Blast-It-All LITTLE BLASTER User manual

BLAST-IT-ALL®

LEADING THE INDUSTRY IN

SURFACE PREPARATION

EQUIPMENT

HESS & ASSOCIATES, INC.

185 Piper Ln.

Salisbury, NC 28147

(800) 535-2612

LIVE CHAT- www.blast-it-all.com

LITTLE BLASTER™

w/ DUST COLLECTOR

LB4024 / LB4824

MANUAL DOWNLOAD

www.blast-it-all.com

** WARNING **

DO NOT USE SAND. SAND WILL CAUSE SILICA DUST, WHICH IS

THE CAUSE OF SILICOSIS DISEASE, A CONDITION OF MASSIVE

FIBROSIS OF THE LUNGS. THIS STATEMENT INDICATES A

POTENTIAL PERSONNEL HAZARD. FAILURE TO COMPLY WITH

THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

© 2020 Hess & Associates

Man. # 561 v02-02 8/2020

Table of Contents

SAFETY .......................................................................................................................................................... 1

OSHA FACT SHEET ................................................................................................................................. 3

INSTALATION : .............................................................................................................................................. 7

LITTLE BLASTER w/CARTRIDGE DUST COLLECTOR .................................................................................... 7

Little Blaster™ AIR CONTROLS................................................................................................................... 8

OPERATION................................................................................................................................................. 11

Little Blaster™......................................................................................................................................... 11

Little Blaster™ CARTRIDGE DUST COLLECTOR.........................................................................................12

TROUBLSHOOTING ..................................................................................................................................... 14

MAINTENANCE ........................................................................................................................................... 15

VENTURI BLAST GUN TUNING :...............................................................................................................16

PARTS :........................................................................................................................................................17

Little Blaster™ BLAST GUN ASSEMBLY PARTS.........................................................................................17

Little Blaster™ STANDARD CABINET PARTS ............................................................................................18

Little Blaster™ LIGHT BOX PARTS............................................................................................................ 19

Little Blaster™ MACHINE AIR CONTROL PARTS.......................................................................................20

Little Blaster™ CARTRIDGE DUST COLLECTOR PARTS .............................................................................21

Little Blaster™ RECOMMENDED CONSUMABLE/SPARE PARTS ..............................................................22

ELECTRICAL .................................................................................................................................................23

Little Blaster™ Electrical Diagram........................................................................................................... 23

WARRANTY................................................................................................................................................. 24

VENTURI BLAST DATA ................................................................................................................................25

INDEX .......................................................................................................................................................... 26

© 2020 Hess & Associates

Man. # 561 v02-02 8/2020

SAFETY

1. DO NOT USE SAND SAND WILL CAUSE SILICA DUST,

WHICH IS THE CAUSE OF SILICOSIS DISEASE, A

CONDITION OF MASSIVE FIBROSIS OF THE LUNGS. THIS

STATEMENT INDICATES A POTENTIAL PERSONNEL

HAZARD. FAILURE TO COMPLY WITH THESE

INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

2. (COLLECTED DUST)THE CUSTOMER (END USER) ASSUMES THE

RESPONSIBILITY FOR CONTACTING THEIR INSURANCE UNDERWRITER

AND ADVISING HESS AND ASSOCIATES, INC. IN REGARD TO SPECIFIC

APPLICATION REQUIREMENTS OF EXPLOSION VENTING OR IF

ADDITIONAL FIRE PROTECTION AND SAFETY EQUIPMENT MAY BE

REQUIRED. THE BUYER (END USER) IS ALSO CAUTIONED TO ADHERE

TO PRESCRIBED OSHA, NFPA, FEDERAL, STATE, AND LOCAL CODES

AND REGULATIONS APPLICABLE TO INDUSTRIAL VENTILATION

SYSTEMS, WHICH HESS AND ASSOCIATES, INC. EQUIPMENT MAY BE

APPLIED ON.

3. HEARING PROTECTION IS RECOMMENDED WHILE OPERATING

MACHINE

4. EYE PROTECTION IS RECOMMENDED WHILE OPERATING MACHINE

5. PROTECTIVE FOOTWEAR IS RECOMMENDED WHILE OPERATING

MACHINE

6. Machine MUST be properly Grounded

*** READ ENTIRE MANUAL BEFORE

INSTALATION/OPERATING EQUIPMENT ***

© 2020 Hess & Associates

Man. # 561 v02-02 8/2020

Page 1

SAFETY (cont’d)

7. Use CAUTION when interacting with any Electrical Components. You

MUST incorporate Lock Out / Tag Out Procedures Prior to Servicing

Equipment.

8. Gun MUST ALWAYS be pointed away from the Operator and

Towards the item being processed.

9. NEVER Blast with ANY Doors OPEN. NO ONE Should be in Front of

the Operating Station at the Front of the Blast Cabinet while Loading

or Unloading Parts.

DO NOT OPEN ANY DOOR WHILE THE MACHINE IS IN OPERATION

10. DO NOT CONNECT TO HIGH PRESSURE BOTTLE GAS, RUPTURE

AND/OR EXPLOSION CAN OCCUR.

© 2020 Hess & Associates

Man. # 561 v02-02 8/2020

Page 2

FactSheet

Protecting Workers from the Hazards of

Abrasive Blasting Materials

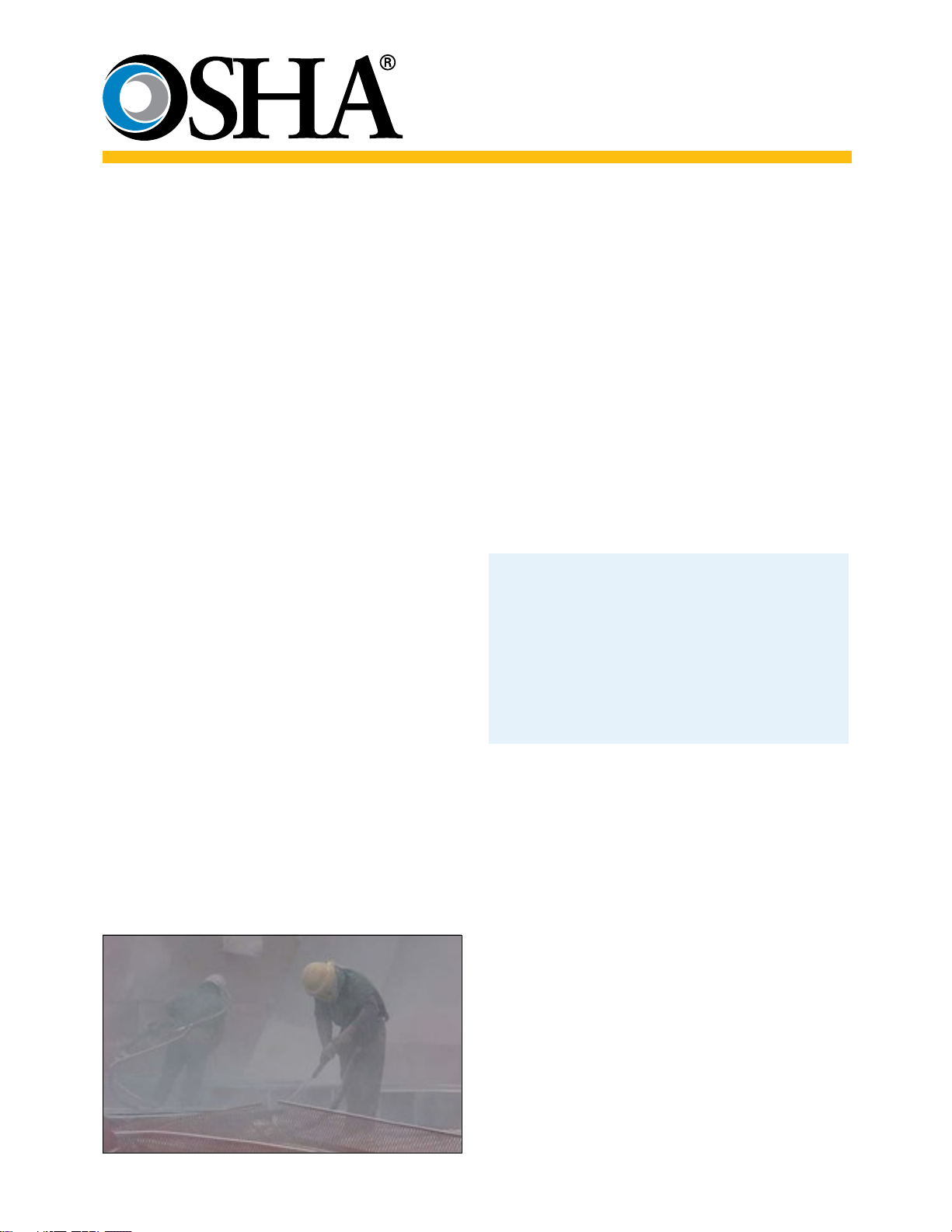

Abrasive blasting uses compressed air or water to direct a high velocity stream of

an abrasive material to clean an object or surface, remove burrs, apply a texture, or

prepare a surface for the application of paint or other type of coating. Employers

must protect workers from hazardous dust levels and toxic metals that may be

generated from both the blasting material and the underlying substrate and coatings

being blasted. This fact sheet provides information on abrasive blasting material,

health hazards, and methods to protect workers.

