Bluebird 968160040 Maintenance and service guide

2

Table of Contents

Safety Information……………………… 3

Safety symbols………………………….. 4

Assembly………………………………... 6

Pre-operation / Starting…………………. 7

Operation……………………………….. 8

Maintenance……………………………. 9

Storage…………………………………… 12

Troubleshooting………………………….. 13

Parts drawings……………………………..15

Parts list by number………………………..19

Notes……………………………………….20

3

Safety Information

Attention; this machine can be dangerous! All operators should ful-

ly read all instructions and use extreme care and awareness when

operating the Unit. Failure to follow the instructions or modify the

equipment can result in personal injury.

Thank you for pur chasing the BlueBir d chipper. It will allow you to clean

up yards of branches and twigs up to 4 inches. Please become familiar with the

unit before operating.

Enter your model number and serial number for future reference.

Model number__________Serial number__________

If you have any problems or concerns about this unit please call your dealer or

contact us at [email protected]

Mandatory Operating preparation:

Read this safety and operation manual to understand proper safety procedures and

operation.

Do not allow anyone to operate this unit without training

Do not allow children to operate the chipper or feed anything into the unit.

Do not put any part of your body in the chute area or near any moving part including

clothing

Never attempt any clearing of the machine while it is operating or coasting to a stop.

All work should be done with the engine off, cooled down and the spark plug dis-

connected and moved away from the spark plug to prevent unwanted accidental start

up.

Do not operate this equipment under the influence of any type of medication or al-

cohol which might impair reflexes or judgment.

Never try to retrieve anything from the feed hopper after inserting .

Keep all observers especially children and pets away from unit including the dis-

charge area.

Wear safety glasses ,hard hat, ear protection, gloves, hard toe shoes and avoid loose

fitting protective clothing.

Check for all safety decals and instructions that should be legible

4

Danger: this machine must be operated in a safe manner ac-

cording to the directions in the manual. Failure to observe the

instructions or modify or use the machine when repair is needed

could result in serious injury or death. As with any power

equipment caution should be observed!

Read the safety and operating manual: read and under-

stand this manual before operating this equipment.

Eye and hearing protection must be worn when operat-

ing this equipment.

Warning : Rotating blades !

Do not insert body parts into the chutes or openings

inlet hopper.

Safety symbols used on equipment

5

Disconnect spark plug and read manual before servic-

ing the equipment

Warning: Do not get in the path of discharge de-

bris, it could cause injury.

Warning : Rotating blades!

Do not insert body parts into the chutes or open-

ings including inlet hopper.

Observe safety decals and their instructions.

Caution : Blades can cause serious injury!

Safety symbols used on equipment continued:

