Blue Diamond Pumps Enviro Series Manual

Re~~re

~n~r

Operating

and

Maintenance

Instructions

Enviro

Series ET4O, ET6O, ET8O,

ET1

00,

ET1

20

Thank

you

for

purchasing

one

of

our

ET

range

of

blowers.

To

ensure the

product

operates correctly

follow

all safety

instructions

and read

information

carefully.

An

authorised

service

facility

should

undertake

any

servicing

required

which

is

not

outlined

in

this

manual.

1)

Prior

to

operation

These

pumps are

precision

instruments which

give

many

years

of

service

provided

that

instructions

on

installation

and

operation

are

followed.

Whilst

the

company

may

offer

advice

as

to

the model they

recommend,

it

is

the

sole

responsibility

of

the

user

to ensure

the

pump

is

suited

to

the

application

for

which

it

is

to

be

used.

The

user must also

ensure

the

materials

offered

for

the

pumps and

motor

components

are

suitable

for

the

performance,

environmental

limitations

and

chemical

resistance

requirements

of

their

application.

WARNINGI

The

Enviro series

is

designed

for

air

only.

Do

not pump

flammable

gas,

liquid

or

hazardous

dust

for

risk

of

ignition,

electric

shock

or short

circuit.

To

avoid

circuit,

only

connect

the

product

to the

specified

power

supply

voltage.

2)

Storage and

Transfer

A

WARNING! Always carry

the

product

with

both

hands.

Do

not

carry

the product

holding

the

filter

cover

or

power

supply

cord

to

avoid

injury

and/or

damage

to

yourself

product

may

get

very

hot

during

operation,

do not

touch

it

until

it

has

cooled down.

This

product

is

not

designed

to

be

stored

in

temperatures below

-8°C.

Please

store

indoors to

avoid

rubber

parts

deteriorating.

3)

Grounding

Instructions

This

product

must

be

grounded.

In

the

event

of

an

electrical short

circuit,

grounding

reduces

the

risk

of

electric

shock

by

providing

an

escape

wire

for

the

electric

current.

This

product

is

equipped

with

a

cord

having

a

grounding

wire with

an

appropriate grounding

plug.

The

plug

must

be

plugged

into

an

outlet that

is

properly

installed

and

grounded

in

accordance

with

all

local

codes

and

ordinances.

WARNING!

Improper installation of

the

grounding

plug

is

able

to

result

in

a

risk

of

electric

shock.

When

repair or

replacement

of

the

cord

or

plug

is

required,

do

not

connect

the

grounding

wire

to

either

flat

blade

terminal.

The

wire with

insulation

having

an

outer

surface

that

is

green

with or

without

yellow

stripes

is

the

grounding

wire.

Check

with

a

qualified

electrician

or

serviceman

when

the

grounding

instructions

are

not

completely

understood,

or

when

in

doubt

as

to

whether

the

product

is

properly grounded.

Do

not

modify

the

plug

provided;

if

it does

not

fit

the

outlet,

have

the

proper outlet

installed

by

a

qualified

electrician.

4850

Golden

Parkway,

Suite

B,

409,

Buford

GA30518,

USA

Tel:

+1770831

1122

Fax:

±17708319888

Email:

www.bluediamondpumps.com

4)

Installation

On

receiving

the

pump,

check

that

it

is

the model

ordered

and

has

not

been

damaged

in

the

pump

outlet,

otherwise

the

pump

will

heat

up

and

may

be

damaged.

To

avoid

anytransit.

Ensure

that

the

voltage

at

which the

pump

operates

is

the

same

as

the

rating

label.

One

or

more

aerators

can

be

connected

to

the

pump

with

piping

and

T

pieces.

Choose

fittings

and

pipe

sizes

that

suit

your installation

requirements,

ensure

all pipes

are

secured

with

clips.

Using

larger

bore

pipe,

and

avoiding

sharp

bends

will

improve performance.

Use

new

and

sufficiently

large

aerators

with

enough

discharge

capacity.

Bends

in

the

air

pipe,

Use

new

and

sufficiently

large

aerators with enough

discharge

capacity.

