Blue Giant M User manual

Issue Date: 10/01/01, Rev. 0 (Part #038-550E)

SERVICE MANUAL

Mechanical Dock Leveler

Mechanical Dock Leveler – M and FMC Group 01, Section 01, Page 1

Issue Date: 10/01/01, Rev. 0 (Part #038-550E)

MECHANICAL DOCK LEVELER

Models M and FMC

Serial Number 9840001 and Up

IMPORTANT

Read and understand Pages 1 through 4 at the beginning of this

binder before proceeding with any repair or maintenance work.

The technician is cautioned and expected to take time to completely

read and understand the first four pages of this binder, including any

special instructions contained in this Mechanical Dock Leveler

portion, to be better prepared to safely perform the necessary work

before beginning any work.

Do not work under or around the Dock Leveler without first placing

adequate barriers to positively prevent vehicle traffic from entering

the work area.

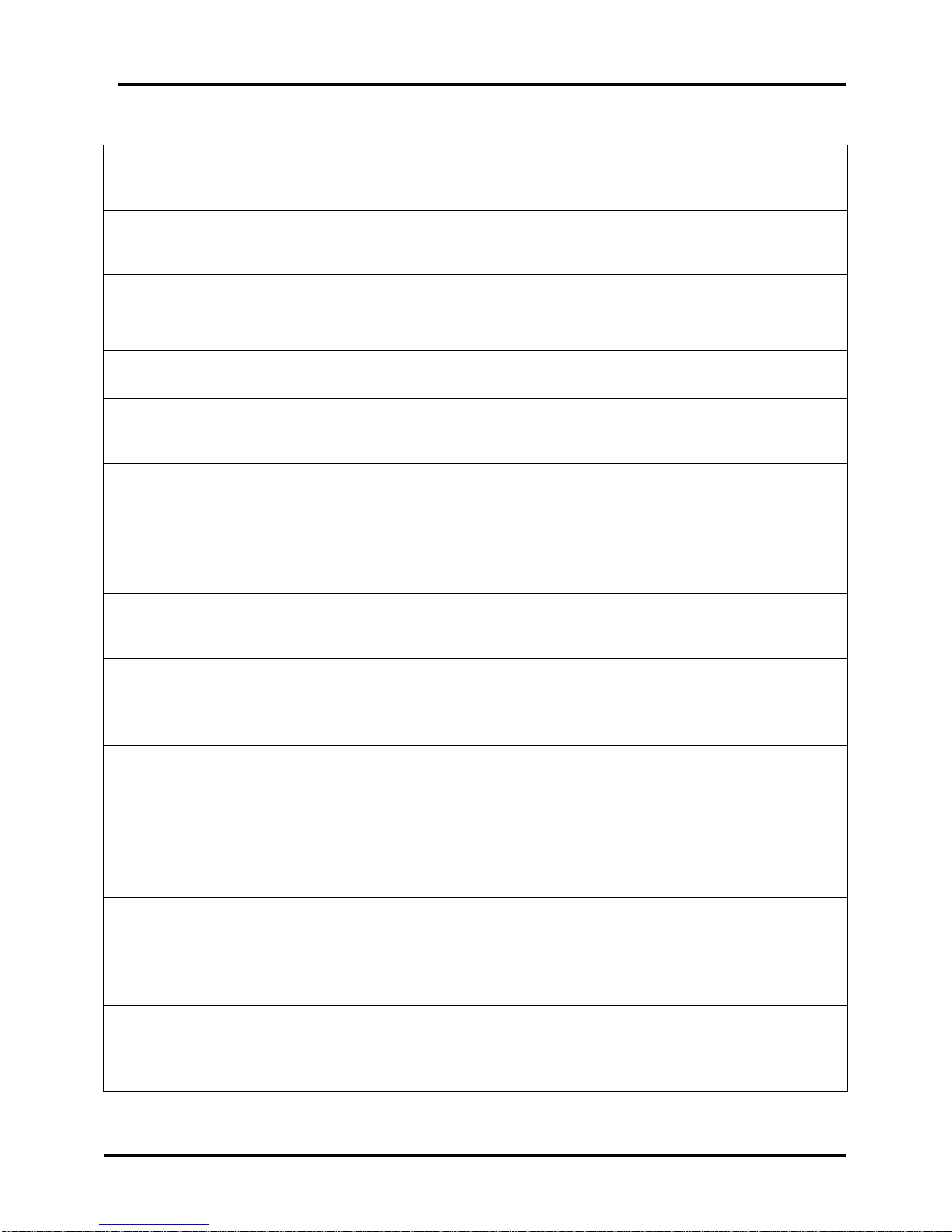

INDEX

Subject Group Section Page

Master Index 01 01 1

Introduction & Component I.D. 02 01 1 - 4

Theory of Operation – Index 03 01 1

Troubleshooting 04 01 1 - 2

Service Adjustments – Index 06 01 1

Service and Repairs – Index 08 01 1

Replacement Parts - Index 12 01 1

Installation Instructions - Index 14 01 2

Maintenance Lubrication 16 01 1 - 3

Mechanical Dock Leveler – M and FMC Group 02, Section 01, Page 1

Issue Date: 10/01/01, Rev. 0 (Part #038-550E)

INTRODUCTION

Mechanical Dock Leveler

Blue Giant dock levelers are identified by information located on

an I.D. plate mounted on the upper, front, right hand side of the

unit.

Model number, Serial number and Capacity information is

included for use when requesting information or ordering service

parts.

The capacity listed must not be exceeded and includes total

weight of fork truck plus total weight of load being transported.

Group 02, Section 01, Page 2 Mechanical Dock Leveler – M and FMC

Issue Date: 10/01/01, Rev, 0 (Part #038-550E)

