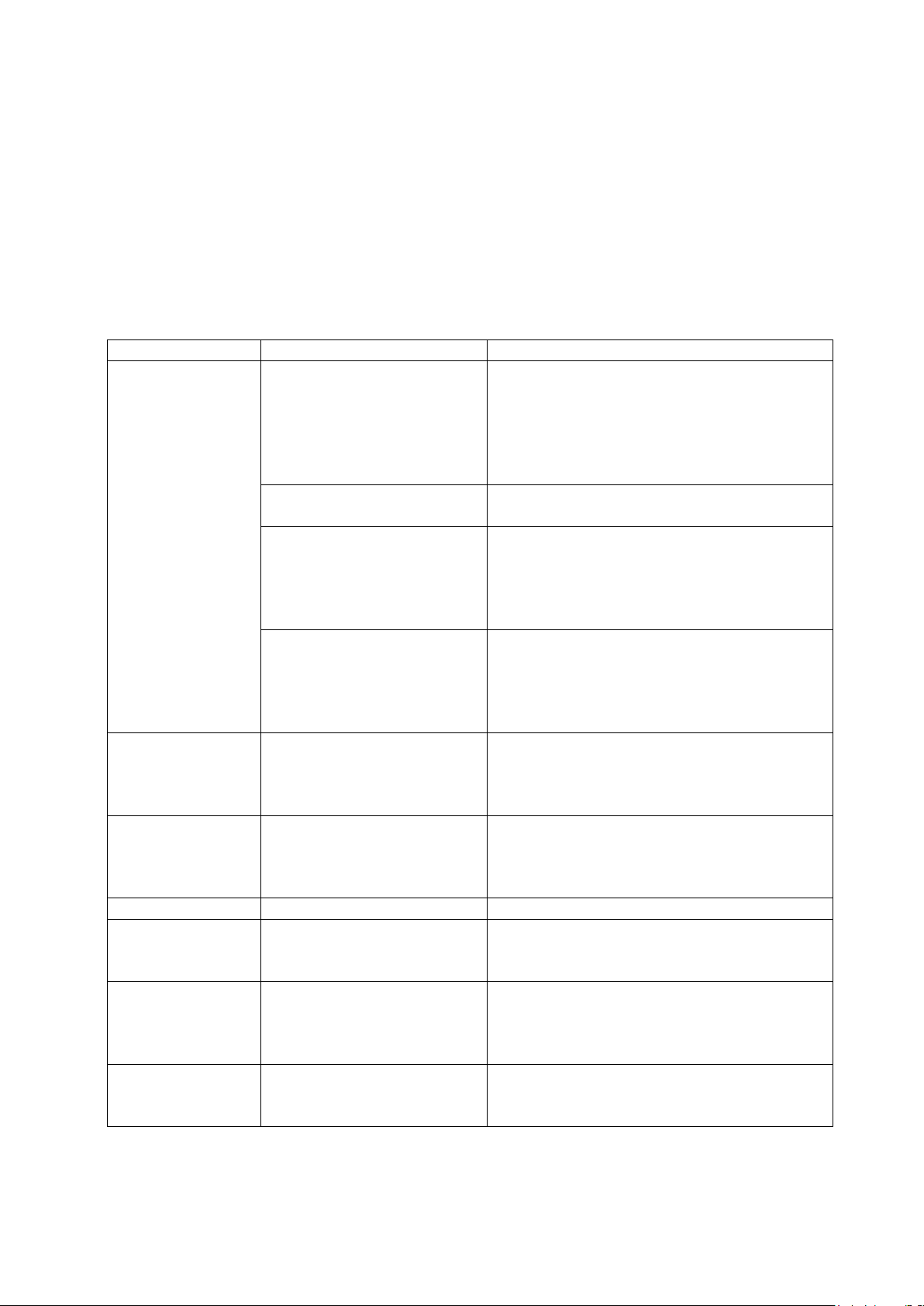

Table 3.

Failure

Potential Reason

Troubleshooting Method

Burner does not start

burning

Lack of fuel

1. Fill the bunker and screw feeder with fuel

pellets.

2.

Remove error on the controller by pressing

«Stop» button.

3.

Repeat firing process by pressing «Start»

button.

