Blue Sea EVOLUTION G47 User manual

Blue Seal Evolution Series - G47 Gas Pasta Cooker © Copyright Moffat Ltd, March 2016

Amendment 6

Service Manual

Pasta Cookers

G47

Blue Seal Evolution Series - G47 Gas Pasta Cooker © Copyright Moffat Ltd, March 2016

Amendment 6

ALL INSTALLATION AND SERVICE REPAIR WORK MUST BE CARRIED OUT BY QUALIFIED PERSONS

ONLY.

WARNING:

MAKING ALTERATIONS MAY VOID WARRANTIES AND APPROVALS.

IMPORTANT:

Blue Seal Evolution Series - G47 Gas Pasta Cooker © Copyright Moffat Ltd, March 2016

Amendment 6

This manual is designed to take a more in depth look at the G47 Pasta Cookers for the purpose of making the units more

understandable to service people.

There are settings explained in this manual that should never require to be adjusted, but for completeness and those special cases

where these settings are required to change, this manual gives a full explanation as to how, and what effects will result.

Section Page No.

1. Specifications ........................................................................................................................... 3

2. Installation ............................................................................................................................... 5

3. Operation ................................................................................................................................ 10

3.1 Description of Controls

3.2 Explanation of Control System

4. Maintenance ........................................................................................................................... 12

5. Fault Finding Guide ................................................................................................................ 13

5.1 Fault Finding Chart

5.2 Fault Diagnosis

6. Service Procedures ................................................................................................................. 16

6.1 Access

6.2 Replacement

6.3 Adjustment / Calibration

7. Accessories ............................................................................................................................. 21

Gas Conversion Kits

Accessories

8. Exploded Parts Diagrams ...................................................................................................... 22

9. Circuit Schematics .................................................................................................................. 28

10. Service Contacts ..................................................................................................................... 29

Appendix A: Gas Type Conversion .................................................................................................. 30

Appendix B: Gas Specifications ...................................................................................................... 32

Contents

Blue Seal Evolution Series - G47 Gas Pasta Cooker © Copyright Moffat Ltd, March 2016

Amendment 6

3

1

Specifications

Blue Seal Evolution Series - G47 Gas Pasta Cooker © Copyright Moffat Ltd, March 2016

Amendment 6

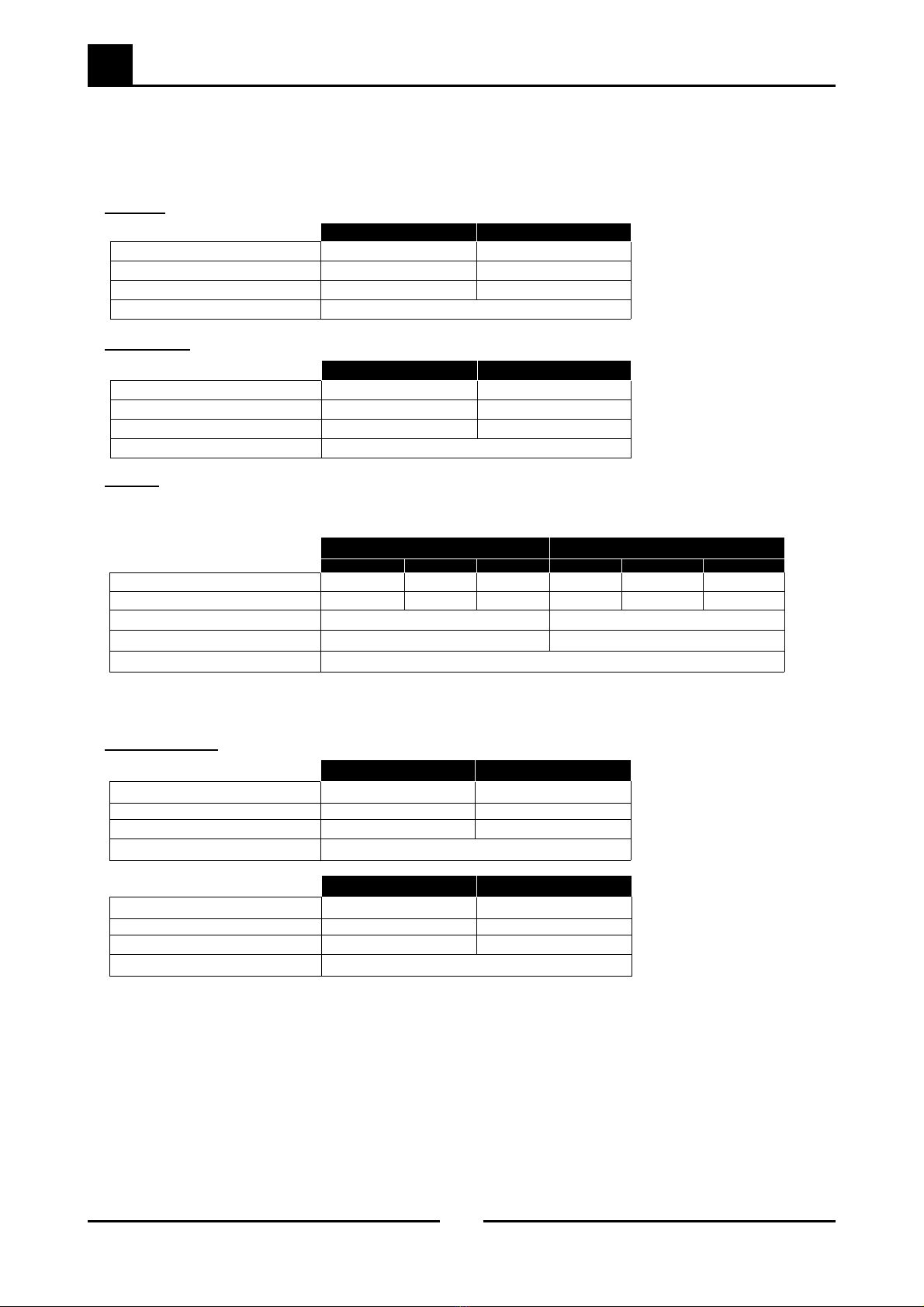

Dimensions shown in millimetres.

Legend

- Gas connection entry point - ¾” BSP male

External Dimensions: G47

4

1

Specifications

Blue Seal Evolution Series - G47 Gas Pasta Cooker © Copyright Moffat Ltd, March 2016

Amendment 6

Model Numbers Covered in this Specification

G47 Pasta Cooker (Single Tank - 40 Ltr).

Gas Supply Requirements

- Australia:

- New Zealand:

- UK Only:

Category: II2H3P.

Flue Type: A1.

NOTE: (*) Measure burner operating pressure at upper test point (Supply Pressure) on gas control valve located behind

control panel, this is to be carried out with burner operating at ‘High Flame’ setting. Refer to ‘Gas Conversion

and Specification’ Section for further details.

