BLO-BLADES OM-KQ-7E User manual

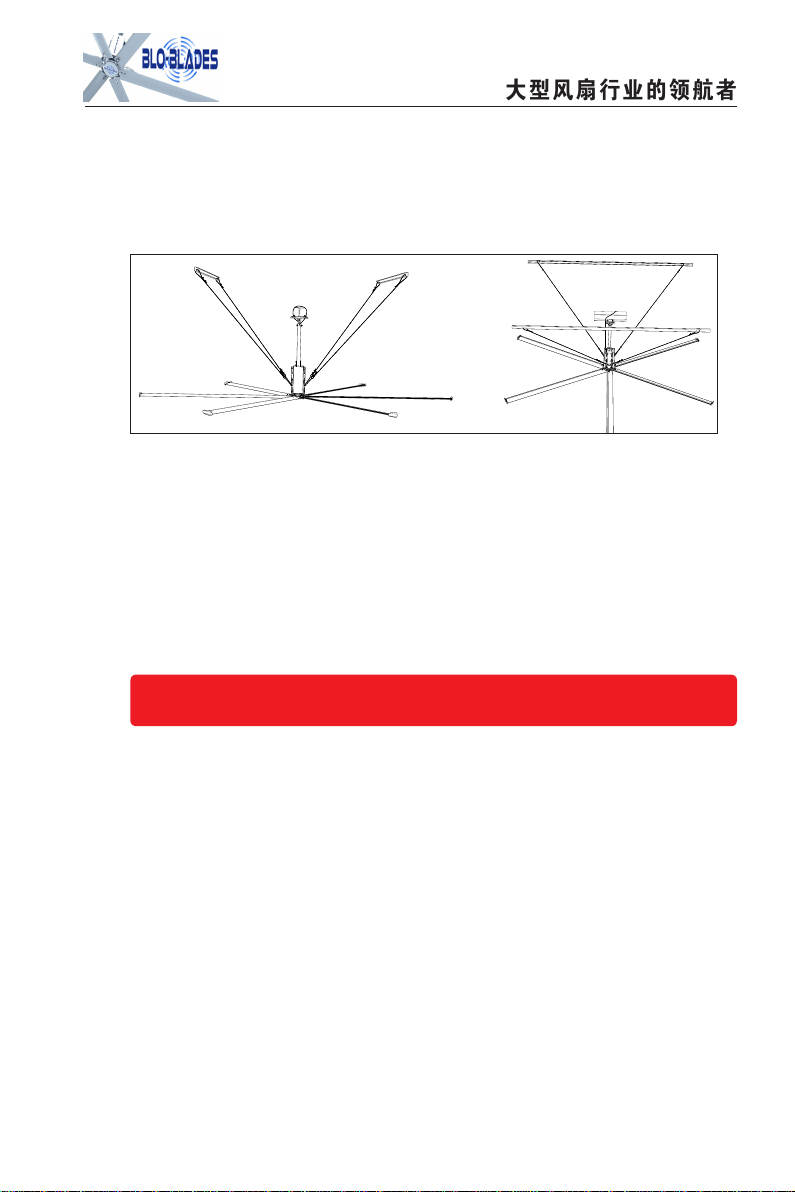

"Open" Large Fans Assembly drawing

………………2-3

1.

Introduction ……………………………………4-7

2. Safety Issues ………………………………7-8

3. Pre-Installation ………………………9-12

4. Installation Procedure & Sequence......................13-19

5.

Electrical installation ……………………19-21

6.Guy Cabling BloBlades ………………………22-23

7.Start-up procedure

…………………23-24

8. Cleaning And User Maintenance ………………24-25

9.General trouble shooting

……………………………26

10.