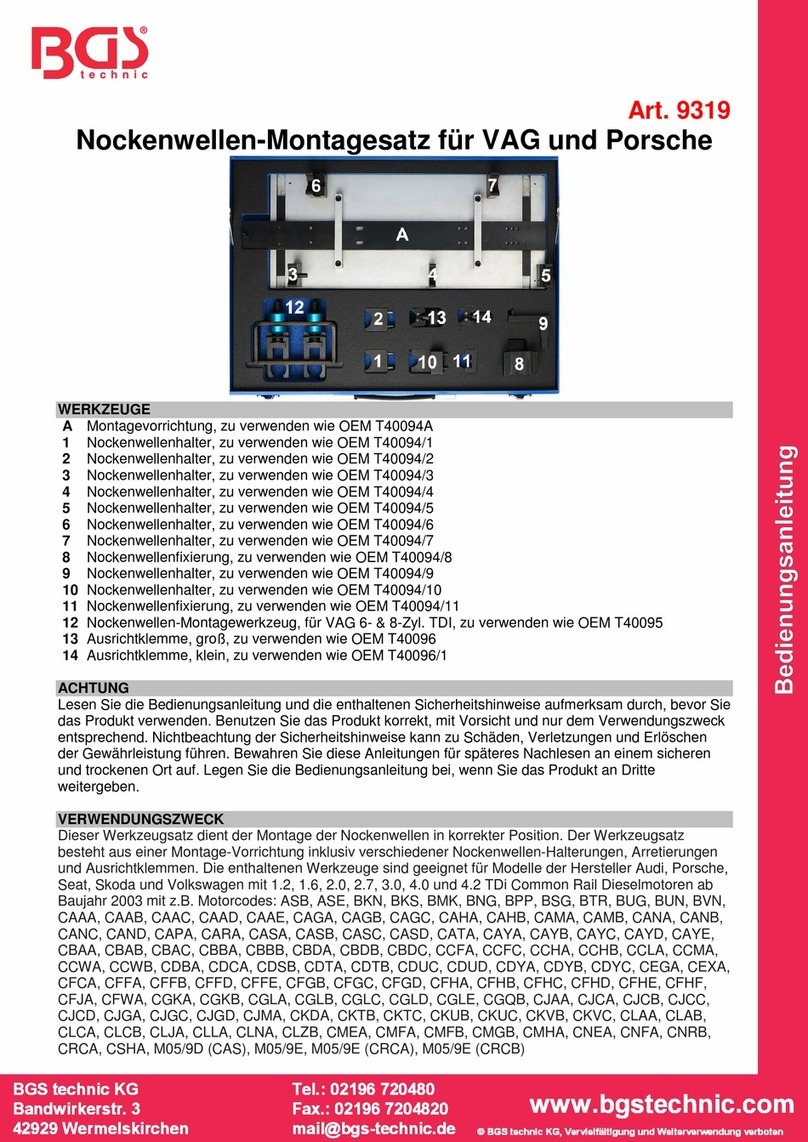

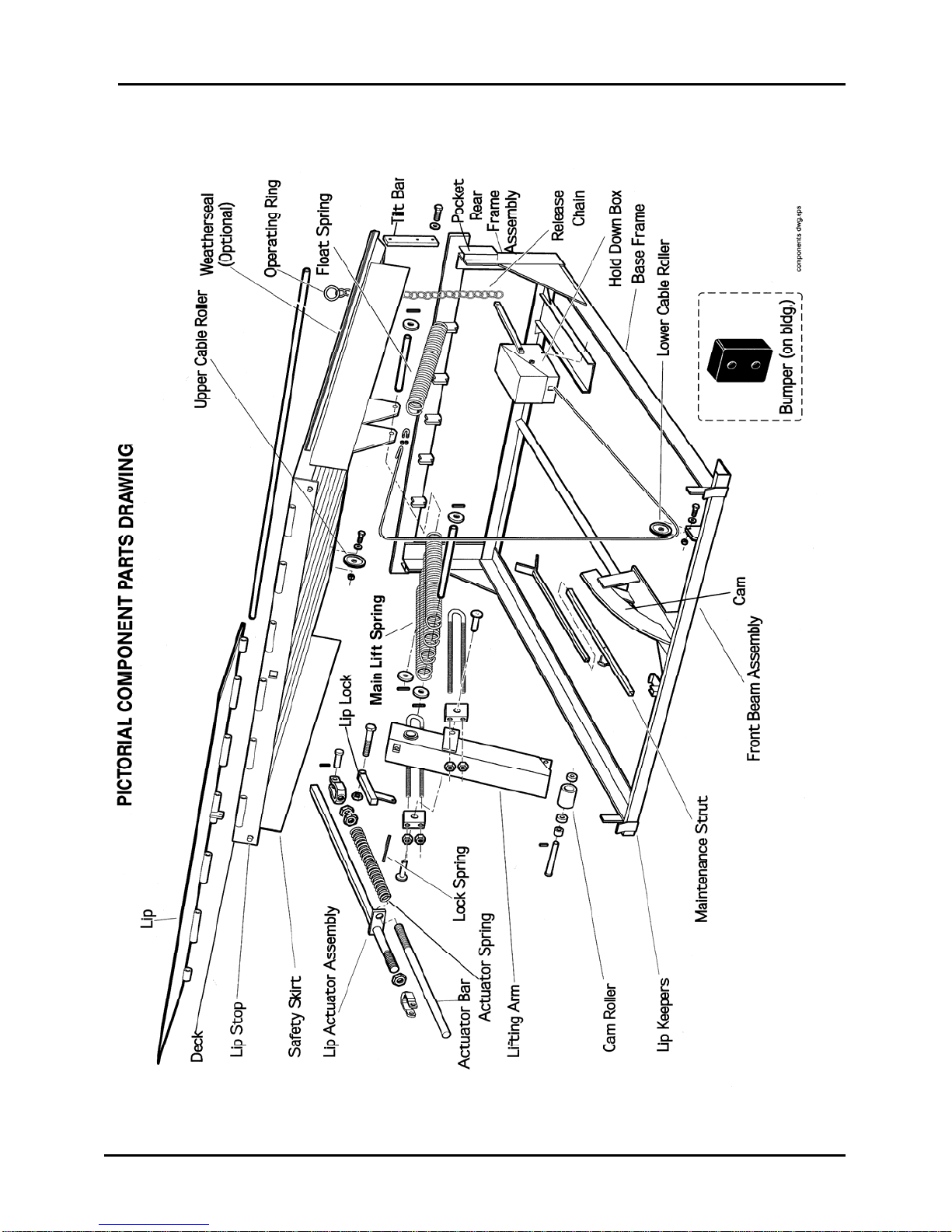

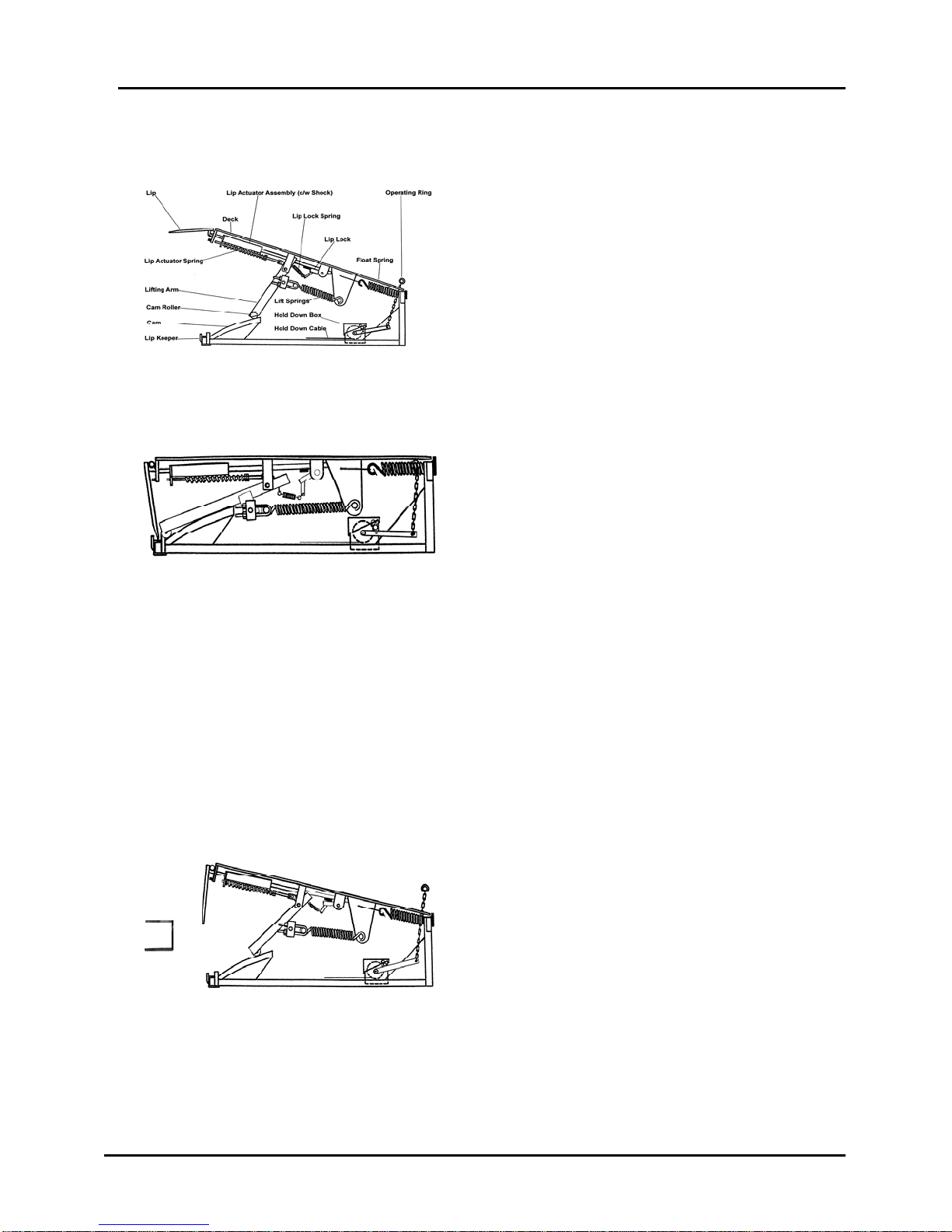

COMPONENT IDENTIFICATION

Mechanical Dock Leveler – M and FMC Group 02, Section 01, Page 3

Issue Date: 10/01/01, Rev. 0 (Part #038-550E)

INTRODUCTION and COMPONENT IDENTIFICATION

Right & Left Side The right side is identified by standing on the dock leveler

while facing the dock door and lip.

Base Frame

The angle iron mounting frame that is the base platform

for the entire dock leveler. It sits firmly on the bottom of

the dock pit and is the base that supports for the entire

leveler

Rear Frame Assembly

The rear portion of the Base Frame that contain the tilt

bar pockets.

Front Beam Assembly Front of Base Frame that contains the Lip Keepers and

provides mounting points for other components.

Cam The curved track that provides a ramp action. This ramp

action works in conjunction with the lifting arm, roller and

Main Lift Springs to elevate the deck.

Lifting Arm Roller

Attached to the lower end of the Lifting Arm, the Cam

Roller travels the contour of the Cam and allows smooth

low resistance movement while raising or lowering the

dock leveler deck.

Lifting Arm When pulled rearward by the Main Lifting Springs this

arm rotates around it's pivot point and by so doing,

transfers motion to the appropriate components of the

deck leveler.

Main Lift Springs Create the potential energy necessary to raise and

suspend the entire weight of the deck and lip.

Deck & Lip

The plates that become the bridge from the dock to the

truck floor

Tilt Bars & Pockets Floating hinge points located at the rear of the deck that

allow the deck to float diagonally and compensate for

irregularities in lateral truck positioning.

Lip This is the hinged plate on the outside edge of the deck.

It rests on the truck floor when the deck is in working

position.

Group 02, Section 01, Page 4 Mechanical Dock Leveler – M and FMC

Issue Date: 10/01/01, Rev, 0 (Part #038-550E)

INTRODUCTION and COMPONENT IDENTIFICATION

Lip Keepers These are the retainers for the Lip when it is in the park

position.

Lip Stops Prevent the Lip from traveling too far when parking the

dock leveler.

Lip Actuator Assembly

(Shock Assembly)

Works in conjunction with the forward motion of Lifting

Arm to extend and position the lip.

Actuator Spring

Provides cushioned thrust action when extending the Lip.