Igniter failed

1. Get in touch with the manufacturer or service

company.

Large amount of bottom ash in

the burner firebox

1. De-energize the burner.

2. Let it get cool up to the safe temperature (lower

45°С).

3. Clean the firebox thoroughly to restore passing

ability of air channels.

Internal screw does not work

1.Check the network for stable power supply.

2.Check fastenings of the internal screw with

gearbox.

3. Check electric wiring (contacts) on gearbox and

burner connector.

Boiler overheat

(overheat detector

light is

ON on the

controller panel)

Rise of maximum temperature

for heat carrier heating

-up in

central heating circuit

1. Press «Stop» button on the controller.

2. Let the boiler get cold.

3. Define the reason for overheat and take

measures to eliminate it.

Damage of

temperature sensor

Damage in chain of the heat

carrier temperature sensor

1. Get in touch with the manufacturer’s service

company if the data on error is not annulled after

pressing «Stop button.

2. Replace the sensor

Failure

Potential Reason

Troubleshooting Method

Damage in chain of the outgoing

gas temperature sensor

1. Get in touch with the manufacturer’s service

company if the data on error is not annulled after

pressing «Stop button.

Burner smokes, soot

appears

Extra amount of fuel in

comparison with air. Burner

firebox is filled with bottom ash

1. Let the burner get cold, and clean the burner

firebox to restore passing ability of air channels.

2. Adjust amount of fuel and fan rpm.

Burner firebox is filled

with bottom ash too

often

Fuel of poor quality is used

1. Change operation mode of the cleaning unit

(See Controller

Manual).

2. Change the fuel supplier.

The examples described above do not exclude other reasons that might result in a

17

malfunction of the burner’s proper operation as well as operation of other units associated

with the burner.These are only examples that can be useful for the user in resolving

emerging problems.

6.

TRANSPORTATION AND STORAGE

The burner and the equipment are always delivered to the user on pallets, in the

original sealed factory packaging that protects the product from potential damage during

transportation.

Always read and take into consideration information signs located on boxes, some

elements might be fragile and shock-sensitive as well as sensitive to the influence of

unfavorable atmospheric conditions. It is forbidden to throw, move sharply, and jam boxes

with heavy elements.

In case of detecting the damaged boxes it is required to open them in the presence of

the supplier and inspect the products located inside. In case of detecting significant damage

to the products (dents, cracks, damage to the control cabinet, etc.) it is necessary to

immediately draw up the damage certificate for the supplier and notify the manufacturer

about this fact.

CAUTION! All shipments shall be always checked at the moment of receipt and

in the presence of the supplier.

Burners are not intended for stockpiling as well as for storage in places not suited for

this purpose within the period exceeding 12 months. Their storage location shall meet the

following requirements:

– on shelves, only in the original, factory and labeled boxes;

– only in dry, closed, and ventilated premises;

–in rooms at a temperature of 5…40 °C and humidity not exceeding 50%

– in premises free of aggressive materials or chemical agents.

CAUTION! It is forbidden to store or stockpile the products in the open air.

Corrosion or damages caused by improper storage conditions are beyond the claim

for replacement. In case of storing burners longer than 12 months they shall be

checked (inspected) by the manufacturer’s technicians who have to confirm the

completion of this inspection in the product warranty letter (this relates exclusively to

the products stored in warehouses or points of sales).

7.

DISPOSAL

Burners of «AIR PELLET 60 KW» type are safe for the environment and follow all the

requirements of norms associated with cleanliness of exhaust as well as exhaust emission

to the atmosphere. Cardboard packages of the delivered units can be used for firing or sent

to the old paper stock. Steel construction and the burner housing do not pose any threat to

the environment as well as the screw feeder housing, and the tank. Once the working life is

over they are handed over for scrap recycling. All used electrical equipment elements are

made of plastic (for example, protective elements, handle, tubes, etc.) and they shall be

sorted and handed over for recycling or processing.

18

8.

WARRANTY

The item of warranty in this context is the pellet burner of «AIR PELLET 60 KW» type.

The manufacturer guarantees failure-free operation of the burner for the period of 12 months

starting from the date of the first startup (putting into operation), but not longer than 24

months from the date of manufacture and on conditions that the unit is operated properly

and undergoes technical maintenance in a timely manner.