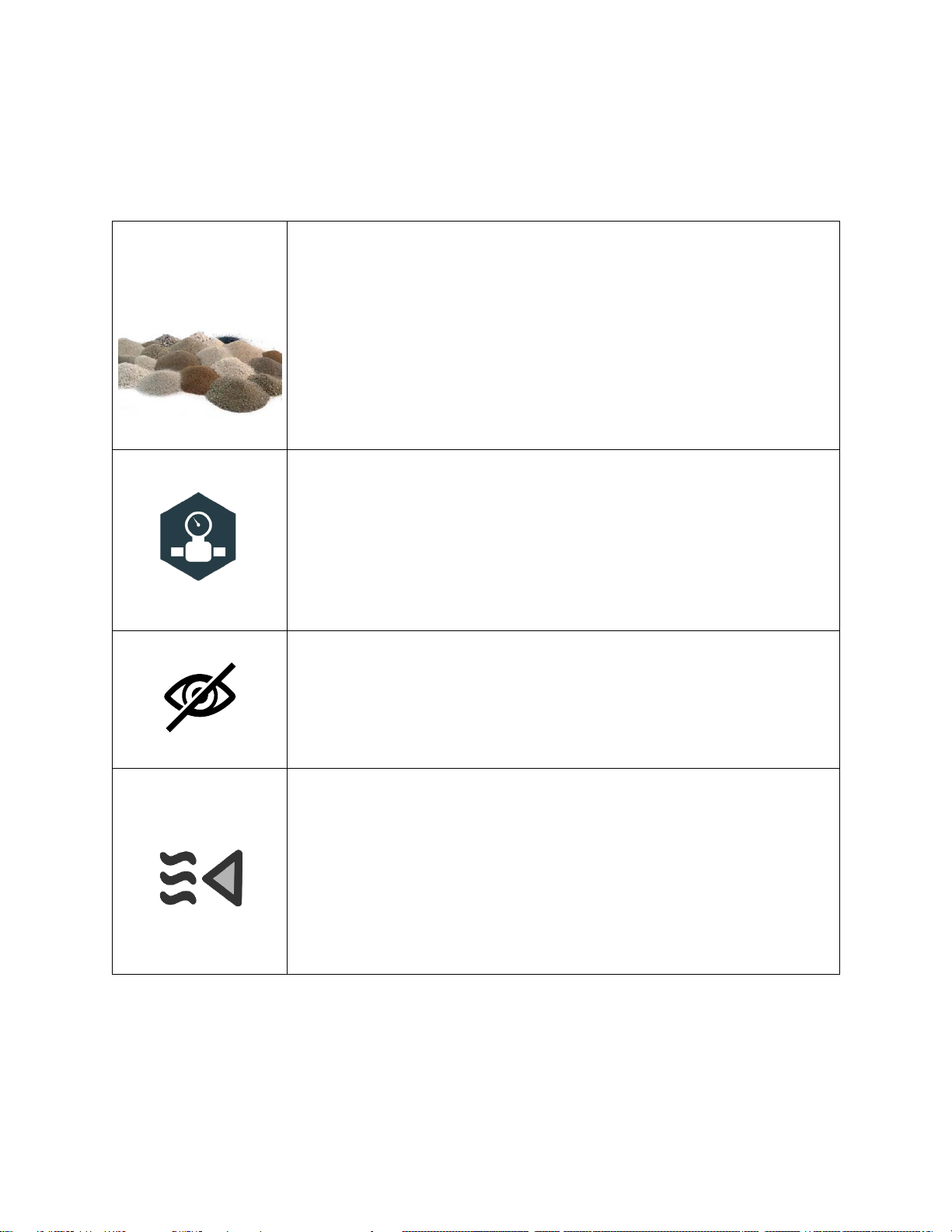

Abrasive Blasting Materials

The decision to use a certain type of abrasive

material can depend on factors such as cost, job

specifications, environment, and worker health.

Commonly used abrasive materials:

• Silica sand (crystalline)

• Coal slag

• Garnet sand

• Nickel slag

• Copper slag

• Glass (beads or crushed)

• Steel shot

• Steel grit

• Specular hematite (iron ore)

Alternative, less toxic blasting materials include:

• Ice cubes

• Dry ice

• Plastic bead media

• Sponge

• Sodium bicarbonate (baking soda)

• Ground walnut shells, ground corn cob and

other biodegradable materials

• High pressure water

Health Hazards

Abrasive blasting operations can create high

levels of dust and noise. Abrasive material

and the surface being blasted may contain

toxic materials (e.g., lead paint, silica) that are

hazardous to workers.

• Silica sand (crystalline) can cause silicosis,

lung cancer, and breathing problems in

exposed workers.

• Coal slag and garnet sand may cause lung

damage similar to silica sand (based on

preliminary animal testing).

• Copper slag, nickel slag, and glass (crushed

or beads) also have the potential to cause

lung damage.

• Steel grit and shot have less potential to cause

lung damage.

• Slags can contain trace amounts of toxic metals

such as arsenic, beryllium, and cadmium.

Abrasive blasting creates high levels of dust. Photo courtesy

of NIOSH.

**** CAUTION ****

Abrasive blasting creates high levels of

noise that can cause substantial hearing

loss. Always wear hearing protection.

Employers must administer a hearing

conservation program as required by the

OSHA Occupational Noise standard.

