Biotector Venturi 19-BAS-001 User manual

PAGE 1OF 25

www.BioTector.com

BioTector Venturi Driven Vacuum Sampler

USER MANUAL

BioTector Venturi Sampler

For connection to BioTector TOC Analyzers.

M3 system with PLC keyboard controls.

Software Venturi Sampler 1-6-stream V5.03

Standard Venturi Sampler

Original instructions

© Copyright BioTector Oct 2017 PB. All rights reserved. Printed by BioTector in the Republic of Ireland.

PAGE 2OF 25

www.BioTector.com

Read the instructions in this manual carefully before installing or starting

the Venturi Liquid Sampler for the BioTector TOC analyzer.

BioTector Analytical Systems Ltd cannot accept liability for damages due to non-

observance of this manual. Use of spare parts not supplied by BioTector Analytical

Systems Ltd will invalidate the warranty. BioTector Analytical Systems Ltd shall not be

liable for omissions or errors contained herein or for incidental or consequential

damages in connection with the furnishing, performance, or use of this material.

The information contained in this manual is subject to change without notice.

The information contained herein is protected by copyright. Reproduction, adaptation,

or translation of any part of this manual without prior written permission is prohibited,

except as allowed under the copyright laws.

Product names mentioned herein are for identification purposes only and may be

trademarks or registered trademarks of their respective companies.

Where manuals are translated into several languages, the source language text is

considered as the original.

Maintenance, operation and/or commissioning should not be

carried out unless personnel have been fully trained in the

operation of the Venturi Sampler.

Prior to working on the inside of the sampler, the technician

should be grounded via an earth strap.

The Venturi Sampler uses pressurized air and water.

Precautionary Labels Attached to the Instrument

Electrical equipment marked with this symbol may not be

disposed of in European domestic or public disposal systems.

Return old or end-of-life equipment to the manufacturer for

disposal at no charge to the user.

