BLIKIR RCP-2 G4 User manual

© BLIKIR.Inc, All rights reserved. BLIKIR and the BLIKIR logo are trademarks or registered trademarks of BLIKIR, Inc.

Date: 08G4/2023/V02/ENG. Subject to change without notice

Installation Manual

RCP-2 G4 |Solar Carport / Canopy

Warning:Please be advised that the installation manual for your carport is

subject to change without notice. As such, we strongly urge you to use the most

recent version of the manual before attempting to install your carport. This is

important to ensure that you have the latest and most accurate instructions to

guide you through the installation process. The latest version of the manual can

always be found on our website at the following link:

https://www.blikir.com/resources

Document Version: 08G4/2023/V02/ENG

Released on: August 1st, 2023

1

Table of Contents

3Disclaimer

4

4

Introduction

Brief Description

4Ratings and Conditions Of Use

5Maintenance

5Torques

6

6

Required tools

Tools

7Main Components

8

9

Standard Dimensions

Pier Location Diagram

10

10

11

11

Components List

Blikir Structure Components

Ironridge racking components

Other components

12

12

12

13

14

14

1 - Build Base

1.1 Mark piers locations

1.2 Dig Piers

1.3 Reinforcing and Concrete

1.4 Align Base Plates

1.5 Install Footings

15

15

15

16

17

18

18

19

2 - Build Structure

2.1 Connect Columns

2.2 Leveling System

2.3 Connect Corners

2.4 Connect Beams to Corner

Connectors

2.5 Slide Connector Sleeves on Beams

2.6 Connect Middle Beams

2.6 Connect Beams at the center

20

20

21

21

22

23

23

3 - Connect Rails

3.1 Connect L-Feet

3.2 Cut Rails to Match Panel Size

3.3 Splice Rails

3.4 Connect Rails to L-Feet

3.5 Connect Grounding Lug to Rail

3.6 Optional: Install MLPE

24

24

25

25

25

4 - Install Solar Panels

4.1 Connect First Panel with CAMO

4.2 Connect First Column of Panels

4.3 Connect Remaining Solar Panels

4.4 Connect Bonding Jumpers

26

26

27

28

5 - Optional Add Ons

5.1 Optional: Decorative Mesh

5.2 Optional: EV Chargers

5.3 Optional: Columns Safety Solar

LED Lights

2

Installation Manual

© BLIKIR.Inc, All rights reserved. BLIKIR and the BLIKIR logo are trademarks or registered trademarks of BLIKIR, Inc.

Date: 08G4/2023/V02/ENG. Subject to change without notice

RCP-2 G4 |Solar Carport / Canopy

Disclaimer

The Installation Manual outlines the necessary procedures and standards for installing the Blikir RCP-

2 and ensuring its proper functionality. It is important that you carefully review this manual before

starting the installation process. Failure to follow the instructions provided in the manual could result in

property damage, personal injury, or even loss of life. Additionally, please note that the RCP-2 Limited

Warranty can be found on the Blikir website at https://www.blikir.com/resources.

PLEASE COMPLY WITH THE FOLLOWING SAFETY MEASURES:

● Ensure safe installation of all electrical aspects of the array. All electrical installation and

procedures should be conducted by a licensed and bonded electrician or solar contractor.

Routine maintenance of a module or panel shall not involve breaking or disturbing the bonding

path of the system. All work must comply with national, state and local installation procedures,

product and safety standards.

● Comply with all applicable local, state and federal building and fire codes, as in effect from

time to time.

● Ensure all products are appropriate for the installation environment, and array under the site’s

loading conditions.

● Use only Blikir parts or parts recommended by Blikir.

● Review the Engineering Package and Certification Letters to confirm design specifications.

● Ensure the accuracy of all information provided.

● Validate foundation parameters prior to installation. A local geotechnical report may be

required to assess ground conditions. Blikir recommends consulting with a local engineer

familiar with local regulations and build site requirements, including soil conditions, terrain and

load criteria. All parameters may impact foundation requirements.

● Ensure bare copper grounding wire does not contact aluminum and zinc-plated steel

components, to prevent risk of galvanic corrosion.

● The Blikir carports and canopies are made of galvanized steel and spray painted with

protective and marine coating. This process ensures your carport or canopy will have teh

longest possible life expectancy. Do not drill or cut the steel components, that will expose the

steel and cause corrosion and void the warranty. Also, drilling or cutting the steel might

compromise the structure strength.