© 2020 Hess & Associates

Man. # 561 v02-02 8/2020

Page 3

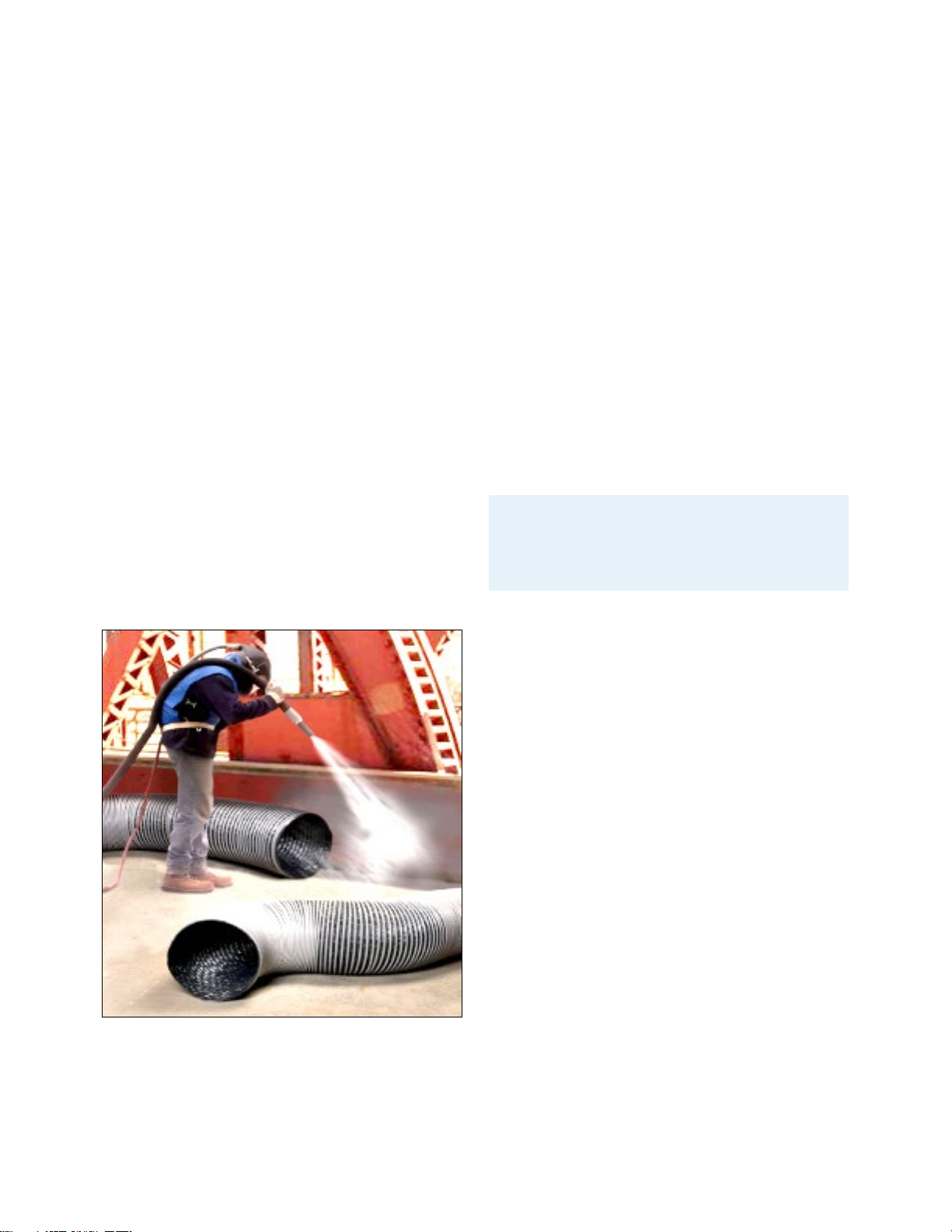

How to Protect Workers from Exposure

to Abrasive Blasting Materials

Each abrasive blasting operation is unique,

involving different surfaces, coatings, blast

material, and working conditions. Before

beginning work, employers should identify

the hazards and assign a knowledgeable

person trained to recognize hazards and

with the authority to quickly take corrective

action to eliminate them. Use engineering and

administrative controls, personal protective

equipment (PPE), including respiratory

protection, and training to protect workers

involved in abrasive blasting activities.

Engineering controls, such as substitution,

isolation, containment, and ventilation are

the primary means of preventing or reducing

exposures to airborne hazards during abrasive

blasting operations. Administrative controls,

including the use of good work and personal

hygiene practices, can also reduce exposure.

When engineering and administrative controls

cannot keep exposures to hazardous materials

below OSHA permissible exposure limits,

respiratory protection must be used.

Engineering Controls

1. Substitution

• Use a less toxic abrasive blasting material.

• Use abrasives that can be delivered with

water (slurry) to reduce dust.

2. Isolation and Containment

• Use barriers and curtain walls to isolate the

blasting operation from other workers.

• Use blast rooms or blast cabinets for smaller

operations.

• Use restricted areas for non-enclosed blasting

operations.

• Keep coworkers away from the blaster.

3. Ventilation

• Use exhaust ventilation systems in

containment structures to capture dust.

Administrative Controls

Perform routine cleanup using wet methods

or HEPA filtered vacuuming to minimize the

accumulation of toxic dusts.

• Do not use compressed air to clean as this will

create dust in the air.

• Clean and decontaminate tarps and other

equipment on the worksite.

• Schedule blasting when the least number of

workers are at the site.

• Avoid blasting in windy conditions to prevent

the spread of any hazardous materials.

Personal Hygiene Practices

• Prohibit eating, drinking, or using tobacco

products in blasting areas.

• Provide wash stations so workers can wash

their hands and face routinely and before

eating, drinking, or smoking.

• Vacuum or remove contaminated work

clothes before eating, drinking or smoking.

Abrasive blasting using a dust collection system with

multiple exhaust ducts. (Photo courtesy of Flexaust, Inc. This

equipment is shown for illustrative purposes only and is not

intended as an endorsement by OSHA of this company, its

products or services.)

Employers can use OSHA’s free On-site

Consultation Program for advice on safety

and health issues.

© 2020 Hess & Associates

Man. # 561 v02-02 8/2020

Page 4

DSG FS-3697 09/2014

This is one in a series of informational fact sheets highlighting OSHA programs, policies or standards.

It does not impose any new compliance requirements. For a comprehensive list of compliance

requirements of OSHA standards or regulations, refer to Title 29 of the Code of Federal Regulations.

This information will be made available to sensory-impaired individuals upon request. The voice phone

is (202) 693-1999; teletypewriter (TTY) number: (877) 889-5627.

• Provide accommodations for end-of-shift

showers and change areas with separate

storage facilities for street clothes, protective

clothing and equipment.

• Keep contaminated clothing and equipment

out of the clean change area.

Respiratory Protection

An abrasive-blasting respirator must cover the

wearer’s head, neck, and shoulders to protect

the wearer from rebounding abrasive. Workers

must use only respirators approved by NIOSH to

provide protection from dusts produced during

abrasive-blasting operations.

• Type CE NIOSH-certified blasting airline

respirator with positive pressure blasting

helmet.

Support personnel involved in cleanup and

other related activities may also need respiratory

protection.

Personal Protective Equipment

• Hearing protection

• Eye and face protection

• Helmet

• Leather gloves that protect to full forearm and

aprons (or coveralls)

• Safety shoes or boots

Worker Training and Hazard Communication

• Provide training to abrasive blasters and

support personnel on blasting health and

safety hazards, how to use controls, personal

hygiene practices, safe work practices and the

use of PPE and respirators.

• Manufacturers are required to include

appropriate health hazard information on

the blasting materials on safety data sheets

(SDS) as required under OSHA’s Hazard

Communication standard (29 CFR 1910.1200).

• Obtain and read the manufacturer’s SDS for

health hazard information on the abrasive

blasting material you are using.

For more information on abrasive blasting

and control measures see: OSHA’s guidance

document: “Abrasive Blasting Hazards in

Shipyard Employment” (2006); and eTool:

Mechanical Removers (Ship Repair).

When respirators are used, employers must

establish a comprehensive respiratory

protection program as required by the

OSHA Respiratory Protection standard (29

CFR 1910.134).

Disclaimer: This OSHA Fact Sheet provides a general overview of the requirements in OSHA standards related to abrasive blasting.

It does not alter or determine compliance responsibilities in these standards or the Occupational Safety and Health Act of 1970. Since

interpretations and enforcement policy may change over time, the reader should consult current OSHA interpretations and decisions by

the Occupational Safety and Health Review Commission and the courts for additional guidance on OSHA compliance requirements.

© 2020 Hess & Associates

Man. # 561 v02-02 8/2020

Page 5

Applicable OSHA Standards and Safety and Health Topic Pages

The following table provides links to several OSHA standards (not all-inclusive) that may contain

requirements that apply to abrasive blasting operations. For example, the removal of lead paint by

abrasive blasting will likely require employers to follow provisions of the OSHA Lead standard. Safety

and health topic pages listed here provide employers and workers with information that may be useful

for safely conducting abrasive blasting.

General Industry Shipyard Industry Construction Industry OSHA Topics Page(s)

1910.94, Ventilation 1915.33 & 1915.34, Chemical &

Mechanical paint removers

Ventilation (as it applies to

shipyard employment, 1910.94)

1915 .13, Cleaning and other

cold work

1926.57, Ventilation Ventilation

1910.95, Occupational noise

exposure

1910.95, Occupational noise

exposure (as per Shipyard

“Tool Bag” Directive, CPL 02-

00 -182)

1926.52, Occupational noise

exposure

1926.101, Hearing Protection

Noise

1910.132, Personal Protective

Equipment

1915 Subpart I, Personal

Protective Equipment

1926 Subpart E, Personal

Protective Equipment

Personal Protective

Equipment

Respiratory Protection

(1910.134)

1915.154, Respiratory

Protection refers to (1910.134)

1926.10 3, Respiratory

Protection (refers to 1910 .13 4)

