Blueair BLMI-300A Manual

Blueair

SERVICE TRAINING

Parameter Control Guidance

Modular Ice Machine Installation

R-290

Reach-ins

Undercounters

Parameter Control

Chapter 1

Blueair

Blueair

1. R-290 Parameter Control

Icon will light up and unit will display “DF” w

hen defrost is activated.

Icon will light up when evaporator fan(s)

are in operation

Icon will light up when compressor is in

operation

Icon will be displayed in Celsius or

Fahrenheit

depending on the user’s selection

Touching these Icons will change the value

of the setting

Icon is used in adjustment confirmation

and control panel locking.

☞Default Set Temperature

➢Refrigerator: 35°F (2°C)

➢Freezer: 0°F (-18°C)

☞Temperature Control Range

➢Refrigerator : 33°F (0.5°C) ~ 39°F (3.9°C)

➢Freezer: -10°F (-23.3°C) ~ 5°F (-15°C)

Overview

☞Note

Our display will be on as soon as the unit is connected to the power, but the compressor starts

operation after 5 minutes to prevent compressor damage.

Error Check Mode

Press button for 3 seconds.

Press button for 5 seconds

Until display shows “no” or error code(s).

If display shows “no”, that means the unit has no error at all.

Error codes are only displayed when the unit has errors.

Press button to check additional error code(s).

Do not touch controller for 15 seconds to exit.

Blueair

1. R-290 Parameter Control

Error Codes

1-1. “S1”: Defective Temperature (Room) Sensor

- Sensor is disconnected, open or cabinet temperature is below -58°F

1-2. “S1_”: Defective Temperature (Room) Sensor

- Sensor is shorted or cabinet temperature is above 149°F

2-1. “d1”: Defective Defrost Sensor

- Sensor is disconnected, open or cabinet temperature is below -58°F

2-2. “d1_”: Defective Defrost Sensor

- Sensor is shorted or cabinet temperature is above 149°F

3. “Df1”: Fail to Defrost

- Defrost time exceeds 50 minutes.

4. “CF1”: Fail to Cool

- Defrost sensor reads 32°F or above after 30 mins compressor

operation.

5. “EHF” (Freezer Only): Cabinet Temperature is High.

- Cabinet temperature is above 45°F for 8 hours after the compressor

starts up.

6. “EHr” (Refrigerator Only): Cabinet Temperature is High.

- Cabinet temperature is above 45°F for 8 hours after the compressor

starts up.

7. “Edr”: Door is open more than an hour.

8. “UFN”: V-FAN is disconnected. (Top Mount Refrigerator Only.)

Blueair

1. R-290 Parameter Control

Test Mode

Press button for 3 seconds.

Press and buttons together until “nd” is displayed.

Press button 18 times until “tE” is displayed.

Press button to check each part’s operation.

Go back to “St”, and do not touch controller for 15 seconds

to exit.

“St” is displayed after “Beep” sound.

Blueair

1. R-290 Parameter Control

Test Codes

1. “CP1”

- Turn on the compressor and fans.

2. “dHt” (Freezer Only.)

- Turn on the defrost heater.

3. “CHt” (Not in use for “-HC” units.)

- Turn on the cord heater.

4. “LP”

- Turn on the LED light.

5. “FS”

- Check temperature (room) sensor.

- Cabinet temperature is displayed if the sensor is okay.

-“t0” or “ts” is displayed if the sensor is defective.

6. “rt”

- Check ambient temperature sensor on control board.

- Cabinet temperature is displayed if the sensor is okay.

-“t0” or “ts” is displayed if the sensor is defective.

7. “ds”

- Check defrost sensor.

- Cabinet temperature is displayed if the sensor is okay.

-“t0” or “ts” is displayed if the sensor is defective.

Blueair

1. R-290 Parameter Control

Ice Machines

Parameter Control

Chapter 2

Blueair

Blueair

2. Ice Machines Parameter Control

Overview

☞Ice Machine Status Check

-Press “Check” button while the ice machine is on.

1) “E”: Displaying real-time evaporator temperature.

2) “F”: Average time of freezing cycle.

3) “H”: Average time of harvest cycle.

4) “三”: Total freezing cycle counts.

Error Codes

1. “E1” : Freezing problem

- Freezing cycle exceeds 60 minutes twice in a row.

2. “E2” : Harvest problem

- Harvest cycle exceeds 25 minutes twice in a row.

3. “E3” : Evaporator temperature problem

-Evaporator sensor temperature is over 140℉ (60℃).

Note: The temperature is generally under 120℉ (49℃).

4. “E4” : Drain problem

- Water is not drained during full storage.

-Press “Power” button once to turn off the alarm.

5. “E5” : Water supply problem

- Water level sensor continues to detect insufficient water levels.

- Water supply time exceeds 4 minutes.

6. “E6” : Evaporator sensor problem

- Evaporator sensor is either damaged or disconnected.

7. “E7” : Main control board problem

- Main control board is not operating properly.

☞Please refer to our service manuals to find out the recommend

resolution for each error code.

Blueair

2. Ice Machines Parameter Control

Test Mode

Press “Power” button for 5 seconds

to turn off the machine.

Press “Wash” button for 5 seconds

to activate test mode.

will be displayed.

Press “Wash” button until will be displayed.

Press “Wash” button until display goes black to exit.

Press “Wash” button to check each component.

Blueair

2. Ice Machines Parameter Control

Test Codes

1. “C”

- Turn on Compressor, Fan Motor, and Liquid Valve.

