YAAHKIEH Version 202106

Content

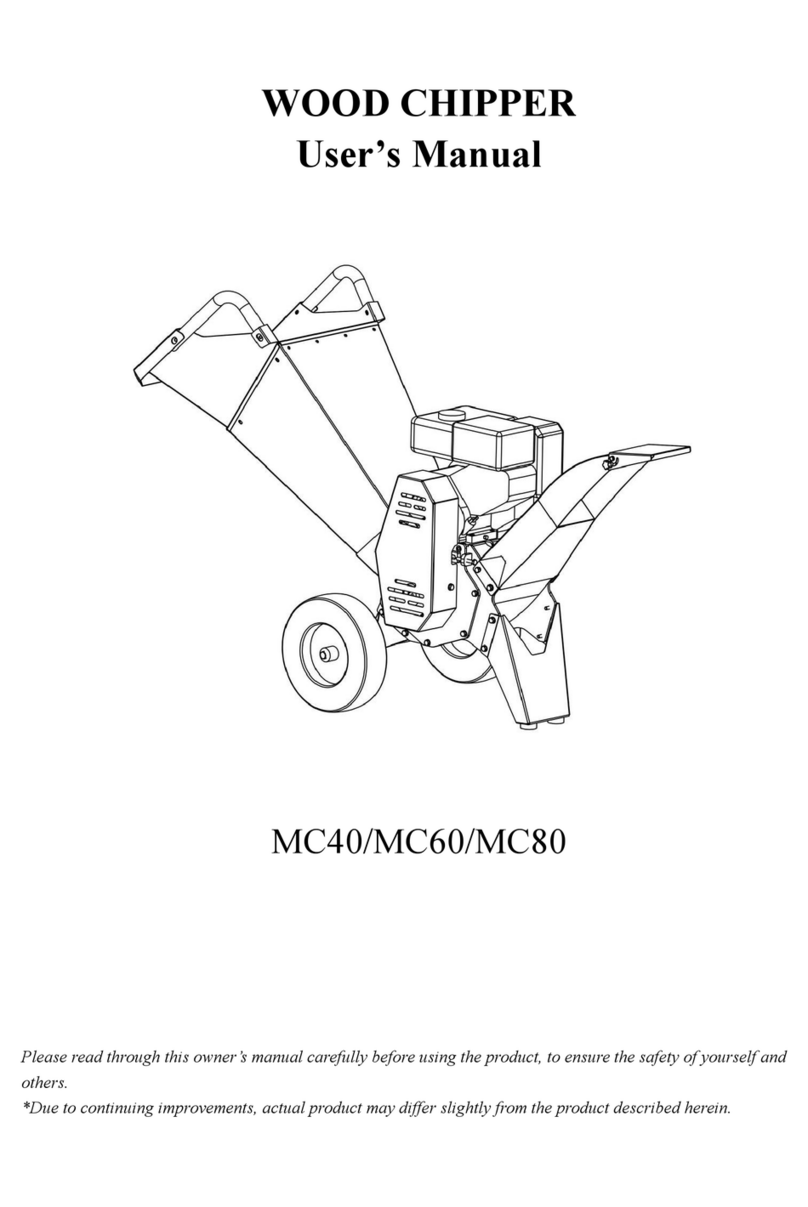

Semi Commercial Wood Chipper ................................................................................................................................... 1

User’s Manual ................................................................................................................................................................ 1

MC100 series (PTO) .......................................................................................................................................................1

1. Specifications ............................................................................................................................................................. 1

2 . General safety rules ................................................................................................................................................... 2