Respiratory Protection

1910.141, Sanitation 1915.88, Sanitation 1926.51, Sanitation

1910.1000, Air contaminants

Table Z-1, Limits for air

contaminants

Table Z-2, Toxic and

Hazardous Substances

Table Z-3, Mineral dusts

1915.1000, Air contaminants

Table Z – Shipyards

1926.55, Gases,vapors,

fumes, dusts, and mists

Appendix A, Threshold

limit values of airborne

contaminants for construction

Permissible Exposure

Limits (PELs) &

Hazardous and Toxic

Substances

Beryllium

See 1910.1000, Table Z-1 for

air contaminants

Beryllium

See 1915.1000, Table Z

Beryllium

See Table 1926.55,

Appendix A

Beryllium

Silica

See 1910.1000, Table Z-3

Silica

See 1915.1000, Table Z

Silica

See 1926.55, Appendix A

Silica

1910.1018, Inorganic Arsenic 1915 .1018 , Inorganic Arsenic 1926.1118, Inorganic Arsenic Arsenic

1910.1025, Lead 1915 .1025, Lead 1926.62, Lead Lead (General Industry)

Lead (Construction)

1910.1026, Chromium(VI) 1915 .1026,Chromium(VI) 1926.1126,Chromium(VI) Hexavalent Chromium

1910.1027, Cadmium 1915 .1027, Cadmium 1926.1127, Cadmium Cadmium

1910.1200, Hazard

Communication

1915 .1200, Hazard

Communication (refers to

1910.1200)

1926.59, Hazard

Communication (refers to

1910.1200)

Hazard Communication

© 2020 Hess & Associates

Man. # 561 v02-02 8/2020

Page 6

INSTALATION :

LITTLE BLASTER w/CARTRIDGE DUST COLLECTOR

1. Remove all shipping protection Check for any concealed shipping

damage, if discovered, report the damage to your freight carrier AS

Non-Disclosed Hidden Damage immediately.

2. Blast Cabinet should be placed in a desired location, away from any

water or moist environment. If moist compressed air is present at

this location, install a good moisture separator.

3. Install Air Controls

(READ INSTALLATION –“ Little Blaster™ AIR CONTROLS”)

4. Install Cartridge Dust Collector: Packaged with machine are bolts,

washers, nuts and gasket material.Apply gasket to back of cabinet

around large hole, press to make a firm bond to cabinet and squeeze

together at seam. Align the 4-hole bolt pattern of the Dust Collector

and install bolts, washers, and nuts. Tighten bolts and nuts securely.

5. Remove Window Frame/Window Glass and Install the Mylar Roll

into the Mylar Dispenser. Pull Mylar from the Mylar Dispenser

Across the Window Opening. Place the Window Glass/Window

Frame on Top of the Mylar, Securing with Plastic Knobs.

6. Install Gloves ( Watch the Video)

7. Plug electrical cord from side of dust collector into plug from light

box.

(READ OPERATION - “Little Blaster™ CARTRIDGE DUST COLLECTOR”)

8. Connect your air supply line to machine air inlet on left rear leg, we

recommend using 1/2" I.D. Hose or Pipe minimum supply line.

(Again, make sure your air supply line is free from oil and moisture).

(If not, install a good moisture separator).

Part #: 16-815 (DO NOT USE ANY QUICK DISCONNECT COUPLINGS)

9. Connect the electrical cord from light box to a grounded electrical

source.

120-volt/60 cycle, single phase

A 20 AMP breaker or fuse should be used.

MAKE SURE MACHINE HAS PROPER GROUND

10. Charge blast machine with abrasive. Pour media into cabinet

through one of the doors and fill to bottom of screen in sump of

cabinet. Media Sold Separately @ Blast-It-All Online Store

DO NOT FILL ABOVE SCREEN.

*** READ BEFORE OPERATING EQUIPMENT ***

© 2020 Hess & Associates

Man. # 561 v02-02 8/2020

Page 7

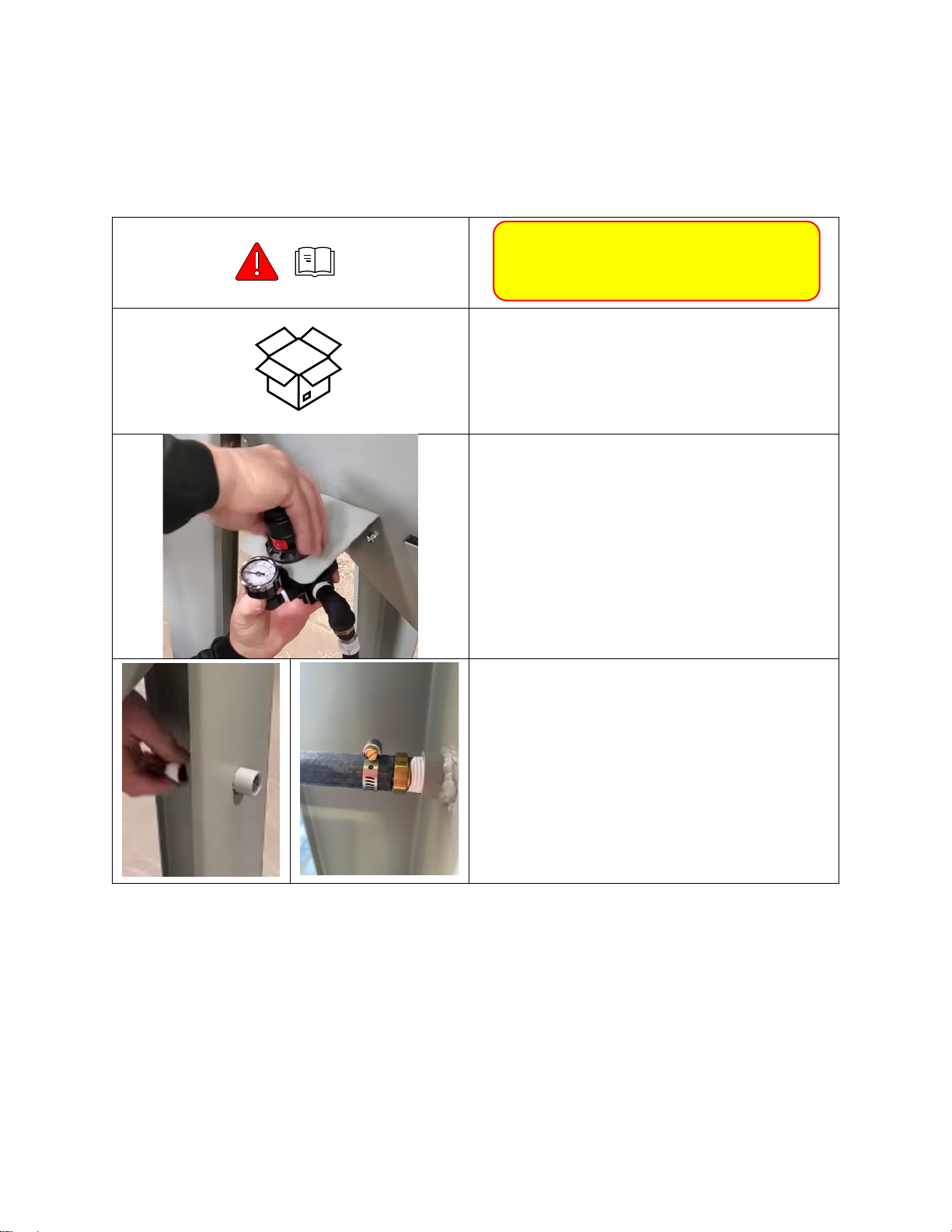

INSTALATION :

Little Blaster™ AIR CONTROLS

1. Remove Box from inside of the Machine.

Box contains :

Foot Petal, ½” Air Regulator

w/Assembled Hoses

Blast Gun w/Assembled Hose

½” Barbed Brass Fitting

2. Connect Air Regulator to the Bracket on

the Front of the Machine w/Lock Ring

3. Apply Teflon Tape to the ½” Barbed Brass

Fitting and install to the to the Inside Left

Leg of the Machine (Coupler).

Attach/Secure Inlet Air Hose to the Barbed

Brass Fitting.