WARNING

PAGE 3OF 25

www.BioTector.com

Table of Contents

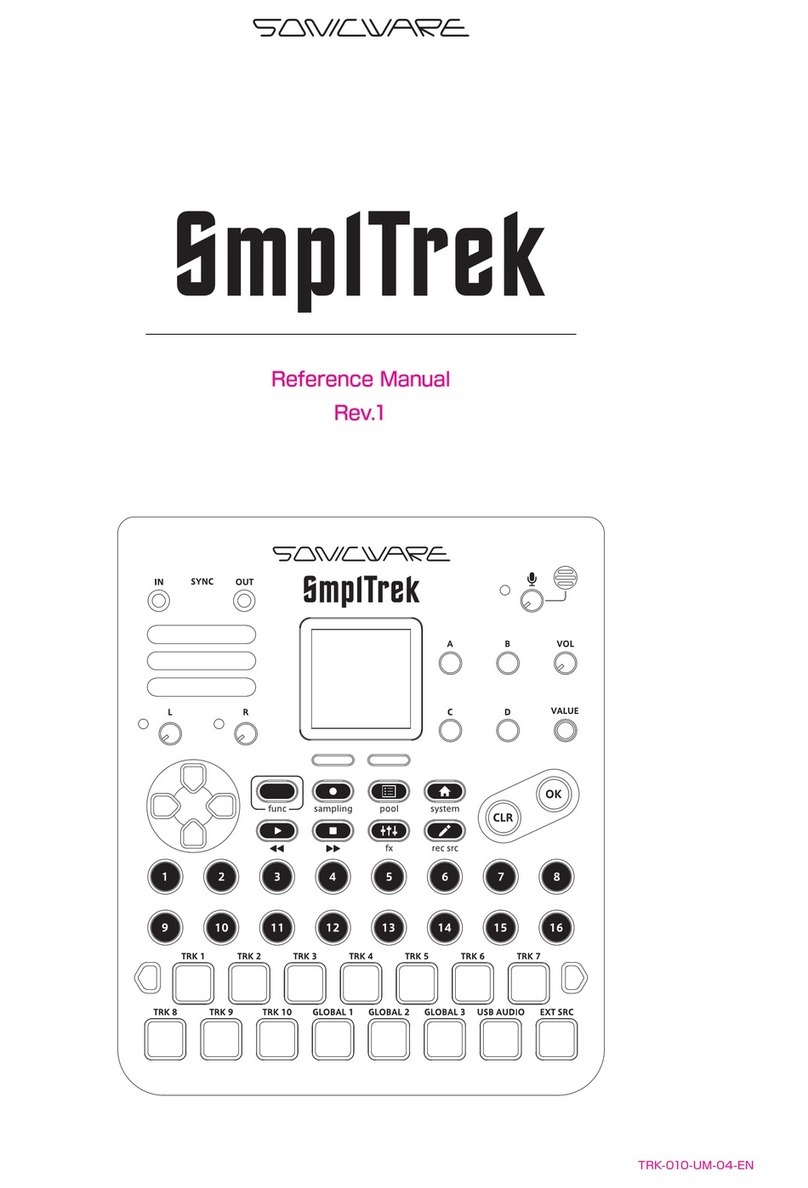

1. Photograph of typical Venturi Sampler................................................................................ 4

2. Venturi Sampler ................................................................................................................... 5

Build Option 1:..................................................................................................................... 5

Build Option 2:..................................................................................................................... 5

Sensor Options: .................................................................................................................... 5

Utilities................................................................................................................................. 5

3. Technical Specifications....................................................................................................... 6

4. Typical Operational Data ..................................................................................................... 8

5. Manual Operation:................................................................................................................ 8

6. Typical Operational sequences, Fill..................................................................................... 9

7. Fill Timer Blocks in the Venturi Sampler PLC.................................................................. 10

8. Typical Operational sequences, Purge. .............................................................................. 11

9. Empty Timer Blocks in the Venturi Sampler PLC............................................................. 12

10. Venturi Water Purge....................................................................................................... 12

11. Fault conditions.............................................................................................................. 12

12. Programming the BioTector for use with the Venturi Sampler. .................................... 13

13. Software Version............................................................................................................ 13

14. Programming the Venturi Samplers PLC....................................................................... 14

15. To save modified program settings to the Memory Card............................................... 14

16. To restore original program settings from the Memory Card or to upgrade Firmware. 14

17. Six Month Maintenance on the Venturi Driven Vacuum Sampler. ............................... 15

18. Pressure ratings on the Venturi Driven Vacuum Sampler. ............................................ 16

19. Test Certificate ............................................................................................................... 17

20. Venturi Sampler Commissioning and Start-up .............................................................. 18

PAGE 5OF 25

www.BioTector.com

2. Venturi Sampler

The Venturi Sampler has 2 possible build options, depending on its construction.

Build Option 1:

The Venturi Sampler can be designed to collect a pressurized sample liquid, reduce the pressure of this

liquid sample to ambient pressure, and supply this sample to the BioTector.

The Venturi Sampler also returns the spent sample back to the pressurised sample point.

Build Option 2:

The Venturi Sampler can be designed to collect a sample of liquid at ambient pressure, from a depth of

up to 7 meters (measured from the bottom of the sampler to the lowest liquid level in the sump, at sea

level), and supply this sample to the BioTector at ambient pressure. The vacuum used in the sampler is

generated with a Venturi pump.

The sampler also returns the spent sample back to the sample point.

Sensor Options:

The Venturi Sampler will have been supplied with one of the sensor options below:

1. Two capacitive level / liquid sensors supplied to detect the sample.

2. One ultrasonic level / liquid sensors supplied to detect the sample.

Systems built with an Ultrasonic sensor, the sensor is enabled on the PLC. Below table shows the

example block settings of a Venturi Sampler with enabled and disabled Ultrasonic Sensor.

Block No.

Block Description

Value

B231

Ultrasonic Sensor Enable

0 = Disabled

1 = Enabled

Utilities

Feed Air requirement: typically 6 bars, 50 LPM when venturi is running.

