Bird Electronic Econoload 8730A User manual

INSTRUCTION BOOK

ECONOLOAD®LOAD RESISTOR

SERIES 8730

INCLUDING MODELS 8730A, 8731

8732A, AND 8738A

©Copyright 2005 by Bird Electronic Corporation

Instruction Book P/N 920-8730S Rev. C

Econoload®and Termaline®are Registered

Trademarks of Bird Electronic Corporation

This Page Intentionally Left Blank

i

Safety Precautions

The following are general safety precautions that are not necessarily

related to any specific part or procedure and do not necessarily appear

elsewhere in this publication. These precautions must be thoroughly

understood and applied to all phases of operation and maintenance.

Keep Away From Live Circuits

Operating personnel must at all times observe normal safety regulations.

Do not replace components or make adjustments inside the equipment

with high voltage turned on. To avoid casualties, always remove power.

Shock Hazard

Do not remove the RF transmission line while RF power is present.

Do Not Service Or Adjust Alone

Under no circumstances should any personnel reach into an enclosure for

the purpose of service or adjustment of equipment except in the presence

of someone who is capable of rendering aid.

Safety Earth Ground

An uninterruptible earth safety ground must be supplied from the main

power source to test instruments. Grounding one conductor of a two

conductor power cable is not sufficient protection. Serious injury or death

can occur if this grounding is not properly supplied.

Chemical Hazard

Dry cleaning solvents for cleaning parts may be potentially dangerous.

Avoid inhalation of fumes or prolonged contact with skin.

Coolant may contain ethylene glycol. Avoid ingestion, inhaling of vapors

and eye and skin contact.

Resuscitation

Personnel working with or near high voltages should be familiar with

modern methods of resuscitation.

Bird 8730 Series Econoload RF Load Resistor

ii

Safety Symbols

NOTE: Calls attention to supplemental information.

Warning Statements

The following safety warnings appear in the text whenever the equipment

is in danger of damage and are shown here for emphasis.

WARNING

Warning notes call attention to a procedure, which if not correctly

performed could result in personal injury.

CAUTION

Caution notes call attention to a procedure, which if not correctly

performed could result in damage to the instrument.

This symbol indicates that a shock hazard exists if the

precautions in the instruction manual are not followed.

The caution symbol appears on the equipment indicating

there is important information in the instruction manual

regarding that particular area.

This symbol indicates that the unit radiates heat and

should not be touched while hot.

WARNING

Disconnect the unit from all power sources before servicing.

The unit may be energized from multiple sources.

The potential for electric shock exists.

WARNING

Improper wiring could result in electric shock and death.

WARNING

If the resistor breaks, there may be splinters or sharp pieces inside the

load housing. Be careful when repairing to avoid being cut.

WARNING

Never attempt to connect or disconnect RF equipment from the

transmission line while RF power is being applied.

Leaking RF energy is a potential health hazard.

iii

Caution Statements

The following equipment cautions appear in the text whenever the

equipment is in danger of damage and are shown here for emphasis.

CAUTION

Incorrect hose connections will reverse coolant flow and

could destroy the load.

CAUTION

Different control systems are used for 115 Vac and 230 Vac. Use the

correct interlock control for your voltage.

CAUTION

If installed, connect optional interlock before applying RF power.

CAUTION

Do not interrupt coolant supply. Even momentary

application of RF power while coolant is not circulating could

cause immediate destruction of the load

CAUTION

Do not remove the resistor plug. Any attempt to do so will cause

leakage and resistor damage.

Bird 8730 Series Econoload RF Load Resistor

iv

Safety Statements

USAGE

ANY USE OF THIS INSTRUMENT IN A MANNER NOT

SPECIFIED BY THE MANUFACTURER MAY IMPAIR THE

INSTRUMENT’S SAFETY PROTECTION.

USO

EL USO DE ESTE INSTRUMENTO DE MANERA NO ESPECIFICADA

POR EL FABRICANTE, PUEDE ANULAR LA PROTECCIÓN DE

SEGURIDAD DEL INSTRUMENTO.

BENUTZUNG

WIRD DAS GERÄT AUF ANDERE WEISE VERWENDET ALS VOM

HERSTELLER BESCHRIEBEN, KANN DIE GERÄTESICHERHEIT

BEEINTRÄCHTIGT WERDEN.

UTILISATION

TOUTE UTILISATION DE CET INSTRUMENT QUI N’EST PAS

EXPLICITEMENT PRÉVUE PAR LE FABRICANT PEUT

ENDOMMAGER LE DISPOSITIF DE PROTECTION DE

L’INSTRUMENT.