- All Other Markets:

NOTE:

(*) Measure burner operating pressure at upper test point (Supply Pressure) on gas control valve located

behind control panel, this is to be carried out with burner operating at ‘High Flame’ setting.

NAT, LPG & Butane Only - Operating pressure is ex-factory set and is not to be adjusted, apart from when

converting between gasses, if required.

TOWN GAS Only - Burner operating pressure is to be adjusted using adjustable gas regulator supplied.

(**) Town Gas Option is only available with specific ex-factory built Town Gas models, which can also be

converted to any other gas. Standard models can only be converted between Nat. Gas, LP Gas and Butane,

but not Town Gas.

Refer to ‘Gas Conversion and Specifications' section in this manual for further details.

Natural Gas (G20) Propane (G31)

Nominal Reduced Pilot Nominal Reduced Pilot

Heat Input (nett) 12.0 kW 5.4 kW 320W 12.5 kW 6.2 kW 320W

Gas Rate 1.27 m3/hr 0.42 m3/hr 0.03 kg/hr 0.97 kg/hr 0.48 kg/hr 0.02 kg/hr

Supply Pressure 20 mbar 37 mbar

Burner Operating Pressure (*) 27.7 mbar

Gas Connection 3/4” BSP Male

9.5 mbar

Natural Gas LP Gas

Input Rating (N.H.G.C.) 46 MJ/hr 47 MJ/hr

Supply Pressure 1.13 - 3.40 kPa 2.75 - 4.50 kPa

Burner Operating Pressure (*) 0.92 kPa 2.6 kPa

Gas Connection ¾” BSP Male

Natural Gas LP Gas / (Propane)

Input Rating (N.H.G.C.) 46 MJ/hr 47 MJ/hr

Supply Pressure 1.13 - 3.40 kPa 2.75 - 4.50 kPa

Burner Operating Pressure (*) 0.92 kPa 2.6 kPa

Gas Connection ¾” BSP Male

Natural Gas Town Gas (**)

Input Rating (N.H.G.C.) 46 MJ/hr 47 MJ/hr

Supply Pressure 1.13 - 3.40 kPa 0.75 - 1.5 kPa

Burner Operating Pressure (*) 0.92 kPa 0.5 kPa

Gas Connection ¾” BSP Male

LP Gas (Propane) Butane

Input Rating (N.H.G.C.) 47 MJ/hr 47 MJ/hr

Supply Pressure 2.75 - 4.50 kPa 2.75 - 4.50 kPa

Burner Operating Pressure (*) 2.6 kPa 2.6 kPa

Gas Connection ¾” BSP Male

2

Installation

5

Blue Seal Evolution Series - G47 Gas Pasta Cooker © Copyright Moffat Ltd, March 2016

Amendment 6

Installation Requirements

NOTE:

It is most important that this appliance is installed correctly and that operation is correct before use.

Installation shall comply with local, gas, health and safety requirements.

This appliance shall be installed with sufficient ventilation to prevent the occurrence of unacceptable

concentrations of health harmful substances in the room, the appliance is installed in.

Blue Seal pasta cookers are designed to provide years of satisfactory service and correct installation is essential to achieve the best

performance, efficiency and trouble-free operation.

This appliance must be installed in accordance with National installation codes and in addition, in accordance with relevant National /

Local codes covering gas and fire safety.

AUSTRALIA / NEW ZEALAND: - AS/NZS5601 - Gas Installations.

UNITED KINGDOM: - Gas Safety (Installation & Use) Regulations 1998.

- BS6173 - Installation of Catering Appliances.

- BS5440 - Parts 1 & 2 Installation Flueing & Ventilation.

IRELAND: - IS 820 - Non - Domestic Gas Installations.

Installations must be carried out by qualified service persons only. Failure to install equipment to the relevant codes

and manufacturer’s specifications shown in this section will void the warranty.

Components having adjustments protected (e.g. paint sealed) by manufacturer, are only to be adjusted by an

authorised service agent. They are not to be adjusted by the installation person.

Unpacking

Remove all packaging and transit protection from the appliance including all protective plastic coating from the door outer

panel and exterior stainless steel panels.

Check equipment and parts for damage. Report any damage immediately to the carrier and distributor.

Report any deficiencies to the distributor who supplied the appliance.

Check that the available gas supply is correct to that shown on the rating plate located on the inside of the access door.

Check that the following parts have been supplied with the appliance:

G47

Baskets LH 165 x 125mm 3.

Baskets RH 165 x 125mm 3.

Basket Support Frame 1.

Location

1. This appliance must be installed in a suitably ventilated room to prevent dangerous build up of combustion products.

2. Installation must allow for a sufficient flow of fresh air for the combustion air supply.

3. Position the appliance in its approximate working position.

4. All air for burner combustion is supplied from underneath the appliance. The legs must always be fitted and no obstructions

placed on the underside or around the base of the appliance, as obstructions will cause incorrect operation and / or failure of

the appliance.

5. Components having adjustments protected (e.g. paint sealed) by manufacturer are only to be adjusted by an authorised

service agent. They are not to be adjusted by the installation person.

NOTE: Do not obstruct or block the appliances flue. Never directly connect a ventilation system to the appliance

flue outlet.

Combustion Air Requirements:

Natural Gas 13m3/hr

LPG 13m3/hr

Town Gas 13m3/hr

2

Installation

6

Blue Seal Evolution Series - G47 Gas Pasta Cooker © Copyright Moffat Ltd, March 2016

Amendment 6

Clearances

NOTE:

Only non-combustible materials can be used in close proximity to this appliance.

In order to facilitate easy operation, drainage and servicing of the appliance, a minimum of 600mm

clearance should be maintained at the front of the appliance.

Any gas burning appliance requires adequate clearance and ventilation for optimum and trouble-free operation. The following

minimum installation clearances are to be adhered to:

Assembly

This model is delivered completely assembled. Ensure that the adjustable feet / rollers are securely attached.

NOTE:

This appliance is fitted with adjustable feet / rollers to enable the appliance to be positioned securely and

level. This should be carried out on completion of the gas connection. Refer to the ‘Gas Connection’ section

overleaf.

The appliance rear leg housings can be fitted with:-

Adjustable feet to assist with levelling of the appliance on uneven floors.

Rear rollers to enable the appliance to be easily moved for positioning and cleaning

purposes.

Optional Accessories (Refer to Replacement Parts List).

Plinth Kit. For installation details, refer to instructions supplied with each kit.