Letter of Warranty ………………………………27

11. Limitation of warranty and liability

………………28-29

Blo-BladesContents

大型风扇行业的领航者

3

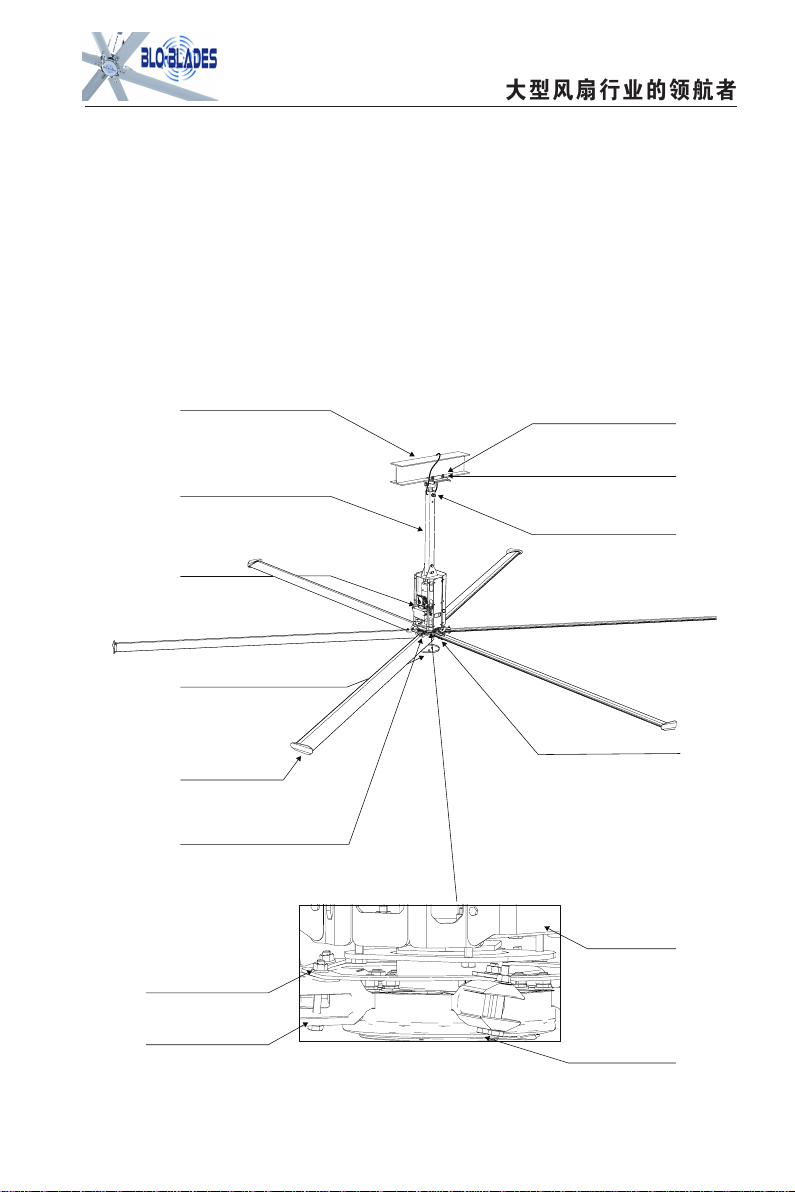

BloBlades Large Fans Components

6ea

Fan

T

ail

Caps

1ea R

oof

Fastening

A

ssembly

6ea

Fan

B

lade

C

onnector

Airfoil Safety

R

etainer

Plug In

B

ottom

C

over

Main

M

otor

1ea

Universal

J

oint

A

ssembly

Structural Support

of the building

- Typical

I Beam 4ea

M16

Nut/Bolt

1ea

Extension

B

ar

- Other

Lengths Available

1ea

Ho

i

st

A

ssembly

6ea

Fan

B

lade

I

nterconnection

Safety

Assemblies

1ea Fan

C

over

-

6ea Fan Blades

Introduction

1.1.Thank you and congratulations on your BloBlades Fan purchase, Younow have

an

efficient and cost effective way to stay cool in summer and warm in the winter. The

sleek revolutionary design of our fans will look great in any commercial or industrial setting.

More importantly, you can rest assured that you have a product that is backed by

extensive research, thorough testing, and quality manufacturing.

If you have any questions or comments, contact us at 833-BLO-FANS or visit our web site

at www.BloBlades.com

1.2 BloBlades represents the number one and leading manufacturer of HVLS Fans,

for

large industrial fans with large coverage and in all directions. For

many decades, there

has been focus on only one thing: HVLS Big Fans development and

innovation,which

are widely use in large warehouses & distribution centers, manufacturing

facilities and

commercial buildings with high ceilings to deliver maximum airflow,Our fans

are not

only the most reliable and efficient ever built, but have also been proven to be the

professional's choice for ventilation needs in large space.