Actuator Bar

As part of the Lip Actuator Assembly it provides for

positively extending the lip.

Lip Lock Engages the Actuator Bar and locks it in the extended

position.

Lip Lock Spring

Transfers motion from the Lifting Arm to engage the Lip

Lock, with the Actuator Bar Lock Block.

Release Chain

Releases the Braking action of the Hold Down Box and

it's components.

Hold Down Box

(Load Roller & Wear Strip)

Provides a braking action through a cable to maintain

deck positioning by opposing the upward action of the

Main Lift Spring.

Float Spring

Located on the upper end of the Hold Down Cable it

allows for over-ride of brake action as the cargo or load is

removed from a truck.

Safety Skirt

The plates located on the sides of the deck commonly

referred to as "Toe Guards".

Maintenance Strut

As a maintenance device the adjustable strut is stowed in

the frame and is used to lock the dock leveler deck in the

up position while personnel are performing maintenance

or repairs on the underside of the dock leveler.

Building Bumpers

Molded rubber blocks mounted outside of the building

protruding from the outer sides of the dock leveler. They

protect the dock and leveler from shock from reversing

trucks (laminated type also available).

BLUE GIANT SERVICE MANUAL

Issue Date: 10/01/01, Rev. 0 Page 1

FORWARD

Each product section is identified by

description and Model Identification

and includes a pictorial listing of

components. A contents index is

placed at the beginning of each

section.

Procedures have been made easier

to use by providing specific steps only

when necessary and general

instructions required to explain the

activity, components, assembly, or

process being worked on. The

technician is expected to include

obvious additional steps of standard

procedures for removal, disassembly,

cleaning, inspection, reassembly,

installation, etc., as needed.

The technician is cautioned and

expected to take time to completely

read and understand the entire

procedure, including any special

instructions, to be better prepared to

do the necessary work before

beginning any work.

This Service Publication provides

information covering normal service,

maintenance and repair of Blue Giant

loading dock equipment listed on

Page 5. It has been specifically

prepared to help owners and service

personnel maintain this equipment in

safe and efficient operating condition.