IMPIEGO

QUALORA QUESTO STRUMENTO VENISSE UTILIZZATO IN MODO

DIVERSO DA COME SPECIFICATO DAL PRODUTTORE LA

PROZIONE DI SICUREZZA POTREBBE VENIRNE COMPROMESSA.

SERVICE

SERVICING INSTRUCTIONS ARE FOR USE BY SERVICE -

TRAINED PERSONNEL ONLY. TO AVOID DANGEROUS

ELECTRIC SHOCK, DO NOT PERFORM ANY SERVICING UNLESS

QUALIFIED TO DO SO.

SERVICIO

LAS INSTRUCCIONES DE SERVICIO SON PARA USO EXCLUSIVO

DEL PERSONAL DE SERVICIO CAPACITADO. PARA EVITAR EL

PELIGRO DE DESCARGAS ELÉCTRICAS, NO REALICE NINGÚN

SERVICIO A MENOS QUE ESTÉ CAPACITADO PARA HACERIO.

v

WARTUNG

ANWEISUNGEN FÜR DIE WARTUNG DES GERÄTES GELTEN NUR

FÜR GESCHULTES FACHPERSONAL.

ZUR VERMEIDUNG GEFÄHRLICHE, ELEKTRISCHE SCHOCKS,

SIND WARTUNGSARBEITEN AUSSCHLIEßLICH VON

QUALIFIZIERTEM SERVICEPERSONAL DURCHZUFÜHREN.

ENTRENTIEN

L’EMPLOI DES INSTRUCTIONS D’ENTRETIEN DOIT ÊTRE

RÉSERVÉ AU PERSONNEL FORMÉ AUX OPÉRATIONS

D’ENTRETIEN. POUR PRÉVENIR UN CHOC ÉLECTRIQUE

DANGEREUX, NE PAS EFFECTUER D’ENTRETIEN SI L’ON N’A PAS

ÉTÉ QUALIFIÉ POUR CE FAIRE.

ASSISTENZA TECNICA

LE ISTRUZIONI RELATIVE ALL’ASSISTENZA SONO PREVISTE

ESCLUSIVAMENTE PER IL PERSONALE OPPORTUNAMENTE

ADDESTRATO. PER EVITARE PERICOLOSE SCOSSE ELETTRICHE

NON EFFETTUARRE ALCUNA RIPARAZIONE A MENO CHE

QUALIFICATI A FARLA.

CONNECT INTERLOCK TO TRANSMITTER/GENERATOR/

AMPLIFIER BEFORE OPERATING.

BRANCHER LE VERROUILLAGE À L’ÉMETTEUR/

GÉNÉRATEUR/AMPLIFICATEUR AVANT EMPLOI.

CONECTE EL INTERBLOQUEO AL TRANSMISOR/GENERADOR/

AMPLIFICADOR ANTES DE LA OPERACION.

VOR INBETRIEBNAHME VERRIEGELUNG AM SENDER/

GENERATOR/VERSTÄRKER ANSCHLIESSEN.

PRIMA DI METTERE IN FUNZIONE L’APPARECCHIO, COLLEGARE

IL DISPOSITIVO DI BLOCCO AL TRASMETTITORE/GENERATORE/

AMPLIFICATORE.

Bird 8730 Series Econoload RF Load Resistor

vi

About This Manual

This manual covers the Bird 8730A, 8731, 8732A, and 8738A Econoload

RF Load Resistor.

This instruction book is arranged so that essential information on safety

is in the front of the book. Reading the Safety Precautions before operat-

ing the equipment is strongly advised. The remainder of this instruction

book is divided into Chapters and Sections.

Operation

First time operators should read Chapter 1 - Introduction, and Chapter 3

- Installation, to get an overview of equipment capabilities and how to

install it. An experienced operator can refer to Chapter 4 - Operating

Instructions. All instructions necessary to operate the equipment are

contained in this chapter.

Maintenance

All personnel should be familiar with preventative maintenance found in

Chapter 5 - Maintenance. If a failure should occur, the troubleshooting

section will aid in isolating and repairing the failure. Parts lists and

repair instructions are also in this chapter.

Changes To The Manual

We have made every effort to ensure this manual is accurate at the time

of publication. If you should discover any errors or if you have suggestions

for improving this manual, please send your comment to our factory. This

manual may be periodically updated. When inquiring about updates to

this manual, refer to the part number and revision level on the title page.