● If loose components or loose fasteners are found during periodic inspection, re-tighten

immediately. If corrosion is found, replace affected components immediately.

● Provide an appropriate method of direct-to-earth grounding according to the latest edition of

the National Electrical Code, including NEC 250: Grounding and Bonding, and NEC 690: Solar

Photovoltaic Systems.

● Disconnect AC power before servicing or removing modules, AC modules, inverters,

microinverters, Rapid Shutdown Devices (RSD) and power optimizers.

● Review module, inverter, Rapid Shutdown Device (RSD), racking (and any other components

that are not manufactured by Blikir) manufacturer’s documentation for compatibility and

compliance with warranty terms and conditions.

● Conform to STD UL 2703 (2015) Standard for Safety First Edition: Mounting Systems,

Mounting Devices, Clamping/Retention Devices, and Ground Lugs for Use with Flat-Plate

Photovoltaic Modules and Panels.

NOTE: Always check with the Authority Having Jurisdiction (AHJ) for additional requirements

3

Installation Manual

© BLIKIR.Inc, All rights reserved. BLIKIR and the BLIKIR logo are trademarks or registered trademarks of BLIKIR, Inc.

Date: 08G4/2023/V02/ENG. Subject to change without notice

RCP-2 G4 |Solar Carport / Canopy

Introduction

BRIEF DESCRIPTION

RCP-2 is a robust double carport / canopy that can accommodate up to 24 x 60/120 cell Panels, or 18

x 72/144 cell panels. It can be installed with a 2-person crew, and without the use of heavy tools or

machinery. The installation should be carried by trained professionals or qualified individuals, who

have been adequately instructed and trained about the tasks involved in the installation, including the

usage of protective devices, protective measures, relevant provisions, accident prevention regulations

and operating conditions and have proven their competence.

Please read carefully this installation manual and all other applicable documents before starting your

installation. Please contact Blikir with any questions that you may have.

The RCP-2 utilizes the IronRidge XR100, Slotted L-Foot, T-Bolts, Grounding Lug, Panel Bonding

Jumpers and CAMO Hidden End Clamps. Download the relevant certification from IronRidge website

for the most updated Specific Allowable Design Load Ratings at: https://base.ironridge.com/pitched-

roof-mounting/resources

Download and read carefully the Structural Engineering Certificate for the Blikir RCP-2 Solar Carport

which can be found here: https://www.blikir.com/resources

The RCP-2 is designed and certified to the structural requirements of the following standards, for the

conditions specified:

2012 International Building Code

2015 International Building Code

2018 International Building Code

2021 International Building Code

ASCE 7-10

ASCE 7-16

Ratings and Conditions Of Use

4

Installation Manual

© BLIKIR.Inc, All rights reserved. BLIKIR and the BLIKIR logo are trademarks or registered trademarks of BLIKIR, Inc.

Date: 08G4/2023/V02/ENG. Subject to change without notice

RCP-2 G4 |Solar Carport / Canopy

Maintenance

1. When you notice signs of rust or peeling/removal of paint, it is essential to address the issue

promptly by removing the rust and repainting the affected areas.

2. Whenever aluminum components are connected to the steel structure, it is crucial to apply

separation, such as EPDM rubber, to prevent galvanic corrosion.

3. Regularly inspect the bolts and ensure they are properly secured at least once a year. Follow the

specified torque specs for tightening.

4. In the event that the columns of the structure are impacted, such as by a vehicle collision,

immediate replacement of the columns is necessary for safety and structural integrity.

WARNING: The RCP-2 Carport/Canopy structure is constructed with hot galvanized steel and coated

with a marine-grade protective layer. It's important to note that any drilling or cutting of the structure

will expose the raw steel, making it susceptible to corrosion and potentially compromising the strength

and integrity of the structure. Such actions will void the warranty and may even lead to the collapse of

the structure under certain conditions. Therefore, we strongly advise against any modifications that

could compromise the structure's durability and safety.

5

Installation Manual

Torques

Horizontal Connections and Bolts Installation Guidelines

All horizontal connections within our system utilize sleeves, and the bolts are intended to

securely hold these sleeves in place. To ensure proper assembly, we recommend tightening

the bolts 1/4 to 1/3 turn beyond "snug tight“ or torque to 21 ft-lbs.