*** READ BEFORE

OPERATING EQUIPMENT ***

© 2020 Hess & Associates

Man. # 561 v02-02 8/2020

Page 8

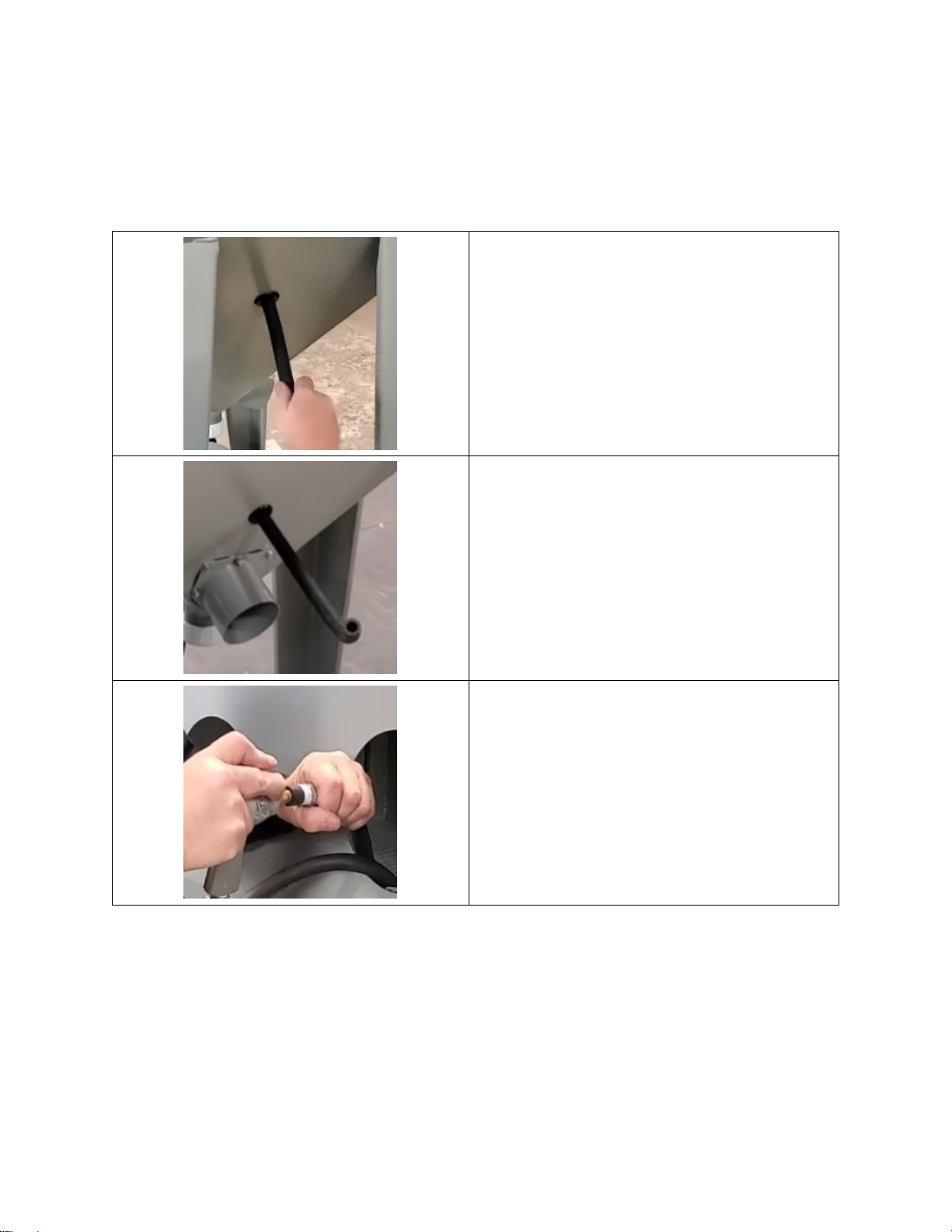

INSTALATION :

Little Blaster™ AIR CONTROLS (cont’d)

4. Insert Air Hose from the Foot Petal

through the Rubber Grommet on the Right

Side of the Sump.

5. Remove Work Grate from inside of the

Machine. Insert the Media Hose

(attached to Gun) from the Inside, through

the Rubber Grommet on the Back Sump.

Replace the Work Grate, ensuring the

hoses are routed through the Work Grate

Opening.

6. Attach/Secure Air Hose to the Back of the

Blast Gun.

© 2020 Hess & Associates

Man. # 561 v02-02 8/2020

Page 9

INSTALATION :

Little Blaster™ AIR CONTROLS (cont’d)

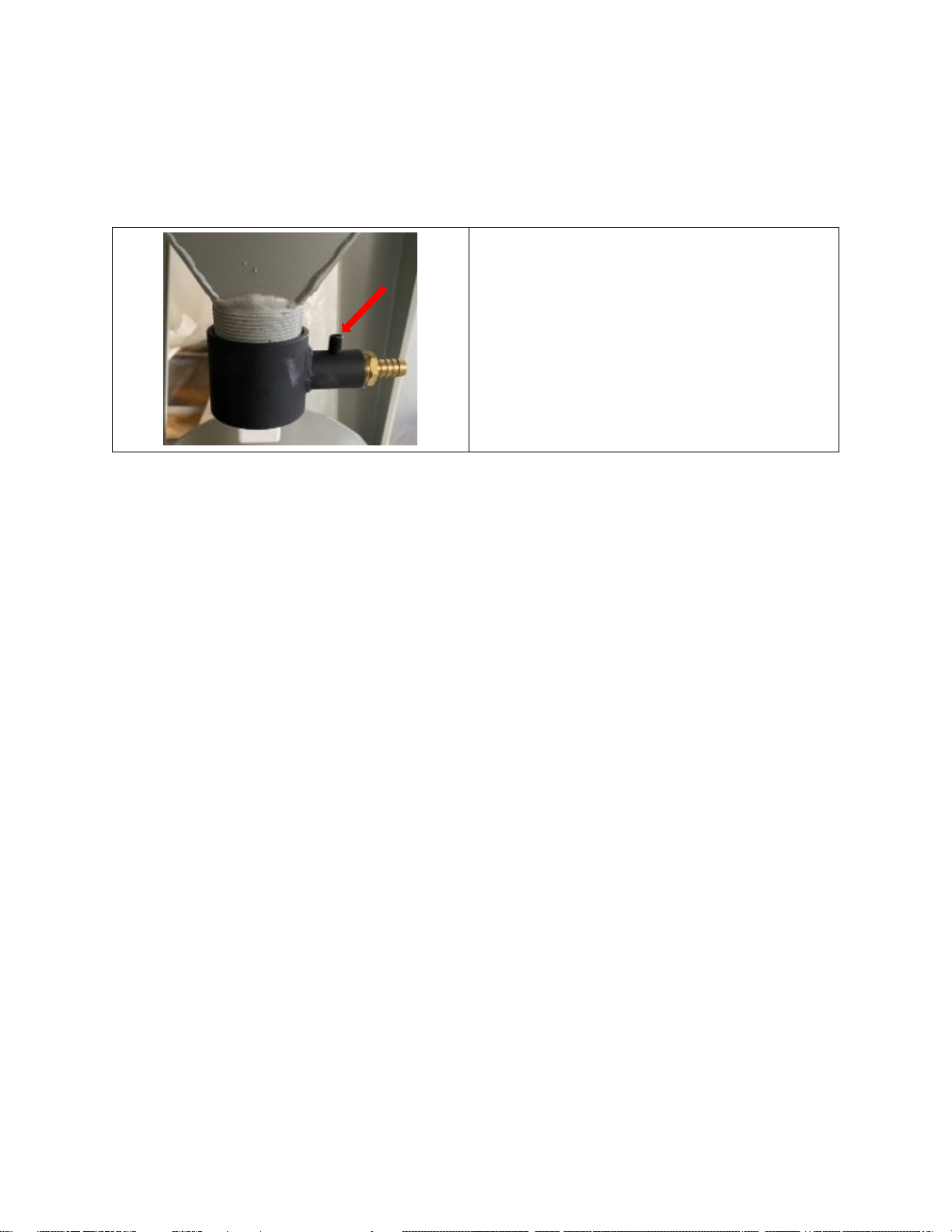

7. Teflon Tape and Attach the Media Valve to

the Bottom of the Sump and

Attach/Secure the Media Hose from the

Back of the Sump to the Media Valve’s

Barbed Brass Fitting. Small Fitting Should

Always be Facing Up an Remain Open.

© 2020 Hess & Associates

Man. # 561 v02-02 8/2020

Page 10

OPERATION

Little Blaster™

1. Preparing Parts for Blasting :

All parts to be processed must be free of oil, grease, and moisture. Make

sure parts are dry before putting into cabinet for processing.

