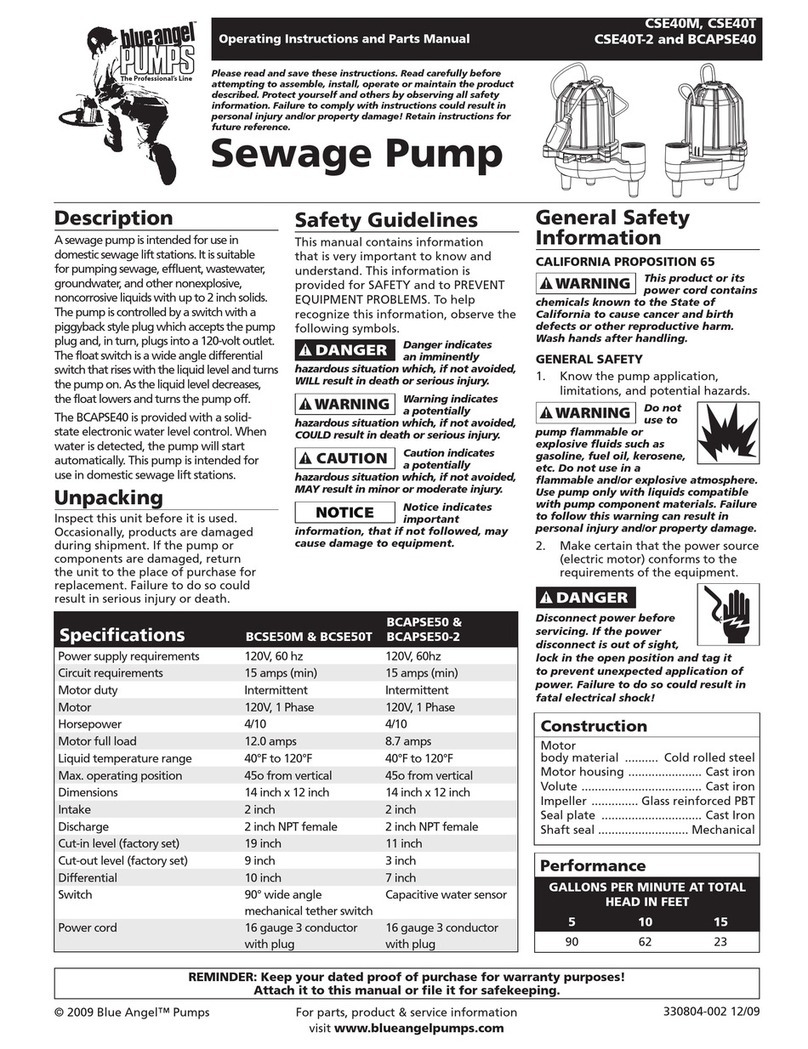

Instructions d‘Utilisation et Manual de Pièces

8 Fr

2. S’assurer que la source de courant

(moteur électrique) se conforme

aux exigences de l’équipement.

Débrancher la source

de puissance avant de

procéder au service. Si la

source d’alimentation est hors vue, la

verrouiller dans la position ouverte et

l’étiquetter afin d’éviter une application

de puissance inattendue. Manque de

suivre ces directives peut résulter en

secousse électrique!

3. Dissiper toute la pression dans

le système avant de procéder au

service de n’importe quelle pièce

détachée.

4. Purger tous liquides du système

avant de procéder au service.

Cette pompe contient

de l’huile à moteur

diélectrique pour le transfert de chaleur du

moteur. Attention en éliminant cette huile.

Ne pas utiliser cette pompe dans les étangs

ou les fontaines car l’huile à moteur pourrait

être dangereux pour la vie aquatique.

5. Fixer la ligne de décharge avant de

démarrer la pompe. Une ligne de

décharge non-fixée peut fouetter et

causer des blessures personnelles et/

ou des dégâts matériels.

6. Inspecter les tuyaux pour la faiblesse

et l’usure avant chaque utilisation

et vérifier le serrage de tous les

branchements.