1.3 About this Fan

1.3.1

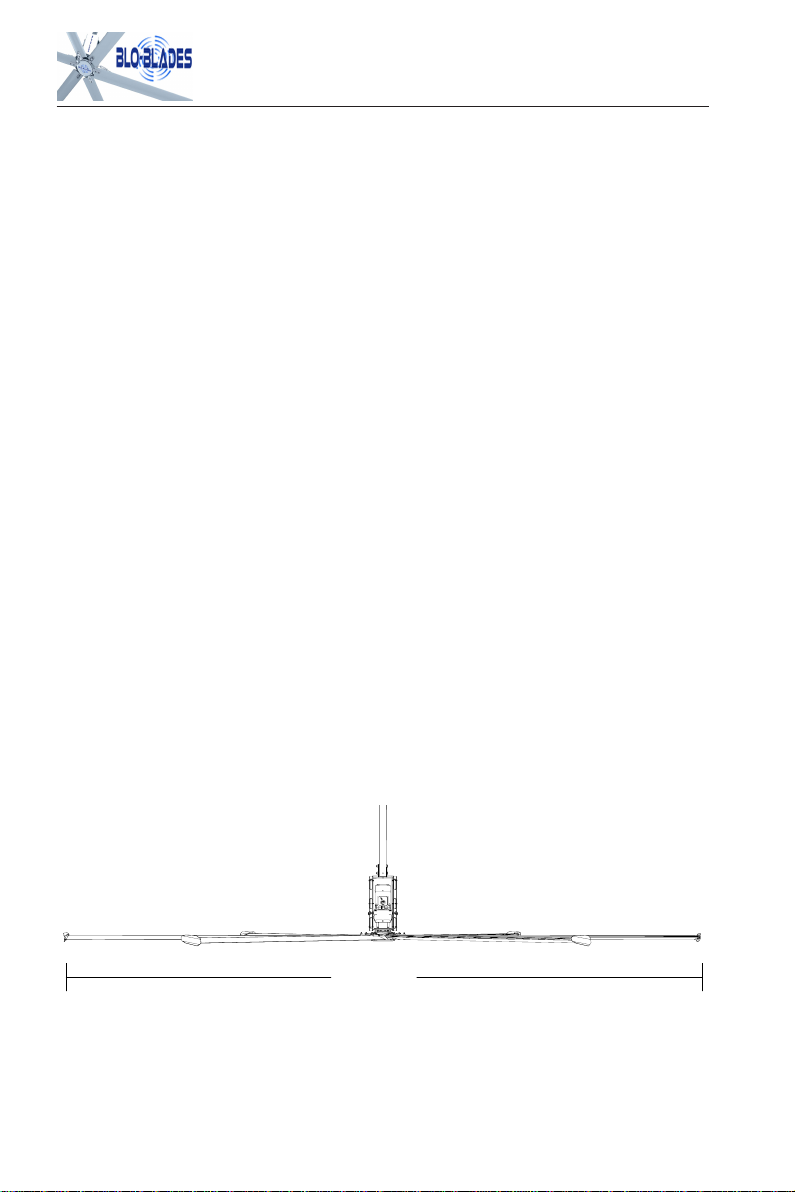

Fans Diameter: 12FT-24 FT/3.7-7.3 Meters

1.3.2 Each fan has six airfoil fan blades; Aluminum alloy, anodized treatment after the

sand blasting and chemical polishing.

4

12' - 24'

大型风扇行业的领航者

1.3.3 Fans Hub:American AA7075 extremely

hard

aluminum alloy,

with high

pressure

precision

forging

forming, dynamic

balancing

test

after

CNC

precision

machining.

1.3.4

Reduction Gear

Germany - NORD SK32F-VL90L/4 coaxial helical gear reducer.

Output shaft uses the SKF VL taped roller bearing, Shell Omala VG680 synthetic gear oil

has 20,000 hours of free maintenance; The output shaft uses Freudenberg Simrithigh

temperature double lipped output oil seal; Gear Box automatic exhaust valve;New

generation

energy-efficient

level

4

motor

with

NEMA

IE2

Standards,

220V/480V/60HZ IP55/F,IM:M4/4/I; Power: 1.5kw;50/60 HZ;480/220V

5

6

1.3.5 Motor Control Panel

(MCP)Danfoss FC51 Built-in RF line filters and brake chopper, with radio functionality

interference suppression and brake

- The functions of ground fault protection、

higher temperature protection, short-circuit

protection and etc.

- Stepless

speed

regulation,

The

peripheral

speed and switch gear

- NEMA

standards

control

box,

PVDF

paint surface treatment.

- IP65 protection class, CAKU cooling fan forced ventilation

- The operation instructions and warning labels are printed in control box.

3Ph/480V/60Hz or 1Ph/220V/60hz are available for power supply.

1.3.6 Safety System Components

BloBlades "Open" fans are engineered with key safety features to prevent pieces of the

fan from

falling in the unlikely event of a catastrophic failure. Used together, these

systems and

devices provide comprehensive protection of people, equipment, and

property. Follow the

detailed instructions precisely when installing fans, including the

following: You must install safety cable for warranty to be in effect.

It completely eliminates

the

riskof

falling

down

due to failure

ofthe hub

or drive shaft connection

of the six extension

blades.

大型风扇行业的领航者

7

Safety issues

IMPORTANT SAFETY INSTRUCTIONS, READ AND SAVE THESE INSTRUCTIONS

警告:

WARNING—TO

REDUCE

THE

RISK

OF

FIRE,

ELECTRIC

SHOCK,

OR

INJURY

TO

PERSONS, OBSERVE THE FOLLOWING:

2.1 Installation work and electrical wiring must be done by qualified person(s) in

accordance with all applicable codes and standards.

CAUTION:

The installation of a BloBlades "Open" fan must be in accordance with the

requirements

specified in this User manual and with any additional requirements set forth

by the national electric code. Code compliance is ultimately YOUR responsibility!

WARNING:

The fan controllers contain high voltage capacitors which take time to

discharge after removal of mains supply.

Before working on the fan controller, ensure isolation of main supply from line inputs at

Safety links should be connected each blade and to the adjacent blades and reinforce the

area between the mounting holes, this precautionary measure will help prevent a blade

from falling should one break off at the hub for any reason.

The four guy wires will keep the fan stable in case of earthquake or in "outdoor"

installations where high wind conditions may occur or indoor situations that may have

drafts that affect the balance of the fan.

6mm (approx 1/4") safety cable will prevent the fan from falling in the unlikely event the

mounting system

should fail.

Hanging Weight (average) :207lbs---276lbs

8

the fan controller's disconnect (L1,L2/N, L3). Wait 3 minutes for capacitors to discharge

to safe voltage levels (note: darkened display LEDs are not an indication of safe voltage

levels). Failure to do so may result in personal injury or death.

CAUTION:Exercise caution and common sense when powering the fan. Do not connect

the fan to a damaged or hazardous power source. Do not attempt to resolve

electrical malfunctions or failures on your own. Contact BloBlades at

833-Blo-Fans

if you have any questions regarding the electrical

installation

of

this fan.

2.2 A scissor lift or movable scaffolds for lifting weight of the fan and at least two

installation personnel will be required, please check and confirm its safety &

reliability,

and each person installing the fans on the site must use a helmet and safety

harness at all

times.