This manual is intended for use by

persons who are trained and

authorized to perform loading dock

equipment maintenance. It is

designed to provide essential

information about the correct and

safe service, maintenance and repair

of the equipment by trained service

technicians.

General and detailed service and

repair procedures are outlined (as

required) for each product. Some

procedures include explanations that

are common to several components

or sub-systems.

NOTICE

The description and specifications included in this manual were in

effect at the time of printing. Blue Giant reserves the right to

discontinue models at any time, or make improvements and

changes in specifications or design without notice and without

incurring obligation. Specifications, pressures, measurements,

adjustments, illustrations, and other items may change at any time.

Contact your Blue Giant distributor for information on possible

updates or revisions.

SERVICE MANUAL BLUE GIANT

Page 2 Issue Date: 10/01/01, Rev, 0

SAFE MAINTENANCE PRACTICES

The following instructions have been

prepared from current industry and

government safety standards

applicable to dock equipment

operation and maintenance. These

recommended procedures specify

conditions, methods, and accepted

practices that aid in the safe

maintenance of dock equipment.

They are listed here for the reference

and safely of all workers during

maintenance and repair operations.

Carefully read and understand these

instructions and the specific

maintenance procedure before

attempting to do any repair work.

When in doubt of any procedure,

contact your Blue Giant distributor

for assistance.

•Dock equipment can become

hazardous if maintenance is

neglected. Therefore, trained

personnel and procedures must

be provided.

•Maintenance and inspection of all

dock equipment shall be done in

conformance with the

manufacturers recommendations.

•A scheduled planned

maintenance, lubrication and

inspection program shall be

followed.

•Avoid fire hazards and have fire

protection equipment present in

the work area.

•Only trained and authorized

personnel shall be permitted to

maintain, repair, adjust and

inspect dock equipment. Work

should be performed in

accordance with the

manufacturers specifications.

•Do not use open pans of fuel or

flammable cleaning fluids for

cleaning parts.

•Before starting work, wear eye

protection and remove all jewelry.

•Always engage maintenance strut

and place traffic barriers before

entering pit area.

•There are numerous variations in

procedures, techniques, tools and

parts for servicing dock

equipment, as well as in the skill

of the individual doing the work.

This manual can not possibly

anticipate all such variations and

provide advice or precautions as

to each. Accordingly, anyone

departing from the instructions

provided in this manual through

procedures used or choice of

tools, materials and parts, may

jeopardize his or her personal

safety and / or the safety of the

equipment operator.

•Improper or careless techniques

cause accidents. Read and

understand the procedures for

safe maintenance outlined in this

manual.

•Work safely and follow the safety

signs and their messages

displayed in the work area and in

this manual.

BLUE GIANT SERVICE MANUAL

Issue Date: 10/01/01, Rev. 0 Page 3

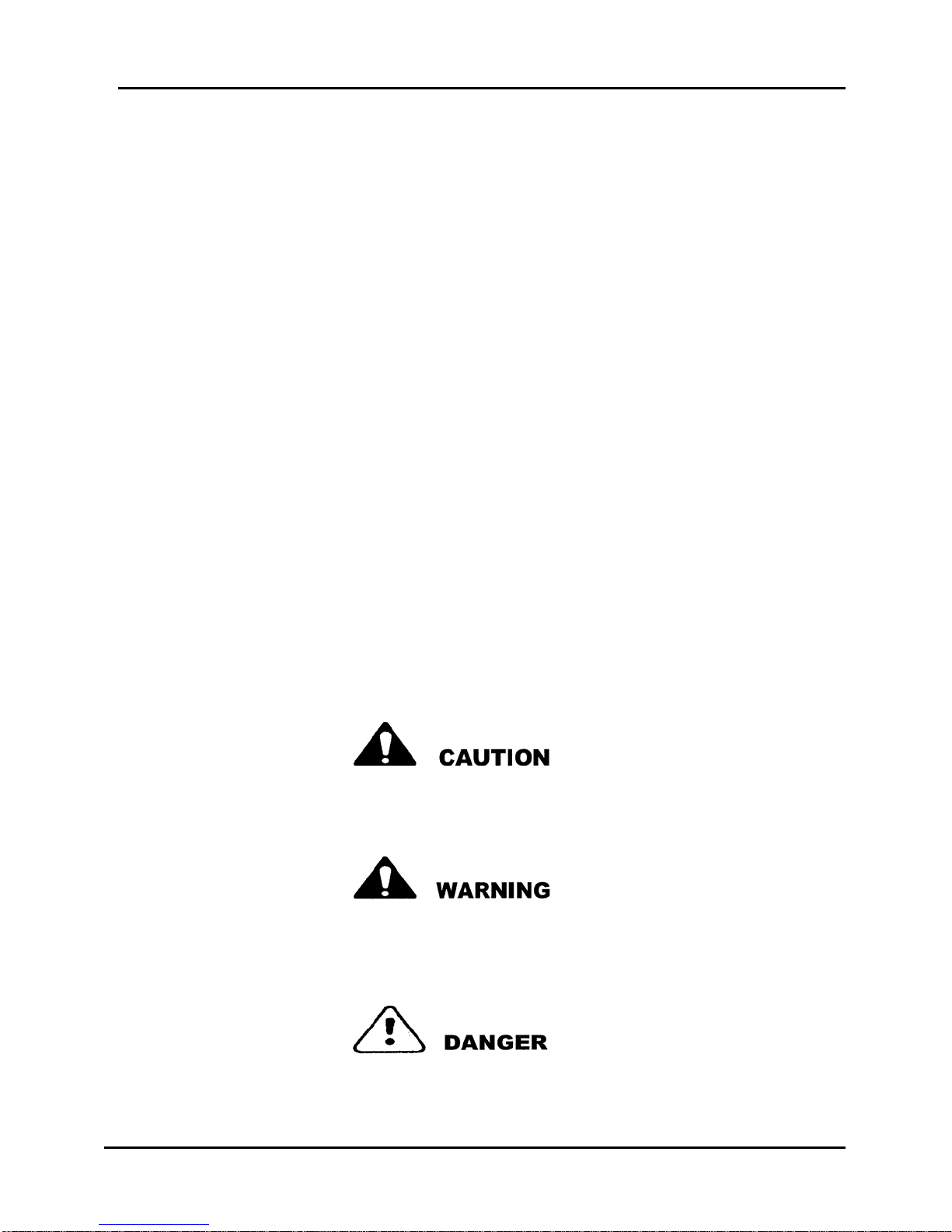

SAFETY SIGNS and SAFETY MESSAGES

Improper operation can cause accidents. Don’t take chances with incorrect or damaged

equipment. Read and understand the procedures for safe operation and maintenance

outlined in this manual. Don’t hesitate to ask for help.