Purge air requirement, typically 100 LPM at 3.5 bars.

Air must be water, oil and dust free (-20°C dew point).

Wash water requirement: 3 bar with customer supplied regulator fitted.

Usage typical 10 liters per hour.

Water can be heated up to 90C if required for hot water backwash.

Note, blowback pressure for water and air must be 1.5 times the sample pressure.

For additional details, please see BioTector Venturi Sampler Technical Specifications.

PAGE 6OF 25

www.BioTector.com

3. Technical Specifications

BioTector Venturi Sampler

Technical Specifications

TYPICAL TECHNICAL DATA

PLC Enclosure: Polystyrene with glazed polycarbonate door

Dimensions (HxWxD): 2010mm x 390mm x 160mm

Weight: 20 kg –30 kg

Noise level: 50-70 dB(A) during filling and purging with short term noise 1 to 2

seconds in duration up to 90 dB(A) when pneumatic valves are

de-energized.

Power Consumption: 24 W (1 Amp 24V DC)

Control Wire Specification: Number of Cores = 6 cores, Current Rating minimum = 3 Amp, CSA

(Cross Sectional Area minimum) = 0.5mm2.

FEATURES IN DETAIL

Operation: PLC with Keyboard

Automatic no sample fill fault indication

Direct control from the BioTector through the 6 core cable

Sample chamber and sample line purge with air and water

Language Options: English (Other languages are available upon request.)

OPTIONAL FEATURES

Multi-stream: Valves for up to 6 streams

CONSUMABLES

Instrument Air: 6 bars

(50 liters/minute flow rate when venturi pump is running at 6bar)

(~100 liters/minute flow rate when venturi sampler is purging at 3.5bar)

Note: If using a standalone compressor please ensure it can continually

supply the above requirements, this may require up to 100% duty cycle.

Air Quality: -20°C dew point (free of water, oil and dust)

Water: 3 bars (~10 liters per hour at 3 bars)

Water can be heated up to 90°C for hot water backwash

Water regulator and/or water heater to be supplied by the user

Service: Typical 6 Monthly Intervals

SYSTEM PARAMETERS

Sample Chamber: PFA

Sample Volume: 70ml available to BioTector

Fittings and Valves: SS-316, EPDM, PTFE

Venturi Pump: SS-316

Sampler Sample Tubing: PFA (1/2” OD x 3/8” ID)

Cycle Time: Controlled by BioTector

PAGE 7OF 25

www.BioTector.com

SAMPLE & ENVIRONMENTAL CONDITIONS

Venturi Vacuum: 900 mbar (maximum)

Sample Lift: 7 meters (maximum, at sea level)

(Measured from the bottom of the sampler to the lowest liquid

level)

Sample Transport: See detailed data on the next page.

Note data refers to sample transport times at sea level

Sample Fill Time: See detailed data on the next page.

Note data refers to sample transport times at sea level

Sample Inlet Pressure: Ambient (for applications with high sample pressures up to 4

bars, alternative systems are available)

Pressure for air and water must be at least 1.5 times greater

than the sample inlet pressure.

Drain Pressure: Ambient (for applications with high drain pressure, alternative

systems are available)

Sample Inlet Temperature: 2°C –90°C (36°F - 194°F)

Sample Particle Size: Up to 2 mm, soft particulates

Ambient Temperature: 5°C –40°C

Humidity: 5% - 85%, non-condensing

PAGE 8OF 25

www.BioTector.com

4. Typical Operational Data

Build parameters.

First chamber volume: 70ml.

Second chamber volume: 270ml.

Sample tubing: ½” OD x 3/8” ID.

Sample distance, 40 meters, typical filling and purging times

Lift,

meters

Time for venturi

sampler to fill tubes

and chamber

Venturi filling time,

including pre-purge

times for 4 streams.

Add 8s for 6 streams.

Purge

time

Typical overall time,

including time for the

BioTector to inject the

sample and flush its lines.