BloBlades Fans must be installed with the BloBlades supplied controllers which are

suitable with this model. Other parts or controllers cannot be substituted.

CAUTION:

When service or replacement of a component in the fan requires the removal

or disconnection of a safety device, the safety device is to be reinstalled or

remounted as previously installed.

2.3 WARNING—TO

REDUCE

THE

RISK

OF

FIRE,

ELECTRIC

SHOCK,

OR

INJURY

TO PERSONS, OBSERVE THE FOLLOWING:

a) Use this unit only in the manner intended by the manufacturer. If you have

questions, contact the manufacturer.

b)

Before servicing or cleaning unit, switch power off at service panel and lock the

service disconnect to prevent power from being switched on accidentally. When

the

service disconnect cannot be locked, securely fasten a prominent warning

device, such as a tag, to the service panel.

CAUTION:

Do not bend the blades when installing, adjusting, or cleaning the fan. Do not

insert foreign objects in between rotating fan blades.

CAUTION:

The Bloblades Fans product warranty will not cover equipment damage or

failure that is caused by improper installation.

大型风扇行业的领航者

Pre-Installation

3.1 3.1

Check lists before installation

Installation Tools

Level; Pliers; Cable Cutters; M8-M10 (2 sets outer hexagonal wrench); Scissor Lift or

Scaffold; Wrench 4 sets; Phillips Screwdriver; Electric Drill; M4.2 bit;

Torque Wrench; M8-M30 Socket Wrench

Typical mounting methods

Each type of building structure requires a specific mounting bracket, BloBlades

Fans can

only be hung from standard mount with an I-beam or concrete beam. For

buildings with

glulam beams (laminated wood), an additional set of brackets is required

and can be purchased separately. Consult a structural engineer for installation methods.

1)

Verify with the contractor, building owner, or structural engineer to ensure the building

structure is sound and adequate to support the load prior to fan installation.

2)

Take measurements of the height of the bottom of I-beam and blade level.

3)

Check if you have the correct power circuit for the fan.

3.2 General Mounting Considerations

CAUTION:

Bloblades Fans product warranty will not cover equipment damage

or

failure that is caused by improper installation.

3.2.1 Weight

A standard six blade 24' fan which is the biggest fan is about 276lbs. In applications

where the

Motor is inverted to below upward (very unusual) there is an additional down

force of 110lbs. Due to fan thrust. If there is any doubt of this, a professional structural

engineer should perform a thorough evaluation of the building prior to purchasing fans

BloBlades Fans can only be hung from an I-beam or concrete beam and angle irons on

main structure of building. Do not mount the fan to single purlins, trusses, or bar

joists. Consult a structural engineer for installation methods not covered in the manual.

9

3.2.2 Torque

The maximum torque (twisting force) that must be handled by the mounting systems

occurs at start up. For a 24' BloBlades Fan the starting torque is potentially 220 N.m.

Maximum. We say "potentially" because with the standard electrical controls supplied,

the

maximum

is

never

even

approached

because

the

controls

employ

soft

start

technology. This prevents full torque from being applied at startup. But there is always the

possibility of failure of the soft start technology. It is important that the mount is

adequate to withstand 220 N.m.

