rWARNING! Before operating the unit ensure you read, understand and apply Section 1 Safety Instructions.

NOTE: Numbers in brackets refer to the item numbers in the Parts Lists.

4.1 Model SB994 (Refer to SB994 parts diagram)

4.1.1. Attach lower handle axle assembly (4) to the barrel assembly (1) using screws (8), washers (6) and nuts (5), do not fully tighten.

4.1.2. Slide the upper handle (2) onto the lower handle and align the hole, using screw (7), washers (6) push the screw through into the

barrel assembly and secure using washer (6) and nut (5). Tighten all screws securely.

4.1.3. Push a split pin (11) through the inner hole of the axle and secure using pliers to bend round the pin, slide a washer (9) on the axle so

that it butts up against the split pin, slide a wheel (10) onto the axle, followed by another washer (9) and secure with a split pin through

the outer hole in the axle shaft. Repeat for the other side.

4.1.4. Slide the front leg (3) into the tube on the barrel assembly, align the holes and secure using screw (7), washers (6) and nut (5).

4.1.5. Slide a hose clamp (13) over the end of the hose and push onto the outlet tube of the barrel assembly.

NOTE: DO NOT push the hose on so far that it cover the vent hole in the outlet tube.

4.1.6. Connect the other end of the hose to the sanding gun (12) using hose clamp (13).

4.1.7. Fit an appropriate air line connection compatible with your air supply, see section 3 and the specifications in section 2.

4.2. Model SB995 (Refer to SB995 parts diagram)

4.2.1. Loosely attach handle (3) to barrel assembly (1) using screws (7), washers (5) and nuts (6).

4.2.2. Loosely attach base support (2) to the barrel assembly using screws (4) washers (5) and nuts (6), ensure that the gun holder is facing

upwards as shown in the parts diagram.

4.2.3. Attach the base bar (8) to the base support bar, align the holes at the rear of the base with the holes in the handle (3) and slide the

axle (9) through both the handle and the base section to locate. Ensure that the axle sticks out evenly on both sides of the handle.

4.2.4. Slide washer (10) and wheel (11) onto one side of the axle, slide the other washer onto the axle and secure using split pin (12).

Repeat for the other wheel assembly.

4.2.5. Tighten all screws, ensuring that the handle and base are square with the barrel assembly.

4.2.6. Attach the end of the hose with the right angle bend (15) to the outlet tube of the barrel assembly using hose clamp (14), ensuring that

the vent hole in the tube is facing upwards.

4.2.7. Attach the other end of the hose onto the guns using hose clamp (14).

4.2.8. Fit an appropriate air line connection compatible with your air supply, see section 3 and the specifications in section 2.

WARNING! Ensure that you read, understand and apply the

safety instructions in Section 1 before use.

WARNING! Wear approved ear, eye, hand and respiratory

protection when operating the blaster.

WARNING! Ensure the air supply does not exceed 120psi

(8.2bar) while operating the unit.

5.1 Fill the hopper with the required abrasive, checking to ensure it

is clean and dry.

5.2 Attach an airline to the gun and press the trigger.

5.3 Before blasting unfamiliar material, spot test to ensure that

damage/pitting will not occur to the material.

5.4 Use even passes of the blaster to remove material such as rust,

body filler or other soft materials. Do not blast in any one area

for more than a few seconds at a time.

5.5 The unit is supplied with 4 ceramic nozzles ranging from 4 to

7mm, select the appropriate nozzle for the task (fig.2).