Combustible Surface Non Combustible Surface

Left / Right Hand Side 50mm 0mm

Rear 50mm 0mm

2

Installation

7

Blue Seal Evolution Series - G47 Gas Pasta Cooker © Copyright Moffat Ltd, March 2016

Amendment 6

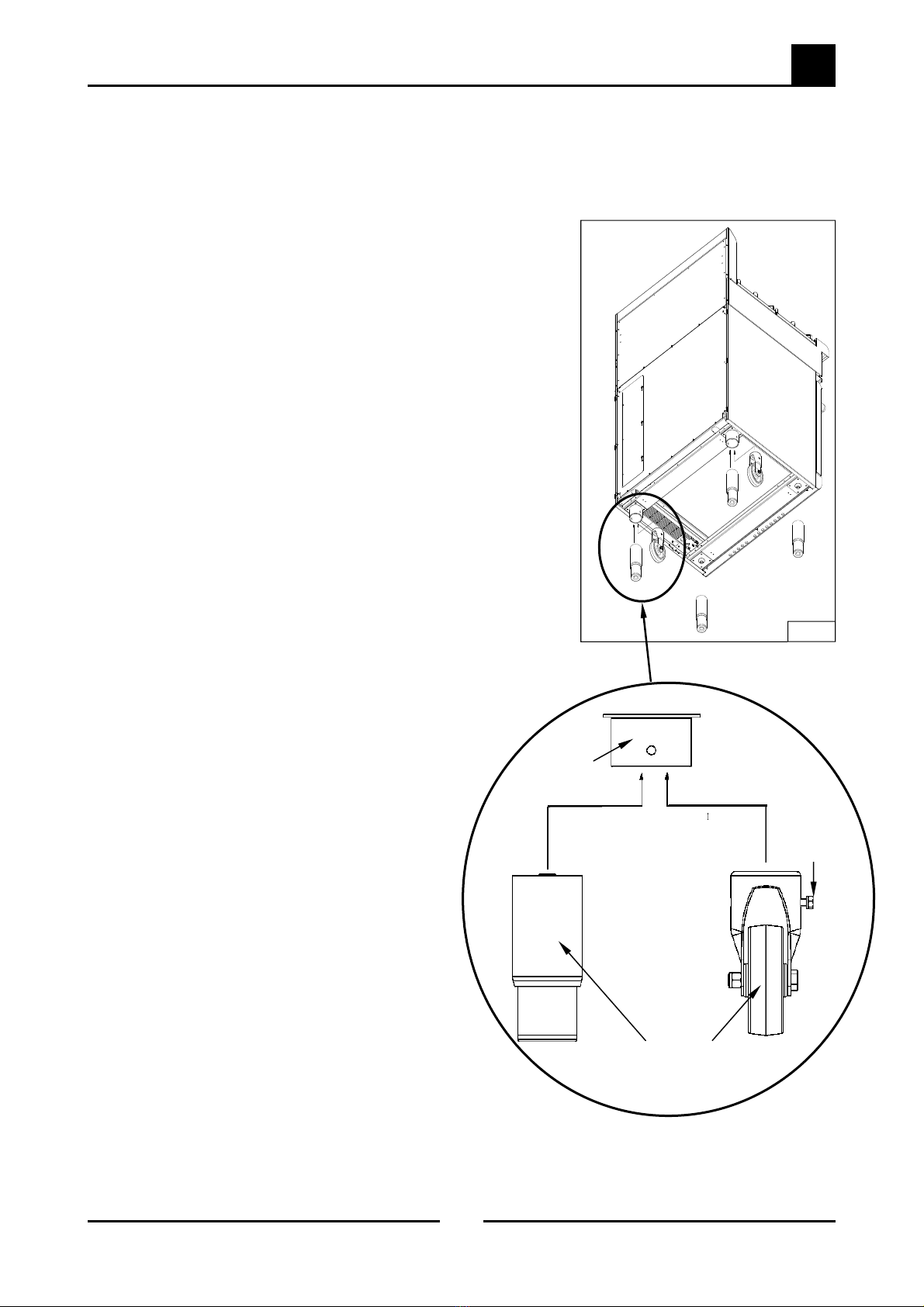

Fitting of Adjustable Feet / Rear Rollers to the Pasta Cooker

This appliance rear leg mount housings can be fitted with:-

Adjustable feet to assist with levelling of the appliance on uneven floors.

Rear rollers to enable the appliance to be easily moved for positioning and cleaning purposes.

Rear Adjustable Legs, fitting:-

1. Raise the appliance from the floor by approximately 75mm using

suitable lifting equipment (i.e. Palletiser / Forklift) to allow the rear

rollers to be removed.

2. Unscrew and remove the securing bolt that secures the rear roller

to the rear leg housing.

3. The rear rollers will drop freely from the rear leg housings.

4. Screw the rear adjustable feet into the rear leg housings and

tighten hand tight.

5. Lower the appliance back to the floor and adjust the adjustable feet

to level the appliance.

Rear Rollers, fitting:-

1. Raise the appliance from the floor by approximately 75mm using

suitable lifting equipment (i.e. Palletiser / Forklift) to allow the rear

adjustable feet to be removed.

2. Unscrew and remove both the rear adjustable feet from the rear

leg housings.

3. Fit the rear roller to the rear leg housing and align the screw hole in

the side of the rear leg housing with the threaded hole in the rear

roller.

4. Locate the rear roller to the leg support with the bolt supplied and

tighten the bolt using a 10mm A/F spanner.

5. Fit the second roller and tighten.

6. Lower the appliance back to the floor and adjust the front

adjustable feet to level the appliance.

Adjustable

Foot

Rear

Roller

Roller Securing

Bolt

Rear Leg

Housing

Fig 2.1

2

Installation

8

Blue Seal Evolution Series - G47 Gas Pasta Cooker © Copyright Moffat Ltd, March 2016

Amendment 6

Gas Connection

NOTE: ALL GAS FITTING MUST ONLY BE CARRIED OUT BY A QUALIFIED SERVICE PERSON.

1. Blue Seal Pasta Cookers do not require an electrical connection, they function totally on the gas supply only.

2. It is essential that the gas supply is correct for the appliance to be installed and that adequate supply pressure and volume are

available. The following checks should therefore be made before installation:-

a. The Gas Type the appliance has been supplied for is shown on coloured

stickers located above the gas entry point and next to the rating plate. Check

that this is correct for the gas supply the appliance is being installed for. The

gas conversion procedure is detailed in this manual.

b. Supply Pressure required for this appliance is shown in the ‘Specifications’

section of this manual. Check the gas supply to ensure that adequate supply

pressure exists.

c. Input Rate of this appliance is also stated on the Rating Plate fitted to the

inside of the access door and in the ‘Specifications’ section of this manual. The

input rate should be checked against the available gas supply line capacity.

Particular note should be taken if the appliance is being added to an

existing installation.

NOTE: It is important that adequately sized piping runs directly to the

connection joint on the appliance, with as few tees and elbows as

possible to give maximum supply volume.

3. A suitable joining compound which resists the breakdown action of LPG must be used

on every gas line connection, unless compression fittings are used.

The connection to the appliance is 3/4” BSP male.

NOTE: A Manual Isolation Valve must be fitted to the individual appliance supply line.