Stay alert! Follow safety rules, regulations, and procedures. Avoid accidents by

recognizing dangerous procedures or situations before they occur.

Safety signs and messages are placed in this manual to provide instructions and

identify specific areas where potential hazards exist and special precautions should be

taken. Know and understand the meaning of these instructions, signs, and messages.

Damage to the dock equipment, death, or serious injury to you or other persons may

result if these messages are not followed. If warning decals are damaged, they must be

replaced. Contact your Blue Giant Distributor for replacements.

NOTICE

This message is used when special information, instructions or

identification are required relating to procedures, equipment, tools,

capacities and other special data.

IMPORTANT

This message is used when special precautions should be taken to

ensure a correct action or to avoid damage to or malfunction of the

dock equipment or a component.

This message indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury

This message indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

This message indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury.

SERVICE MANUAL BLUE GIANT

Page 4 Issue Date: 10/01/01, Rev, 0

PLANNED MAINTENANCE

The importance of proper

maintenance through planned

service, inspection, and qualified

repairs can not be emphasized too

strongly. Planned maintenance

instructions are provided for

reference in setting up and

conducting a recommended periodic

Planned Maintenance (PM) program.

Planned maintenance is a program in

which inspections, cleaning, minor

adjustments, are performed on a

scheduled and systematic basis. A

solid PM program should incorporate

a method of record keeping which

enables you to better determine PM

schedules and enables you to track

the maintenance costs.

An effective PM program should

incorporate two basic phases:

•An inspection performed by

operator or maintenance man at

the beginning of each shift. This

is a quick visual check for obvious

damage.

•A planned maintenance routine

performed every three months

based on a single shift operation

or monthly for multi-shift

operations.

Minimum work to be performed at

each planned maintenance interval:

•Cleaning, including surrounding

area.

•Visual inspection of all

components.

•Test operate all functions.

•Lubricate as required.

•Adjustment and retest if required.

•Check for damaged dock

bumpers.

•Record inspection details and

findings for owners files.

If the PM is routinely followed, need

for repair, major adjustment, and

component replacement will be

discovered automatically and such

work can be scheduled, eliminating

unnecessary down-time and cost.

The objectives of PM are:

•To reduce costly unscheduled

down-time.

•Reduce maintenance costs.

•Increase loading dock

productivity.

•Increase personal safety of

operators and other personnel.

Refer to the Operators Manual,

located with the dock equipment, for

additional information on care and

maintenance of your equipment.

NOTICE

Contact your Blue Giant Distributor for more information on

Maintenance and Re

p

air of

y

our Dock E

q

ui

p

ment.

BLUE GIANT SERVICE MANUAL

Issue Date: 10/01/01, Rev. 0 Page 5

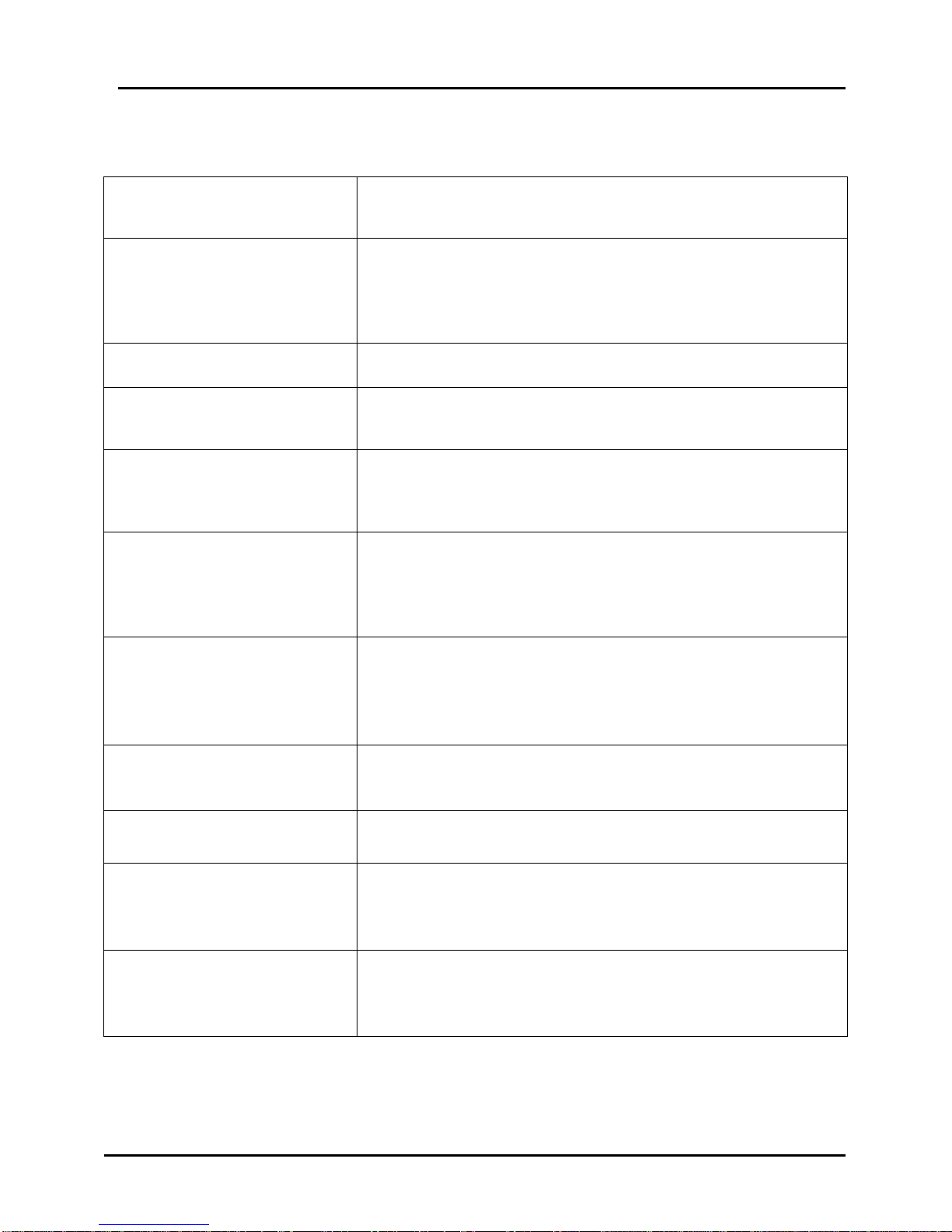

PRODUCTS COVERED BY THIS MANUAL

PRODUCT MODEL CODE

M 721

Dock Leveler – Mechanical – Pit Mounted FMC 722

FH 731

Dock Leveler – Hydraulic – Pit Mounted FHE 732

FHC 733

Dock Leveler – Hydraulic – Vertical Storing VS 751

E.O.D. Dock Leveler – Mechanical – Edge of Dock MD-M 704

E.O.D. Dock Leveler – Hydraulic – Edge of Dock MD-H 704

Truck Restraint – Mechanical ML-10 730

Truck Restraint – Hydraulic – Self-Contained Power Pack TL-85 735

Truck Restraint – Hydraulic – Remote Power Pack TL-85A 735

Truck Restraint and Dock Leveler - Combination TL-85A 740

ED 815

Elevating Dock – Hydraulic – Pit / Surface Mounted Lomaster 812

Elevating Dock – Hydraulic – Semi-Portable 4S/ 5S x 6S 810

Lift Table – Hydraulic – Pit / Surface Mounted FS 830

Lift Table – Hydraulic – Double Scissor DS 840

HOW TO USE THIS MANUAL

Separated and Identified by ‘Tab Pages’.