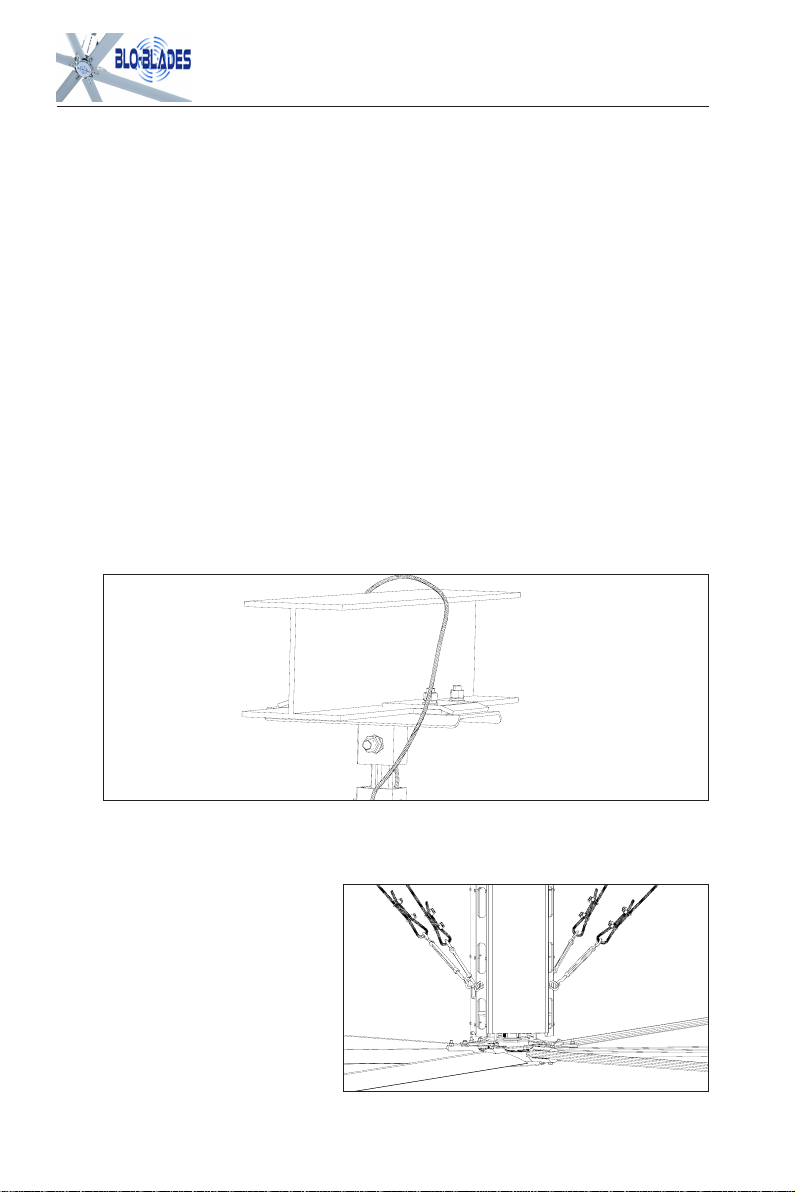

3.2.3 Safety Cable

Because of the obvious risk of a falling fan, whatever mounting method is used to suspend

the fan, it should always be backed up with a safety cable.

Safety cable, along with all required hardware, is supplied with every fan. An HVLS fan

should never be run without a properly installed safety cable. Refer to fig. 3.1 for

proper installation of safety cable.

3.2.4

Clearance and Guy Cables

In some cases space

considerations dictate that

blades swing

close

to

beams,

column, lights, etc. Anything less

than 12" can be considered "close

clearance”because these fans

have the potential to move around

quite a

bit.

Fig3.2 Install methods of Guy Cables

10

Fig3.1

OODNO G GOOD

大型风扇行业的领航者

It is important to try to avoid close clearance. Where clearance turns out to be a real

problem, bear in mind that both longer down extension rods and shorter blades are

available for purchase. In any case, since the standard mounting is free swiveling, we

strongly recommend that all fans be guy wired as shown in fig.3.2. if close clearance is

involved, the fan must be guy wired. Where the fan frame is bolted directly to a rigid

beam, it may not require guy wiring.

3.3. Positioning

It is important that an HVLS fan not be positioned where a person could actually come in

contact with it. This means that a fan should never be mounted lower than 10' above the

floor. Similarly, if there is a mezzanine section in the facility, it is important that a fan not be

placed so close to the mezzanine, that a person on an upper tier could reach out and

contact the fan.

Wherever there is a potential for a forklift to elevate something into the fan, or people

working with long material inadvertently making contact with the fan, the floor directly

below the fan should be painted in such a way (i.e. a large crosshatched circle) so as

to alert workers to the fan above. In such cases, the fan may have to be guarded.

3.3.1

Horizontal Positioning

The way these fans spread air flow over such a large area is that the down flowing

11

4.5

Fig3.2 Install methods of Guy Cables

8"

12"

14.5'- 49'

12"

143.5"

42"

air column, upon reaching the floor, turns into a horizontal floor jet radiating out in all

directions. Under ideal conditions a 24' diameter overhead fans can serve up to

19,375sq/ft of floor space. Ideal conditions are: a fairly symmetrical area equates to

very few obstructions on the floor, and walls at the boundary of the area.

Obstructions on the floor, such us partitions or machinery tend to block the floor jet,

reducing the reach of the fan. The ideal center to center spacing, therefore, will vary

depending on the amount and size of these floor obstructions, as well as the nature of the

operations being conducted in the affected area and the construction of the building (i.e.

beams, etc.). In a manufacturing environment where there are many work stations each of

which must get good air movement, a solution is fans with close centers, running slowly.

For example, 24' long blade fans located on 60' centers, running at about 53rpm, might

be appropriate.

Conversely, in a warehouse where workers are moving around a lot and a little windiness

here and there is not a problem, 24' long blade fans on 110' centers might be suffice.

3.3.2 Vertical positioning

In many applications physical limitations——overhead cranes, low ceilings, etc.-dictate

vertical positioning, Where there is some latitude, here are the primary points to consider:

From a strictly performance point of view, 19.5' to 33' is the optimum height range for a

24' fan, but we have seen fans mounted as low as 9.75' and as high as 52.5' working

well. (HVLS fans should never be lower than 9.75' above the floor)

A fan must not be so close to the ceiling that is starved of air; it should be no less than

15% of its diameter from the ceiling. If the ceiling is pitched,the blades can come closer

on one side so long as there is ample open area on the other side.

If possible, fans should be high enough to be beyond the reach of forklifts and any long

material that workers might be handling.

Conversely, where fans are used to cool people working in just one part of very large

building with a very high ceiling, lower mounted fans may be in order. In such an extreme

case high mounted fans would re-circulate cooler air, leveling the hot air undisturbed.