Please follow this torque guideline unless otherwise specified by the manufacturer for

specific connections subject to vibration or with bolt tightness requirements.

For the installation of base plate anchors and Solar Racking L-Feet, adhere to the

manufacturer's specifications provided in their respective installation manuals.

Important Maintenance Note:

To maintain the integrity of your installation over time, we kindly request that you periodically

inspect and tighten the bolts and nuts. This maintenance check should be conducted

regularly, and particularly after any significant weather events such as storms or

earthquakes.

By performing these routine inspections and tightening, you help ensure the continued

stability and safety of your structure.

© BLIKIR.Inc, All rights reserved. BLIKIR and the BLIKIR logo are trademarks or registered trademarks of BLIKIR, Inc.

Date: 08G4/2023/V02/ENG. Subject to change without notice

RCP-2 G4 |Solar Carport / Canopy

Required Tools

Tools

● Post Hole Digger or Powered Auger

● Socket Drive (7/16”, 9/16”, ¼” and ½” Sockets)

● Torque Wrenches (0-250 in-lbs)

● Transit, String Line, or Laser Level

● Spirit level

● Rotary hammer with concrete drill 20mm

● Cordless screwdriver

● Rubber hammer

● Hammer

● 2 x Scaffolding ladders

● Chalk line

● Folding rule / tape measure 7m

● Metal Saw

NOTE: The customer is responsible for sourcing materials for the footings based on the

specifications provided by the structural engineer or as indicated in the Structural Engineering

Package Notes applicable to their location (download at https://www.blikir.com/resources) -

recommended:

● Concrete

● Qty 48 x #4 Rebar 30”

● Qty 16 x Wire Mesh, 10 Gage min., 6” grid

● Qty 16 x Hilti HAS Rods

● HIT-HY 200 Adhesive

● Non-Shrink Grunt

6

Installation Manual

© BLIKIR.Inc, All rights reserved. BLIKIR and the BLIKIR logo are trademarks or registered trademarks of BLIKIR, Inc.

Date: 08G4/2023/V02/ENG. Subject to change without notice

RCP-2 G4 |Solar Carport / Canopy

Main Components

Overview

The following is a diagram that lists the main components of the RCP-2

A - Columns - lower end (9’)

B - Columns - height end (10’-7’’)

C - Corner connector A

D - Corner connector A Opposite Hand (O.H)

E - Corner connector B

F - Corner connector B Opposite Hand (O.H.)

G - Beam A

H - Beam B

I - Sleeve connector

J - Middle Connector

K - Base Plate

L - Escutcheon Plate (base plate cover)

7

G

J

C

D

H

F

K

E

I

L

B

B

Installation Manual

A

A

G

G

G

G

G

I

I

I

I

I

I

I

H

H

H

H

H

G

G

G

G

G

G

J

J

J

© BLIKIR.Inc, All rights reserved. BLIKIR and the BLIKIR logo are trademarks or registered trademarks of BLIKIR, Inc.

Date: 08G4/2023/V02/ENG. Subject to change without notice

RCP-2 G4 |Solar Carport / Canopy

Standard Dimensions

8

Installation Manual

© BLIKIR.Inc, All rights reserved. BLIKIR and the BLIKIR logo are trademarks or registered trademarks of BLIKIR, Inc.

Date: 08G4/2023/V02/ENG. Subject to change without notice

RCP-2 G4 |Solar Carport / Canopy

9

Installation Manual

© BLIKIR.Inc, All rights reserved. BLIKIR and the BLIKIR logo are trademarks or registered trademarks of BLIKIR, Inc.

Date: 08G4/2023/V02/ENG. Subject to change without notice

RCP-2 G4 |Solar Carport / Canopy

1 X Base Plate

Template

36 x Flanged Nuts

36 x 1” Hex Bolts

108 x Bolts and Nuts

2 X 10’-7’’ back

columns

4 X Escutcheon Plates 32 X EPDM

Separators

13

56

2

7

Prior to commencing your installation, please ensure that you have obtained all the components listed below.

Blikir Structure Components:

1 X Corner Connector

A O.H.

1 X Corner Connector B 1 X Corner Connector

B O.H.