2. Air Pressure :

Set air pressure at 40 ~ 80 PSI. Most parts for blasting should be blasted at

80 PSI. Designate parts to be processed, start at lower pressure, and work up

the PSI scale to obtain desired finish.

DO NOT CONNECT TO HIGH PRESSURE BOTTLE GAS, RUPTURE AND

EXPLOSION CAN OCCUR.

3. Gun Angle and Distance:

Direct blast at part with an approximate (45-60) degree angle

with ricochet toward the back side of cabinet. Do not hold at

90 degree to part being processed. This will cause the media to

blast to bounce back into the blast stream and slow blasting

action. Also 90-degree angle will cause excessive wear on gun

and viewing window. Hold gun approximately 6 inches from

part being cleaned.

GUN MUST ALWAYS BE POINTED AWAY FROM THE OPERATOR AND

TOWARD ITEM BEING PROCESSED. NEVER BLAST WITH ANY OF THE

CABINET DOORS OPEN. WHILE LOADING AND UNLOADING, NO ONE

SHOULD BE AT THE OPERATOR STATION AT FRONT OF THE BLAST

CABINET.

4. Media :

Media should be good quality and dry. Damp media will cause the media

not to flow and will clog abrasive flow.

Media Available @ Blast-It-All Online Store

IF YOU ARE HAVING A PROBLEM SELECTING MEDIA FOR A SPECIFIED JOB,

CONTACT YOUR DISTRIBUTOR FOR THEIR RECOMMENDATIONS

*** READ BEFORE OPERATING EQUIPMENT ***

© 2020 Hess & Associates

Man. # 561 v02-02 8/2020

Page 11

OPERATION

Little Blaster™ CARTRIDGE DUST COLLECTOR

After installing the Dust Collector, it is very IMPORTANT to follow the next steps. This will ensure your

machine will blast satisfactorily and have good visibility in blast chamber.

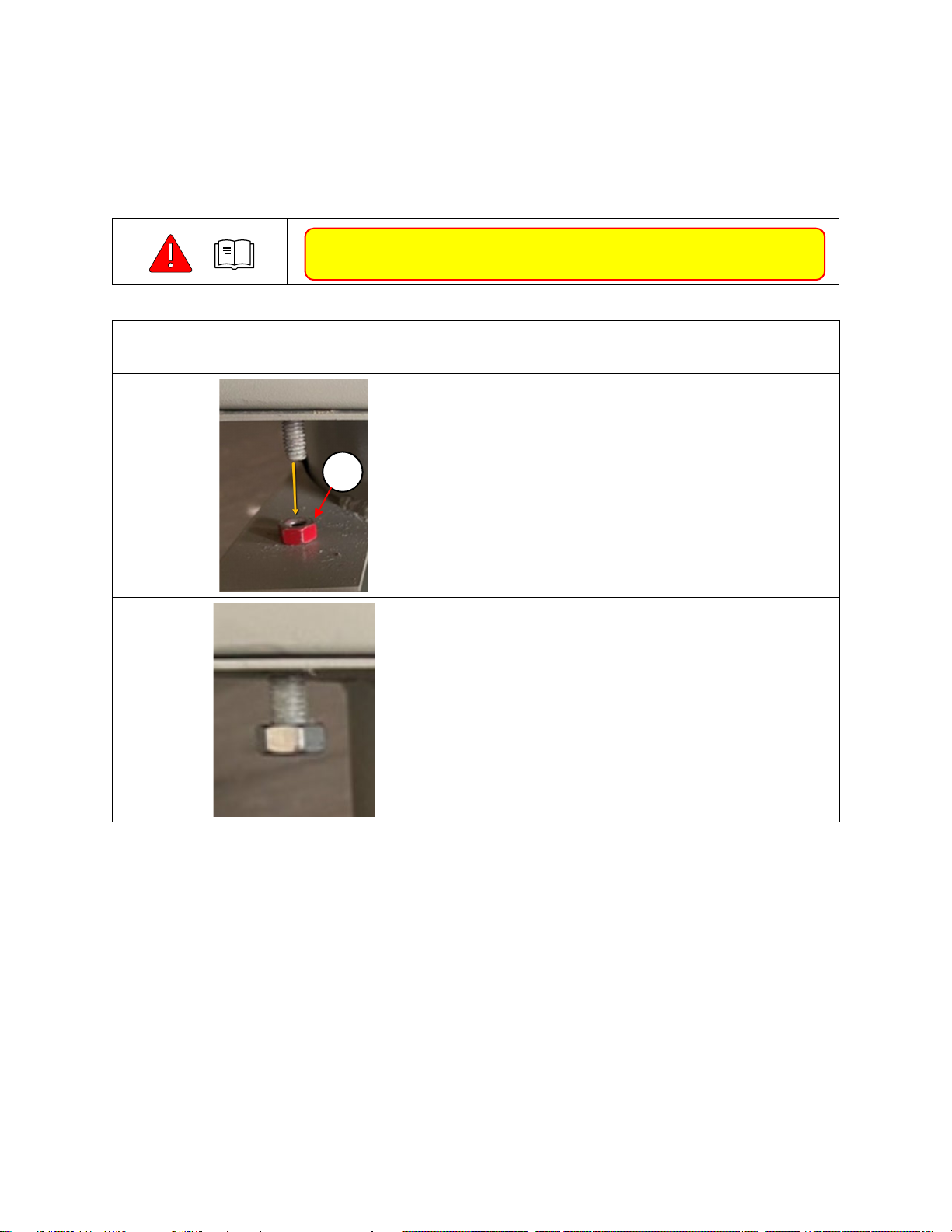

1. Remove RED nuts securing the motor

housing and cartridge holder to dust

collector body. (Item 1) Discard these

nuts, they are not used.

2. Loosen nuts on back corners. Loosen until

the nut is to the bottom on the bolt

thread. This will allow the motor housing

and cartridge holder to rest securely on

the gasket seal.

*** READ BEFORE OPERATING EQUIPMENT ***

1

© 2020 Hess & Associates

Man. # 561 v02-02 8/2020

Page 12

OPERATION

Little Blaster™ CARTRIDGE DUST COLLECTOR (cont’d)

3. To clean cartridge: Turn Dust

Collector switch off. Grasp lift handle

and raise up and down vigorously

allowing the top housing to thump on

the body lip. Do this repeatedly, until

loose dust on the cartridge falls off

into the dust sump. This should be

done every 30 minutes of blasting, or

each time before use. It is a good

idea occasionally to remove motor

housing and with 10-15 PSIof airline

pressure from air nozzle, blow the

cartridge pleats clean.