0

40s

76s

90s

324s, 5m24s

2

49s

85s

90s

336s, 5m36s

4

59s

95s

90s

348s, 5m48s

6

83s

119s

90s

378s, 6m18s

7

122s

158s

90s

427s, 7m07s

Sample distance, 80 meters, typical filling and purging times.

Lift,

meters

Time for venturi

sampler to fill tubes

and chamber

Venturi filling time,

including pre-purge

times for 4 streams.

Add 8s for 6 streams.

Purge

time

Typical overall time,

including time for the

BioTector to inject the

sample and flush its lines.

0

124s

160s

120s

459s, 7m39s

2

145s

181s

120s

486s, 8m06s

4

179s

215s

120s

528s, 8m48s

6

255s

291s

120s

624s, 10m24s

7

345s

381s

120s

735s, 12m15s

Notes:

•The typical overall times above are also the minimum BioTector cycle time.

•It is essential that the tube slopes gently back to the sample point, dips and rises in the

sample tube increases the sample transport time.

•Any point of the sample tube must never be higher than 7 meters above the sample

point.

5. Manual Operation:

To manually fill the sampler, press the [A] key on the PLC for > 2 seconds. The PLC latches

this input, and this simulates the operation of the BioTectors SAMPLER FILL command.

To manually empty and purge the sampler, press the [B] key on the PLC for > 2 seconds. The

PLC latches this input, and this simulates the operation of the BioTectors SAMPLER EMPTY

command.

To reset the sampler at any time, press the [ESC] key.

PAGE 9OF 25

www.BioTector.com

6. Typical Operational sequences, Fill.

Operation: Fill

Default duration

(note that all times are

approximate, and will vary with

the specific application)

Sampler action

Note: If the air used for pressurizing the sampler is below its set point at any time, the samplers fault

output is activated.

BioTector gives fill command or

[A] key on the PLC is held down

for > 2 seconds.

1-2 seconds

No action taken for 1 second.

Purge stream valves with air

4 times 4 seconds

(6 times 4 seconds for 6 stream

option)

Open each stream inlet valve (if

fitted) for 4 seconds.

Close the valve to the venturi.

Open the purge air valve.

Purge the stream valve with

instrument air.

Purge sample chamber and line

with air.

20 seconds

Open the selected stream inlet

valve.

Close the valve to the venturi.

Open the purge air valve.

Purge the sample line with

instrument air.

Fill External Chamber*

0 seconds

Open the selected stream inlet

valve.

Open the venturi air valve.

Allow the External chamber to fill.

Settling Time*

0 seconds

No action

*Note: If a particulate separation chamber “External Chamber” option is being used at the sampling point

externally, Fill External Chamber & Settling Time timers will need to be adjusted according to the site

specific requirements.

Fill the sampler

100 seconds

Open the selected stream inlet

valve.

Open the venturi air valve.

Allow the sampler to fill.

Sampler full

N/A

Close the selected stream inlet

valve.

Deactivate the venturi pump.

There is also a timer which times

out even if the sampler is not full.

After the timer has timed out:

Open the valve to the BioTector.

If the sampler is not full when the

timer times out, an error is

generated.

Note: The sampler remains in the Sampler Full condition, until reset by an empty command from the

BioTector, or the [B] key on the PLC is held down for >2 seconds.

PAGE 10 OF 25

www.BioTector.com

7. Fill Timer Blocks in the Venturi Sampler PLC.

Block No.

Block Description

Default Value

Unit

B106

Timers used to control the purge sequence for up to 4 or 6

optional stream valves, for 4 and 6 stream venturi sampler

option.

ON: 40

OFF: 1

ms

B126

161 / 241

ms

B147

16 / 24

s

B148

Purge chamber and line prior to filling timer.

20

s

Note: Some applications may have a certain size particulate separation chamber “External Chamber”

option which gathers and settles the sample at the sampling point prior to the Venturi Sampler is filled

with the sample. In applications where this chamber is present, B170 & B172 are changed from the

default zero second value to the site specific values.

B170

External chamber fill time.