910 11

6 X Beams B (no

holes)

8 X straight connector

sleeves

4 X middle connector

sleeves

13 14 15

2 X 9’ Front Column

1X Corner Connector A

4

8

12 X Beams A (with

holes)

12

Components List

10

Installation Manual

76 x 6”

32 x 5 ½”

NOTE: CUSTOMER NEEDS TO SOURCE materials for footings based on structural engineer

specification or the Structural Engineering Package Notes if applies for your location (download at

https://www.blikir.com/resources) - recommended:

● Concrete

● Qty 48 x #4 Rebar 30”

● Qty 16 x Wire Mesh, 10 Gage min., 6” grid

● Qty 16 x Hilti HAS Rods

● HIT-HY 200 Adhesive

● Non-Shrink Grunt

© BLIKIR.Inc, All rights reserved. BLIKIR and the BLIKIR logo are trademarks or registered trademarks of BLIKIR, Inc.

Date: 08G4/2023/V02/ENG. Subject to change without notice

RCP-2 G4 |Solar Carport / Canopy

32 X L feet 16 X XR100 Rails 8 X Bonded Splices

96 X CAMO Hidden

Clamps

3 X Panel Bonding

Jumpers

8 X XR100 End Caps

17 19

21 22

18

23

Ironridge racking components:

Grounding Wire (Sold

Separately)

24 X 60 cell Solar Panels

(sold separately)

26 27

Decorative Mesh

(optional)

EnelX EV Charger

(optional)

Self Tapping Screws

for EV Charger

Backplate

29

30 31

1 X Grounding Lug

32 X IronRidge T-Bolt

20

24

Sealing gasket

(optional)

28

EV Charger

Backplate (optional)

32

6 x Decorative Mesh

Carabiners

2 X Safety Column Solar

LED Light (optional)

2 X 3M VHB tape for

safety lights

33

34 35

Other components (order separately):

11

Installation Manual

© BLIKIR.Inc, All rights reserved. BLIKIR and the BLIKIR logo are trademarks or registered trademarks of BLIKIR, Inc.

Date: 08G4/2023/V02/ENG. Subject to change without notice

RCP-2 G4 |Solar Carport / Canopy

1 - Build Base

1.1 Mark Piers Locations

Mark the locations of the piers following the diagram.

Confirm that all angles are square. For a larger

version of the diagram, refer to page 9.

1.2 Dig Piers

Dig piers according to site conditions and system specifications in the Structural Engineering Package

(download at https://www.blikir.com/resources) and based on your structural engineer instructions for

foundations requirements.

Read section 1.5 of the installation manual before deciding on the depth of the piers. If you would like

to follow option B, dig deeper piers and cover the base anchors with gravel (to allow water to drain)

and top with concrete (instead of option A of using the base anchors decorative plates), add the

additional desired depth to the piers that you dig.

TILTED SURFACE: If the surface is tilted, you should dig the piers at the highest point deeper to

make sure all ballasts will eventually be leveled.

WARNING: Never install the carport tilted. The columns must be straight.

TIP: To measure how much deeper the highest point should be, connect 2 of the supplied solar rails

with the splice, position one end on the highest point, use a level to make sure it is leveled and

measure the space between the lower marked pier location to the rail. This is the additional depth you

need to dig the highest point location in order to have them leveled.

IMPORTANT: The structure's foundations should be calculated taking into account site conditions,

frost line, soil type, maximum wind and snow loads for the site location and the product mechanical

loading specifications. In some cases, a geotechnical study is required. Please consult with your local

AHJ and a structural engineer.

WARNING: In areas subject to freezing, pier depths may increase to resist freeze heave. Always

consult a structural engineer to confirm.

WARNING: Before you dig any holes, contact all utilities in the area to locate any underground lines,

pipes, and wiring.

12

Installation Manual

© BLIKIR.Inc, All rights reserved. BLIKIR and the BLIKIR logo are trademarks or registered trademarks of BLIKIR, Inc.

Date: 08G4/2023/V02/ENG. Subject to change without notice

RCP-2 G4 |Solar Carport / Canopy

1.3 Build Reinforcing Steel Grid and Fill Holes with Concrete

If you want to run the electric wires through the back columns, bend a conduit, run all the wires through

the conduit and lay it in the desired location.

NOTE: Not all carports and canopies are fabricated with wire path through the column. Make sure you

know where the wire run before pouring the concrete. In most models, the two back columns will have

wire path and EV charger assembly pilot holes.