12

大型风扇行业的领航者

Installation Procedure & Sequence

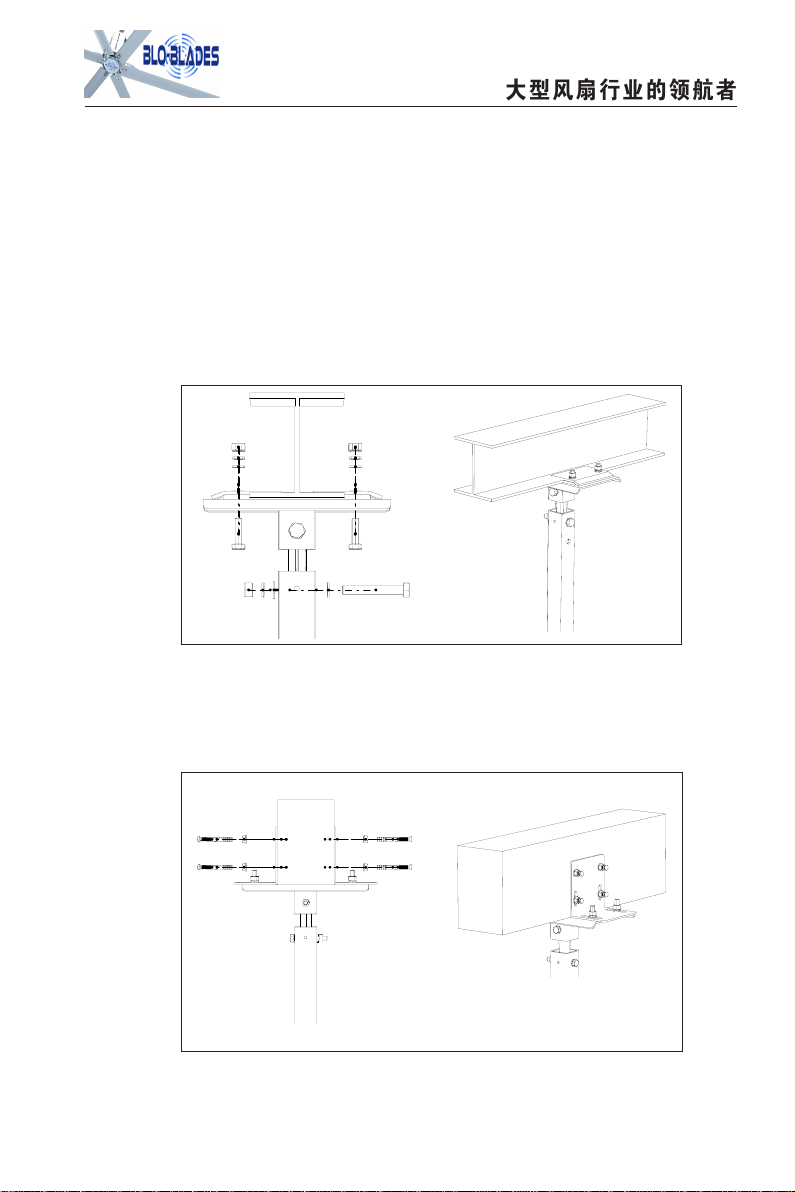

4.1 Equipment and Beam Connection

There are two standard installation methods that the fan is connected to the

(1)Connection with Steel I-beam by adjustable standard clip device, the fan can be easily

clip on any steel I-beam, without the need to change any steel beam (figure 4.1).

(2)Connection with concrete beam, the standard device is fixed by expansion bolts on the

concrete beam, the device can be adjusted according to the width of the beam, meeting

the

demand of concrete beams with different dimensions .

(3)If your facility has another structure please call (833-BLO-Blades) for potential

mounting options.

13

Note:

If

the beam is level,it is sometimes OK to bolt directly to the I-beam e.g.

14

Fig4.1 Installation Method of I-Beam

4.2 Installation of the Universal Joint

The standard mounting hardware that comes with an BloBlade fan has a 300mm

extension or drop, and clamp designed for use on a steel I beam without modification to

the beam (fig.4.2). since beams are often sloped so the roof can shed water, and not all

roofs slope the same, the mount is free- swiveling. This allows the fan to find its own level

position no matter what the slope.

Fig4.2

Univisal Joint

大型风扇行业的领航者

if head room is a problem-as long as there is adequate“breathing room” above the fan.

But, be advised that sometimes a fan would run with almost no sway when hung from our

free swiveling mount, will sway radically when bolted directly to a lightweight beam of

commonly found in steel building. This is because a slight imbalance can, at a certain

rpm, excite the natural frequency of the beam in torsion, thereby amplifying the sway. Also,

without the free swiveling mount, more noise is telegraphed back to the building structure.

4.3

Installation of the drive device

(1)The drive device has been installed into a unit before shipping out, only fix it to the

extension rod by using bolts, as shown in figure 4.3.

(2)Due to the drive device weight, 2-3 people are

needed to install. If there is a scissors lift, you can use the

lift to assist in assembly, the hoisting weight of the lifting

equipment shall not be less than 440lbs, the hoisting

process must be slow, even, and at the same time it needs

someone to hold the drive device, to prevent oscillation.

(3)Do not remove oil plug until fan is properly mounted. If

the oil plug is removed before the fan is mounted, oil in the

gear reducer may spill out.

4.4

Run the conduit and install wiring,

(1)

along the facility structure, along the top of the beam layout, per code.

15

Fig4.3

Installation of the driving unit

(2)Run

the wire conduit layout in as short of a run as possible.

(3)Before wiring, be sure to have the power supply turned off and then wire the motor circuit,

if the factory power supply is 480V, connect the motor according to the Y type

connection wiring,

if the factory power supply is 220 V, the motor according to the

△connection

wiring.