0

s

B172

External chamber settling time.

0

s

B155

This block serves two purposes:

1. There are liquid sensors to stop the Venturi fill sequence

once sample is detected. If no sample is detected within

the duration of this block the fill sequence is automatically

stopped and a fill error activated, this could be due to dry

stream etc. The BioTector Sample valve opens once this

timer elapses also.

To account for variations in the stream the duration of this

block should be longer (~40%) than the typical time taken

for the sensors to detect sample once the ‘Filling Sampler’

message appears on the PLC Display.

2. If the sample is successfully detected during this timer the

sample is allowed to settle while the timer elapses. If the

site conditions require some settling of the sample prior to

sampling by the BioTector then this timer can be extended

to accommodate this need.

100

s

Default FILL SEQUENCE TIME 4 Stream

136

s

Default FILL SEQUENCE TIME 6 Stream

144

s

Note: B126 not included in calculation of FILL SEQUENCE TIME

The SAMPLER time in the BioTectors SAMPLE PUMP menu must be greater than FILL SEQUENCE

TIME of the Venturi Sampler. The FILL SEQUENCE TIME in seconds can be found by pressing the [+]

key on the PLC while in Standby Mode. This will automatically adjust if times are changed from default

settings to show the new FILL SEQUENCE TIME.

In the default configuration the fill sequence of the Venturi sampler takes 136 seconds, this allows 100s

for the Venturi sampler to fill its tubes and chamber, (the other ~40 seconds being used for the initial

purge of the Venturi sampler). This configuration is suitable for sites with a 40m sample line and a lift up

to approximately 5 to 6 meters. Longer sample lines will require the default time in both the Venturi

samplers PLC and BioTector Sampler setting to be changed.

PAGE 11 OF 25

www.BioTector.com

8. Typical Operational sequences, Purge.

Operation: Purge

Default duration (note

that all times are

approximate, and will

vary with the specific

application)

Sampler action

Note: If the air used for pressurizing the sampler is below its set point at any time, the samplers fault

output is activated.

BioTector gives sample pump

reverse run command.

N//A

Open the valve to the BioTector.

The BioTectors sample pump runs in

reverse. The sample and reverse

cleaning acid are pumped back into

the sampler.

BioTector gives empty command,

or [B] key on the PLC is held down

for > 2 seconds.

5 seconds

Close the valve to the BioTector.

Purge sample chamber and line

with air.

10 seconds

Open the inlet valve.

Close the valve to the Venturi.

Open the purge air valve.

Purge the sample line with instrument

air.

Purge sample chamber and line

with air and water.

5 seconds

Open the inlet valve.

Close the valve to the Venturi.

Open the purge air valve.

Open the water valve.

Purge the sample line with instrument

air and water.

Purge the sample chamber and

line with water.

40 seconds

Open the inlet valve.

Close the valve to the Venturi.

Open the water valve.

Purge the sample line with water.

Purge the Venturi, sample chamber

and line with air and water.

5 seconds

Open the inlet valve.

Open the purge air valve.

Open the water valve, but only if the

counter has reached its set-point.

Open the Venturi air valve.

Purge the Venturi, sample chamber

and line with air and water.

Purge the Venturi, sample chamber

and line with air.

10 seconds

Open the inlet valve.

Open the purge air valve.

Purge the Venturi, sample chamber

and line with air.

Purge sample chamber and line

with air.

90 seconds

Open the inlet valve.

Close the valve to the Venturi.

Open the purge air valve.

Purge the sample line with instrument

air.

Standby.

N/A

Close the inlet valve. Open the drain

valve.

PAGE 12 OF 25

www.BioTector.com

9. Empty Timer Blocks in the Venturi Sampler PLC.

Block No.

Block Description

Default Value

Unit

B158

Wait until BioTector valve closes.

5

s

B161

Purge sampler with air.

10

s

B162

Purge sampler with air and water.

5

s

B167

Purge sampler with water.

40

s

B184

Purge Venturi and sampler with air and water.