Naming Conventions

The following terms will be used throughout this manual to refer to

certain components of the Econoload:

Econoload or Load: The entire unit. It contains the RESISTOR.

Resistor: A subcomponent of the LOAD. This is the ceramic resistor

which actually absorbs the RF power.

vii

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Items Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Optional Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Theory Of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Resistor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Optional Flow Interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Optional Thermal Interlock (8732A Only) . . . . . . . . . . . . . . . . . 3

Calorimetry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . 5

DC Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Coolant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Interlock (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Thermoswitch (8732A Only) (Optional). . . . . . . . . . . . . . . . . . . . . 8

Connecting RF Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation without Interlock . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Normal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Emergency Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation with the Optional Interlock . . . . . . . . . . . . . . . . . . . . . 12

Shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Emergency Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

viii

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

DC Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Flow Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Time Delay Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Safety Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Resistor Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Resistor Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Resistor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Conductor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Preparation for Storage or Shipment . . . . . . . . . . . . . . . . . . . . . . 20

Customer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Bird 8730A, 8732A, and 8738A . . . . . . . . . . . . . . . . . . . . . . . 22

Bird 8731 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Interlock (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1

Chapter 1 Introduction

Bird 8730 Series Econoloads are compact, nonradiating, low reflection

terminations for medium power RF lines. They dissipate up to 10 kW

with a VSWR of less than 1.1:1 from 1 kHz to 1000 MHz.

Features yUseable with CW, AM, FM, SSB, and TV modulation, and certain

pulse types. Contact Bird Electronic Corporation for information

on using Econoloads with pulsed signals.

yMake precise, calorimetric measurements by using an Econoload

with a Bird 6085 Calorimeter.

yDesigned for easy field repair of all components.

Items Supplied yLoad, Water-cooled

yInstruction Manual

Optional Items yControl system with red pilot light that turns on when the load is

working properly. Also has flow switch and 12 second time delay

interlock to ensure steady coolant flow before RF power is applied.

Bird 8730 Series Econoload RF Load Resistor

2

Figure 1

8730 Series

Econoload Outline

Drawing

TERMALINE®

ECONOLOAD®

2.5"

(

64 mm

)

12"

(305 mm)

Depends On

Connector

Depends On

Connector

Water

Outpu

t

Water

Input

3

Chapter 2 Theory Of Operation

Resistor Bird 8730 Series Econoloads consist of a thin-film-on-ceramic resistor

immersed in externally-supplied coolant. The coolant flows directly

over the resistor instead of using an intermediate heat transfer

system, reducing the load size to a minimum. After passing over the

entire length of the resistor, the coolant leaves the load and can

either be discarded or cooled in a heat exchanger and reused.

Coolant The load’s electrical and thermal performance is reduced by

impurities or chemical additives in the coolant, especially ones which

are deposited as scale on the resistor. This may cause the load to

overheat and fail. Salt water will have a similar effect and should not

be used. For recommended coolant, refer to “Coolant” on page 6 and to

“Specifications” on page 21.

Optional

Flow Interlock

A minimum coolant flow of four galons per minute is required at all

times to dissipate the heat from RF power. When the flow rate drops

below this point, the flow switch opens causing immediate

transmitter shutdown. The flow switch is a “normally open” type, and

is closed during normal operation.

After flow is restored, a time delay switch keeps the interlock open for

an additional 12 seconds. This ensures proper operation of the cooling

system before applying RF power, preventing resistor burnout.

Optional Thermal

Interlock

(8732A Only)

The 8732A can be supplied with an optional passive overtemperature

thermoswitch. Normally closed, it opens at a preset temperature,

turning off transmitter power. The temperature setting is preset at

the factor for either 72 or 79 °C (162 or 175 °F). The interlock system

will not permit use of the transmitter until the load has reached a

safe temperature.

Bird 8730 Series Econoload RF Load Resistor

4

Calorimetry Almost all the RF power in the load is transferred to the coolant as

heat. There is no heat transfer to the outer housing of the load,

leaving it at ambient temperature even at full power. The flow rate,

and the difference between the input and output coolant

temperatures, can be used to calculate the power dissipated in the

load with the following formula:

where

P = Power in kilowatts

k = 0.263 for temperature in °C, 0.146 for temp. in °F

Tout = Water temperature at the output of the load

Tin = Water temperature at the input to the load.

