Biosan ES-20/60 User manual

2

Contents

1. Safety precautions ...................................................................................................3

2. General Information .................................................................................................4

3. Getting started..........................................................................................................4

4. Operation .................................................................................................................6

5. Specifications...........................................................................................................8

6. Maintenance.............................................................................................................9

7. Warranty and Claims..............................................................................................10

8. EU Declaration of Conformity.................................................................................11

3

1. Safety precautions

The following symbols mean:

Caution! Make sure you have fully read and understood the present Manual

before using the equipment. Please pay special attention to sections

marked by this symbol.

GENERAL SAFETY

Use only as specified in the Operating Manual provided.

Do not use a dropped or damaged unit.

Store and transport the unit in a horizontal position (see package label).

After transportation or storage and before connecting to electric circuit, keep the unit

under room temperature for 2-3 h.

Before using any cleaning or decontamination methods except those recommended

by the manufacturer, check with the manufacturer that the proposed method will not

damage the equipment.

Do not make modifications in design of the unit.

ELECTRICAL SAFETY

Connect only to electric circuit with voltage corresponding to that on the serial number

label.

Do not plug the unit into an ungrounded power socket, and do not use an ungrounded

extension lead.

Ensure that the power switch and plug are easily accessible during use.

Disconnect the unit from the electric circuit before moving.

Disconnect the plug from power socket to turn off the unit.

If liquid penetrates into the unit, disconnect it from the electric circuit and have it

checked by a repair and maintenance technician.

Do not operate the unit in premises where condensation can form. Operating condi-

tions of the unit are defined in the Specification section.

DURING OPERATION

Do not impede the platform motion.

Make sure that all sample vessels are tightly sealed. Humidity caused by evaporation

from unsealed vessels inside the incubator will damage the unit.

Do not operate the unit in premises with aggressive or explosive chemical mixtures.

Please contact manufacturer for possibility of unit operation in specific atmosphere.

Do not use outside laboratory rooms.

Do not place a load exceeding the maximum load value mentioned in the Specifica-

tions section of this Manual.

Do not operate the unit if it is faulty or has been installed incorrectly.

BIOLOGICAL SAFETY

It is the user’s responsibility to carry out appropriate decontamination if hazardous

material is spilt on or penetrates into the equipment.