5

s

B185

Purge Venturi and sample with air.

10

s

B186

Purge sampler / sample line with air.

90

s

Default SAMPLER EMPTY TIME 4 Stream

165

s

Default SAMPLER EMPTY TIME 6 Stream

195

s

The SAMPLER EMPTY TIME in seconds can be found by pressing the [-] key on the PLC while in

Standby Mode. This will automatically adjust if times are changed from default settings to show the new

SAMPLER EMPTY TIME.

It is important to note that the:

𝐹𝐼𝐿𝐿 𝑆𝐸𝑄𝑈𝐸𝑁𝐶𝐸 𝑇𝐼𝑀𝐸 + SAMPLER EMPTY TIME must be less than the BioTector Reaction Time

This is not an issue for default settings but for applications with long sample lines or large sample lifts

this time may exceed the BioTector Reaction Time and a REACTION DELAY will need to be added to

the BioTector.

10. Venturi Water Purge.

A counter (B133) is part of the software so that the Venturi does not have to be purged with water each

purge cycle. The default is 2 (i.e. purge with water every second cycle) but this can be changed if

required.

Block No.

Block Description

Default Value

B133

Water Wash Counter

2

11. Fault conditions.

To reset the fault on the sampler, press the [ESC] membrane keyboard switch on the sampler for >1

second.

Possible fault conditions:

1. Low purge instrument air pressure –check air pressure.

2. Sampler does not fill on time –check sample, Venturi and / or valves.

3. Sampler shows full when it is not full –confirm that the chamber next to the liquid detection

sensors is clean and dry.

PAGE 13 OF 25

www.BioTector.com

12. Programming the BioTector for use with the Venturi

Sampler.

Programming the BioTector to use a sampler is carried out in the Sample Pump menu.

First, ensure that the sampler has been selected in the system Configuration / System Setup menu.

Time for the fill command

In the Sample Pump menu, set the time for the sampler. This is typically 137s (FILL SEQUENCE TIME

+ 1 second) (145s for 6 stream option), and should not be changed unless the PLC timers have also

been changed.

The FILL SEQUENCE TIME in seconds can be found by pressing the [+] key on the PLC while in

Standby Mode. This will automatically adjust if times are changed from default settings to show the new

FILL SEQUENCE TIME.

Time for the sample pump forward.

If the Venturi Sampler is positioned close to the BioTector, then the BioTectors sample pump will require

around 40-50 seconds to transport the sample into the BioTector.

Time for the sample pump reverse.

The time for the sample pump reverse should be long enough to empty the BioTectors sample line of

sample and reverse wash cleaning fluid back into the sampler, typically this will be 50-60 seconds.

Time for the empty command.

The empty command is a 5 second pulse which is automatically generated when the sample pump

reverse stops.

13. Software Version.

The revision of software version loaded on the PLC can be found by viewing Block B232.

Block No.

Block Description

Default Value

B232

Software Version

xxxx

The first two digits are the Major Revision and the remaining two digits are the minor Revision.

For example 0503 = V5.03

PAGE 14 OF 25

www.BioTector.com

14. Programming the Venturi Samplers PLC.

Generally, no changes should be required, as the default fill time is sufficient for most applications.

To change the timers in the PLC:

1. Press the ESC and OK buttons on the PLC together.

2. Press OK to select the STOP command.

3. Press OK again to confirm the STOP command.

4. Press the –(down) key to select PARAMETERS. Press OK.

5. The display should show FBD:000, with the cursor is blinking on all the last three characters.

6. If FBD:000 is not selected, Press OK, and the three numbers will blink.

7. Select for example FBD:155 with the –and + keys, and press OK.

8. Press the –key to select the required time setting.

9. Press OK, and the numbers will blink.

10. With the –and + keys, select the time required for your application.

11. Press OK, and the cursor will blink on your setting.

12. Press ESC, and the cursor will blink on RUN.

13. Press the OK button twice, and then the ESC button to return to the M3 Vacuum Sampler

Standby screen.