7. Inspecter la pompe et les

pièces détachées du système

périodiquement. Exécuter l’entretien

ordinaire (Se référer à la section

d’Entretien).

8. Fournir un système de soulagement

de pression pour les pompes avec

lignes de décharge qui peuvent

devenir obstruées ou coupées.

9. Sécurité Personnelle:

a. Toujours porter des lunettes de

sécurité si vous travaillez avec les

pompes.

b. Garder l’endroit de travail propre,

non-encombré et bien illuminé.

Ranger tous outils et équipement

après l’usage.

c. Garder les visiteurs à une distance

sûre de l’endroit de travail. Protéger

l’atelier pour les enfants avec des

cadenas, interrupteurs principals et

en enlevant les clefs de démarrage.

10. Pendant l’installation de fils d’une

pompe électrique telle que celle-ci,

suivre tous les codes de sécurité ainsi

que les codes récents du National

Electrical Code (NEC) et l’ Occupation-

al Safety and Health Act (OSHA).

Risque

de secousse électrique! Ne

jamais brancher le fil vert

(ou vert et jaune) à une

borne électrisée!

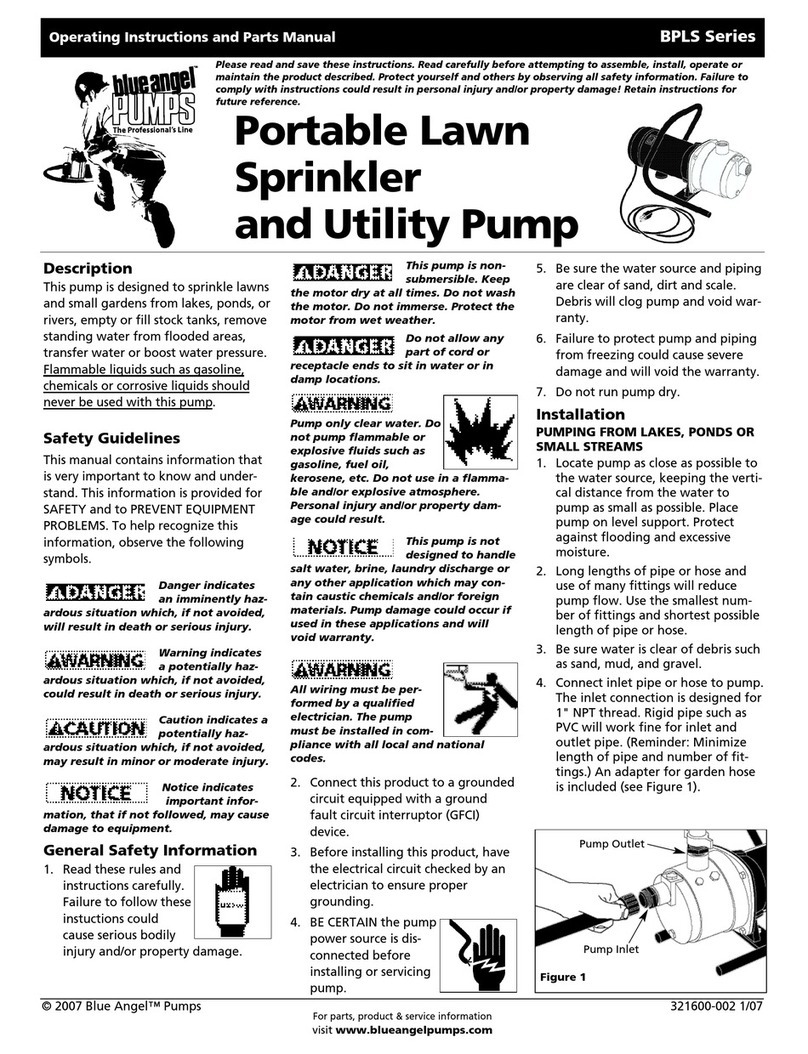

11. Cet équipement est conçu pour un

circuit de 120 v (monophasé) et est

équipé d’un cordon approuvé à trois

conducteurs et une fiche de terre à

trois broches telle qu’indiquée dans

la Figure 1A et 1B.