Bends

in

the

air

pipe,

aerators

placed

too

deep,

or

old

or

dirty

ones,

will

all reduce

capacity

and

make

the pump

I

I~)

~T

AU

Wiring Diagram

A

WARNING!

The

~T

A0

version

must

be

installed

and

serviced

by

a

qualified

electrician

or

serviceman.

The

pump

must

remain

disconnected

from

any

power

supply until

it

~s

installed.

________

llOVSipply

0.O4Bar

((((

~arm

OBar

0.10-0.15Bar

Resaire

~ns~r

110

L

PJarm~ble

E

_____________

N

~itch

Ration

,n~

,

‘I

~

~~/\

‘,

S..,

\,

T~r

MUTE

RJN

v~c

MAX2

~

L

~Jarm~ble

E

N

0.O4Bar

(((~arm

0

Bar

0.10-

0.15

Bar

~Jr

Row

23OVSipply

>))PJrR0

work

harder.

Ensure

the pump

can

discharge

sufficient

air

at all times, never

close

off

backflow of

water

into

the

pump,

install

the

pump

above

water

level,

If

this

is

not

possible,

a

non-return

or

check

valve

must

be

used

in

the

outlet

pipe.

Any

additional

fittings

or

equipment

attached

to

the

pump

airline

must

be

safely installed

without

risk

of

harm

to

others.

5)

Locating

The

Blower

A

WARNING’

Do

not

place

the

pump

where

it

might

come

into

contact

with

liquids,

or

near

flammable or

other

dangerous

materials

or

objects.

Never

immerse

the

pump

in

water.

Sunlight

heat

may

shorten

diaphragm

and valve life,

therefore

place

in

a

shaded

area

where

possible.

Dust

may block

the

filter

which

will

cause

overheating

and

result

in

shortening

diaphragm

and valve

life.

The

electricity

supply

must

be

grounded

to

protect

the

operator

from

electric

shock.

If

the

pump

falls into

the

water,

unplug

from

the electricity

supply

before

attempting

to

retrieve

it.

Let

qualified

technicians

check

the

pump before reconnecting

it.

Before

installation,

and

periodically,

examine

the

power

cord.

If it

is

damaged

it

must

be

replaced

by

the

supplier

or

service

agent

or

similarly

qualified

person

in

order

to

avoid

a

hazard.

6)

High

Temperature

Use

If

the

temperature

may

reach

over

120°F,

a

cooling fan

with

ventilation

is

recommended.

During

high

temperatures

the

pump

will

turn

off

~‘ia

the

thermal

cutout.

The

pump

will

automatically

restart

when

cooled.

If

your

septic

system

has

been

without air

for

a

few

days,

a

build

up

of

solid

around

the

airstone/diffuser

can

cause

a

build

up

of

back

pressure

which

will

overheat

the pump,

causing

the

thermal

cutout

to

stop

the

pump.

The

pump

will

restart

after

it

cools

down

and

blockages

are

often

cleared

after

a

couple

of

goes.

7)

Connection

The

exhaust

port

should

be

connected

with

the

L-joint

hose

supplied.

If

using

a

smaller

diameter

pipe,

excess

pressure and

overheating

may

occur,

shortening

the

diaphragm

and

valve

life.

A

hose

c

ip

should

be

used

to

secure

place

of

connection.

Plumbing

should

be

as

short

and

straight

as

possible,

if

over

33ft

I

1

Om

please

consult

your

distributor.

8)

Periodical

Maintenance

Any

dust

or

foreign

matter

entering

the

air

inlet

may

cause

abnormal

noise,

or

result

in

failure

of

the

pump.

Therefore,

clean

the

filter

element

at

least once

every

six

months,

frequency

will

depend

on

environment.

Product

must

always

be

disconnected

from

power

before

servicing.

Failure

to

do

so

could result

in

electrical

shock,

personal

injury

or

death.

9)

Filter

Element

Cleaning

•

With

a

screwdriver, lever the

plastic

filter

cover off.

•

Take

filter

out

and

clean

the

air

inlet,

filter

cover,

and

sponge

mounting

surface,

washing

with

clean

water

before drying

thoroughly

out

of

direct

sunlight.

•

Put

filter

back

in

and

replace

cover.

10)

Diaphragm

Replacement

A\WARNINGI

Ensure

pump

is

disconnected

from

mains

supply

before

servicing.