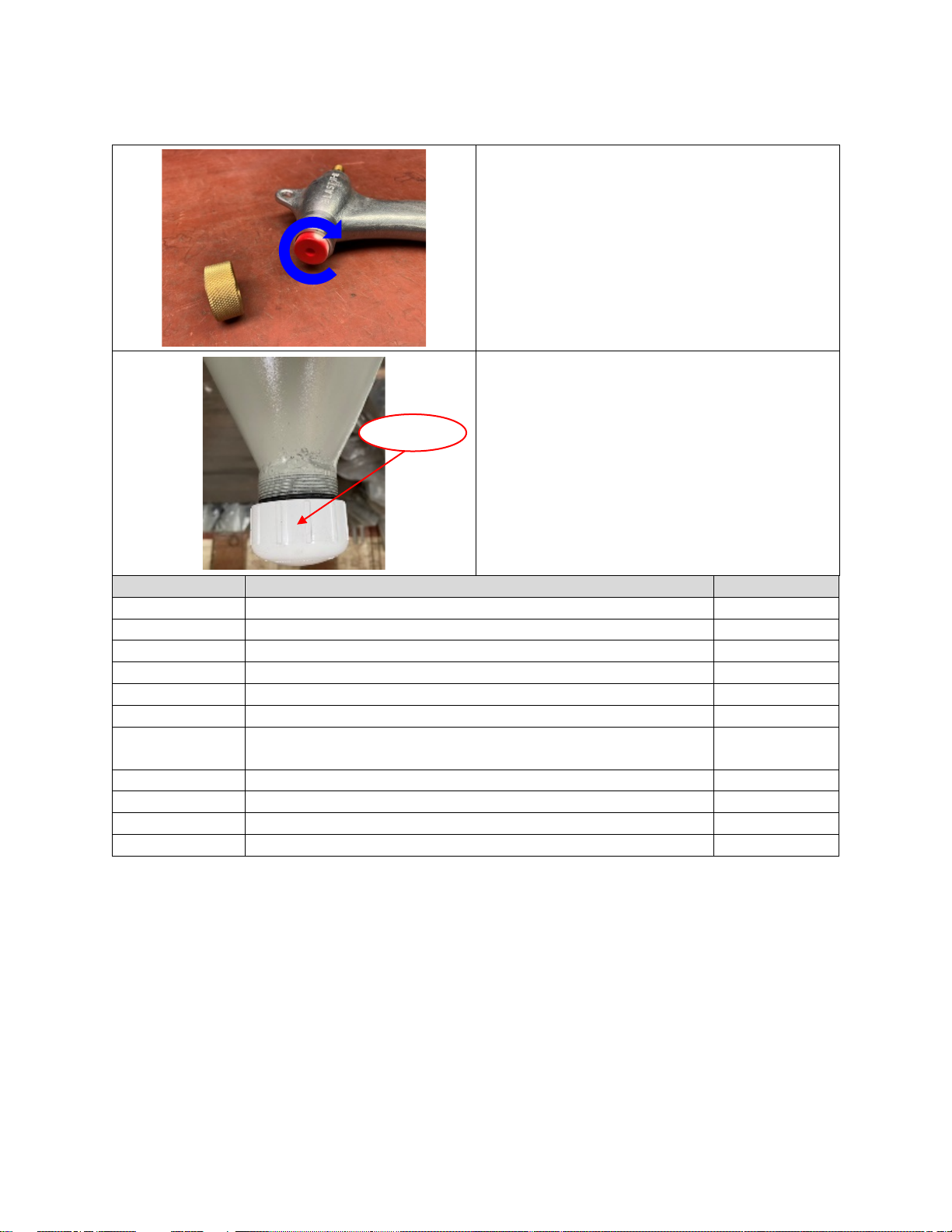

4. After thumping the cartridge, the drain

cap should be removed and the dust

emptied from dust collector sump into a

box, bag or container, for ease of

disposing.

Maintained properly, you will enjoy the performance of this reliable type dust collector.

Lift

Handle

Top

Housing

Body

Lip

Cartridge

Drain Cap

© 2020 Hess & Associates

Man. # 561 v02-02 8/2020

Page 13

TROUBLSHOOTING

1. Caking of Media :

A. Media caking is caused by moisture in compressed air supply or

oily and greasy parts. If this is not corrected, media will not flow

and will clog gun. Check air supply. If water or moisture is present,

install a good moisture trap. If oily or greasy parts are being blast

treated, you should first degrease and dry parts.

B. If blast gun should occasionally clog, tightly seal the front of the

nozzle against the inside front the blast cabinet and push foot

valve down 3 to 4 seconds. This will cause the system to back blast

through the gun and media hose and clear the media hose.

2. Gun Air Pressure Drop :

Set air regulator at 80 PSI on air gauge. Push foot valve and if

gauge reading should drop, check the air supply pipe or hose. A

restriction in the supply line such as reducers or quick couplers will

cause pressure drop. Also, if the blast cabinet is too far from the

air compressor, a pressure drop can occur. We recommend 1/2" -

1" I.D. air supply line. The bigger the better.

3. Poor Visibility - Excessive Dust :

A. Cabinet Air inlet blocked, check for blockage.

B. Dust collector sump full and needs emptied.

C. Cartridge contaminated. Clean by pushing up and down.

D. Media breakdown - replace media and clean dust collector.

4. Poor Media Flow :

A. Wet or damp media caused from moisture or oil in compressed air

line.

Use dry air or install a moisture filter.

B. Replace media and clean media sump and hose.

C. Media level should be below media screen.

D. Hole in media hose from wear, replace hose assembly.

E. Poor Air Flow/CFM

F. Worn Gun Body, Nozzle or Orifice

© 2020 Hess & Associates

Man. # 561 v02-02 8/2020

Page 14

MAINTENANCE

1. Blasting Gun :

After 10 - 12 hours of blasting time the air

orifice and nozzle should be checked. If

the nozzle shows wear, rotate 1/4 Turn to

prevent uneven wear. If this is not

checked, it could result in the destruction

of nozzle and damage to the gun housing.

If wear is detected on the orifice tip,

replace.

2. After thumping the cartridge, the drain

cap should be removed and the dust

emptied from dust collector sump into a

box, bag or container, for ease of

disposing.

ITEM

DESCRIPTION

FREQUENCY

NOZZLES

INSPECT FOR WEAR

DAILY

MEDIA HOSE

INSPECT FOR WEAR / HOLES

MONTHLY

GUN BODY

INSPECT FOR WEAR

MONTHLY

GUN ORIFICE

INSPECT FOR WEAR

MONTHLY

MYLAR

INSPECT FOR POOR VISABILITY

PER USE

VIEW WINDOW

INSPECT FOR DAMAGE

PER USE

DUST / DEBRIS

REMOVAL

REMOVE DUST / DEBRIS ACCUMULATION PER USE

DUST FILTERS

CLEAN

AS NEEDED

FLEX HOSE

INSPECT FOR WEAR / LEAKS

WEEKLY

GLOVES

INSPECT FOR WEAR / HOLES

WEEKLY

WEAR PLATES

INSPECT WEAR PLATE / LINERS FOR WEAR

MONTHLY

Drain Cap

© 2020 Hess & Associates

Man. # 561 v02-02 8/2020

Page 15

VENTURI BLAST GUN TUNING :

WATCH THE VIDEO FROM BLAST-IT-ALL®

https://www.youtube.com/watch?v=dKT9XeFhNNY

1. Attach & Secure Vacuum Gage Hose to the

Bottom of the gun.

Vacuum Gauge Part # 011267

Vacuum Gauge Kit Part # ( TBD )

2. Attach & Secure Compressed Air (80psi) Hose

to the Orifice Inlet.

3. Open Air Flow into the Orifice Inlet and Adjust

the Orifice Inlet IN or OUT until 15 ~ 18 in Hg

Vacuum is Achieved. Tighten Lock Nut to

Maintain Position.

4. When Range of Vacuum Can Not be Achieved,

Part/Parts Replacement will be Required.