4

2. General Information

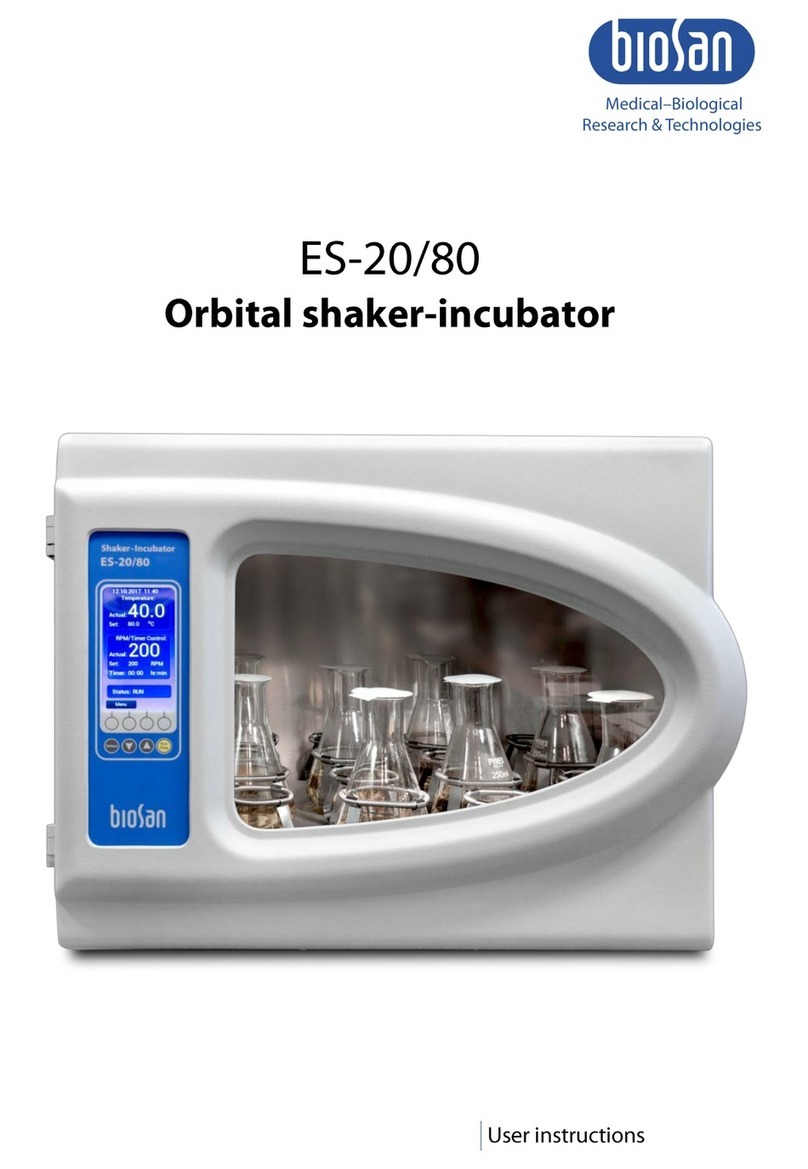

ES-20/60 Orbital Shaker-incubator for biotechnological and pharmaceutical labor-

atories is a professional category equipment designed for cultivation of micro organisms cells

and eukaryotic cells, including animal, plant and insect cells. Shaker is equipped with a di-

rect-drive mechanism for platform motion. It provides reliable and stable operation for the

long term experiments needed for cell cultivation.

ES-20/60 Orbital Shaker-incubator provides smooth (or intensive) mixing in flasks

installed on the platform. Built-in thermoresistant brushless fan provides precise temperature

distribution inside the chamber (from 10°C above ambient up to +80°C). The inner chamber

is made of stainless steel. State-of-the-art motor, newest thermal insulation materials used,

program provided soft start of the platform motion and temperature regulation PID-control

decrease the energy consumption and make the shaker-incubator highly energy efficient

despite its relatively large size.

3. Getting started

3.1. Unpacking

Remove packing materials carefully and retain them for future shipment or storage of

the unit. Examine the unit carefully for any damage incurred during transit. The war-

ranty does not cover in-transit damage. Warranty covers only the units transported in

the original package.

Caution! Due to its size and weight (41 kg), the unit requires two people to lift

or move it.

3.2. Complete set. Package contents:

Standard set

- ES-20/60 Orbital Shaker-Incubator ...............................................................1 piece

- power cord ....................................................................................................1 piece

- spare fuse (inside fuse holder).......................................................................1 piece

- four screws and a wrench ..................................................................................1 set

- Operating Manual; Certificate .........................................................................1 copy

Optional accessories

- P-30/100 platform .................................................................................on request

- P-16/250 platform .................................................................................on request

- P-9/500 platform ...................................................................................on request

- P-6/1000 platform .................................................................................on request

- PP-400 platform ....................................................................................on request

- UP-168 universal platform .....................................................................on request

- FC-100, FC-250, FC-500, FC-1000 clamps for UP-168............................on request

5

3.3. Setup:

- place the unit upon even horizontal non-flammable surface at least 30 cm away

from any flammable materials;

Note! Ensure that the unit is placed on solid, level surface, which is able to

support its weight.

- remove protective film from the display;

- plug the power cord into the socket on the rear, and position the unit so that there is

easy access to the power switch and plug.

3.4. Platform installation:

- remove the silicone mat from the platform;

- secure the platform on the stands on top of the unit with the four screws using the

provided hex driver and cover the platform with the silicone mat.

Table of contents

Other Biosan Accessories manuals