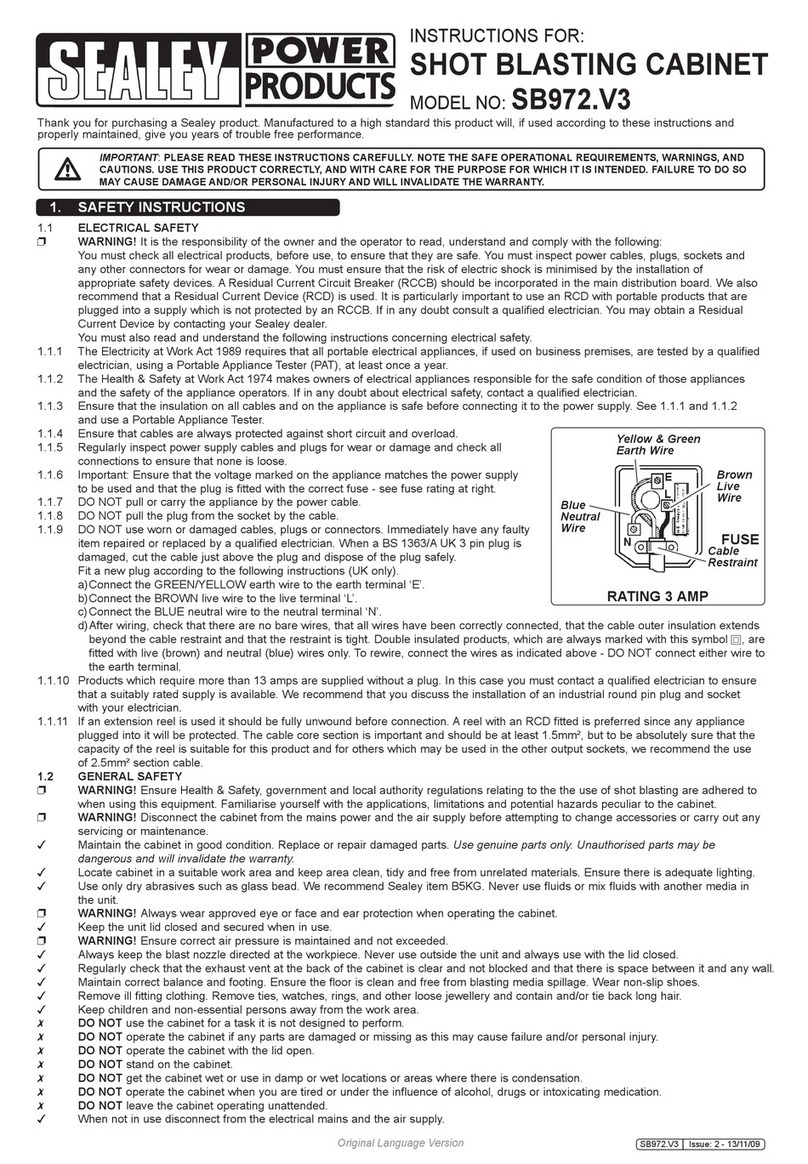

5.5.1. To change the nozzle, disconnect from the air supply and

unscrew the head screw, insert the nozzle as shown in fig.2 and

refit the head screw.

rWARNING! DO NOT use the sand blaster without a nozzle fitted.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

01284 757500

01284 703534

sales@sealey.co.uk

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

www.sealey.co.uk

Web

Original Language Version SB994, SB995 Issue: 4(I) - 31/08/16

© Jack Sealey Limited

fig.2

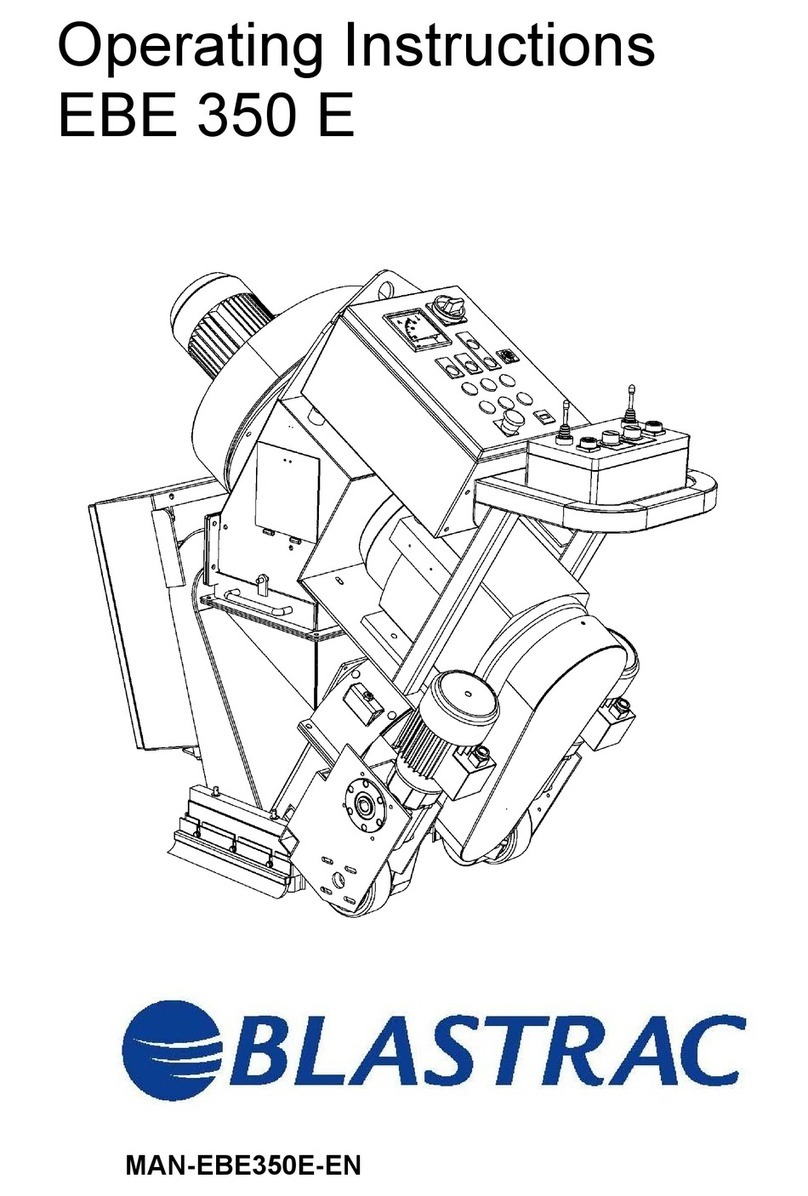

fig.1

4. ASSEMBLY

5. OPERATION

Environmental Protection

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be

sorted, taken to a recycling centre and disposed of in a manner which is compatible with the environment.

When the product becomes completely unserviceable and requires disposal, drain off any fluids (if applicable)

into approved containers and dispose of the product and the fluids according to local regulations.