4. Correctly locate the appliance into its final operating position and using a spirit level, adjust the legs so that the unit is level and

at the correct height.

5. Connect the gas supply to the appliance.

6. Check gas operating pressure to as shown in the “Specifications” section. If the pressure is incorrect, adjust the pressure by

adjusting the regulator screw of the gas control valve as shown in the ‘Gas Conversion and Specifications’ section.

7. Check all gas connections for leakages using soapy water or other gas detecting equipment.

NOTE: Measure operating pressure at Burner Operating Pressure

test point on gas control valve, this is to be carried out with

burner operating at 'High Flame' setting. Operating pressure

is ex-factory set, through the appliance regulator and is not

to be adjusted, apart from when carrying out gas

conversion, if required. Refer to ‘Gas Conversion and

Specification’ Section for further details.

8. Turn ‘OFF’ the mains gas supply and bleed the gas out of the

appliance gas lines.

9. Turn ‘ON’ the gas supply and the appliance.

10. Verify the operating pressure remains correct

11. Check the pilot flame size. (Re-adjust if required by changing the

pilot injector. Refer to the Gas Conversion Section).

Rating Plate

Location

Fig 2.2

DONOT USE ANAKED FLAME TO CHECK FOR GAS LEAKAGES.

Warning

Gas Control

Valve

Burner Operating

Pressure Test Point

Fig 2.3

2

Installation

9

Blue Seal Evolution Series - G47 Gas Pasta Cooker © Copyright Moffat Ltd, March 2016

Amendment 6

Water Connection

NOTE: The water connection shall be installed in accordance with local water regulations in force and the applicable

standard/code, e.g. EN 1717 in UK / Ireland, PCA in Australia.

A cold water supply must be connected to the water inlet connection (R1/2" BSP), located 50mm from the LH side, 555mm from rear

and 135mm from the floor.

The water inlet pressure must be as follows:-

Minimum water supply pressure 150 kPa (22 psi).

Maximum water supply pressure 550 kPa (80 psi).

Drainage Connection

The water is drained from the appliance by means of a valve located behind the front control panel.

A waste water tundish must be fitted below the appliance drain outlet. This should be a minimum of 127mm (5”) major

diameter.

If required the drain outlet can be extended in order to exit above the tundish. All drain piping must be with materials

suitable for conveying boiling water.

Drain connection is R1" BSP drain / overflow.

Commissioning

The following commissioning checks must be carried out before the pasta cooker is handed over for use, to ensure

that the unit operates correctly and the operator(s) understand the correct operating procedure.

1. Before leaving the new installation;

a. Check the following functions in accordance with the operating instructions.

Light the Pilot Burner.

Light the Main Burner.

b. Ensure that each operator has been instructed in the areas of correct lighting, operation, and shutdown procedures for

the appliance.

NOTE: If it is not possible to get the appliance to operate correctly, shut off the gas supply and contact the supplier

of this unit.

3

Operation

10

Blue Seal Evolution Series - G47 Gas Pasta Cooker © Copyright Moffat Ltd, March 2016

Amendment 6

Burner Control

OFF Position

PILOT Burner

HIGH Flame

LOW Flame

Gas Control Knob

Piezo Igniter

(Behind Access Door)

Water Control Valve

3.1 Description of Controls

NOTE: A full user’s operation manual is supplied with the appliance and can be used for further referencing of installation,

operation and service.

3

Operation

11

Blue Seal Evolution Series - G47 Gas Pasta Cooker © Copyright Moffat Ltd, March 2016

Amendment 6

3.2 Explanation of Control System

Safety System

The purpose of the safety system is to shut off the flow of gas if

the pilot flame goes out. It is comprised of the flame itself, the

thermocouple, and the flame failure gas valve.

The pilot flame is lit by holding in the gas control knob, which in

turn temporarily pushes the plunger inside the safety valve

open and allows gas to flow through.

Once the burner is lit, the thermocouple will begin to generate

millivolts (after about 10 to 30 seconds of being heated) and

will energize the electromagnet inside the gas valve.

Once energized the electromagnet holds the plunger inside the

gas valve in the open position. The plunger has to have been

pushed all the way in for the electromagnet to be able to hold it

in place.

If the burner flame goes out, the thermocouple will cool after

about 10 to 30 seconds and stop generating millivolts. The

electromagnet will then de-energize, and the plunger will snap

shut, cutting off the flow of gas.

Detail of each component in the safety system is explained

below.

Sometimes a problem with the flame not staying lit after

releasing the button can be attributed to not pushing the

plunger all the way in.

This millivolt circuit is interrupted by a safety cut-out

thermostat. If the cut-out trips it cuts the millivolt supply to the

pilot valve magnet, shutting off the burners. The pasta cooker

is then inoperable until the cut-out has cooled below 100°C.

The purpose of this is to shut off the burners should the tank

run dry.

The Troubleshooting Guide (Section 5) should be used to

identify any incorrect operation. On correct identification of the

operating fault the Troubleshooting Guide will make reference

to the corrective action required, or refer to the Fault Diagnosis

section and / or Service section to assist in correction of the

fault.

The tip of the thermocouple is located in the pilot burner flame,

and the nut at the other end of the thermocouple screws into

the back of the gas valve.

Inside the copper tubing is a wire which is joined at the tip but

insulated from the rest of the tubing.

These two parts (the copper tubing and wire) make up the

‘Wiring’ for an electrical circuit. When these two dissimilar

metals, wire and tip, are heated an electrical voltage is

produced.

This type of thermocouple generates between 7 and 30

millivolts when heated in the pilot flame.

There are two reasons for this; gas has to flow through the

safety valve to make it possible to light the pilot burner,

secondly the plunger has to be pushed all the way in for the

electromagnet to hold it in. i.e. the electromagnet is strong

enough to hold the plunger in once there, but is not strong

enough to pull it in by itself.

Figure 3.2a

Figure 3.2b

Thermocouple

Gas flow

Electromagnet

Plunger

Shaft

Knob

Gas flow Plunger

Insulator Nut Conductor Tip

Internal

Wire

Thermocouple

The thermocouple is a device that generates electricity when

heat is applied to the tip.

Electromagnetic Flame Failure Gas Valve

The purpose of the safety valve is to shut off the flow of gas if

the pilot flame goes out.

Inside the body of the gas valve is an electromagnet connected

to a spring loaded plunger. When the electromagnet is

energized, it holds the plunger in, allowing gas to flow through

the valve. When the electromagnet is de-energized, the

plunger snaps to the closed position, stopping the flow of gas.

Millivolts are provided to the electromagnet by the

thermocouple (not shown) which generates millivolts when

heated. The thermocouple screws into a fitting at the back of

the gas valve to make an electric connection. By pressing in

the gas control knob, the plunger can be temporarily held open

while lighting.

