Installation

4

Delivery and Inspection

Upon delivery of your Blodgett Conveyor Grill:

Inspect the shipping container for external dam-

age. Any evidence of damage should be noted on

the delivery receipt and the bill of lading, which

must be signed by the driver. Uncrate the Blodgett

Conveyor Grill and check for internal damage.

Inspect the unit immediately upon receipt. Do not

sign off on shipment until the packaging has been

removed and the unit has been inspected for dam-

age. Blodgett cannot assume responsibility for loss

or damage suffered in transit. The carrier assumed

full responsibility for delivery in good order when the

shipment was accepted. We are, however, prepared

to assist you in filing a claim if necessary.

Unpacking the unit:

Open all parts boxes carefully. DO NOT USE A

BLADECUTTERORKNIFE!One of the boxes

contains the woven glass Teflon impregnated

cooking belts which can easily be cut and dam-

aged or destroyed. The warranty will not cover ac-

cidental cutting of belts during unpacking.

Remove all shipping bands and loose packaging

material from the unit. Remove all loose parts from

theupperandlowerplatenassemblies.Donot

discard the shipping crate or materials until instal-

lation is complete and unit is operating.

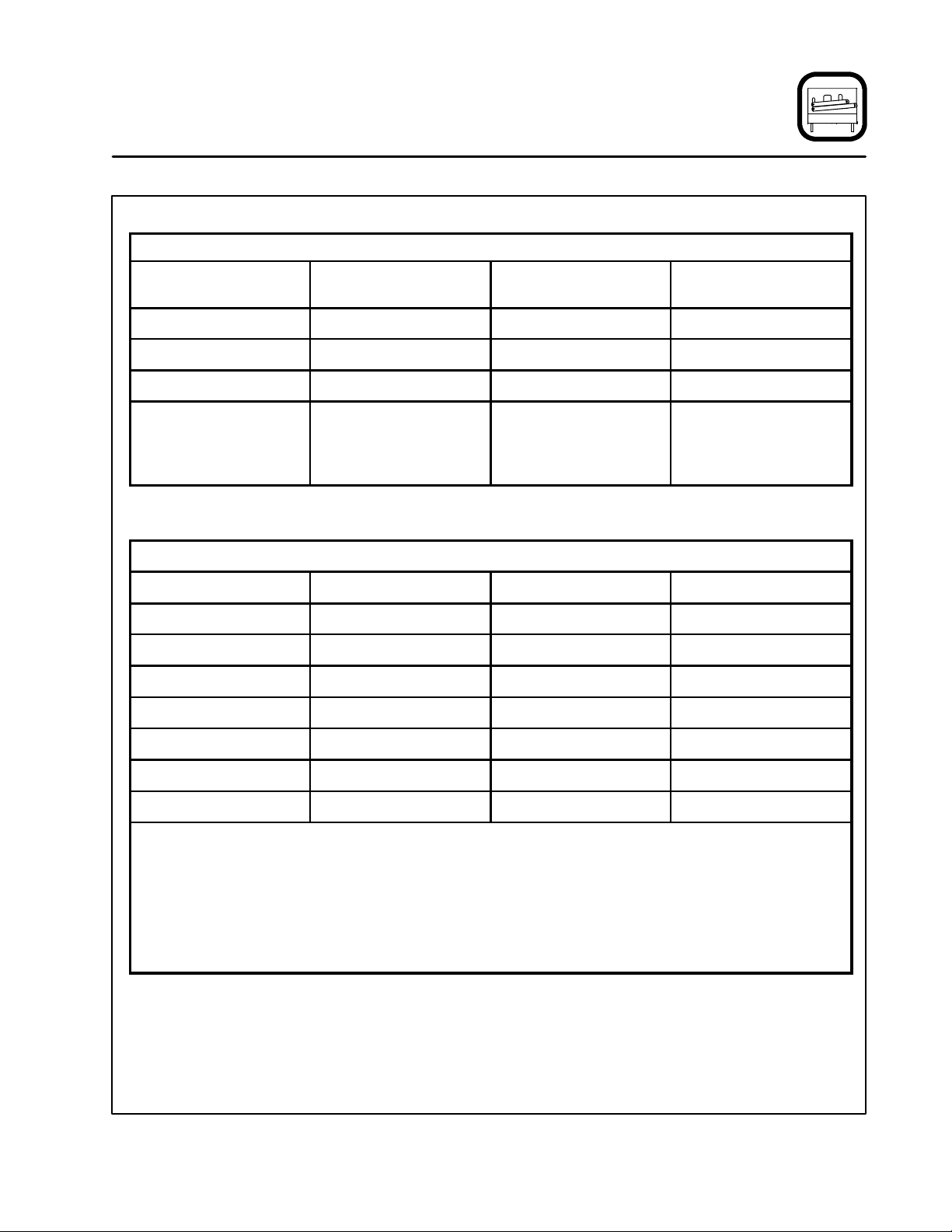

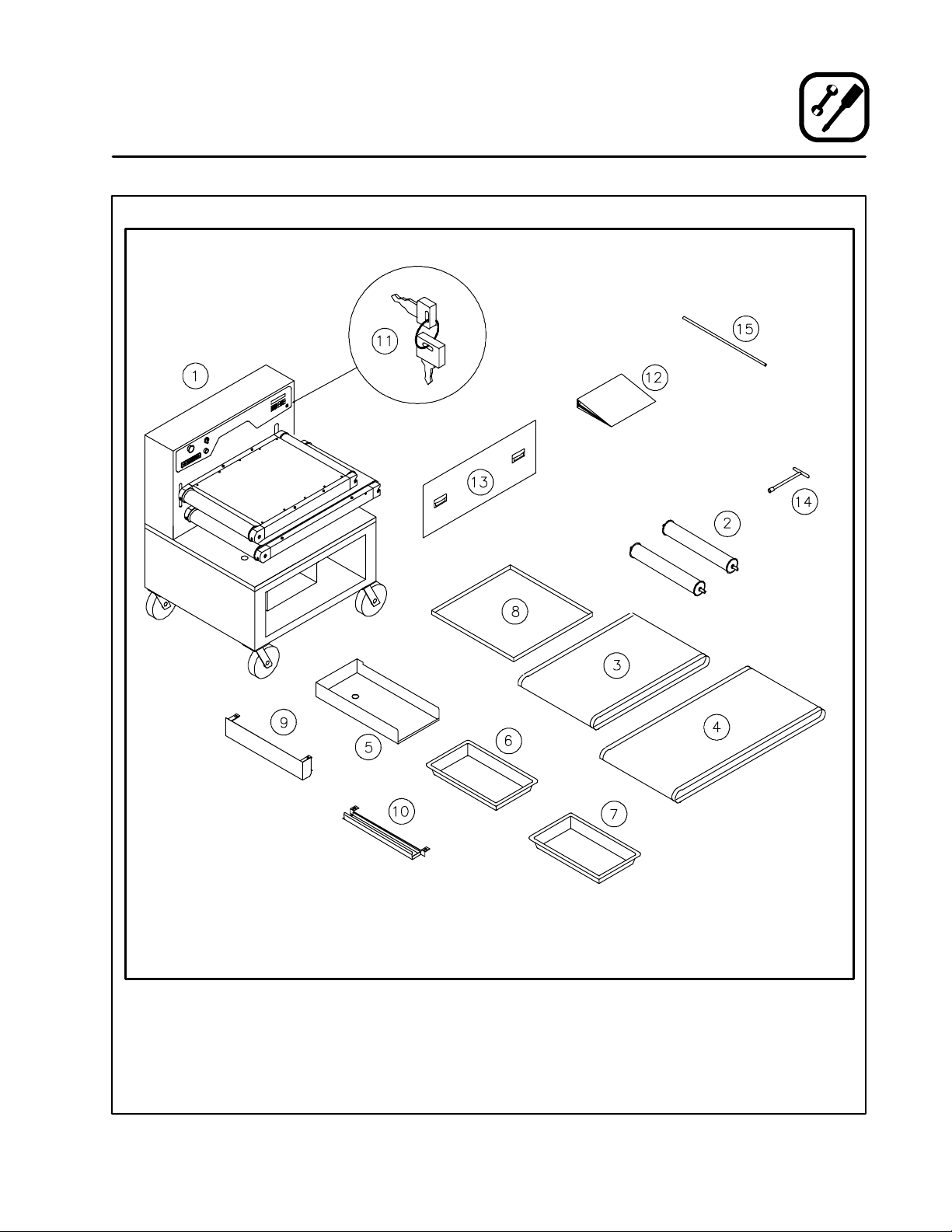

Check that all of the following parts have been re-

ceived. Contact Blodgett immediately if any of the

components are damaged or missing.

ITEM DESCRIPTION QTY.

1Blodgett Conveyor Grill, Model TBG36 (TBG36-FM shown) 1

2Idle Rollers 2

3UpperConveyorBelt 2

4LowerConveyorBelt 2

5Drain Pan 1

6Product Receiving Pan 1

7Grease Pan / Bucket 1

8Crumb Tray 1

9Upper Wiper Box 1

10 Lower Wiper Box 1

11 Controller Programming Keys 2

12 Owner’s Manual 1

13 Door Panel (FM and S models only) 1

14 9/16” Tee Handle Wrench 1

15 1/2” Calibration Rod 1

Items not

Wiper Blades 2

shown Bacon Scraper Blade 1