Products:

Each product is divided into ‘Groups’ of common information.

Group:

Each group is separated into main component ‘Sections’.

Section:

Each section page is numbered individually.

Page:

Mechanical Dock Leveler – M and FMC Group 03, Section 01, Page 1

Issue Date: 10/01/01, Rev. 0 (Part #038-550E)

Theory of Operation

Mechanical Dock Leveler

Index

SUBJECT GROUP SECTION PAGE

Description of Operation 03 01 2

Walking the Dock into Working Position 03 01 2 –3

Return to Stored Position 03 01 3

Diagonal Float Ability 03 01 3

Fall Safe Feature 03 01 4

Detail of Component Functions 03 01 5 - 7

Hold Down in Locked Position 03 01 8

Hold Down in Unlocked Position 03 01 8

Below Level Feature 03 01 9

Maintenance Strut 03 01 10

Group 03, Section 01, Page 2 Mechanical Dock Leveler – M and FMC

Issue Date: 10/01/01, Rev, 0 (Part #038-550E)

DESCRIPTION OF OPERATION

Before moving the dock leveler from

the stored position, it is most important

to chock the vehicle wheels or

otherwise secure the vehicle to prevent

its movement away from the dock,

before operating the Dock Leveler.

In stored position the lift springs are

stretched and the lifting arm is at the

base of the cam. The loaded springs

are fully tensioned in this position and

are always trying to pull the Lifting Arm

to the rear. The dock leveler can not

move upward however since it is held

in position at floor level by a “hold

down" mechanism. As you can see

above the "Lip" is folded down and is

being retained by the "Lip Keepers".

To raise the Dock Leveler deck, one must firmly pull up the release ring in the left-rear

corner of the deck and hold it up until the deck lift springs fully raise the deck. The lip will

automatically extend and will lock as the deck reaches its fully raised height.

WALKING THE DOCK INTO

POSITION

The deck is lowered by the operators

weight as he walks up it’s slope. The

extended lip makes firm contact with

the truck bed. At this point the bridge

is formed and the entire weight of the

outer end of the dock deck is supported

by the lip resting on the truck bed

Note: It is important to note that even though the lift springs are always trying to lift

the dock deck, their upward force is being opposed by the action of the “Hold Down

Mechanism". The unit is now considered to be ready for lift truck traffic.

Mechanical Dock Leveler – M and FMC Group 03, Section 01, Page 3

Issue Date: 10/01/01, Rev. 0 (Part #038-550E)

RETURN TO STORED POSITION

To return the deck to stored position after

the vehicle is Loaded or Unloaded and is

still at the dock, pull up and hold the

release chain "only long enough" for the

lip to clear the truck bed and fold in fully.

WALK THE DECK DOWN

Walk the deck down to the stored

position, ensuring that the lip is located

inside the lip keepers.

Note: Releasing the operating ring at any time will stop the upward travel of the deck.

Note: Should the truck depart before the dock leveler is returned to stored position, the

lip will automatically swing down to a hanging position. If the truck being serviced was

lower than the dock and the lip is not located inside the keepers, raise the deck

approximately 12” above dock height and then walk it down to stored position.

DIAGONAL FLOAT ABILITY

Irregularities in left to right corner height of the truck floor are sometimes caused by

uneven paving or lop sided loads. The design of the Blue Giant Dock Leveler

incorporates the use of "Tilt Bars and Pockets". These are floating hinge and mount

points located at the rear of the deck that allow the deck to float diagonally and

compensate for irregularities in left to right corner height of the truck floor. This

extends deck life by preventing deck twisting and also prevents lift truck tire damage

by allowing full width lip contact.

Note: In use, the Dock Leveler deck adjusts itself to tilted load beds and raises and

lowers automatically with movements of the load bed. (It is normal for a rear corner

to raise above floor level during use to compensate for a tilted truck bed).

Group 03, Section 01, Page 4 Mechanical Dock Leveler – M and FMC

Issue Date: 10/01/01, Rev, 0 (Part #038-550E)

FALL SAFE FEATURES

A fall safe device is included on all U.S. dock levelers and is available

as an option in all other countries.

Its purpose is to limit the free fall of the deck to 1-1/2” below dock

height if a trailer pulls away when a fork truck is on the dock leveler.

Two solid steel support legs are maintained in position between the

underside of the deck and the pit floor to limit the downward travel of

the deck.

The support legs are welded to a common shaft and maintained in

working position by a spring.

Pulling a control ring and chain at the front left corner will retract the

support legs to allow below level operation. Deck must be raised

approximately 4” to retract legs.

Mechanical Dock Leveler – M and FMC Group 03, Section 01, Page 5

Issue Date: 10/01/01, Rev. 0 (Part #038-550E)

DETAIL OF COMPONENT FUNCTIONS

In the previous descriptions outlined in

this section we explained the general

operation of the Mechanical Dock

Leveler. In this part of the operation

section we will explain the detail of the

various key components such as the

Lifting Arm, Lip Actuator Assembly,

Hold Down box and Cable, etc.

Notice that as the arm travels rearward on

the cam, two motions occur. The cam

roller and arm move rearward. The upper

part of the arm moves forward above the

pivot point. Because the roller is moving

rearward – it is traveling up the cam –

raising the deck. Because the top of the

Lift Arm is moving forward – its motion is

transferred through the Lip Actuator Spring

to extend the lip. This “point of contact”

(spring to lip) is what decides at what

“deck raising point” the lip is extended and

also modulates or cushions the action

extending the lip. This is a critical

adjustment that rarely changes and is

made at the factory.

Did you notice that in the previous statement we were careful to say that the Lift Springs

were “being allowed” to pull the Lift Arm rearward. When the Operating Ring and chain

are in their normal position, the hold down box and cable are always creating a

resistance or braking action that does not “allow” the weight of the deck to be lifted by

the biased Lift spring, Lift Arm and Cam action. When there is no weight on the deck, it

is always capable of being lifted by the springs.

