Biosan ES-20 User manual

2

Contents

1. Safety Precautions...................................................................................................3

2. General information..................................................................................................4

3. Getting started..........................................................................................................5

4. Operation .................................................................................................................6

5. Specifications...........................................................................................................8

6. Maintenance.............................................................................................................9

7. Warranty and Claims. Registration.........................................................................10

8. EU Declaration of Conformity.................................................................................11

3

1. Safety Precautions

The following symbols mean:

Caution: Make sure you have fully read and understood the present Manual

before using the equipment. Please pay special attention to sections

marked by this symbol.

GENERAL SAFETY

Use only as specified in the Operating Manual provided.

Do not use a dropped or damaged unit.

Store and transport the unit in a horizontal position (see package label).

After transportation or storage and before connecting to electric circuit, keep the unit

under room temperature for 2-3 h.

Before using any cleaning or decontamination methods except those recommended

by the manufacturer, check with the manufacturer that the proposed method will not

damage the equipment.

Do not make modifications to the design of the unit.

ELECTRICAL SAFETY

Connect only to electric circuit with voltage corresponding to that on the serial number

label.

Ensure that the switch and plug are easily accessible during use.

Do not plug the unit into an ungrounded power socket, and do not use an ungrounded

extension lead.

Disconnect the unit from electric circuit before moving. Switch the unit off and

disconnect the power cord plug frompower socket to disconnect the unit from electric

circuit.

If liquid penetrates into the unit, disconnect it from electric circuit and have it checked

by a repair and maintenance technician.

Do not operate the unit in premises where condensation can form. Operating

conditions of the unit are defined in the Specifications section.

DURING OPERATION

Do not impede the platform motion.

Do not load over the maximum load value mentioned in the Specifications section of

these operating instructions.

Do not leave the operating unit unattended.

Do not operate the unit in environments with aggressive or explosive chemical

mixtures. Please contact manufacturer for possible operation of the unit in specific

atmospheres.

Do not operate the unit if it is faulty or has been installed incorrectly.

Do not use outside laboratory rooms.

BIOLOGICAL SAFETY

It is the user’s responsibility to carry out appropriate decontamination if hazardous

material is spilt on or penetrates into the equipment.