© 2020 Hess & Associates

Man. # 561 v02-02 8/2020

Page 16

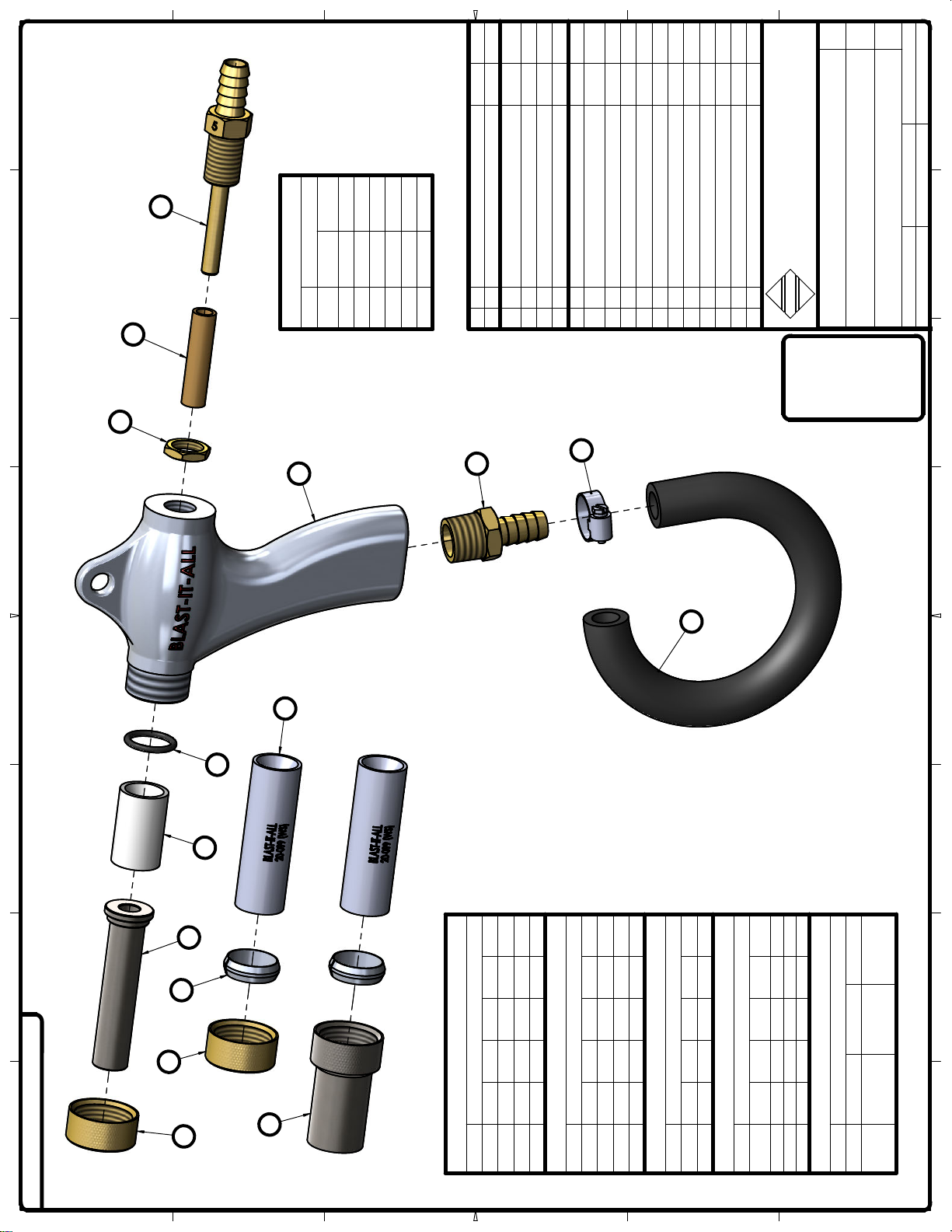

7

F

F

E

D

2

C

B

A

1 1234F5678

F

E

D

C

B

A

2

F

1F 1234568

CONSENT OF LARRY

CONFIDENTIAL

THE INFORMATION

CONTAINED IN THIS

DRAWING IS THE

EXCLUSIVE PROPERTY

OF BLAST-IT-ALL ©, A

DIVISION OF LARRY

HESS & ASSOCIATES,

INC. ANY AND ALL

REPRODUCTION,

REGARDLESS OF

FORM, IS STRICTLY

PROHIBITED WITHOUT

THE EXPRESS WRITTEN

HESS & ASSOC., INC.

©

BLAST-IT-ALL

DREV:

LARRY HESS & ASSOCIATES, INC.

185 PIPER LANE, SALISBURY, NC 28147-7949

P: 1.800.535.2612 ■F: 1.704.638.9311 ■WWW.BLAST-IT-ALL.COM

DWG BY: DATE: SCALE:

SIZE:

PART#

TITLE /

DESC:

MAT: SHT#: OF DWG TYPE:

DWG#

XXXX:

BDP 05-Aug-20 1:1

MANUAL: GUN, BLAST, STD, BIA

11 MDSEE BOM

---

C

.A-WM9009B.A--

X

-WM9009B.A--

#: QTY: DESC/ MAT: PRT#: DWG#:

11 1 HOSE, MEDIA, 1/2 ID (SEE TABLE) * EPDM 18-084 ---

10 1 CLAMPS, DRIVE, WORM, SAE:006, 1/2" (7/16 - 25/32) *

BAND, S.S. & SCREW, STEEL, ZINC 21-031 ---

9 1 FITTING, BRASS, 1/2 BARB X 1/2 MNPT 14-301 ---

81

ORIFICE, AIR, 5/32 ID, #5 * BRASS, YELLOW, 360,

HEXBAR, 3/4IN 20-065 ---

7 1 COVER, ORIFICE * TUBE, LATEX, RUBBER, NATURAL 20-063 ---

6 1 LOCKNUT, ORIFICE * BRASS 20-052 ---

5 1 NUT, HOLDING, NOZZLE * BRASS, YELLOW, 360 20-054 ---

***4 1 EXTENSION, NOZZLE, 3IN * STEEL, 1018, CARBON

NITRATE HARDENED 20-502 ---

3 1 NOZZLE, 5/16 ID, #5 * CERAMIC 20-075 ---

2 1 O-RING, SEAL, NOZZLE * RUBBER, BUNA-N 20-053 ---

1 1 BODY, GUN, BLAST * ALUM, TENZALOY 20-040 ---

STANDARD GUN NOZZLES: (#3)

NOZZLE - # & (IN):

MATERIAL: #4 (1/4) #5 (5/16) #6 (3/8) #7 (7/16) #8 (1/2)

CERAMIC 20-074 20-075 20-076 20-077 20-078

TUNGSTEN 20-084 20-085 20-086 20-087 20-088

BORON 20-094 20-095 20-096 20-097 20-098

STANDARD GUN ORIFICES: (#8)

ORIFICE - # & (IN):

MATERAIL: #4 (4/32) #5 (5/32) #6 (6/32) #7 (7/32) #8 (8/32)

BRASS 20-064 20-065 20-066 20-067 20-068

STANDARD GUN ASSYS: (#1 - #8, NOT # ***4)

TOP - NOZZLE # & (IN) * BOTTOM: ORIFICE # & (IN):

MATERAIL: #4 (1/4)

#4 (4/32)

#5 (5/16)

#5 (5/32)

#6 (3/8)

#6 (6/32)

#7 (7/16)

#7 (7/32)

#8 (1/2)

#8 (8/32)

CERAMIC: 20-041-4 20-041-5 20-041-6 20-041-7 20-041-8

TUNGSTEN: 20-042-4 20-042-5 20-042-6 20-042-7 20-042-8

BORON: 20-043-4 20-043-5 20-043-6 20-043-7 20-043-8

#: QTY: DESC/ MAT: PRT#: DWG#:

*14 1 NUT, NOZZLE, WIDE SPRAY, NO COVER * BRASS,

YELLOW, 360 20-055NC ---

*13 1 RING, COMPRESSION, NOZZLE * ALUM 20-056 ---

*12 1 NOZZLE, WIDE SPRAY, #6 (3/8) * BORON 20-099 (WS) ---

#: QTY: DESC/ MAT: PRT#: DWG#:

*15 1 NUT, NOZZLE, WIDE SPRAY, W/ COVER * STEEL, CRS 20-055 ---

BLAST HOSE REQ'D: (#10)

HOSE, MEDIA, 1/2IN

MACH

MODEL 700 CFM 900 CFM

3636 18-084 7FT N/A

4426 18-084 6FT N/A

4836 18-084 7FT 18-084 10FT

4848 18-084 8FT 18-084 11FT

6048 18-084 8FT 18-084 11FT

6060 18-084 9FT 18-084 12FT

WIDE SPRAY STANDARD GUN NOZZLES: (#12)

NOZZLE - # & (IN):

MATERIAL: #4 (1/4) #5 (5/16) #6 (3/8) #7 (7/16) #8 (1/2)

CERAMIC --- --- 20-079(WS) --- ---

TUNGSTEN --- 20-085WS 20-090(WS) --- ---

BORON --- 20-095WS 20-099(WS) --- ---

STANDARD GUN NOZZLE EXTENSIONS: (# ***4)

EXTENSION LENGTH

MATERIAL: 3 IN 6 IN 9 IN

CARBON

NITRATED

STEEL

20-502 20-505 20-508

8

5

3

2

10

9

6

1

7

11

***4

*** OPTIONAL NON-STANDARDPART

D:\Users\Pete2\Documents\000_SW19Data\01_OTSParts\GUNS&NOZZ\20-04X_GunBlastSTD_BIA_20200805\UWM9009B.A_MANUAL-A_GunBlastStandard.SLDDRW

LAST SAVED: Tuesday, 18 August, 2020 01:30:39 PM

*14

*13

*12

*15

© 2020 Hess & Associates

Man. # 561 v02-02 8/2020

Page 17

Little Blaster™ STANDARD CABINET ASSEMBLY PARTS

© 2020 Hess & Associates

Man. # 561 v02-02 8/2020

Page 18

This manual suits for next models

2

Table of contents

Other Blast-It-All Power Tools manuals

Popular Power Tools manuals by other brands

Powerfix Profi

Powerfix Profi 276186 Operation and safety notes

Bosch

Bosch GDS 18 V-LI Original instructions

Bosch

Bosch GST Professional 90 E Original instructions

Black & Decker

Black & Decker LI2000 instruction manual

Black & Decker

Black & Decker Mouse MS100 instruction manual

CPS

CPS BLACKMAX BTLDTW manual