Control Knob

4

Maintenance

12

Blue Seal Evolution Series - G47 Gas Pasta Cooker © Copyright Moffat Ltd, March 2016

Amendment 6

BLUE SEAL PASTA COOKERS - MAINTENANCE SCHEDULE

Business Name and Address:

Date: Service Report No.

Phone:

Serial No:

Clients Order No. Serviceman:

Model: Blue Seal G47 Remarks

1 Inspect exterior condition of unit.

2 Check working gas pressure, correct to rating plate. Pressure kPa

3 Check for gas leaks.

4 Check pilot flame, adjust as required.

5 Check burner operation.

6 Inspect thermocouple.

7a Check millivolt of thermocouple to safety cut-out. mV

7b Check millivolt of thermocouple to valve. mV

8Inspect is clean and free from blockages.

9 Check piezo ignition of pilot.

10 Check flue for build up of foreign objects.

Service Comments:

Additional work/repairs required:

Customers approval:

Name (print): Title:

Customers signature: Date:

Fax:

Suggestion: Photocopy this form and keep on file for continued use.

5

Fault Finding

13

Blue Seal Evolution Series - G47 Gas Pasta Cooker © Copyright Moffat Ltd, March 2016

Amendment 6

Fault Possible Cause Remedy

Piezo ignitor not sparking. Short in high tension lead.

(Refer Fault Diagnosis 5.2.2).

Piezo ignitor faulty.

(Refer Fault Diagnosis 5.2.2).

Replace lead.

(Refer Service Section 6.2.10).

Replace ignitor piezo.

(Refer Service Section 6.2.9).

Pilot won’t light. No gas supply.

Gas pressure too low.

Knob on gas control won’t go fully in.

Blocked pilot injector.

Ensure gas is connected and on and bottles

not empty.

Check gas supply pressure.

(Refer Specifications Section).

Remove obstruction. Correct control /

wrapper mounting.

Replace gas control valve.

(Refer Service Section 6.2.7).

Clean or replace pilot injector.

(Refer Service Section 6.2.9).

Pilot goes out when knob released. Releasing knob before the thermocouple

heated.

Pilot flame too small.

(Refer Fault: Pilot Flame Small).

Thermocouple faulty.

(Refer Fault Diagnosis 5.2.1).

Safety cut-out thermostat faulty.

(Refer Fault Diagnosis 5.2.1).

Gas control valve faulty.

Hold control in for longer (10 s), see if pilot

will stay lit.

Correct fault.

Replace thermocouple.

(Refer Service Section 6.2.1).

Replace safety cut-out thermostat.

(Refer Service Section 6.2.4).

Replace gas control valve.

(Refer Service Sections 6.2.7).

Pilot flame small. Gas pressure too low.

Pilot injector restricted.

Check gas supply pressure.

(Refer Specifications Section).

Clean pilot injector.

(Refer Service Section 6.2.2).

Pilot goes out when main burner comes on. Incorrect gas pressure.

Faulty gas control.

Check supply / adjust pressure.

(Refer Specifications Section).

Replace gas control valve.

(Refer Service Section 6.2.7).

Pilot goes out while in use. Gas supply - incorrect or fluctuating

pressure.

Draught at installation site(blowing pilot

out).

Thermocouple faulty.

(Refer Fault Diagnosis 5.2.1).

Safety cut-out thermostat faulty.

(Refer Fault Diagnosis 5.2.1).

Main gas control valve faulty.

Check supply / adjust pressure.

Shield pasta cooker from excessive breeze

Replace thermocouple.

(Refer Service Section 6.2.1).

Replace safety cut-out thermostat.

(Refer Service Section 6.2.4).

Replace gas control magnet.

5.1 Fault Finding Chart

ALL INSTALLATION AND SERVICE REPAIR WORK MUST ONLY BE CARRIED OUT BY QUALIFIED PERSONS.

Warning

5

Fault Finding

14

Blue Seal Evolution Series - G47 Gas Pasta Cooker © Copyright Moffat Ltd, March 2016

Amendment 6

Fault Possible Cause Remedy

Main burner will not light. Incorrect supply pressure.

Wrong size or blocked main burner

injector.

Small pilot flame.

(Refer fault: Small Pilot Flame).

Faulty gas control.

(Refer Fault Diagnosis 5.2.3)

Check supply correct pressure.

Replace / clean main burner injector.

(Refer Service Section 6.2.5).

Correct fault.

Replace gas control valve.

(Refer Service Section 6.2.7).

Pilot flame yellow / lazy. Gas pressure incorrect.

Restriction in pilot injector or aeration.

Check gas supply pressure.

(Refer Specifications Section).

Clean or replace injector as required.

(Refer Service Section 6.2.2).

Burner does not burn correctly (roar / light

back / incorrect colour).

Incorrect supply pressure.

Incorrect main injector size.

Burner faulty.

Check supply pressure.

Check main injector size and replace if

required.

(Refer Service Section 6.2.5).

Replace burner.

(Refer Service Section 6.2.6).

5

Fault Finding

15

Blue Seal Evolution Series - G47 Gas Pasta Cooker © Copyright Moffat Ltd, March 2016

Amendment 6

5.2 Fault Diagnosis

5.2.1 Pilot Drops Out

Pilot flame too small

If the pilot can be lit but the flame is too small to impinge on

the thermocouple, then check the gas pressure. If ok, then

remove the pilot injector from the pilot burner and check for

blockages and / or correct size.

Figure 5.2.1a

Thermocouple faulty

Check the thermocouple connection is firm and the safety

cut-out lead connection to the interrupter block on the

thermocouple is secure. (Loose connections will cause

resistance in the millivolt circuit and result in pilot outage.

If all connections are satis, light the pilot and whilst holding the

control knob in, measure the voltage from the pilot side of the

connecter block to earth (e.g. the body of the control valve).

This should read approximately 30mV.

If this reading is less than 20mV and there is good impingement

of the pilot flame onto the thermocouple, the thermocouple is

faulty - replace the thermocouple.