(4)After the motor wire has been connected, then connect the electric wires to the

electric cabinet.

4.5 Installation of the guy wires

Each BloBlade Fan has four circular uniform guy wires, try to ensure that the angle

between each gay wire and the drive device is 45 °, too big or too small will effect the

guy wire. The function of the guy wire is mainly the following:

(1)To reduce the fan shake when running.

(2)The guy wires ensure that the level of the fan, improve the dynamic balance of the fan.

(3)The safety protection devices to prevent falling the fan.

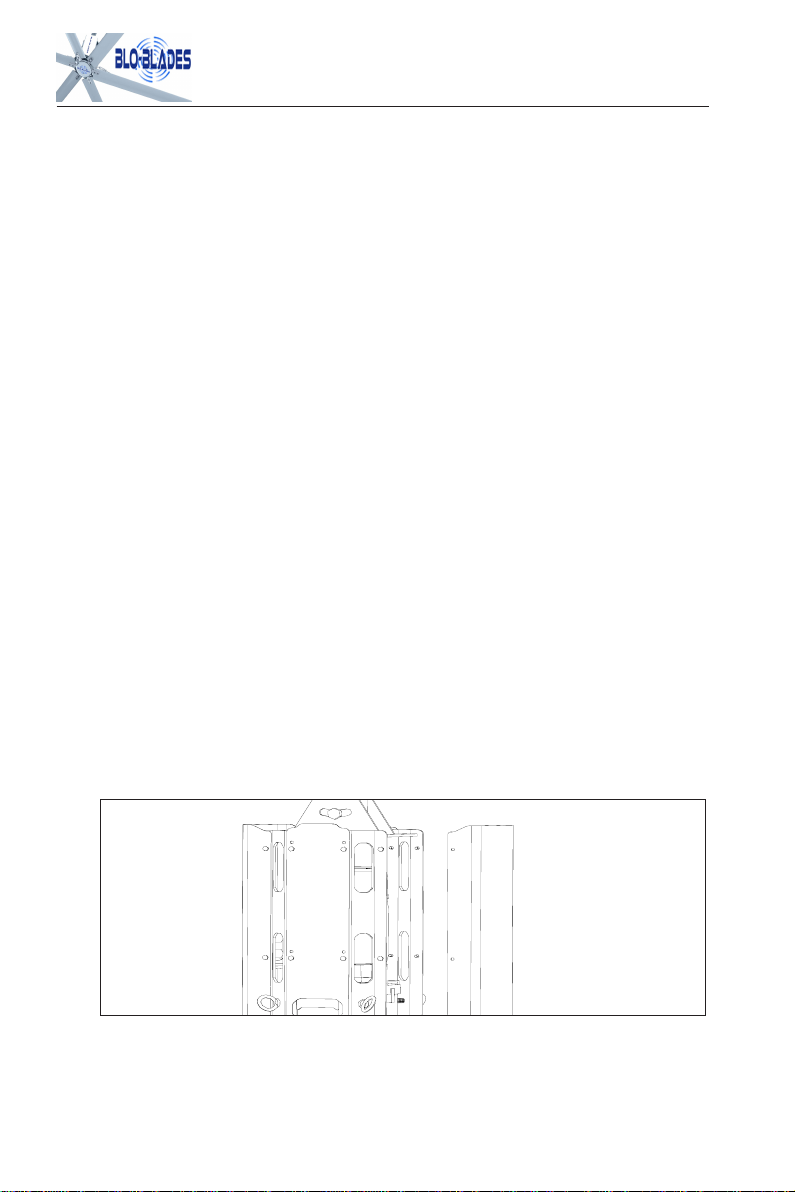

4.6 Installation of the outer shell

From both sides assemble the two outer shells to the drive device, then adjust and align

with screw and fasten, lack of bolts or didn't lock is not allowed, the outer shell less

shaking is also not allowed, as shown in figure 4.4

Fig4.4 Installation of the outer shell

16

大型风扇行业的领航者

4.7 Attach Winglets to Air Foil Blades

Attach the winglets to the airfoil using the Winglet Hardware as shown in figure 4.5. You

will

need to use Philips screwdriver to properly secure the fasteners. Attach winglets

to

all six (6) airfoils before attaching the airfoils to the fan.

4.8

Attach Airfoils to Hub

(1)WARNING:

Disconnect power to the fan before installing the airfoils.

(2)Slide the airfoils onto the tabs of the fan hub. This is usually done after the motor/hub

assembly has been mounted and the guy cables have been installed. The blades

should

slide on easily, if not, a little finesse works better than force. Refer to fig.4.6 to

make sure

you

are installing the blades facing the right way. An airfoil will only attach to the

fan hub in one direction. Do not force an airfoil into place.

(3)The bolt holes on the blade and the bolt holes on the Hub align.

17

图 4.5

Fig4.5

(4) Attach the (6) airfoil retainers using the Airfoil Hardware. Moving clockwise around the

fan

hub, position the airfoil retainers end over end as shown in figure 4.7. Do not tighten

the bolts until all the airfoil retainers have been attached.

First, tighten the bolts along the outside perimeter to 29 ft·lbf (39 N·m) using a

Socket with torque wrench;

Second, tighten the bolts along the inside perimeter to 29 ft·lbf (39 N·m) using a

Socket with torque wrench;

4.9

CAUTION:

Do not bend the blades when installing, adjusting, or cleaning the fan. Do

notinsert foreign objects between rotating fan blades.