•

Loosen

the

four

screws

around

the

aluminium

upper

housing

and

take

housing

off.

•

Locate

pump

inside

housing.

•

Loosen

the

four

screws

either

side

and

remove the

air

chamber

cover.

•

Loosen

the nut

and

remove

the

chamber

block,

antistatic membrane

and

the

diaphragm.

•

Replace

diaphragm

making

sure

the

diaphragm

fits

exactly

to the slot

of

the

air

chamber.

•

Install

all

parts

by

counter

steps.

•

Put

aluminium

cover

on

and

secure

the

four

screws

firmly.

The

most

common

cause

of

premature

diaphragm

failure

is

excessive

back

pressure

or

overheating.

This

can

be

caused

if

the pump

is

producing

too

much

air for

your

diffusers,

or

if

the

tank

is

too

deep

for

your

pump.

The

depth

of

the

tank

should

be

as

follows:

ET4O

47”

1

.2m

ET6O

62”

1.5m

ET8O

69”

1.75m

ET100

75”

1.9m

ET12O

80”

2.Om

If

the

depth

is

higher,

please

contact

your distributor.

11)

ETA

-

Blower

with

Built

In

Alarm

The

ETA

blower

range

have

a

built

in

alarm

which

will

activate

when the pump

has

lost

pressure.

Once

installed,

place

the

alarm

switch

to the

on

setting.

The

alarm

can

be

tested using

the

test

setting

or

silenced

via

the mute

button.

If

the

blower

also

has

an

output

wire

this

is

for

the connection

to

an

external

beacon

or alarm

kiosk.

~

WARNING!

Do

not

attempt

to open

the

alrm

module.

If

the

unit

is

connected to

electricity,

opening

of

the

alarm module

can

result

in

a

risk

of

electric

shock.

If

the

outside

of

the

alarm module or

light

lens

becomes cracked

or

damaged,

unplug or

shut-off

the electric

power

immediately

and

contact

a

qualified

electrician

or

serviceman.

Do

not

carry

the

unit

by

the

alarm module

or

electrical

cord.

It

could

damage

the

alarm

module.

Tel:

+1

770

831

1122

www.bluediamondpumps.com [email protected]