GENERAL: Center all footings under columns above. Contractor shall locate all buried utilities prior to

excavation. Refer to the Structural Engineering Package Notes (download at

https://www.blikir.com/resources)

FOUNDATIONS: Footings are designed for an allowable soil bearing pressure of 1,5000 PSF.

CONCRETE: Concrete strength shall be as follows:

F’c W/C MIN CEMENT MAX AGGREGATE SIZE SLUMP

3000 PSI 0.58 470 LBS 1" 4” (+/-) 1”

Cement shall conform to ASTM C150, Type 1. Fly ash conforming to ASTM C618, Type F or Type C,

may be used to replace up to 20% of the cement content. Aggregate shall conform to ASTM C33.

Concrete shall be cured immediately after finishing operations.

REINFORCING STEEL: Reinforcing steel shall conform to ASTM A615, Grade 60, and shall be

securely tied in place with #16 annealed iron wire. Required clear concrete cover: 3” bottom and sides,

2” top.

SLOPED SURFACE: If the surface is sloped, you should dig the piers at the highest point deeper to

make sure all ballasts will eventually be leveled. In this case, you will need to fill the gap between the

base anchors and the surface with gravel to allow water to drain out of the column and base plate, if

penetrated. You can cover part with gravel and the remaining with more concrete after you complete

the installation.

If you choose to follow option B that is described in section 1.5 and install the base anchors lower than

the surface, pour the concrete up to the desired height under the surface.

13

Installation Manual

© BLIKIR.Inc, All rights reserved. BLIKIR and the BLIKIR logo are trademarks or registered trademarks of BLIKIR, Inc.

Date: 08G4/2023/V02/ENG. Subject to change without notice

RCP-2 G4 |Solar Carport / Canopy

1.5 Install footings

Mark the locations of the anchors and remove the column base plate template (1).

Using a concrete drill bit, create holes that are ⅛” larger than the specified rod size for your location. Install the

four concrete anchors (not provided by us) into the concrete. Please follow the installation instructions and torques

specified by the Encore manufacturer for the specific type being used.

OPTION A: Place the escutcheon plate (6) over the footing to conceal the concrete anchors and base plate (1).

OPTION B: As an alternative installation method, you may choose to dig the piers (section 1.2 of the installation

manual) 3” to 5” deeper than the specified requirement. Position the base anchors lower than the surface, and

after completing the installation, cover the base anchors with gravel and additional concrete to conceal the footing

in concrete. The use of gravel is necessary to facilitate proper water drainage.

14

(1)

1 X

1.4 Align the Base Plates

Wait for the concrete to solidify.

Your kit includes 1 base plate template.

Align the base plate template (1) with the horizontally punched hole facing forward.

Use the footings locations template to locate the other base plates accurately. You should measure exactly 18’

between the center of adjacent footings or 17’ between the internal edge of the base plate, and 25'-5 ½” between

the center of the base plate along the diagonal (see sketch on page 9 of this installation manual). These

measurements change when installing the EX-HD base plates, Tandem Kit or RCP-1 for one car.

Installation Manual

(1)

1 X

© BLIKIR.Inc, All rights reserved. BLIKIR and the BLIKIR logo are trademarks or registered trademarks of BLIKIR, Inc.

Date: 08G4/2023/V02/ENG. Subject to change without notice

RCP-2 G4 |Solar Carport / Canopy

2.2 Prepare sleeves and connectors with leveling system

2 - Build Structure

2.1 Connect columns

Decide where you want the carport to face. The front columns should be the 9’ front columns (4), and

the back columns should be the 10’-7’’ back columns (5).

Slide the 9' front columns base plate (4) and 10'-7" back columns base plate (5) onto the anchored

footing and secure them to your enchores.

Slide the Escutcheon Plate (base plate cover) (6) on each column and cover the base plates.

(4) (5) (6) (7)

2 X 2 X 4 X 4 X 5”

15

Installation Manual

(8) (9) (10) (11) (14) (15) (2)

1 X 1 X 1 X 1 X 8 X 4 X 36 X

In order to level the system, the corner sleeves (8, 9, 10, 11), straight connector sleeves (14), and

middle connector sleeves (15) are equipped with precut hex holes that perfectly accommodate the

provided flanged nuts (2).

Using these flanged nuts and 1” bolts, you can apply pressure to the beams (12, 13) during the final

assembly phase to level the roof of the structure.