All functions work in combination with,

and as a result of the lifting arm motion

as it is rotated around its axis by the

Lift Springs. As you can see here, the

cam and by the action of the Lift

Springs “being allowed” to pull the Lift

Arm rearward, the deck is raised. It is

important to observe the rotation action

of the arm around it’s pivot point.

Group 03, Section 01, Page 6 Mechanical Dock Leveler – M and FMC

Issue Date: 10/01/01, Rev, 0 (Part #038-550E)

DETAIL OF COMPONENT FUNCTIONS – cont’d

In this view the deck has been allowed to

raise to the point where the actuator

extended the lip. Notice that as the

actuator assembly moved forward – the lip

lock was pulled into its locking position.

The spring will maintain tension on the lip

lock while the deck is in the raised

position. When the deck is walked down

by the weight of the operator – the weight

of the lip will be supported by the lip lock.

After the loading / unloading process is complete – the operator pulls the release

chain to release the hold down device. The operator can now allow the dock deck to

raise high enough to allow the lip (now unlocked) to drop into its hanging position.

The lip is now ready and in position to enter the lip keepers when the operator walks

it down.

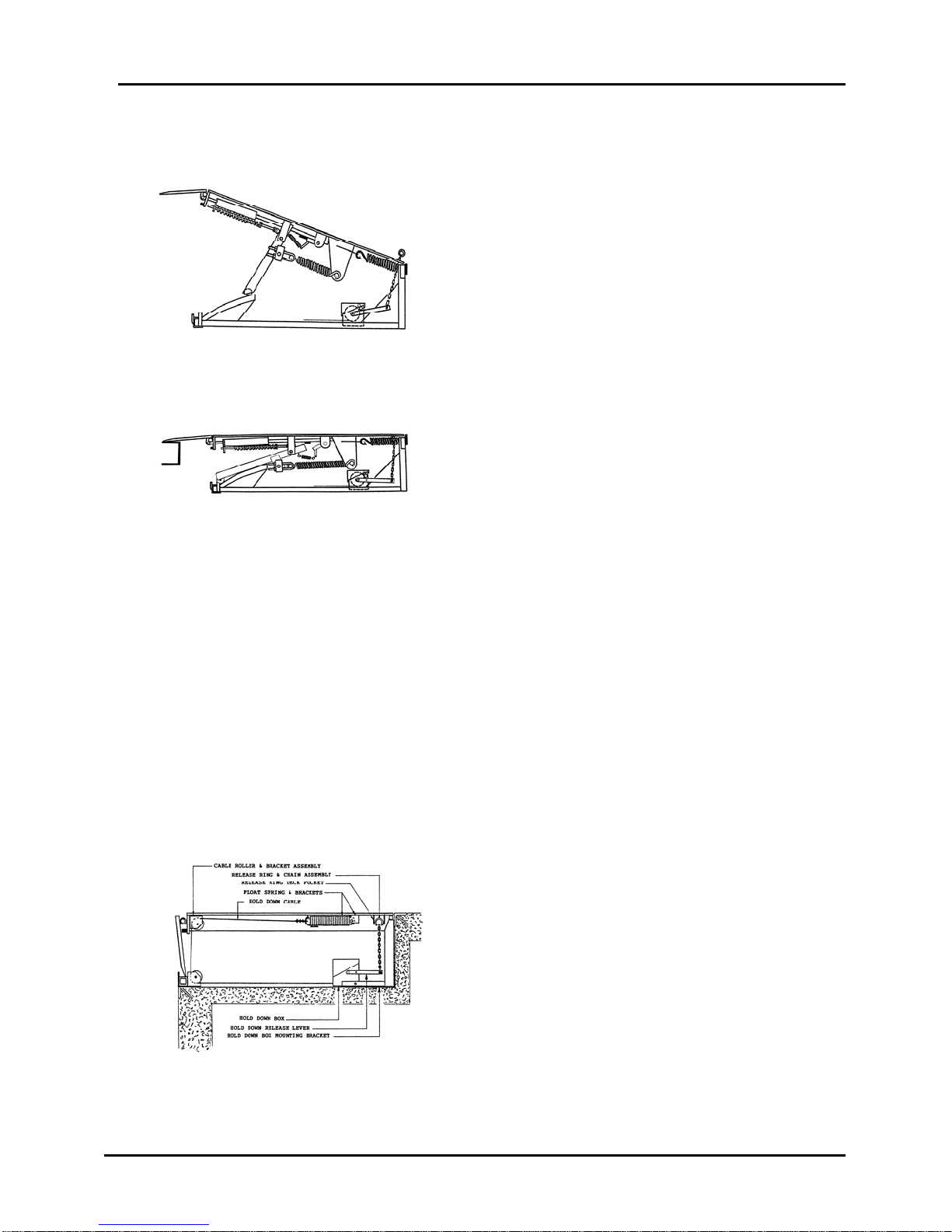

The lip and the lip keepers will now support the outer weight of the deck assembly in

the stored position. We have previously referred to the

opposing force or braking action of the

hold down box and cable, on the biased lift

springs. In this picture we can follow the

cable routing. The cable is attached

through a float spring to the rear solid

portion of the dock leveler deck. It is

routed forward to a pulley that is mounted

at the front of the deck. It then proceeds

downward through another pulley that is

mounted on the lower front beam of the

stationary frame. The cable then extends

rearward where it enters the hold down

box where tension is applied by a rewind

spring.

This view shows the deck lowered and the

weight of the deck now being supported by

the truck floor.

At this time the actuator and the lip lock

have done their job. Because the weight of

the lip has been taken by the truck floor –

the weight of the lip is no longer exerting

force on the lip lock. The fact that the Lift

Arm is now in a lower position – the spring

is relaxed – gravity takes over and allows

the lip lock to drop out of locked position.

Mechanical Dock Leveler – M and FMC Group 03, Section 01, Page 7

Issue Date: 10/01/01, Rev. 0 (Part #038-550E)

DETAIL OF COMPONENT FUNCTIONS – cont’d

In this picture you can see the

working components of the hold

down system.

They are:

–Handle Assembly

– Rewind Wheel

– Coil Spring

– Wear Strip

– Counter Weight

– Knurled Lock Roller

– Cable, etc.