4

2. General information

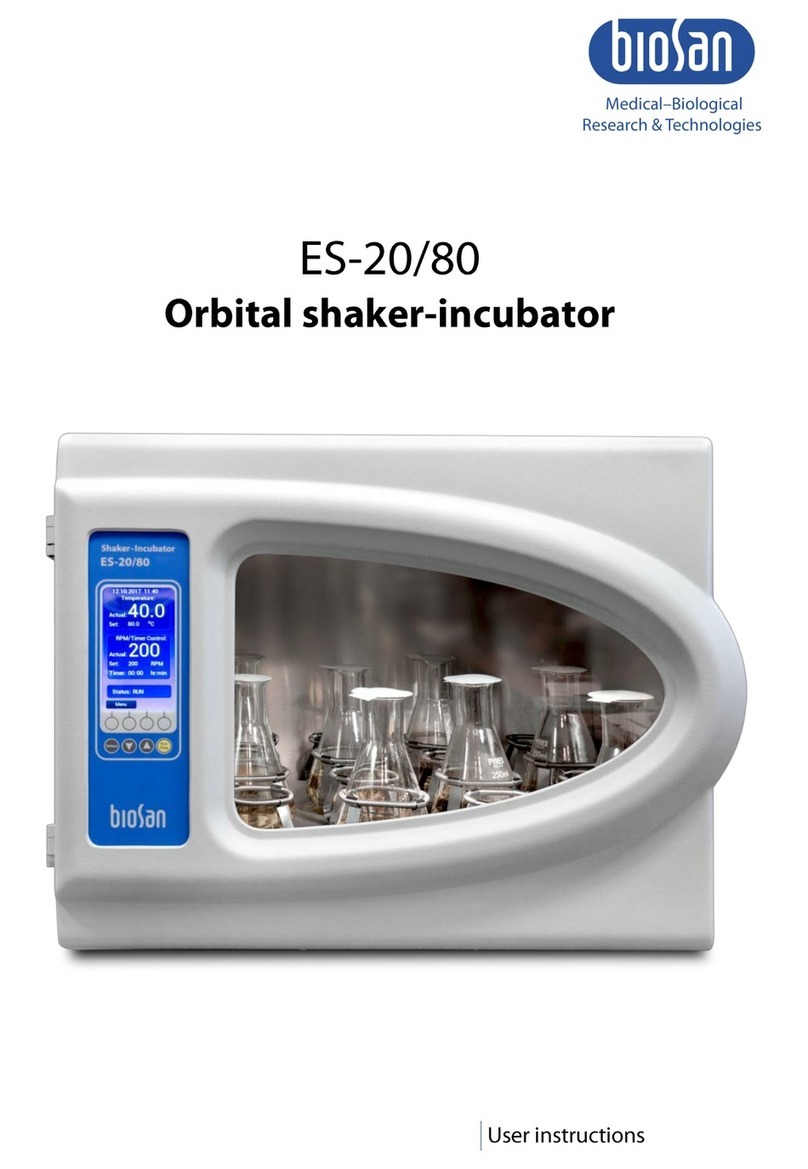

The ES-20 is a compact desktop shaker-incubator used for mixing of biological liquids

as well as incubation and cultivation of biological liquids according to the program set by the

operator.

Built-in microprocessor thermocontroller provides constant temperature control in the

incubator chamber. Forced heated air circulation inside the transparent Plexiglas chamber

guarantees even temperature distribution. Dismountable construction makes transportation

easy. Orbital shaking is controlled by the digital tachometer (rpm) and digital timer

regardless of the temperature. The unit is equipped with the direct-drive system ensuring

most reliable stable long-time operation (up to 30 of 24 hour cycles).

The ES-20 is easy to operate. The two-line LCD display shows both set and actual

values for temperature, time and speed.

The device consists of a thermal regulator and control block, shaking block and a

Plexiglas chamber.

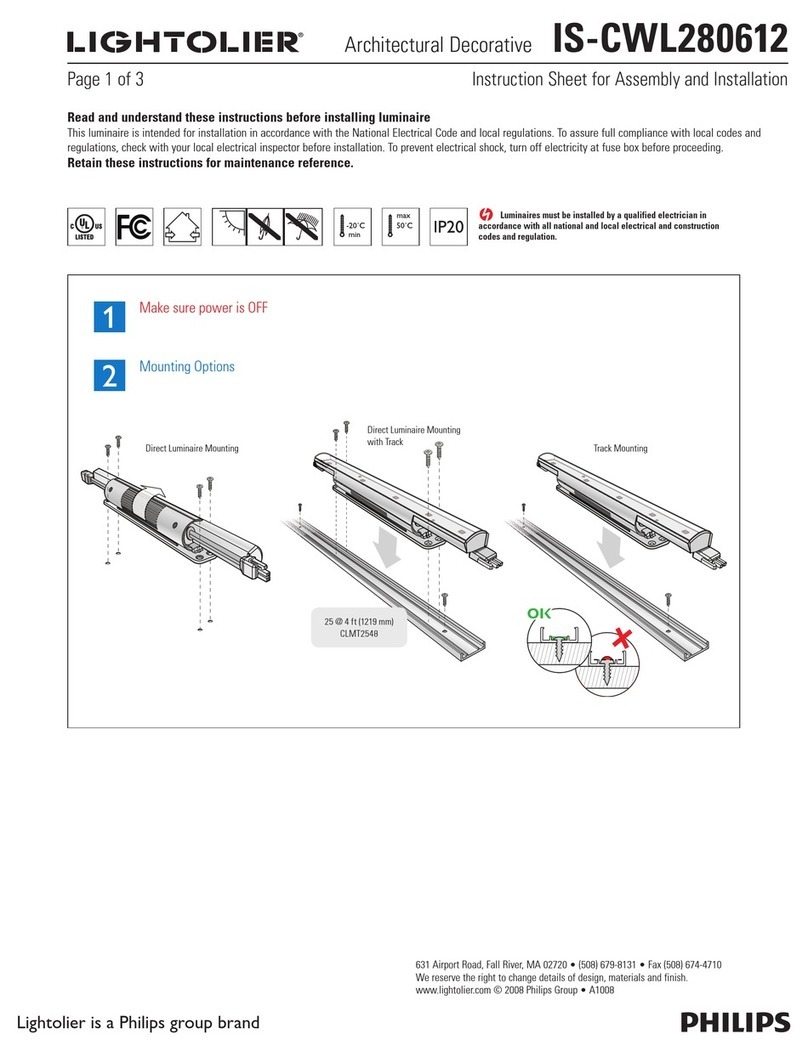

The elements located on the front panel:

- power switch (fig.1/);

- display (fig.1/);

- control buttons (fig.1/).