Figure 5.2.1b

Pilot side of Interrupter Block

Control Valve

Pilot Burner

Figure 5.2.1c

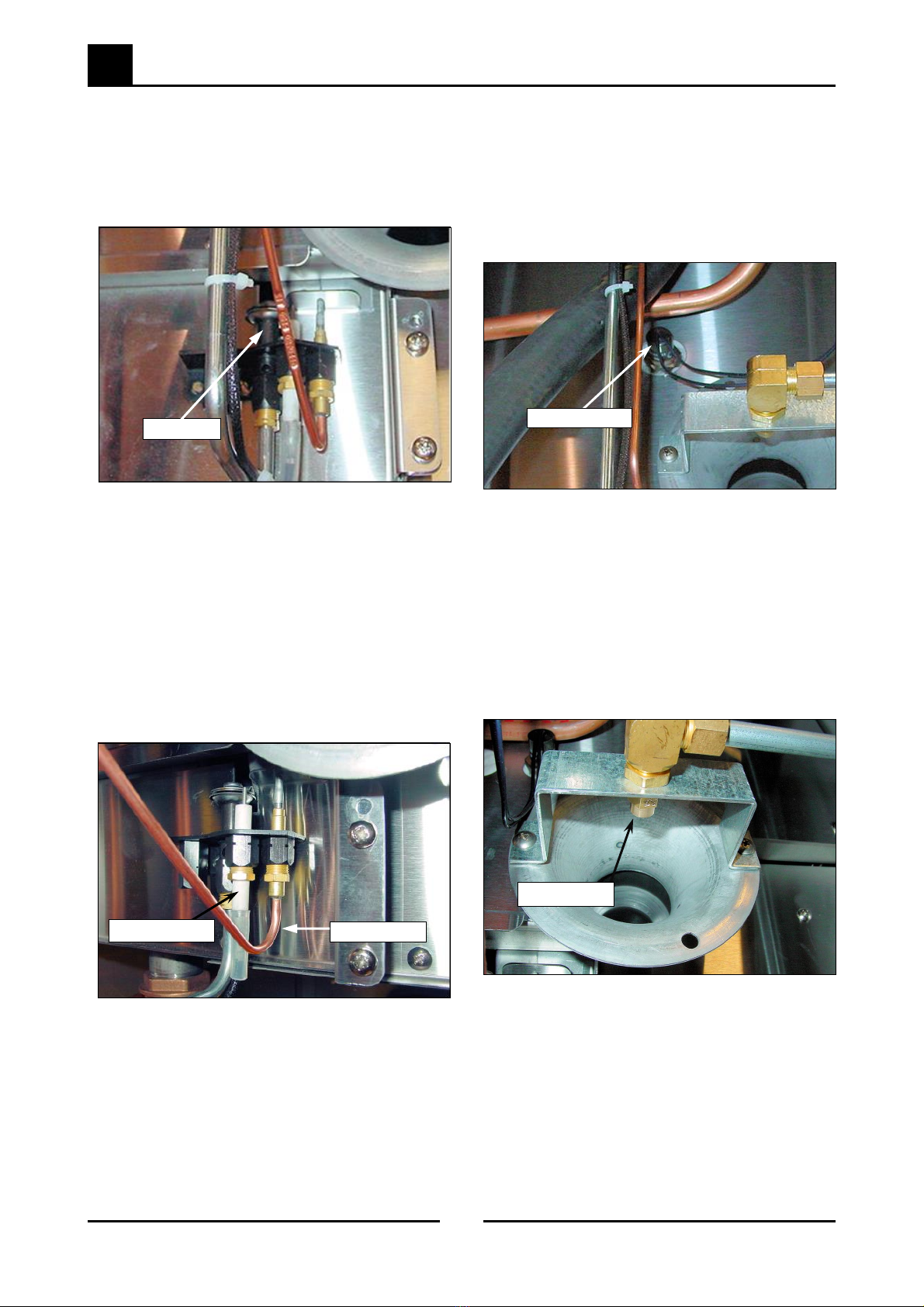

5.2.2 Piezo Ignitor Not Sparking

Short in high tension lead

If repeated sparking of the piezo shows only intermittent

sparking at the electrode, then the lead should be traced to find

the area of short. This can be visually seen as the spark arks.

If the lead is shorting the best solution is to replace it, as the

electrical insulation of the lead may have deteriorated.

If the spark arc can be seen at the electrode insulator at the

pilot burner instead of at the electrode tip, then the insulator

probably has a fracture and should be replaced.

Safety cut-out faulty

To check if the safety cut-out is faulty hold in the gas control

button and light the pilot (leaving the control button depressed

to keep the pilot alight). With a multimeter measure the voltage

from the gas control side of the thermocouple interrupter block

to earth. If the voltage is under 5mV (and the thermocouple is

generating at least 20mV) then the safety cut-out is faulty -

replace the safety cutout.

If all of the above checks out ok then check gas control or

thermocouple.

Gas Control side of Interrupter Block

Control Valve

Figure 5.2.2

Piezo ignitor faulty

If no spark at all can be generated, remove piezo ignitor and

hold close to cabinet body. Depress the piezo ignitor and if a

spark cannot be generated to the cabinet body the piezo ignitor

is faulty and should be replaced.

Note: If piezo ignition fails, the pilot can be manually lit

using a standard taper torch, lighter or matches,

until the piezo circuit is repaired.

Safety cut-out tripped

The safety cut-out is set at 115°C. If there is water in the tank

and the safety cut-out has tripped (open circuit) then the safety

cut-out is faulty.

6

Service Procedures

16

Blue Seal Evolution Series - G47 Gas Pasta Cooker © Copyright Moffat Ltd, March 2016

Amendment 6

ALL INSTALLATION AND SERVICE REPAIR WORK MUST BE CARRIED OUT BY QUALIFIED PERSONS

ONLY.

ENSURE GAS SUPPLY IS SWITCHED OFF BEFORE SERVICING

ALWAYS CHECK / TEST FOR GAS LEAKS AFTER SERVICE REPAIRS ON THE GAS SYSTEM

WARNING:

Section Page No.

6.1 Access......................................................................................................................................17

6.1.1 Control Panel........................................................................................................................................ 17

6.2 Replacement ...........................................................................................................................17

6.2.1 Thermocouple ..................................................................................................................................... 17

6.2.2 Pilot Injector ........................................................................................................................................ 18

6.2.3 Pilot Burner .......................................................................................................................................... 18

6.2.4 Safety Cut-out Thermostat ................................................................................................................... 18

6.2.5 Main Burner Injector............................................................................................................................. 18

6.2.6 Main Burner ......................................................................................................................................... 19

6.2.7 Gas Control Valve ................................................................................................................................ 19

6.2.8 Piezo Ignition Electrode ........................................................................................................................ 20

6.2.9 Piezo Ignitor......................................................................................................................................... 20

6.2.10 High Tension Lead ................................................................................................................................ 20

6.3 Adjustment / Calibration........................................................................................................ 20

6.3.1 Gas Control Valve Re-greasing............................................................................................................... 20

6.3.2 Low Fire Adjustment ............................................................................................................................. 20

6

Service Procedures

17

Blue Seal Evolution Series - G47 Gas Pasta Cooker © Copyright Moffat Ltd, March 2016