To proceed, insert one flanged nut into each hex hole, ensuring the flange sits within the sleeve while

the hex nut protrudes from the hole. Next, secure each nut in place by screwing in a 1” bolt to prevent

it from falling out. Ensure that the bolt does not extend beyond the flange to avoid any interference

when later sliding the beams (12, 13) into the sleeves.

Keep in mind that you must connect all 36 bolts and nuts during the process.

Once the installation is complete, tighten all the bolts (2) to level the beams (12, 13) effectively.

2.2 Prepare sleeves and connectors with leveling system

© BLIKIR.Inc, All rights reserved. BLIKIR and the BLIKIR logo are trademarks or registered trademarks of BLIKIR, Inc.

Date: 08G4/2023/V02/ENG. Subject to change without notice

RCP-2 G4 |Solar Carport / Canopy

2.3 Connect corners

5’’ Sleeves

Extension

There are four types of corner

connectors:

Corner connectors A (8) and A O.H. (9)

are designed to connect to the high 10’-

7’’ columns, with these connectors

featuring an angled down orientation.

Corner connectors B (10) and B O.H.

(11) are meant for the low 9’ columns,

and they have an angled up orientation.

It's important to note that corner

connector A (8) and A O.H. (9) have a

distinguishing feature: the position of the

extension relative to the sleeves.

Similarly, corner connector B (10) and B

O.H. (11) are mirror images of each

other.

Slide the corner connectors (8, 9, 10, 11)

onto the columns (4, 5) and firmly fasten

them using four of the provided 6” bolts,

eight washers (two per bolt), and four

nuts (2).

(8) (9) (10) (11) (3)

1 X 1 X 1 X 1 X 4 X 6”

2 - Build Structure

10’-7’’ column

Corner

Connector A (8)

9’ column

Corner

connector B (10)

9’ column

Corner

connector B O.H. (11)

Take extra care to ensure you are using the appropriate corner connector orientation: the 5"x5" sleeves should face

the structure frame, and the extension should face outward. Additionally, the high column corner connector sleeve

should be angled downward, while the low column corner connector sleeve should be angled upward.

10’-7’’ column

Corner

connector A O.H. (9)

16

Installation Manual

Decorative Mesh

Installation Ring

© BLIKIR.Inc, All rights reserved. BLIKIR and the BLIKIR logo are trademarks or registered trademarks of BLIKIR, Inc.

Date: 08G4/2023/V02/ENG. Subject to change without notice

RCP-2 G4 |Solar Carport / Canopy

2.4 Connect beams to corner connectors

During this step, you will install two types of beams: Beams A (12),

which have pre-drilled holes, and Beams B (13), which do not have

holes.

Beams A (12) will be placed in the E-W direction, between corner

connectors of the same height. On the other hand, Beams B (13) will

be installed in the N-S direction, between corner connectors of

different heights.

To proceed, follow these steps for each type of beam:

For Beams A (with holes) (12):

1. Slide Beams A (12) onto Corner Connector A towards Corner

Connector A O.H and vice versa.

2. Slide Beams A (12) onto Corner Connector B towards Corner

Connector B O.H and vice versa.

3. Secure the beams with 6” bolts, using two washers for each bolt

and three nuts. To do this, slide a washer onto the bolt screw, insert

the bolt screw through the hole in the beam and corner connector,

then slide another washer onto the bolt before securing with a nut.

For Beams B (without holes) (13):

1. Slide Beams B (13) onto Corner Connector A towards Corner

Connector B O.H and vice versa.

2. Slide Beams B (13) onto Corner Connector B towards Corner

Connector A O.H and vice versa.

3. Secure the beams using the same method as with Beams A, with 6”

bolts, two washers for each bolt, and three nuts.

Finally, tighten the set screws you installed on the corner sleeves in

step 2.2 until the beams are appropriately leveled.

4 X 4 X 16 X 6”

Beams A installed E-W:

Beams B installed N-S:

SIDE VIEW: TOP VIEW:

17

Installation Manual

Note the order of the

nuts and bolts to allow

tightening both without

hitting the two nuts

(12) (13) (3)

© BLIKIR.Inc, All rights reserved. BLIKIR and the BLIKIR logo are trademarks or registered trademarks of BLIKIR, Inc.