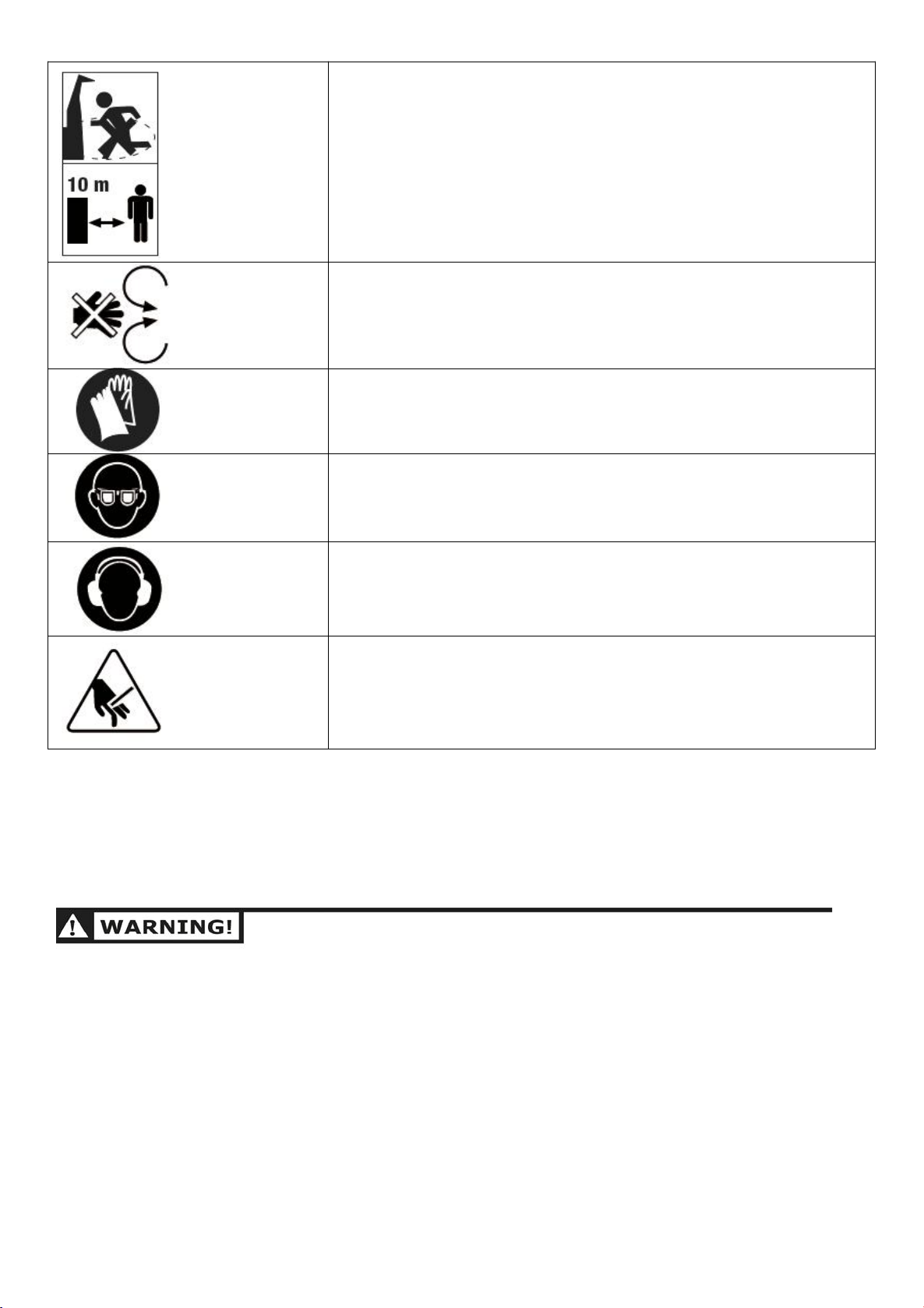

2.1 Labels ............................................................................................................................................................... 2

2.2 Safety for Yourself and Those Around You..................................................................................................... 3

2.3 Safety for Children and Pets .............................................................................................................................5

2.4 General Safety .................................................................................................................................................. 5

2.5 Transportation Safety ....................................................................................................................................... 8

3. Setting up .................................................................................................................................................................... 9

3.1 Controls and Features .......................................................................................................................................9

3.2 Unpacking .........................................................................................................................................................9

3.3 Assembly ........................................................................................................................................................ 11

3.3.1 Attaching hopper assembly ................................................................................................................. 11

3.3.2 Attaching the conveyor assembly ....................................................................................................... 11

3.4 Attaching chipper and tractor ......................................................................................................................... 11

3.4.1 Connecting the chipper and tractor ..................................................................................................... 12

3.4.2 Calculating length of PTO Shaft needed ............................................................................................ 13

3.4.3 Modifying the PTO Shaft-if required ..................................................................................................15

4. Operating .................................................................................................................................................................. 16

4.1 Starting ........................................................................................................................................................... 17

4.2 Processing .......................................................................................................................................................18

4.3 To Free a Jammed Rotor ................................................................................................................................ 19

5. Maintaining the chipper ............................................................................................................................................20

5.1 Regular Maintenance Check List ................................................................................................................... 20

5.2 Grease Fittings ................................................................................................................................................21

5.3 The Drive Belt maintenance ...........................................................................................................................22

5.4 The Blade and Counter Blade maintenance ................................................................................................... 23

5.5 Storage ............................................................................................................................................................ 24

6. Troubleshooting ........................................................................................................................................................25

7. Troubleshooting Table .............................................................................................................................................. 25

8. Spare Parts Diagram ................................................................................................................................................. 26