The elements located on the rear panel:

- shaking block control cable (fig.1/);

- socket for connecting the power cord

(fig.1/);

- fuse holder (fig.1/).

Fig.1. Overall view

Five interchangeable platform types allow using the shaker for:

Growing cell cultures in flasks and other laboratory glassware.

Extracting tissue samples at physiological temperatures.

Other sample preparation processes.

The unit is applicable in all the areas of clinical, biotechnology and microbiology

laboratory research.

5

3. Getting started

3.1. Unpacking.

Remove packing materials carefully and retain for them future shipment or storage of

the unit. Examine the unit carefully for any damage incurred during transit. The

warranty does not cover in-transit damage. Warranty covers only the units

transported in the original package.

3.2. Complete set. Package contents:

Standard set:

- Shaker-Incubator ES-20 ................................................................................1 piece

- Power cord.....................................................................................................1 piece

- Control cable..................................................................................................1 piece

- spare fuse (inside the fuse holder) ................................................................1 piece

- Operating manual, Certificate .........................................................................1 copy

- ES-20 Shaker-Incubator Assembling Instruction.............................................1 copy

Optional accessories:

- UP-12 platform ......................................................................................on request

- PP-4 platform ........................................................................................on request

- P-12/100 platform .................................................................................on request

- P-6/250 platform ...................................................................................on request

- P-16/88 platform ...................................................................................on request

- HB-200 holding bar ...............................................................................on request

6

3.3. Setup.

- Assemble the unit, using the enclosed ES-20 Orbital Incubator Shaker Assembling

Instruction as a guide.

- Place the unit on a horizontal even working surface.

- Remove protective film from the display.

- Connect the shaker control cable (fig.1/) into the corresponding sockets on the

rear of the thermostatic and shaking blocks.

- Plug the mains cable into the socket on the rear (fig.1/) and position the unit so

that there is easy access to the power switch and connector.

3.4. Platform installation.

- Install the platform by inserting the pins on the bottom side of the platform into the

holes on the supporting platform on the shaker.

Note! Move the unit carefully and only in a vertical position.