2. “P”

- Turn on Pump Motor to C.W. (Water Supply)

3. “P1” (Modular only.)

- Turn on Pump Motor to C.C.W. (Drainage)

4. “H”

- Open Hot Gas Valve.

5. “F”

- Turn on Fan Motor.

6. “三”

- Open Water Valve.

7. “AC”

- Open Cleaning Valve.

5. “AS”

- Open Liquid Valve.

9. “d”

- Drain the water.

10. “Dyc” (Factory use only.)

- Open Water Valve, Cleaning Valve, Drain Valve.

☞The test mode only shows available parts for each machine. If the ice machine does not have

a certain part, the test code for that part will not show up on the display

Blueair

2. Ice Machines Parameter Control

Additional Functions

1. Manual Harvest

-Press “Power” and “Wash” buttons together, while the unit is on.

2. Manual Drainage

-Press “Wash” button once, while the unit is off.

3. Vacuum (Opening all valves to expedite service time.)

-Press “Wash” and “Check” buttons together, while the unit is off.

Blueair

2. Ice Machines Parameter Control

+

+

Modular

Ice Machine

Installation

Chapter 3

Blueair

Check Valves

☞These valves must be opened prior to operating the ice machine.

Blueair

3. Modular Ice Machine Installation

▪Located in the back panel of the

unit.

▪Disassemble the panel to acces

s the valves.

BLUI-250A

(Undercounter)

BLMI-300A/500A/500AD/650A/900A

(Modular)

▪Located in the inside of the unit.

▪Disassemble the front panel to access

the valves.

1. Location of Valves (BLUI-100A/150A do not come with the valves.)

▪Uncap the safety caps. ▪Turn the valve counterclockwise until stop.

▪Put the safety caps back.

MUST OPEN

BOTH VALVES Close Open

2. How to open the valves?

Requirements

Blueair

3. Modular Ice Machine Installation

1. General

2. Water supply and drainage

☞ Must maintain 8” of minimum clearance at each side of the ice

machine for proper air circulation.

Modular Installation

Blueair

3. Modular Ice Machine Installation

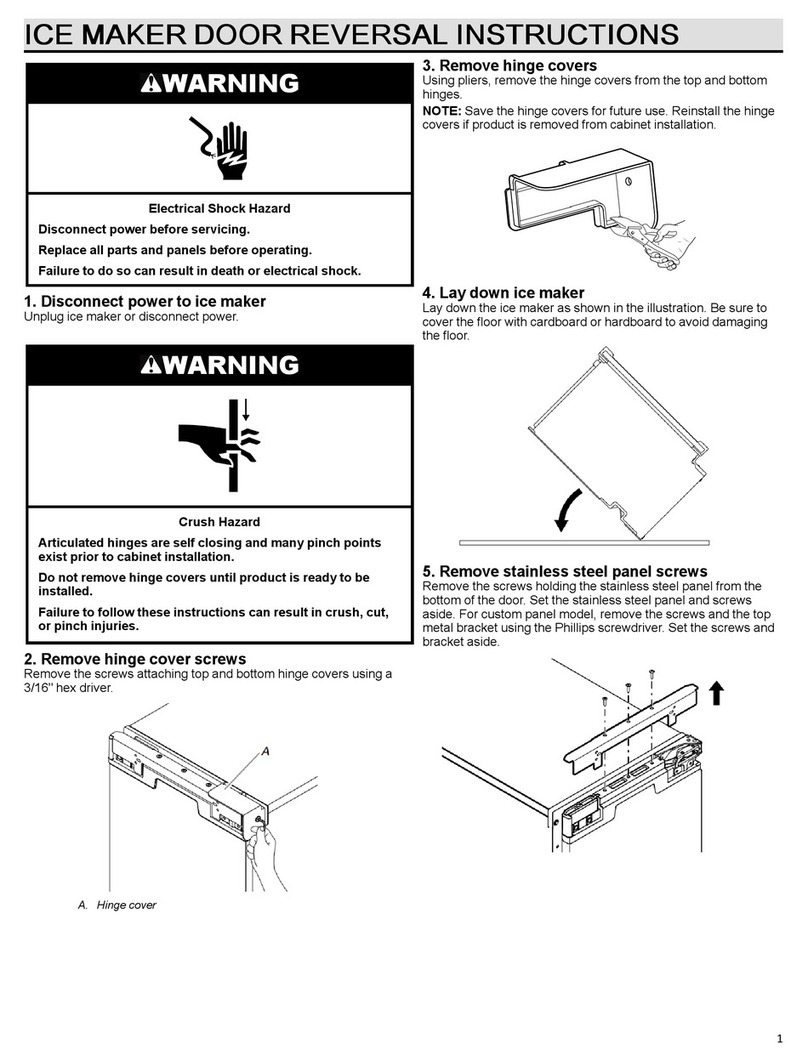

1. Disassemble All Panels

Modular Installation

Blueair

3. Modular Ice Machine Installation

2. Install Modular on the Storage Bin

- Make sure the modular and bin are leveled.

Modular Installation

Blueair

3. Modular Ice Machine Installation

3. Install Bin Switch

- Bin switch and thumbscrews are in a bag next to the

compressor.

Modular Installation

Blueair

3. Modular Ice Machine Installation

4. Connect Water Supply and Drain Lines.

-Maintain 2” vertical air gap between the end of each

pipe and floor drain.

Other manuals for BLMI-300A

2

This manual suits for next models

3

Table of contents

Other Blueair Ice Maker manuals