F = Water flow rate in gallons per minute

NOTE: This calculation is performed automatically in the Bird

6085 Calorimeter.

P = k ×(Tout – Tin) ×F

5

Chapter 3 Installation

This chapter provides information on site requirements, unpacking,

inspection, and preparing the Bird 8730 Series Econoload for use.

Unpacking and

Inspection

1. Carefully inspect the shipping container for signs of damage. If

damage is noticed, do not unpack the unit. Immediately notify the

shipping carrier and Bird Electronic Corporation.

2. If the container is not damaged, unpack the unit. Save the packing

materials in case the unit should need to be shipped again.

3. Inspect all of the components for visible signs of damage.

Immediately notify the shipping carrier and Bird Electronic

Corporation of equipment damage or missing parts.

DC Resistance Before first using the load, get a resistance baseline for future

maintenance. Refer to “DC Resistance” on page 14 for instructions.

Placement yDo not use outdoors or in areas of condensing humidity.

yVentilation or buffer space is not required. The Econoload may be

placed in very small spaces.

yThe load may be mounted in any position. Rotate the load so that

the warning label is visible and the water connections are easily

accessible.

yAccess to a coolant supply or pump is required. Make sure the

coolant supply can meet the required flow rate.

yTo use the optional interlock, AC power is required.

Bird 8730 Series Econoload RF Load Resistor

6

Coolant

For operation at 1kHz or lower, use only distilled water as the

coolant. For operation above 1kHz use distilled or potable water.

Refer to the specifications for the definition of potable water. If the

water quality is doubtful, use distilled water.

Hoses

The Econoload is supplied with standard 3/4” hose fittings. For rigid

piping, replace the hose adapters with 1/2” male pipe fittings. If the

optional flow switch is installed, it is attached to the water INPUT.

yThe Econoload’s water INPUT is located in the center of the back

of the load. Connect the coolant supply to the load’s INPUT.

Secure with hose clamps.

yThe Econoload’s water OUTPUT is on the rear side of the load, at

a 90° angle to the INPUT. Connect the coolant drain to the load’s

OUTPUT. Secure with hose clamps.

CAUTION

Incorrect hose connections will reverse coolant flow and

could destroy the load.

Installation

7

Interlock (Optional)

The interlock control box has four 1/4” mounting holes in a 5” x 5”

(127 x 127 mm) square. Mount it where the safety light will be clearly

visible. Wire the control box as follows (refer to Figure 2):

yConnect the flow switch leads to terminals 3 and 5.

yConnect the transmitter interlock to terminals 6 and 7.

yConnect the ac power source to terminals 2 and 3, making sure

that ac common is connected to terminal 2.

WARNING

Disconnect the unit from all power sources before servicing.

The unit may be energized from multiple sources.

The potential for electric shock exists.

WARNING

Improper wiring could result in electric shock and death.

CAUTION

If installed, connect optional interlock before applying RF power.

CAUTION

Different control systems are used for 115 Vac and 230 Vac. Use the

correct interlock control for your voltage.

Figure 2

Interlock

Connections

Flow Interlock Control

Trans.

Interlock

AC

Input

Common

WHITE

WHITE

BLACK

BLACK

YEL/WHT BLK/WHT

BLUE

ORANGE

VIOLET

GREY

Time Delay

Relay (NO)

12 sec.

Flow Switch (NO)

Red Lamp

1 2 3456 7

Bird 8730 Series Econoload RF Load Resistor

8

Thermoswitch (8732A Only) (Optional)

The 8732A, only, can be equipped with an optional interlock

thermoswitch, P/N 2450-095-x. To install or replace this:

1. Stand the unit with the water connectors up to prevent spills.

2. Remove the water outlet connector.

3. Replace the connector with the thermoswitch. Sparingly apply

pipe sealing compound to the external threads, only, of the

thermoswitch. Do not contaminate the coolant with pipe sealant.

4. Check for coolant leaks upon completion.

Connect the thermoswitch to the interlock as follows (see Figure 3):

1. Unscrew the large knurled ring-nut [A] at the lower end of the

coupling jack assembly. Pull it off the thermoswitch jack [B].

Unscrew the small knurled cover fitting from the base plug [D] of

the connector to release the base.

2. Thread the control switch wires through the clamp [E] with the

washers [F] inside and its threaded fitting in place. Use short tips

on the wires and put spaghetti sleeves over the ends if necessary.

3. Solder the switch leads to the lugs [G] of the connector base.

NOTE: The ring-nut [A] must be in place over the base plug [G]

with the knurled end facing out.