4. Operation

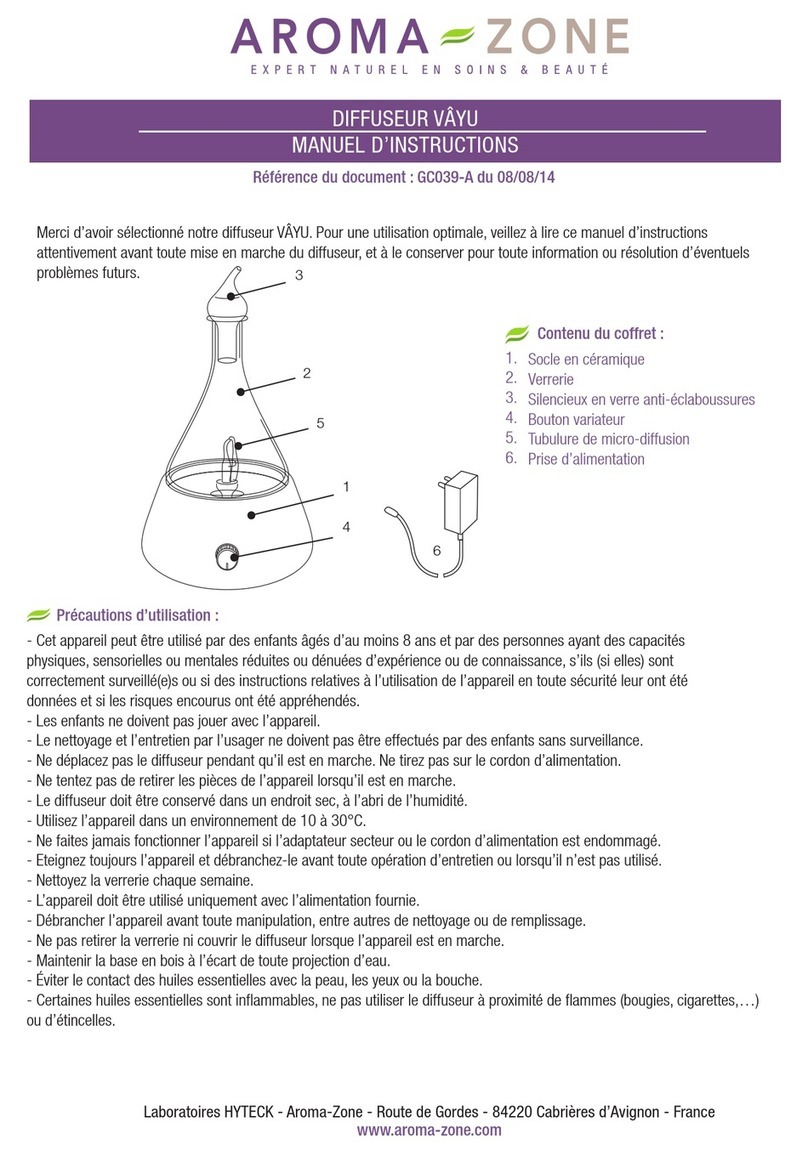

Fig.2 Control panel

4.1. Connect the unit to a grounded power socket. Set the Power switch to position I (ON).

4.2. The display will turn on with the upper line (Set p.) showing the previously set time,

speed and temperature and the lower line (Actual p.) showing current readings of

the same parameters (STOP –time, 000 –speed and incubator temperature °C,

which automatically starts rising according to the temperature set in the upper line).

4.3. Setting the parameters. Use the readings in the upper line of the display (Set p.),

while setting the parameters required. The set parameters can also be changed

during operation.

4.3.1. Setting time (Time). Using the ▲ and ▼ Time keys (Fig. 2/1), set the required

working time interval in hours and minutes (increment - 1 min). Pressing the key for

more than 3 seconds will increase the increment.

4.3.2. Setting speed (RPM). Using the ▲ and ▼ RPM keys (Fig. 2/2), set the required

shaking speed (increment 10 RPM). Pressing the key for more than 3 seconds will

increase the increment.

7

4.3.3. Setting temperature (Temp.°C).Using the ▲ and ▼ Temp. keys (Fig. 2/3), set the

required temperature (increment 0.1°C). Pressing the key for more than 3 seconds

will increase the increment.

Caution! The chamber heating can be turned off only by setting the

temperature value below 25 °C (the display will show OFF –

Temp.°C–Set p.).

4.4. Program execution.

4.4.1. Place samples on the platform.

4.4.2. Press the Shaker-Run/Stop key (Fig. 2/4). The platform will start rotating and the

timer indicator will start counting the time interval (with 1 min precision).

Note! If the rotation speed is set to zero, pressing Shaker-Run/Stop key

starts the timer but the platform does not move.

4.4.3. After finishing the program (after the set time elapses), the platform motion will stop

and the timer will be showing the flashing reading STOP accompanied by the

repetitive sound signal until the Shaker-Run/Stop key is pressed.

Caution! At the end of the set time period the platform movement is stopped

automatically, but the heating can be stopped ONLY manually by

reducing the temperatureusing the ▼Temp. key (Fig. 2/3 –the lower

key) till the OFF sign appears in the upper line of the display.

4.5. If the working time is not set (the timer indicator in the upper line shows 00:00),

pressing the Shaker-Run/Stop key will start continuous operation of the unit (with

countdown timer in the lower line and indication OFF in the upper line) until the

Shaker-Run/Stop key is pressed again.

4.6. The timer can be reset during operation if required. Press the Timer-Run/Stop key

twice (Fig. 2/5), first –to stop the timer, second –to restart the timer.

4.7. The platform motion can be stopped at any time by pressing the Shaker-Run/Stop

key. In this case, the program execution and the platform motion will stop and the

timer will switch into the STOP mode saving previously set time. Press the Shaker-

Run/Stop key to repeat the operation with the same time and speed.

4.8. After finishing the operation, set the power switch, located on the rear panel of the

unit, in position O (Off) and disconnect the external power supply with from electric

circuit.

8

5. Specifications

The unit is designed for operation in cold rooms, incubators (except CO2incubators)

and closed laboratory rooms at ambient temperature from +4°C to +40°C in a non-

condensing atmosphere and maximum relative humidity 80% for temperatures up to 31°C

decreasing linearly to 50% relative humidity at 40°C.