Date: 08G4/2023/V02/ENG. Subject to change without notice

RCP-2 G4 |Solar Carport / Canopy

2.5 Slide connector sleeves on Beams

Install the straight connector sleeves (14) on beams between columns

of the same height (9' to 9', and 10'-7" to 10'-7"). Ensure the precut

hex holes face the ground.

Place the middle connector sleeves (15) on beams between columns

of different heights (9' to 10'-7" and vice versa). Ensure the precut

hex holes face the ground.

Position the sleeve fully on the beam, leaving space for the middle

beam to slide between the connected beams.

(14) (15)

4 X 4 X

2.6 Connect middle beams

This step is similar to step 2.4 and involves installing beam

A (12) in the E-W direction and beam B (13) parts in the N-

S direction, as shown in the diagram.

Place the middle beam between the already installed

beams. Slide the connector sleeves back to cover both

beam pieces, and then secure them using the 6” bolts,

washers (2 per bolt, one on each side of the sleeve), and

nuts (3).

Finally, tighten the set screws you installed on the sleeves

in step 2.2 until the beams are appropriately leveled.

(12) (13) (3)

2 X 2 X 16 X 6”

Beam A (12)

Beam B

(13)

TOP VIEW:

18

Installation Manual

© BLIKIR.Inc, All rights reserved. BLIKIR and the BLIKIR logo are trademarks or registered trademarks of BLIKIR, Inc.

Date: 08G4/2023/V02/ENG. Subject to change without notice

RCP-2 G4 |Solar Carport / Canopy

(12) (14) (3)

6 X 4 X 16 X 6”

2.7 Connect beams at the center

To connect the beams at the center of the structure, follow these steps:

a. Slide Beams A (12) onto middle connector sleeves (15) and secure them using 6” bolts,

washers (2 per bolt, one on each side of the sleeve), and nuts (3). Tighten the set screws

from step 2.2 until the beams are leveled.

b. Install straight connector sleeves (14) on the beams installed in step 1. Ensure the precut

hex holes face the ground and fully position the sleeve on the beam, leaving space for the

middle beam to slide between the connected beams.

c. Place the middle beam between the installed beams. Slide the connector sleeves back to

cover both beam pieces, and secure them using 6” bolts, washers (2 per bolt, one on each

side of the sleeve), and nuts (3). Finally, tighten the set screws from step 2.2 until the beams

are appropriately leveled.

19

Installation Manual

(a) (b) (c)

© BLIKIR.Inc, All rights reserved. BLIKIR and the BLIKIR logo are trademarks or registered trademarks of BLIKIR, Inc.

Date: 08G4/2023/V02/ENG. Subject to change without notice

RCP-2 G4 |Solar Carport / Canopy

3 - Connect Rails

(17) (16) (7)

To proceed with the assembly, refer to the IronRidge Installation Guide available at the

following link: https://base.ironridge.com/pitched-roof-mounting/resources

Please note that the information provided here is a general description of the assembly

process and should not be used as a standalone guide. It is essential to read the IronRidge

installation manual thoroughly, as it may be subject to frequent updates.

Installing the IronRidge components without following their official installation manual could

potentially void the IronRidge Product Limited Warranty. Therefore, we highly recommend

consulting the installation manual for accurate and up-to-date instructions.

Important: When installing your system, make sure to utilize the installation manual provided by the

racking manufacturer.

Vertical side of L feet faces this way

20

Installation Manual

3.1 Connect L-Feet

(17) (7) (3)

32 X 32 X 32 X 5 ½”

Depending on the dimensions of the solar panel used, choose the appropriate location for the L-Feet

on middle beams A (12). The placement of the L-Feet will vary based on the specific dimensions of

your solar panels.

Cover the selected pre-drilled holes on middle beams A (12) with L-Feet EPDM separators (16).

Please refer to the diagram below for the positioning of the L-Foot (17). The L-Foot has both a

horizontal and vertical face. Place the L-Foot with the vertical face on the right side for L-Feet to the

right of the center of the structure. Conversely, for L-Feet to the left of the center, position the vertical

face on the left side.

Secure the L-Feet using the provided 5 ½” bolts, washers (2 per bolt - one on the L-Foot and one

under the beam), and nuts (3). Torque to 250 in-lbs (21 ft-lbs).

© BLIKIR.Inc, All rights reserved. BLIKIR and the BLIKIR logo are trademarks or registered trademarks of BLIKIR, Inc.