Amendment 6

Figure 6.1.1b

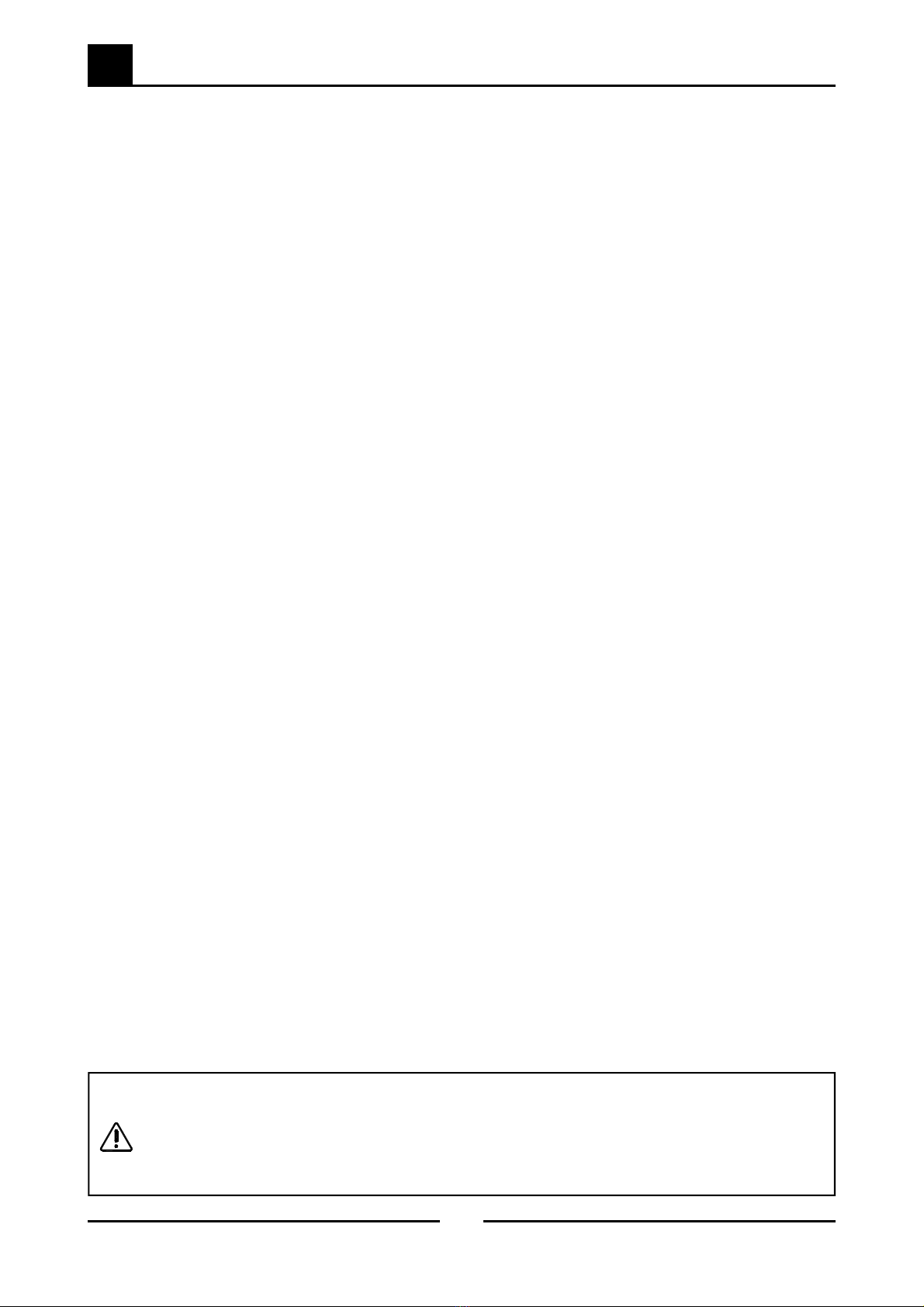

6.1.1 Control Panel

6.1 Access

1. Remove gas control knob by pulling knob from valve.

2. Remove water valve knob by levering out plastic cap in

centre of knob and undoing centre screw.

Figure 6.2.1a

6.2 Replacement

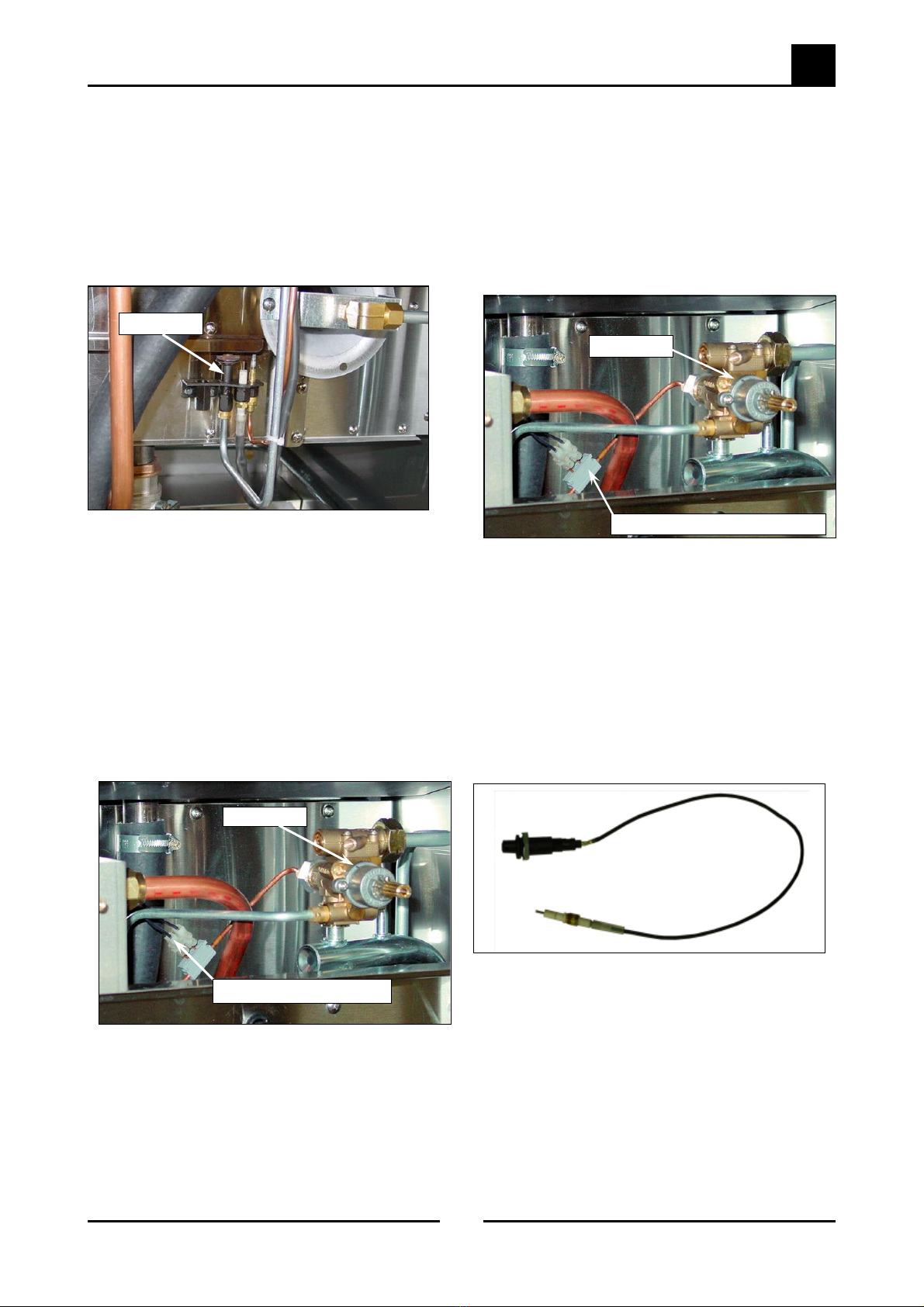

6.2.1 Thermocouple

Figure 6.2.1b

1. Disconnect thermocouple from gas control.

2. Unscrew the safety cut-out thermostat wires from the

connector block on the thermocouple.