LISTED

This manual suits for next models

4

Table of contents

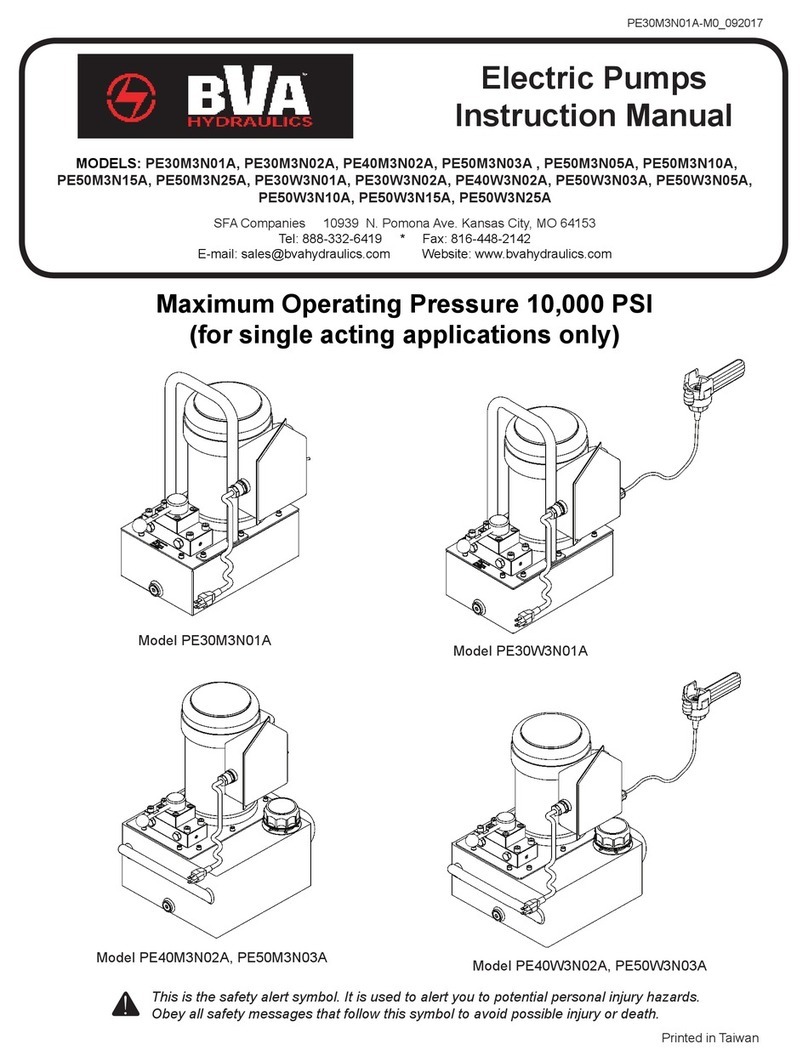

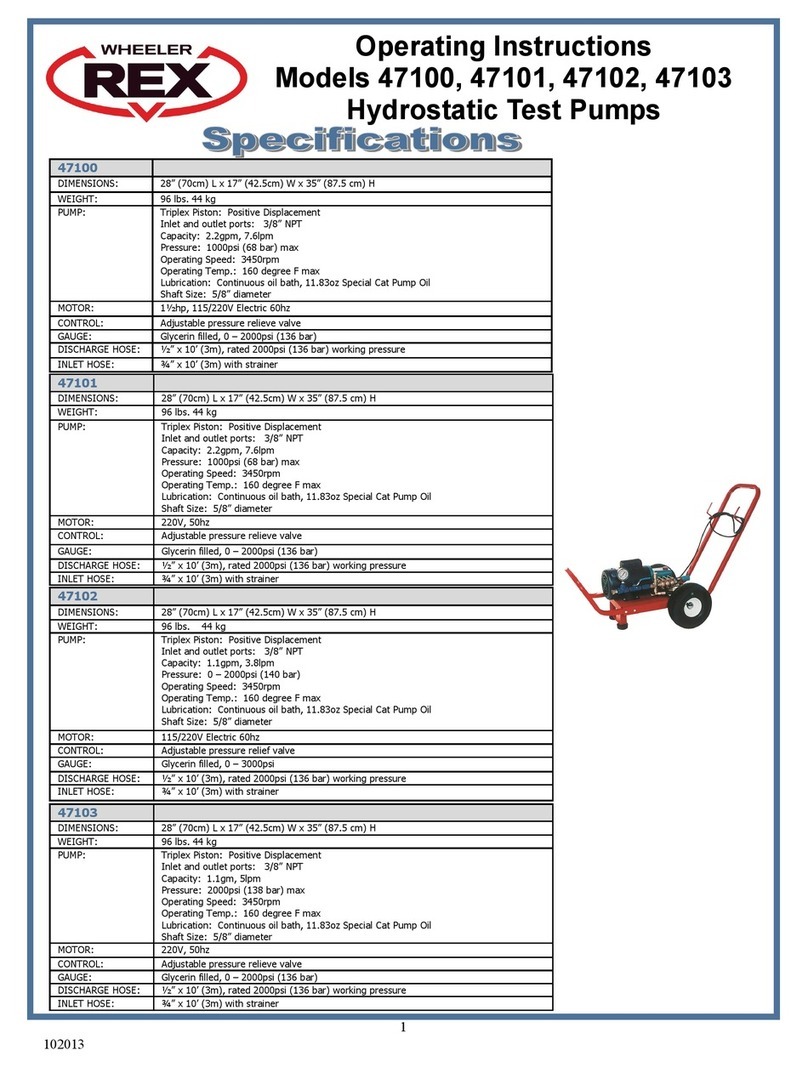

Popular Water Pump manuals by other brands

Accudyne Industries

Accudyne Industries LMI ROYTRONIC EXCEL AD9 Series instruction manual

SKF

SKF Lincoln PMV V406000000 Installation and maintenance guide

Talon

Talon TP-72S manual

POMPE CUCCHI

POMPE CUCCHI Series WPP Operating and maintenance manual

Garland

Garland AMAZON 300 E instruction manual

Medline

Medline Compat 9517455 operating instructions