4. Screw on the cover ring, then fasten the cable clamp [E] in place

and tighten both yoke screws [H].

5. Put the plug back on the thermoswitch and tighten the nut [A].

CAUTION

If installed, connect optional interlock before applying RF power.

Figure 3

Thermoswitch

Assembly

Installation

9

Connecting RF Power

After installing the Econoload, the RF transmission line can be

attached using standard coaxial line coupling kits.

Swivel Flanged Coupling: To couple the swivel flange with a flanged

RF transmission line, use an appropriate coupling kit. Refer to

Figure 4 while following the instructions below:

yInsert the center bullet and push it in until it is fully seated.

yConnect the coaxial input in a straight line and push carefully on

the center conductor to close.

NOTE: The swivel flange on the load makes connection

independent of the orientation of the fixed flange on the coaxial

input outer conductor.

yInsert the bolt sets and tighten evenly all around to transmission

line manufacturer’s recommended torque. Use all of the bolts.

WARNING

Never attempt to connect or disconnect RF equipment from the

transmission line while RF power is being applied.

Leaking RF energy is a potential health hazard.

Figure 4

Swivel Flanged

Coupling

B

O

LT BULLET L

O

ADRF

CO

AXIAL LINE

Bird 8730 Series Econoload RF Load Resistor

10

Unflanged Coupling: To couple the unflanged connector with an

unflanged RF line, use an appropriate coupling kit. Refer to Figure 5

while following the instructions below:

yInsert the center bullet and bottom it on the midpoint nibs.

yPosition the outer sleeve, with clamping bands, over the input

connector.

ySet the transmission line snugly against the coupling stops.

yPosition the clamping bands evenly about 3/4” from the ends of

the sleeve.

yTighten the clamping bands.