Installation of bottom cover with LOGO

Take

the

bottom

cover

close

to

the

blade

wheel,

bolt

holes

alignment,

bolts

tightened, make

sure

no

bolts

are missing or loose, the bottom

cover does not move after

installation, as shown in figure 4.8

Fig4.7Attach (6) safety ring to Airfoil

Fig4.8 Installation of bottom cover with LOGO

4.10

Checking Strength and

Clearance

If there is any doubt in your mind as to the ability of building structure to which you are

mounting to handle the weight of fan a structural engineer should be consulted.

18

大型风扇行业的领航者

Electrical installation

5.1

Control Options

BloBlades series HVLS fans are driven by standard three phase, dual input voltage

(220V/480V) motors. Standard single fan control panels available from BloBlades

include, a variable frequency drive, a control switch , and an enclosure. They are available

for single phase inputs of 220 volts, and for three phase inputs of 480v.

The VFDs in these control panels are preprogrammed for proper normal operation of the

fan. The factory can assist you in configuring them to receive special inputs-i.e. If you

want the fans to be controlled from a remote location, or want them go on and off at certain

19

After making sure safety cables are installed, an easy way to test the mounting's ability t

o

handle the torque is to insert a 3-5' long 2x4 in the motor frame and try to twist it

as

shown in fig.4.10. if the fan is hanging from an extension you will have to use one hand

on the 2x4 and the other on the motor frame so as to create a torque without exerting a

big

side load. The mount should withstand a 110lb force applied 3' from the center of fan.

Lastly, if there is any potential for a clearance problem, before you start the fan for the first

time, rotate it one time by hand to find the position and blade of least clearance. Grasp

the blade and shake it vigorously both up and down and in and out, make sure there is no

chance of it hitting the obstructions, whether it is due to blade deflection or movement of

the

fan as a whole.

4.11Specification parameter table

times, change speed at certain temperatures, interface with a fire sprinkler system, etc.

Instructions for mounting and wiring the control panel are supplied with the control panel.

5.2 Wiring

5.2.1 General considerations

VFDs can induce voltage spikes that can be harmful to motors. They can also create

electrical noise and RF( radio frequency) that can interfere with low voltage control wiring

machines, computers networking lines, radios, etc. there are a variety of filters,

reactors, isolators, etc. that can deal with these type of problems. However most of these

problems can be avoided by observing the following guide lines:

(1)Never allow the conduit to run between the MCP and the fan or to exceed 30 meters on

480V,

or 40 meters on 220V. Excessively long runs between the MCP and the fan can amplify

the voltages spikes created by the VFD.

(2)Never use larger wire than code requires. Excessively large wire can also amplify the

voltages spikes.

(3)Put the wires to each fan in separate grounded metallic conduit. Do not bundle them

together with the power wires going into the control panel, or with wires going to other fans. Use a

section of flex conduit between the building structure and the fan to accommodate

fan movement.

(4)Be sure to pull 4 wires; you need 3 for power, and 1 for ground.

(5)Alternatively, you can use 4 conductor shielded cable. When using shielded cable,

ground one only to avoid ground loops that can negate the ground effect.

(6)

Separate fan wires (cable or conduit) from other wires running parallel (especially

low voltage control wires) by at least 6 inches.

5.2.2 Grounding

Always run a separate ground wire from the fan motor. Do not rely on the motor being

grounded through the fan mount or the conduit. The ground wire from the motor should be

grounded at the same space as the ground from the VFD. That may be the control panel

if it is mounted to a well grounded steel beam or column. If not, the ground wire from the

motor and the VFD can be connected together, along with a wire grounding the control.

20

大型风扇行业的领航者

21

5.2.3

Motor wiring

The wiring diagrams in fig.5.1, fig.5.2, fig.5.3, fig.5.4 are for motors supplied in

German, for Nord rated motors. It is essential that you wire the motor correctly for voltage you

are using. Please verify that the correct VFD has been supplied to match the voltage being

supplied.

A Mistake Here Could Ruin The Motor, The VFD or Both!

As noted previously it is important to run a separate ground wire from the motor. It should

be grounded to the same space as the ground wire from the VFD. If the control panel is

attached to a steel beam or column, then grounding to the control panel is Ok. If the panel

is attached to a non-conductor-i.e. wood or dry-wall, you will have to extend the ground

wires back to the power panel.

The proper direction of rotation is indicated by Fig.5.7, if upon initial start up the fan is

going the wrong way, shut it down . Simply switching any two of three power wires going

to

the fan motor will reverse the direction of rotation. This can be done at the motor, or at

the

control panel.

Fig5.7 the right direction of rotation

This manual suits for next models

3

Table of contents

Popular Fan manuals by other brands

Craftmade

Craftmade Woven WVN52 installation guide

coframo

coframo Ecofan BelAir 806CA-BBX operating instructions

Vortice

Vortice Lineo Series Instruction booklet

Sonnenkonig

Sonnenkonig FLEX FAN instruction manual

Brookstone

Brookstone Bed Fan with Wireless Remote user manual

Hunter

Hunter 42678-01 Owner's guide and installation manual