Date: 08G4/2023/V02/ENG. Subject to change without notice

RCP-2 G4 |Solar Carport / Canopy

Table of contents

Popular Tent manuals by other brands

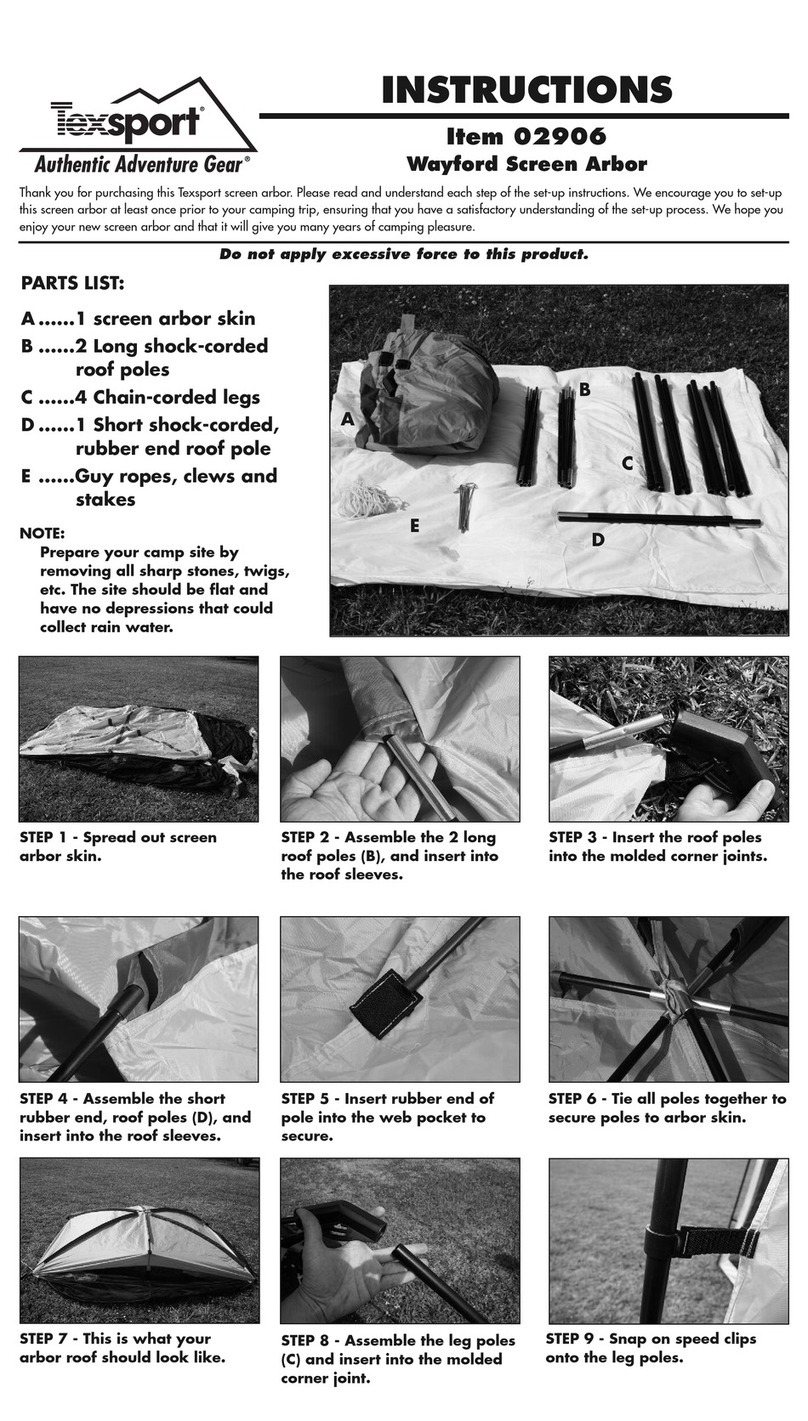

Texsport

Texsport 02906 instructions

Otter

Otter Pro XT Lodge Installation and setup instructions

aluSKY

aluSKY aluSKYcrown Mounting instructions

Caravan

Caravan Domain V-10201386 Installation instructions and operators manual

Atleisure

Atleisure GAZ-902220 Assembly and user's manual

Cabanon

Cabanon BORA BORA Instructions for setup