15. To save modified program settings to the Memory

Card.

When the modification has been validated, the modified program must be stored to the Memory

Cartridge. Proceed as follows:

1. Press the ESC and OK buttons on the PLC together.

2. Press OK to select the STOP command.

3. Press OK again to confirm the STOP command.

4. Press the –(down) key to select MEMORY CARD. Press OK.

5. Select SAVE. Press OK.

6. Press OK again to confirm the SAVE command. Wait a few seconds while the SAVE

sequence runs.

7. Press OK, and the cursor will blink on RUN.

8. Press the OK button twice, and then the ESC button to return to the Venturi Driven Vacuum

Sampler Standby screen.

16. To restore original program settings from the Memory

Card or to upgrade Firmware.

If any modification you made to the program causes the sampler PLC to fail, the original program can

be downloaded from its Memory Cartridge. Proceed as follows:

1. Press the ESC and OK buttons on the PLC together.

2. Press OK to select the STOP command.

3. Press OK again to confirm the STOP command.

4. Press the –(down) key to select MEMORY CARD. Press OK.

5. Press the –key to select RESTORE. Press OK.

6. Press OK again to confirm the RESTORE command. Wait a few seconds while the

RESTORE sequence runs.

7. Press OK, and the cursor will blink on RUN.

8. Press the OK button twice, and then the ESC button to return to the Venturi Driven Vacuum

Sampler Standby screen.

PAGE 15 OF 25

www.BioTector.com

17. Six Month Maintenance on the Venturi Driven Vacuum

Sampler.

Confirm that the chamber is clean.

_____

Confirm that the Venturi pump is clean, and there is no build-up of lime-scale or other

material inside the Venturi pump. Clean the Venturi pump with appropriate cleaning agent

if necessary.

_____

Confirm that the air supply for the valves and air supply for the purge is at the correct

pressure. See section 3 for details.

_____

Confirm that the water pressure and temperature for the purge is at the correct pressure.

See section 3 for details.

_____

Confirm that the chamber is filling correctly.

_____

Confirm that the chamber is purging correctly.

_____

Confirm that the membrane valves are not leaking.

_____

Confirm that the valve isolating the Sampler from the BioTector is not leaking.

_____

Confirm the Venturi is detecting sample correctly.

_____

PAGE 16 OF 25

www.BioTector.com

18. Pressure ratings on the Venturi Driven Vacuum

Sampler.

The sampler has a working pressure of 6 bar.

The pressure ratings and / or test pressure of the individual items in the sampler are given below.

Item

Pressure rating

Data sheet or test

certificate attached

Pressure Chamber, first chamber.

Manufacturer Adtech / Scantube.

Material, PFA, ½” OD x 3/8” ID

23 bar working pressure

Data sheet

Pressure Chamber, second chamber.

Manufacturer Adtech / Scantube.

Material, PFA, 3/4” OD x 5/8” ID

16 bar working pressure

Data sheet

Air Purge valve.

Manufacturer Burkert.

Type 6013, 134233

12 bar

Data sheet

Venturi Air valve.

Manufacturer Burkert.

Type 6013, 134233

12 bar

Data sheet

Water Purge valve.

Manufacturer Burkert.

Type 6013, 134233

12 bar

Data sheet

Inlet valve.

Manufacture Burkert.

Type 2031, threads G1/4”, SS 1.4404 body,

EPDM diaphragm.

10 bar.

Data Sheet

BioTector sample valve.

Manufacture Burkert.

Type 2031, threads G1/4”, SS 1.4404 body,

EPDM diaphragm.

10 bar.

Data Sheet

Venturi valve.

Manufacture Burkert.

Type 2031, threads G1/4”, SS 1.4404 body,

EPDM diaphragm.

10 bar.

Data Sheet

The items listed below, while part of the overall sampler and not in direct contact with the pressure

sampler media, they are only in contact with the instrument air supply.

Air solenoid valve.

Manufacturer Norgern.

Type M/49

10 bar.