Warranty for heating elements is granted for the period of 1 year. Two-year warranty

for the burner is valid only if the burner firebox is cleaned off ash and noncombustible

residues regularly enough for the purpose of avoiding deformation and damage of the

combustion chamber.

Warranty is valid:

– only on the territory of the country where the burner was sold;

–if a user has not incorporated (made) any changes into the burner configuration and

construction;

– if the works on putting the burner into operation and adjustment of burner operation

parameters have been carried out by the authorized representative of the manufacturing

plant.

Warranty does not cover defects occurred through:

– user’s fault due to improper assembling of the burner;

– user’s fault due to violation of operation rules for the burner and the boiler;

– lack of reasonable diligence;

– loss of burner’s delivery set items;

– willful damage;

– repair (or attempt to repair) performed by an unauthorized individual;

– power outages;

– use of low quality fuel;

– for burners that were installed and adjusted by a company or individual that are

non-authorized by the manufacturing plant;

– natural disasters (lightning strike, fire, flood, submergence, etc.).

CAUTION!DEFORMATION AND BURNING-OUT OF THE COMBUSTION

CHAMBER AND CLEANING AGITATOR CAUSED BY UNTIMELY SERVICE ARE NOT

CONSIDERED TO BE MANUFACTURING FLAW AND NOT COVERED BY WARRANTY

OBLIGATIONS.

The list of authorized representatives of the manufacturing plant can be found on

website of LTD «Bioprom Company Kharkov» bioprom.ua.

Company-manufacturer address: 126/1, Plekhanovskaya Str., Kharkov city, 61037,

Ukraine

19

Warranty Ticket

Burner Model

Product Number

Date of Sale

Name of Company-Seller

Date of installation/putting into operation

Owner Details Installer Name and

Signature Name _

Tel _

City _

Street/House

# ___________

For all issues relating to warranty and post-warranty service, please feel free to

contact us at the address of: 126/1, Plekhanovskaya Str., Kharkov city, 61037, Ukraine.

Telephone of Service Center: + 38 (095)654-67-19; + 38 (098)232-52-15.

http://bioprom.ua/

Е-mail – no12serv[email protected]om.ua.

20

Record on warranty repair

Defect description: ______________________________________________________

Reason for failure: _______________________________________________________

______________________________________________________________________

Repair work performed: ___________________________________________________

______________________________________________________________________

Name of repair company: _________________________________________________

License # ____________ Expert ________________ Repair date _________________

stamp

Record on warranty repair

Defect description: ______________________________________________________

Reason for failure: _______________________________________________________

______________________________________________________________________

Repair work performed: ___________________________________________________

______________________________________________________________________

Name of repair company: _________________________________________________

License # ____________ Expert ________________ Repair date _________________

stamp

Record on warranty repair

Defect description: ______________________________________________________

Reason for failure: _______________________________________________________

______________________________________________________________________

Repair work performed: ___________________________________________________

______________________________________________________________________

Name of repair company: _________________________________________________

License # ____________ Expert ________________ Repair date _________________

stamp

Record on warranty repair

Defect description: ______________________________________________________

Reason for failure: _______________________________________________________

______________________________________________________________________

Repair work performed: ___________________________________________________

______________________________________________________________________

Name of repair company: _________________________________________________

License # ____________ Expert ________________ Repair date _________________

stamp

Table of contents

Popular Burner manuals by other brands

Riello

Riello RLS 160/EV Installation, use and maintenance instructions

Riello

Riello RS 28/M Installation, use and maintenance instructions

True Induction

True Induction TI4B user guide

Riello

Riello RG1RKD Installation, use and maintenance instructions

Weishaupt

Weishaupt WG20 Series manual

Carolina Cooker

Carolina Cooker M116672 owner's guide

AESYS

AESYS TurboFire II Installation, operation and maintenance manual

IKEA

IKEA GRILLSKÄR manual

baltur

baltur TBL 1000 ME Instruction manual for installation, use and maintenance

Riello Burners

Riello Burners P 200 P/G Installation, use and maintenance instructions

WLD-TEC

WLD-TEC powerjet instruction manual

Riello

Riello RDB 3.2 BX 32/50 Installation, use and maintenance instructions