3. Unscrew thermocouple securing nut from pilot burner.

NOTE: It may be necessary to remove the piezo

ignition electrode from the pilot assembly before

removing thermocouple.

4. Replace thermocouple and reconnect.

5. When screwing thermocouple back into gas control,

once thread has tightened up tighten another ¼ turn

only. Do not over tighten.

Thermocouple

Figure 6.1.1a

3. Remove 2 screws from underside of control panel and lift

panel off.

1 Screw

2 Screws

Water Valve Gas Control Valve

Thermocouple

6

Service Procedures

18

Blue Seal Evolution Series - G47 Gas Pasta Cooker © Copyright Moffat Ltd, March 2016

Amendment 6

Figure 6.2.3

Figure 6.2.4

Figure 6.2.5

6.2.4 Safety Cut-Out Thermostat

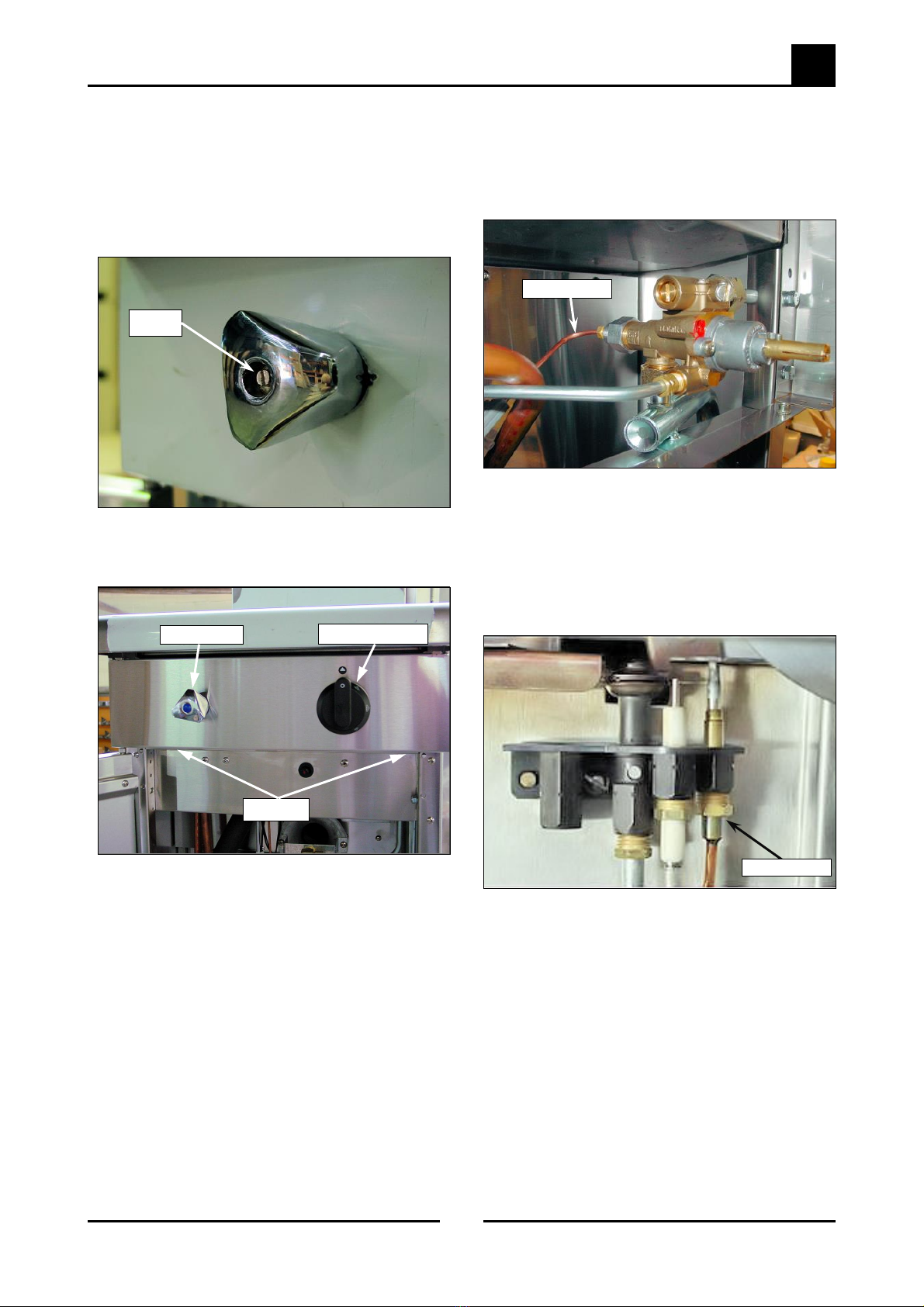

6.2.3 Pilot Burner

6.2.2 Pilot Injector

1. Remove ignition electrode.

2. Disconnect pilot supply tube from pilot burner by

unscrewing nuts and olive.

3. Remove pilot injector, and clean or replace as necessary.

1. Disconnect the thermocouple and / or the piezo electrode

from the pilot burner.

2. Disconnect pilot supply tube from pilot burner by

unscrewing nut and olive.

3. Remove screw securing the pilot burner to front of the

pasta cooker, and remove pilot burner assembly.

NOTE: Ensure correct size injector is used (refer

Specifications section).

4. Re-assemble in reverse order.

1. Drain water from pasta cooker.

2. Remove control panel (refer 6.2.1 )

3. Disconnect safety cut-out leads from interrupter on the

thermocouple.

4. Using

7/8” tube spanner, remove the safety cut-out

thermostat from fryer tank.

1. Unscrew injector out of injector mounts.

2. Remove injector, and clean or replace as necessary.

Ensure correct size of injectors are refitted (refer

Specifications Section).

4. Replace pilot burner and re-assemble. Ensure correct

pilot injector is re-fitted (refer to the Specifications

Section).

5. Replace and re-assemble in reverse order, using sealant

suitable for 115°C on threads (Loctite 567

recommended).

6.2.5 Main Injector

Figure 6.2.6

Main Injector

Pilot Burner

Thermocouple

Piezo Electrode

Safety Cut-Out

Table of contents