Figure 5

Unflanged

Coupling

RF

CO

AXIAL

LINE

C

LAMPIN

G

BANDS

CO

NNE

C

T

O

R

SLEEVE

BULLET

L

O

AD

This manual suits for next models

4

Table of contents

Popular Industrial Electrical manuals by other brands

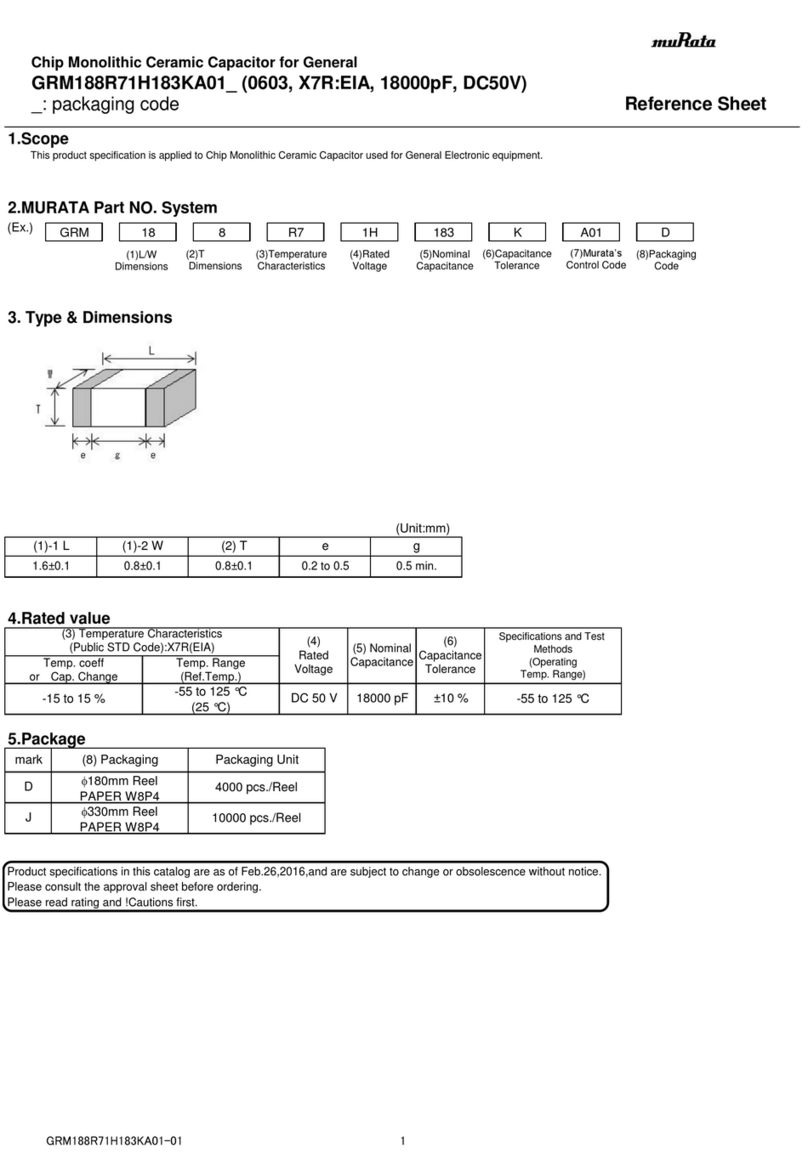