6

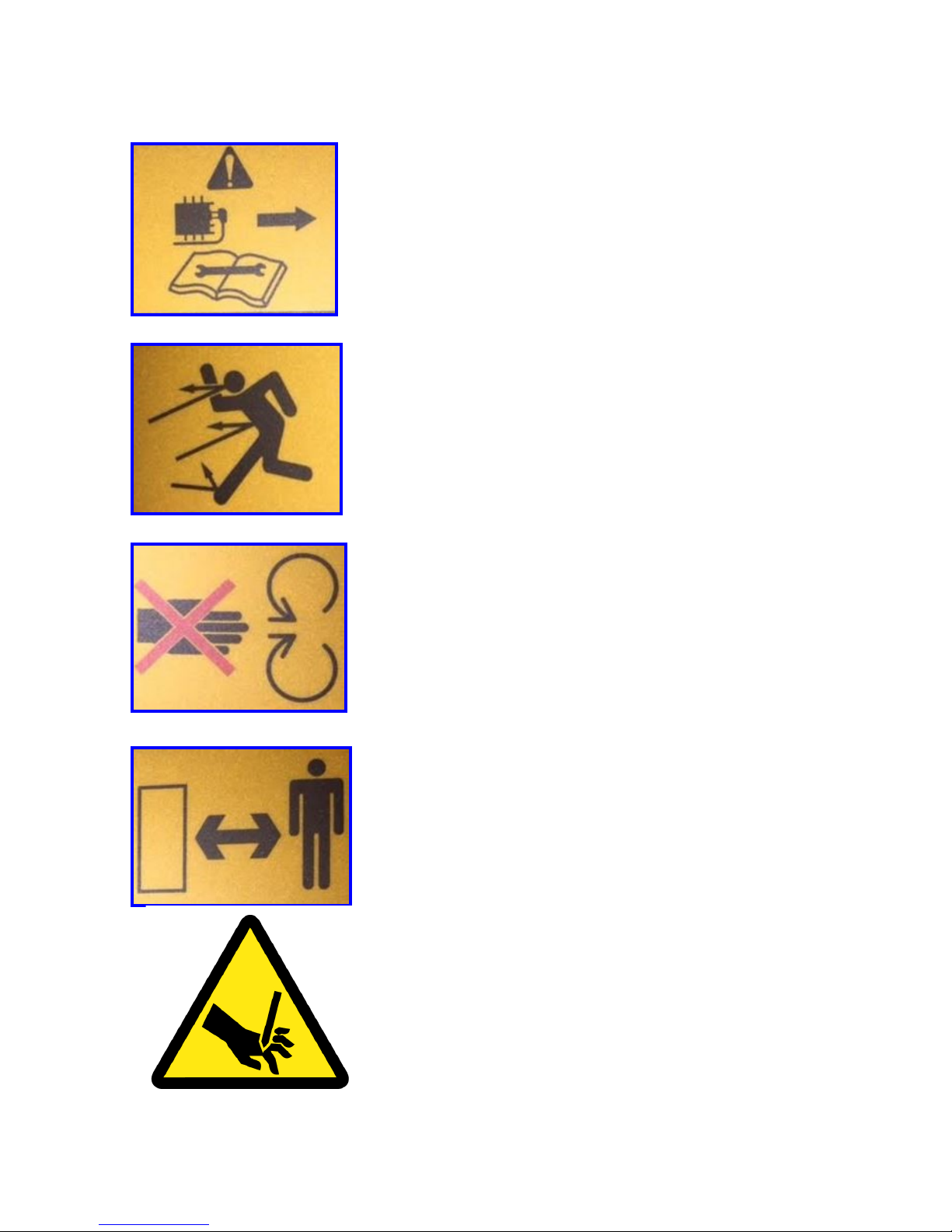

Assembly

The unit is full assembled. The crate is held down by four clips, two on each end. Lift off the

shipping crate and remove straps holding down the unit to the pallet.

The tamping rod is located in the intake chute and is wrapped to prevent damage. After read-

ing the operators manual secure in the owners manual tube for on-sight reference.

Safety switch is shown to kill engine at anytime the unit is running.

Operator’s manual tube

Operator manual tube

Tamping rod

Safety switch

7

Pre-operation

Never fuel the unit or run the unit in an enclosed space. Residual gas fumes could be ignit-

ed by a water heater or furnace in a garage. Gas fumes are very flammable and you

should change clothes if some is spilled on you.

Clean up any spills and do not dispose of gas soaked rags in the trash, they may spontane-

ously combust.

Never smoke while fueling the unit. Make sure the fuel cap is secure on both the machine

and the gas can after fueling.

Use fresh gasoline and keep lid on gas can when not refueling.

Store fuel away form heat or flame.

Use a fuel stabilizer to insure gas will remain volatile.

Make sure the unit is on a stable level surface.

Check all bolts and guards to make sure they are tight and in proper working order.

Starting information

Check to make sure the discharge and inlet are empty.

Fill fuel tank before starting and also check the oil level.

Start engine based on engine manual directions.

Allow unit to reach full speed and then insert material no larger than 4 inches. Forcing larg-

er than specified material could harm you or damage the equipment.

Do not touch muffler during operation.

Not every situation can be covered in a manual, use good judgement and never push equip-

ment beyond its capability.

8

This machine is designed to chipping small branches. Any other use is not intended.

The customer is responsible for third parties and any damage to their property.

When feeding in branches, make sure there are no nails or screws on the wood going

into the chipper.

Do not overload the machine, never attempt to alter engine governor to increase speed.

When the discharge pile grows larger move the chipper or the debris so as not to affect

the discharge flow. When moving the unit always shut off the unit and allow to stop.

Never modify a guard and keep them in good working order.

Never look into the intake or discharge chutes when the unit is running, debris could

kick-back at operator.

Keep the air intake on the engine clean of debris.

Never remove the air cleaner while the engine is operating.

Never leave the unit running unsupervised.

The unit should only be used with ample lighting (daylight preferred).

Operation

9

Maintenance

When performing any maintenance on this unit, spark

plug wire must be disconnected and placed away from

spark plug to prevent accidental starting!

Servicing the blade:

Turn off engine and remove spark plug wire.

After removing make sure the plug wire is not laying near the spark plug!

Remove the nuts from the intake (or discharge) chute and rotate the chute out of

the way.

Rotate the drum until the blade is visible like the above photo. You can rotate the

drum by pulling the starter cord but can be rotated by hand (wearing gloves) more

precisely. Remove the three bolts holding the blade and remove. Rotate the blade,

using the other cutting surface or replace the blade. Torque bolts to 37 ft/lbs.

Use blue Loctite on clean threads.

10

Maintenance

Belt replacement and Adjustment:

Remove the 4 bolts from the shroud ( two on each side)

Loosen (4) engine plate hold down bolts (not the engine bolts ).

Loosen tensioning bolts and move engine plate to remove belt.

Tighten to tension belt to about 1/4 inch deflection.

1/4 inch

*It may be easier to remove engine plate bolts and tip engine to replce belt.

This manual suits for next models

1

Table of contents