Note, connected to

instrument air supply

only, not directly to the

sampler.

Data Sheet.

Pressure regulator.

Manufacture Norgren.

Type R07-200-RNKG

20 bar.

Note, connected to

instrument air supply

only, not directly to the

sampler.

Data Sheet

Pressure switch.

Manufacturer Norgren.

Type 0880300, 0.5-8 bar.

30 bar

Data Sheet

PAGE 17 OF 25

www.BioTector.com

BioTector Analytical Systems Limited

Raffeen House, Ringaskiddy, Co. Cork, Ireland.

Tel +353 21 4374237 Fax +353 21 4374236

e-mail: info@biotector.com

19. Test Certificate

Test Certificate

Item: Venturi Sampler

Manufacturer: BioTector Analytical Systems Ltd.

Address: Raffeen House,

Ringaskiddy,

Co. Cork,

Ireland.

Design Pressure: 10 bar.

Working Pressure: 6 bar.

PAGE 18 OF 25

www.BioTector.com

20. Venturi Sampler Commissioning and Start-up

The check list below must be used to ensure that the installation has been properly carried out. Please

proceed through the check list in the given order.

The check list refers to the standard Venturi sampler.

Bolt the Venturi Sampler to a wall ideally within 1 meter of the BioTectors sample in port.

Venturi sampler cannot be exposed to the direct sunlight and needs to be protected from rain.

Connect the Venturi Sampler to earth (ground).

_____

_____

Connect the sample tube from the sample point to the Venturi Sampler using the supplied ½”

OD tube. It is important that this tube is installed so that it falls gradually to the sample point.

The tube should have no sharp bends, and should not rise above the level of the bottom of

the Venturi Sampler at any point.

The sample point should be installed using the typical sample point installation drawing (as

attached to the last page of this document) for guidance, or if supplied a site specific

installation drawing.

The photograph below shows the sample inlet connections on a typical 2-stream venturi

sampler.

_____

Stream 2

Stream 1

PAGE 19 OF 25

www.BioTector.com

Connect the outlet from the Venturi pump to a pressure free drain using ½” OD PFA tube or

similar. CAUTION: This should be outside any enclosure or house, as the liquid discharged to

this drain in abnormal conditions can result in the discharge of the customers sample to this

drain which could potentially be hot and corrosive.

_____

Connect the air supply to the Venturi Sampler. The typical connection is ¼” Swagelok.

The air for the venturi pump is typically set to 5 bar. It has been found that 5 bar is the

optimum pressure for generating the best vacuum in the venturi sampler. Using a higher

pressure will not generate a higher vacuum.

The air for the purge is typically set to 3.5 –4 bar. This pressure must always be greater than

the water pressure. If it is lower than the water pressure, then water can feed into the air line.

_____

Venturi pump

outlet

Venturi air, 5 bar

Air

connection

Purge air, 3.5-4 bar

PAGE 20 OF 25

www.BioTector.com

Connect the water supply to the Venturi Sampler. The connection is ¼” Swagelok.

The water pressure is typically set to a maximum of 3 bar. The pressure must always be

lower than the purge air pressure. If it is higher than the purge air pressure, then water can

feed into the air line.

_____

In cases where there is sticky or fatty material in the sample, it may be necessary to use hot

water to backwash the venturi sampler.

_____

Connect the sample tube (or tubes) from the Venturi Sampler to the BioTector in accordance

with the supplied drawing package.

_____

If a particulate separation chamber “External Chamber” option is supplied, install the chamber

at the sampling point.

_____

Electrically connect the Venturi Sampler to the BioTector with the supplied cable, in

accordance with the supplied drawing package.

_____

Check the electrical connections and confirm there are no loose connections within the Venturi

Sampler.

_____

Check the Swagelok / PFA tube connections and confirm there are no loose connections within

the Venturi Sampler.

_____

Water connection

Water pressure

set to 3 bar

maximum using

customer

supplied water

regulator

BioTector

connection,

¼” OD tube

This manual suits for next models

4

Table of contents