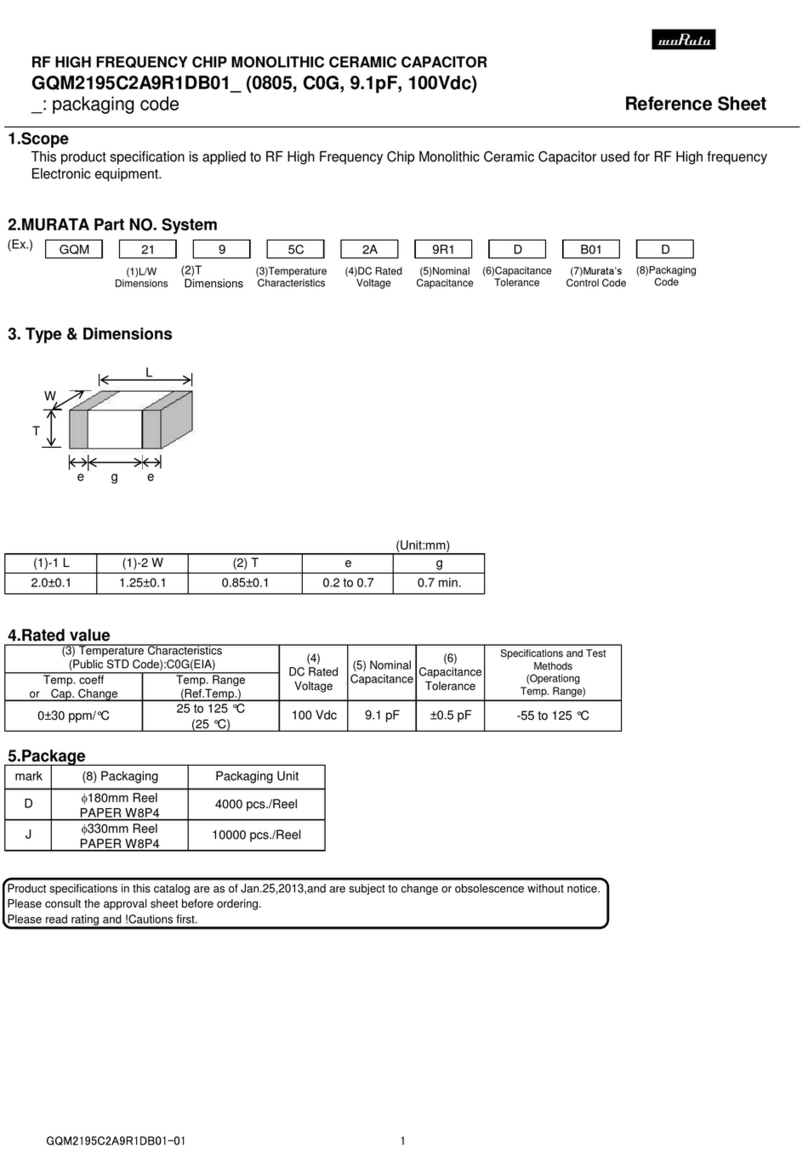

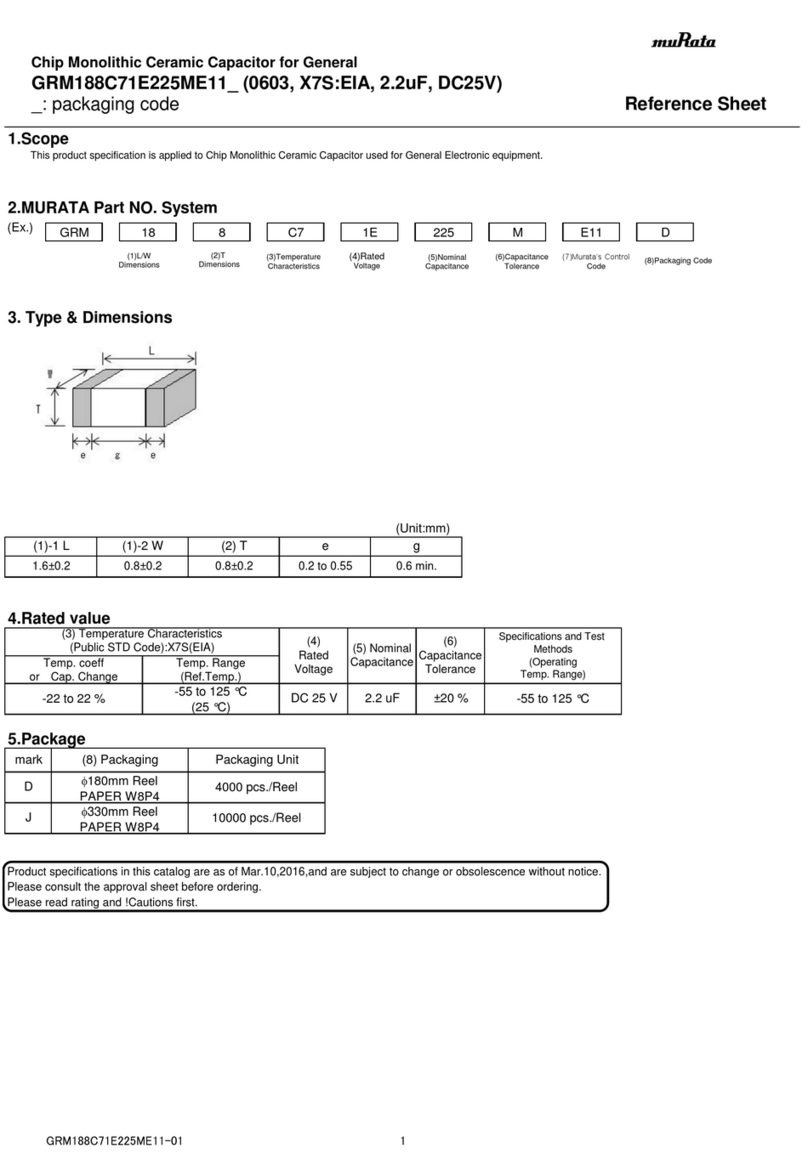

Murata

Murata GRM022R60J103KE19 Series Reference sheet

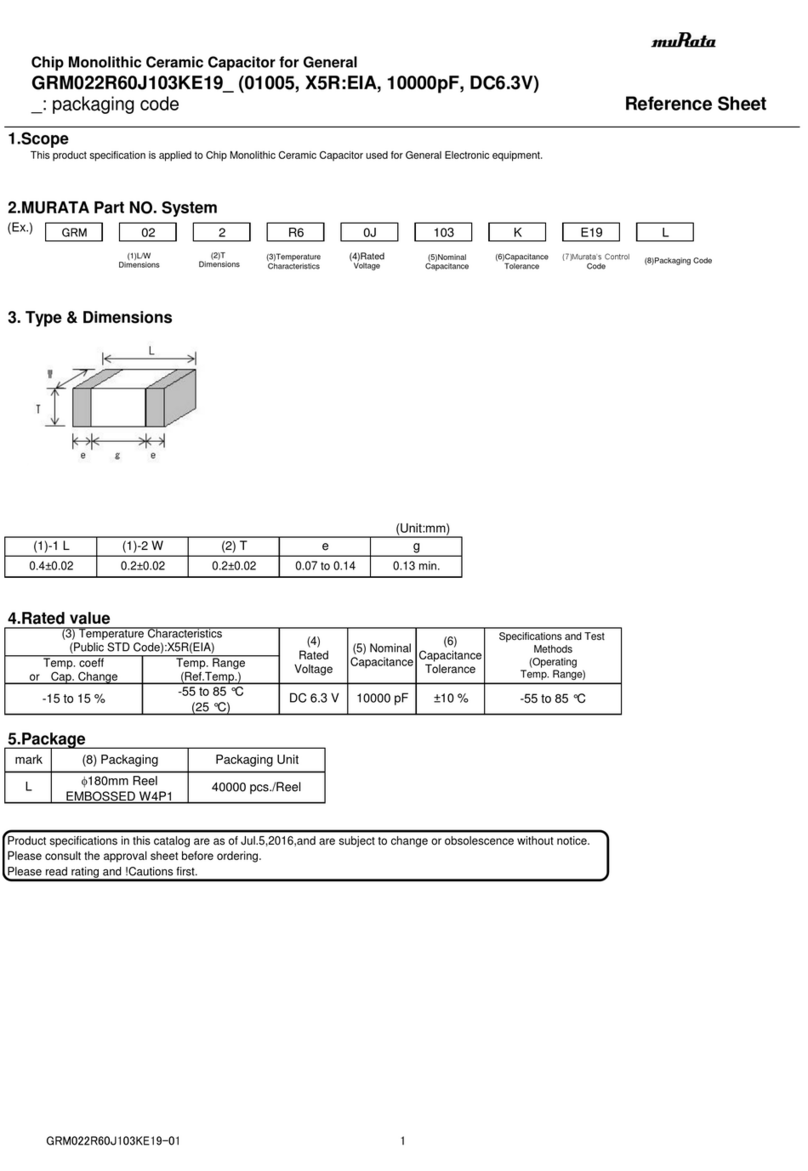

Murata

Murata GCM188R71H333JA55 Series Reference sheet