Temperature setting range ...............................................................+25°C ... +42°C

Temperature control range * ........................................5°C above ambient ... +42°C

Temperature setting resolution .........................................................................0.1°C

Speed control range ..............................................50–250 RPM (increment 10 rpm)

Maximum load..................................................................................................2.5 kg

Orbit ...............................................................................................................10 mm

Digital time setting..................................................1 min –96 hrs (increment 1 min)

Continuous operating time, not more ...........................................................30 days

Recommended interval between operation sessions not less than 8 hours

Display ........................................................................................... 2x16 signs, LCD

Dimensions of the inner chamber ................................................. 305x260x250 mm

Dimensions .................................................................................. 340x340x435 mm

Current/power consumption ...............230 V, 0.7 A / 160 W or 120 V, 1.6 A / 170 W

Voltage .............................................................230 V, 50/60 Hz or 120 V, 50/60 Hz

Weight**.........................................................................................................13.2 kg

Optional

accessories

Description

Catalogue

number

PP-4

Metallic flat platform with non-slip rubber mat.

Working dimensions 215x215 mm

BS-010108-BK

UP-12

Universal platform with adjustable bars for different

types of flasks, with non-slip rubber mat. Working

dimensions 265x185 mm

BS-010108-AK

HB-200

Additional holding bar for PUP-12

BS-010108-FK

P-12/100

Platform with clamps for flasks, 100 ml (12 places).

Working dimensions 250x190 mm

BS-010108-EK

P-6/250

Platform with clamps for flasks, 250 ml (6 places).

Working dimensions 250x190 mm

BS-010108-DK

P-16/88

Platform with spring holders for up to 88 tubes up to

30 mm diameter (e.g. 10 ml, 15 ml, 50 ml tubes).

Working dimensions 275x205x75 mm

BS-010116-BK

Biosan is committed to a continuous program of improvement and reserves the right

to alter design and specifications of the equipment without additional notice.

* In cold room, the unit provides stable thermostatic temperature control 30°C above room temperature.

** Accurate within ±10%.

9

6. Maintenance

6.1. If the unit requires maintenance, disconnect the unit from the electric circuit and

contact Biosan or your local Biosan representative.

6.2. All maintenance and repair operations must be performed only by qualified and

specially trained personnel.

6.3. Standard ethanol (75%) or other cleaning agents recommended for cleaning of

laboratory equipment can be used for cleaning and decontamination of the unit.

6.3.1. The door and side panels are made of organic glass (polymethyl methacrylate,

Plexiglas®) and are prone to scuffing and scratches if improperly cleaned. Care during

cleaning of the door and side panels is recommended to reduce wear of the Plexiglas

surface.

Caution! Clean the door and side panels with a mild detergent; never use

organic based compounds, pure alcohol, alcohol-containing cleaners

(more than 15%) or ammonia containing cleaners for Plexiglas! Do

not use abrasive pads or cleansers.

6.3.2. For decontamination, it is recommended to use a special DNA/RNA removing

solution (e.g. DNA-Exitus Plus™, RNase-Exitus Plus™).

The table below shows the interreaction of Plexiglas with ethyl alcohol and other

solutions.

Liquid

Interreaction with Plexiglas

DNA-Exitus Plus™

No reaction.

RNase-Exitus Plus™

No reaction.

Ethyl alcohol 10-15%

No reaction.

Ethyl alcohol 30%

Limited reaction

Ethyl alcohol Pure

Full reaction. Do not use!

H2O2 6%

No reaction.