Pour réduire le risque de secousse

électrique, le moteur doit être mis à la terre

correctement et avec sûreté comme suit:

• Introduirelafichedirectementdans

une prise de terre tripolaire, installée

correctement et mise à la terre (tel

qu’indiquée dans la Figure 1).

• Compléteruneinstallationdefils

permanante avec un système de

canalisation en métal mis à la terre.

• Autresmoyensacceptables.

Remplacer les prises à deux broches

avec des prises à trois broches mises à

la terre correctement selon les codes et

ordonnances locaux et de NEC.

12. Toute installation de fils doit être

performée par un électricien qualifié.

13. Il est recommandé que le modèle

soit branché dans un disjoncteur de

fuite à la terre (DDFT). Consulter un

électricien local pour la disponibilité

et l’installation.

Le moteur de

la pompe est

équipé d’un protecteur thermique à

réenclenchement automatique et peut

se mettre en marche subitement. Le

déclenchement du protecteur est une

indication de surcharge du moteur

résultant du fonctionnement de la pompe

à basse pression (restriction de décharge

basse), tension extrèmement élevée ou

basse, installation de fils insuffisante,

conditions de moteur incorrectes, ou un

moteur ou une pompe défectueux.

14. Cette pompe est conçue pour

transporter l’eau en cycles.

Utiliser cette pompe dans une

application continue en manipulant

l’interrupteur pour qu’il reste

enclenché affectera la performance

et l’espérance de vie du produit.

15. Protéger le cordon d’alimentation des

objets pointus, surfaces chaudes, huile

et produits chimiques. Ne pas tortiller

le cordon. Remplacer ou réparer

les cordons usés ou endommagés

immédiatement. Utiliser des fils de

taille suffisante pour minimiser la

chute de tension au moteur.

16. Ne pas manipuler une pompe ou une

pompe de moteur avec les mains

trempes ni lorsque vous êtes debouts

sur une surface trempe ou humide, ou

dans l’eau.

17. Ne pas pendre ce produit par

l’anse. Les pompes pour eaux usées

devraient être placées fermement sur

leurs jambes et supportées avec de

la tuyauterie rigide. Ceci empêche le

tortillement et le dommage pendant

le fonctionnement de la pompe.

18. Ne pas utiliser un cordon

prolongateur.

Ne pas

marcher

dans un endroit trempe

jusqu’à ce que toutes les

sources de puissance soient

coupées. Si la boîte d’arrêt est dans le

sous-sol, contacter votre compagnie

d’électricité pour couper le service

à la maison ou contacter le corps de

pompiers pour des directives. Enlever

la pompe et la réparer ou la remplacer.

Manque de suivre ces conseils peut

résulter en secousse électrique mortelle.

Installation

Utiliser un/des

système(s) de

sauvegarde là où il y a risque de dégâts

matériels et/ou blessures presonnelles

résultant d’une pompe qui ne fonctionne

pas ou qui a des fuites à cause des

manques de puissance, canalisations de

décharge obstruées ou autres raisons.

1. Fileter le tuyau de décharge ou le

mamelon de tuyau dans le raccord

de décharge.

2. Si un clapet est utilisé, monter le clapet

dans une position horizontale ou à

un angle de 45º avec le pivot de la

soupape en haut. Dans une position

verticale, les solides on tendance à se

déposer sur le volet de la soupape et

peuvent l’empêcher de s’ouvrir.

3. Percer un trou de 1/8 po dans le tuyau

de décharge environ 1 à 2 po par dessus

le décharge de la pompe lorsque vous

utilisez un clapet. Le trou empêche le

blocage par l’air de la pompe au départ

initial et si elle perd l’amorçage.

Broche

de terre

Figure 1B

Figure 1A

Prise de

courant

mise à la

terrre

Cordon d’eau

capacitif

Cordon

d'alimentation

Généralités Sur La

Sécurité (suite)