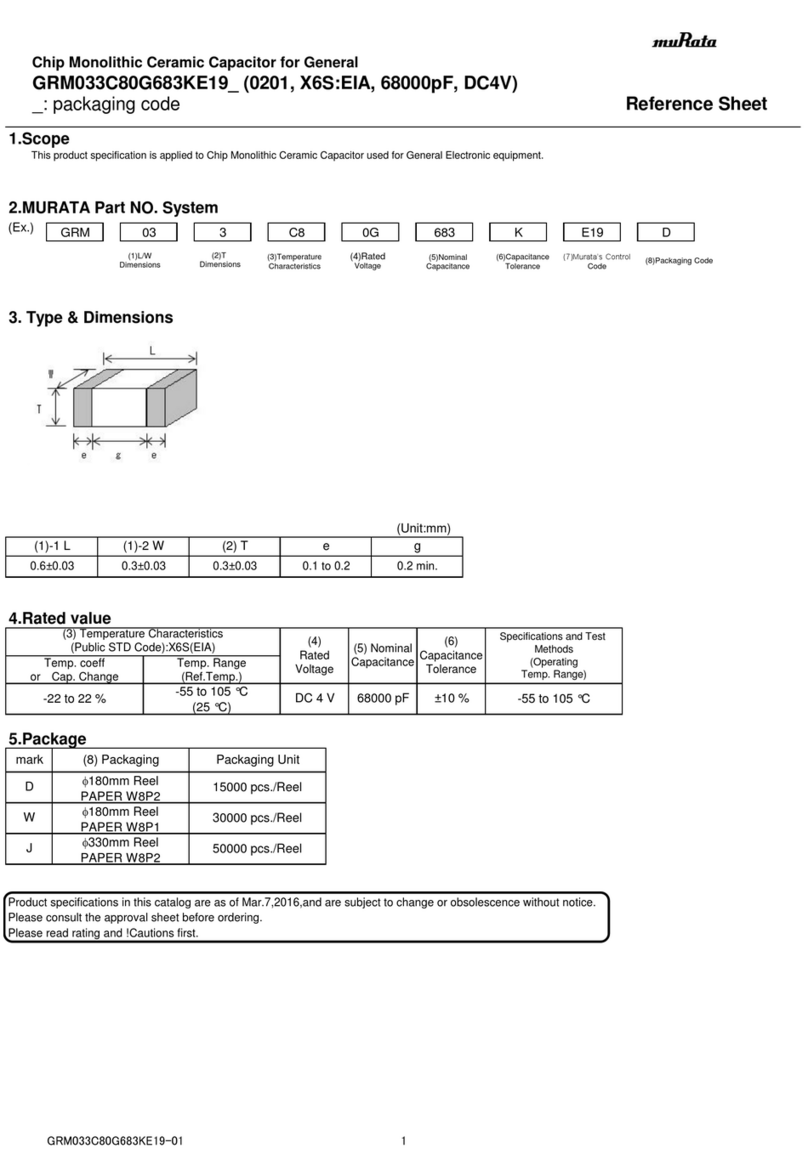

Murata

Murata GRM033C80G683KE19 Series Reference sheet

Murata

Murata GQM2195C2A9R1DB01 Series Reference sheet

Murata

Murata GRM1885C1H181JA01 Series Reference sheet

Murata

Murata GRM188C71E225ME11 Series Reference sheet