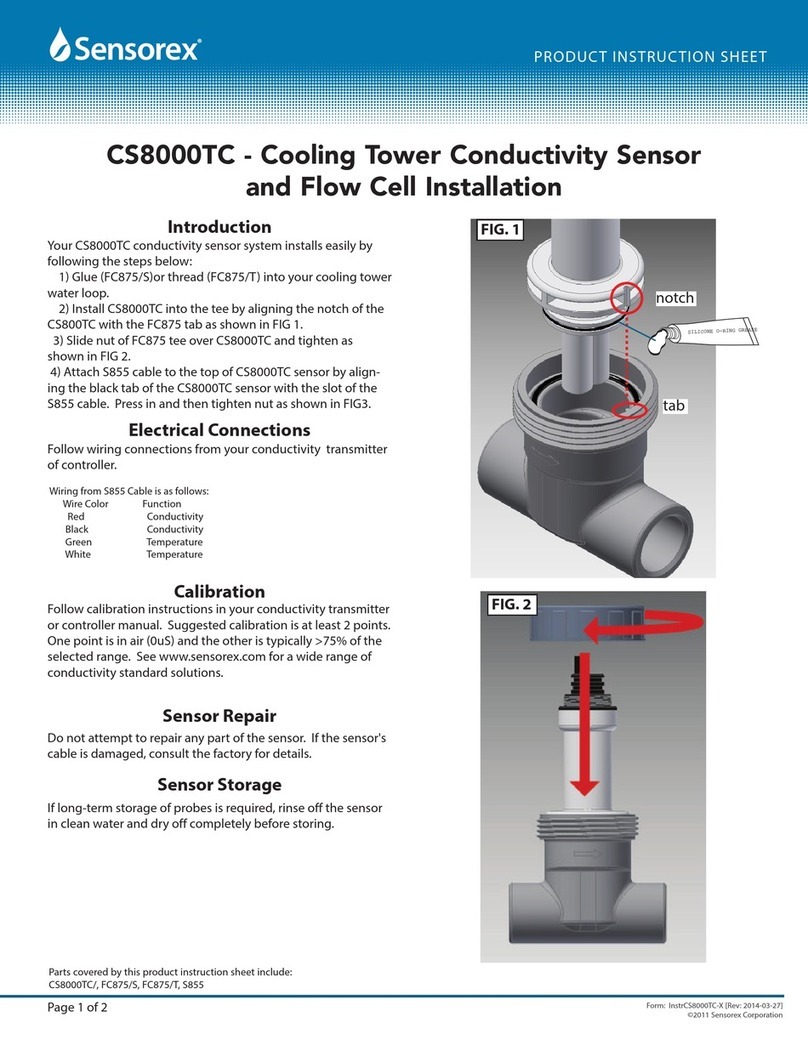

6.4. Fuse replacement

Disconnect from electric circuit.

Remove the power plug from the rear of the unit.

Pull out the fuse holder by applying leverage in recess (A).

Remove the fuse from the holder. Check and replace with the correct fuse if

necessary: for 230 V, M 1 A or for 120 V, M 2 A (type M- time lag: Medium).

Fig.4. Fuse holder

10

7. Warranty and Claims. Registration

7.1. The Manufacturer guarantees the compliance of the unit with the requirements of

Specifications, provided the Customer follows the operation, storage and trans-

portation instructions.

7.2. The warranted service life of the unit from the date of its delivery to the Customer is

24 months (excluding platforms mentioned in the table on page 8). For extended

warranty, see p. 7.5.

7.3. Warranty covers only the units transported in the original package.

7.4. If any manufacturing defects are discovered by the Customer, an unsatisfactory

equipment claim shall be compiled, certified and sent to the local distributor ad-dress.

To obtain the claim form, visit section Technical support on our website at link

below.

7.5. Extended warranty. For ES-20, a Basic Plus class model, extended warranty is a paid

service. Contact your local Biosan representative or our service department through

the Technical support section on our website at the link below.

7.6. Description of the classes of our products is available in the Product class de-

scription section on our website at the link below.

Technical support

Product class description

biosan.lv/en/support

biosan.lv/classes-en

7.7. The following information will be required in the event that warranty or post-warranty

service comes necessary. Complete the table below and retain for your records.

Model

ES-20, Orbital shaker-incubator

Serial number

Date of sale

11

8. EU Declaration of Conformity

Unit type Shakers-incubators

Models ES-20, ES-20/60

Serial number 14 digits styled XXXXXXYYMMZZZZ, where XXXXXX is

model code, YY and MM –year and month of production,

ZZZZ –unit number.

Manufacturer SIA BIOSAN

Latvia, LV-1067, Riga, Ratsupites str. 7/2

Applicable Directives EMC Directive 2014/30/EC

LVD Directive 2014/35/EC

RoHS2 2011/65/EC

WEEE 2012/19/EU

Applicable Standards LVS EN 61326-1: 2013

Electrical equipment for measurement, control and

laboratory use. EMC requirements. General requirements.

LVS EN 61010-1: 2011

Safety requirements for electrical equipment for

measurement, control, and laboratory use. General

requirements.

LVS EN 61010-2-010: 2015

Particular requirements for laboratory equipment for the

heating of materials.

LVS EN 61010-2-051: 2015

Particular requirements for laboratory equipment for mixing

and stirring.

We declare that this product conforms to the requirements of the above Directives

____________________ ____________________

Signature Signature

Svetlana Bankovska Aleksandr Shevchik

Managing director Engineer of R&D

____________________ ____________________

Date Date

Biosan SIA

Ratsupites 7, build. 2, Riga, LV-1067, Latvia

Phone: +371 67426137

Fax: +371 67428101

http://www.biosan.lv

Edition 2.04 - December 2016

Table of contents

Other Biosan Accessories manuals