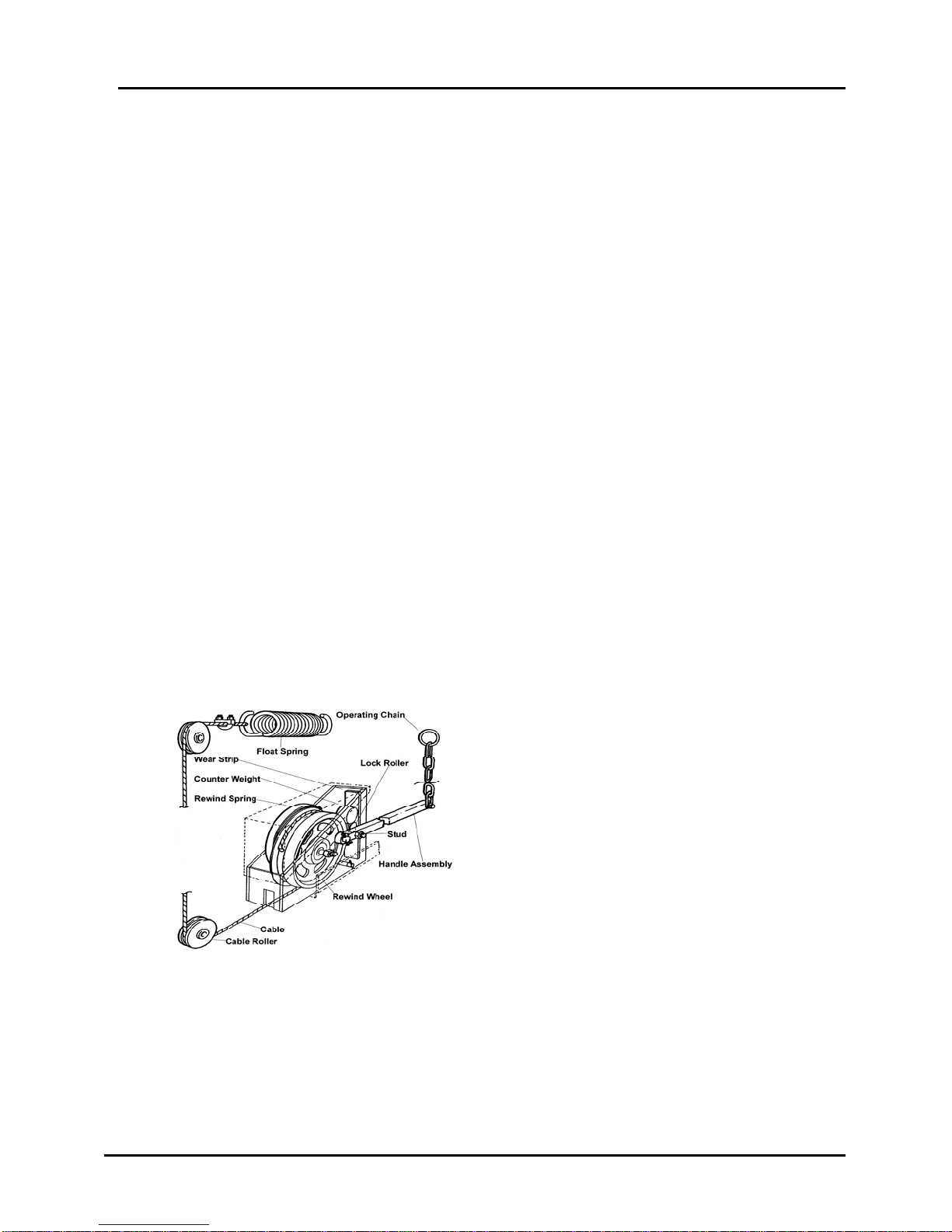

The hold down mechanism is

designed to work as a one-way

direction check for the cable.

As you can see here, the rewind spring is always trying to pull the cable

towards the hold down box. The rewind spring only has enough power

to rewind the cable as the deck moves downward.

The cable can always move toward the box when the deck is moving

downward however, because of the braking action applied to the cable

by the hold down box, the cable can not move outward until the brake is

released by pulling the operating chain.

This devices makes sure that the dock leveler always maintains a

positive downward force – through the lip when it is engaged with the

truck floor.

Since the brake creates a positive downward action to keep the lip

engaged with the truck floor, it is necessary to provide for and allow

movement of the deck and lip in an upward direction. This would occur

as a truck is being unloaded. As the load on the truck lightens, the

suspension tends to raise the truck bed.

As you can see here – this non-positive cushioned action is provided

through the cable by the float spring.

Group 03, Section 01, Page 8 Mechanical Dock Leveler – M and FMC

Issue Date: 10/01/01, Rev, 0 (Part #038-550E)

HOLD DOWN IN LOCKED POSITION:

The “one-way direction check” is created by

the action of the lower “Lock Roller” which is

held downward by the upper “Counter

Weight” roller.

In this position the “Lock Roller” is wedged

between the “Wear Strip” and the flat

surface of the “Rewind Wheel”. This

wedging action is sufficient to prevent the

“Rewind Wheel” from turning clockwise.

This prevents the cable from pulling outward

due to opposing lift spring force (which is

always present) attempting to lift the deck.

External force trying to lift the dock leveler

deck as explained earlier, (truck-load

lightening and forcing the lip and deck

upward) will not pull the cable through the

brake. Instead the “Float Spring” allows for

this necessary flexibility while maintaining a

positive contact from lip to truck.

HOLD DOWN IN UNLOCKED POSITON:

The “Handle Assembly” shown here pivots around the shaft on which it is mounted.

A short distance from this shaft is a horizontal “Stud” that is positioned underneath the

“Lock Roller”.

When the operator wishes to raise the deck he / she must pull up on the “Handle

Assembly” by pulling the “Operating Chain” upward. The horizontal “Stud” then lifts the

“Lock Roller” from its wedged position between the flat surface of the “Rewind Wheel”

and the “Wear Strip”.

This releases the cable and allows the deck to move upward as required. After the

deck reaches the desired level and the “Lip” is extended – the operator releases the

“Operating Chain” – walks up the raised deck and with his / her own weight forces the

deck and extended lip down to contact the truck floor.

During the “walk down” process the “Rewind Spring” is pulling and winding the

slackening cable back on the wheel until deck travel stops. The only way the deck can

move upward now is by overcoming the tension of the “Float Spring”.

The “Float Spring” allows the deck to raise with the truck bed. If there was no “Float

Spring” the cable or some other component would break.

Mechanical Dock Leveler – M and FMC Group 03, Section 01, Page 9

Issue Date: 10/01/01, Rev. 0 (Part #038-550E)

BELOW LEVEL FEATURE

Fall Safe support legs prevent

service of below dock height truck

bed and / or end load.

Raise dock leveler approximately

4”. Pull and hold control ring and

chain.

Pull and hold control ring and chain

located in front left corner of deck.

Legs retract and lip moves out

beyond lip keepers.

Hold tension on control chain and

walk the deck down. Support legs

will retract further, as required.

Deck will lower to below level stops

(not shown for clarity of other

components). End or below level

loads may be serviced.

A vehicle loadbed that is lower than dock height may be serviced by using

the below level feature.

This manual suits for next models

1

Table of contents

Other Blue Giant Tools manuals