YOUR LIMITED WARRANTY ON YOUR NEW

wander lodge

Whoare the parties to this Warranty?

Blue Bird Wanderlodge, a division ofBlue Bird Body Com-

pany, gives this Warranty. The terms "we," "us," and "our"

in this Warranty refer to that division. The Warranty extends

to the owner of the Wanderlodge <t.The terms "you" and

"your" in this Warranty refer to the owner.

What parts are covered?

This Warranty covers all parts of the Wanderlodge e that

are made or bought by our factory and installed there, those

major power train components that are warranted from other

manufacturers are not covered by this Warranty, such as en-

gine, transmission and batteries . Those separate warranties

are contained in the owner's package furnished to you by your

dealer at the time ofdelivery. Our Warranty also does not in-

clude parts or accessories which you or your dealer bought or

install ed.

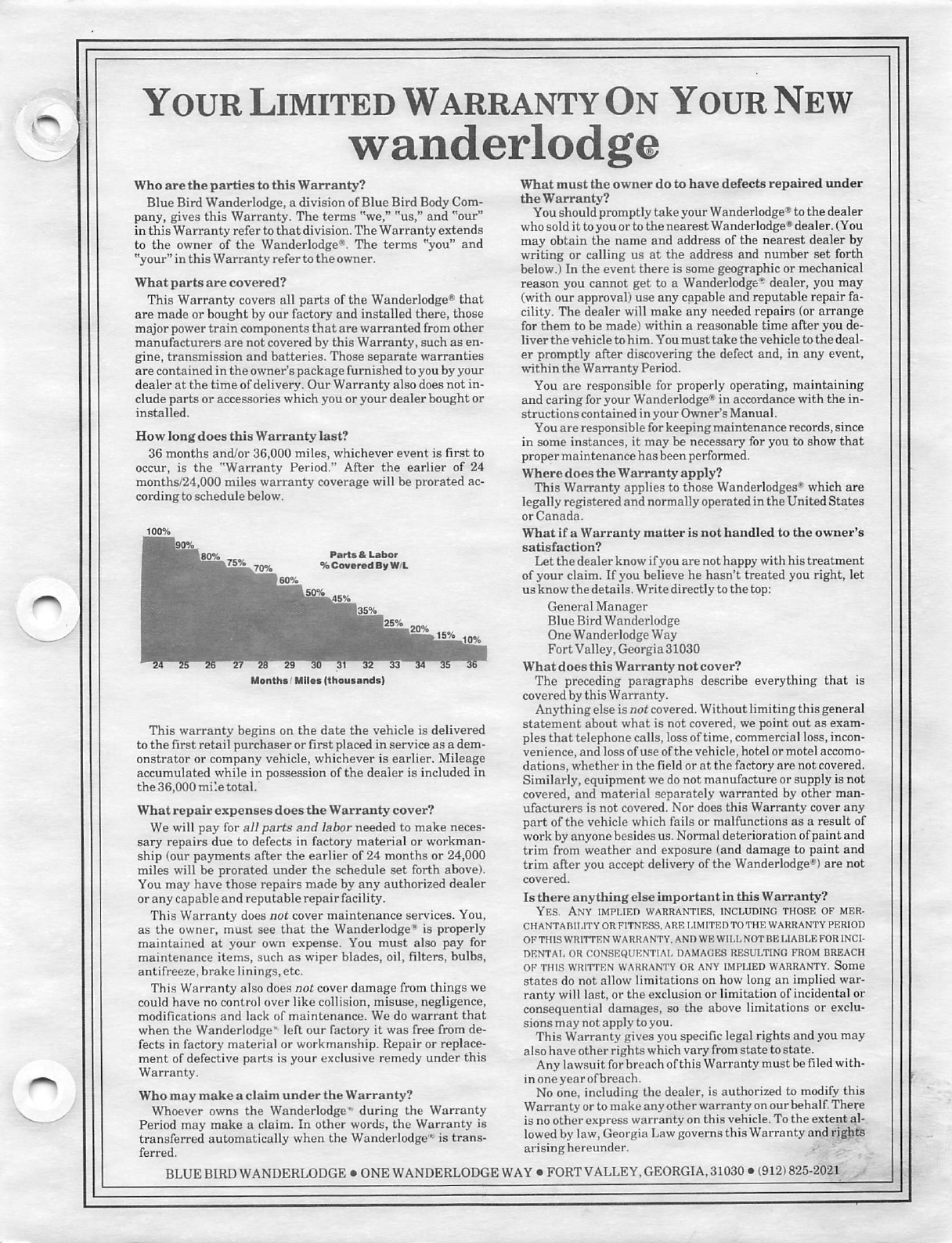

How long does this Warranty last?

36 months and/or 36,000 miles, whichever event is first to

occur, is the "Warranty Period." After the earlier of 24

month s/24,000 miles warranty coverage will be prorated ac-

cording to schedule below.

Parts & Labor

% Covered By W/L

Month aI Miles (thousands)

This warranty begins on the date the vehicle is delivered

to the first retail purchaser or first placed in service as a dem-

onstrator or company vehicle, whichever is ear lier. Mileag e

accumulated while in possession of the deal er is included in

the 36,000 mi:e total.

What repair expenses does the Warranty cover?

We will pay for all parts and labor needed to make neces-

sary repairs due to defects in factory materia l or workman-

ship (our payments after the ear lier of 24 month s or 24,000

miles will be prorated under the schedule set forth above).

You may have those repairs made by any author ized dealer

orany capable and reputable repair facility.

This Warranty does not cover maintenanc e services. You,

as the owner, must see that the Wanderlodge• is properly

maintained at your own expense. You must also pay for

maintenance items, such as wiper blades, oil, filters, bulbs,

antifre eze,brake linings, etc.

This Warranty also does not cover damage from things we

could have no control over like collision, misuse, negligence,

modifications and lack of maintenance . We do warrant that

when the Wanderlodge • left our factory it was free from de-

fects in factory material or workmanship. Repair or replace-

ment of defective parts is your exclusive remedy under this

Warranty.

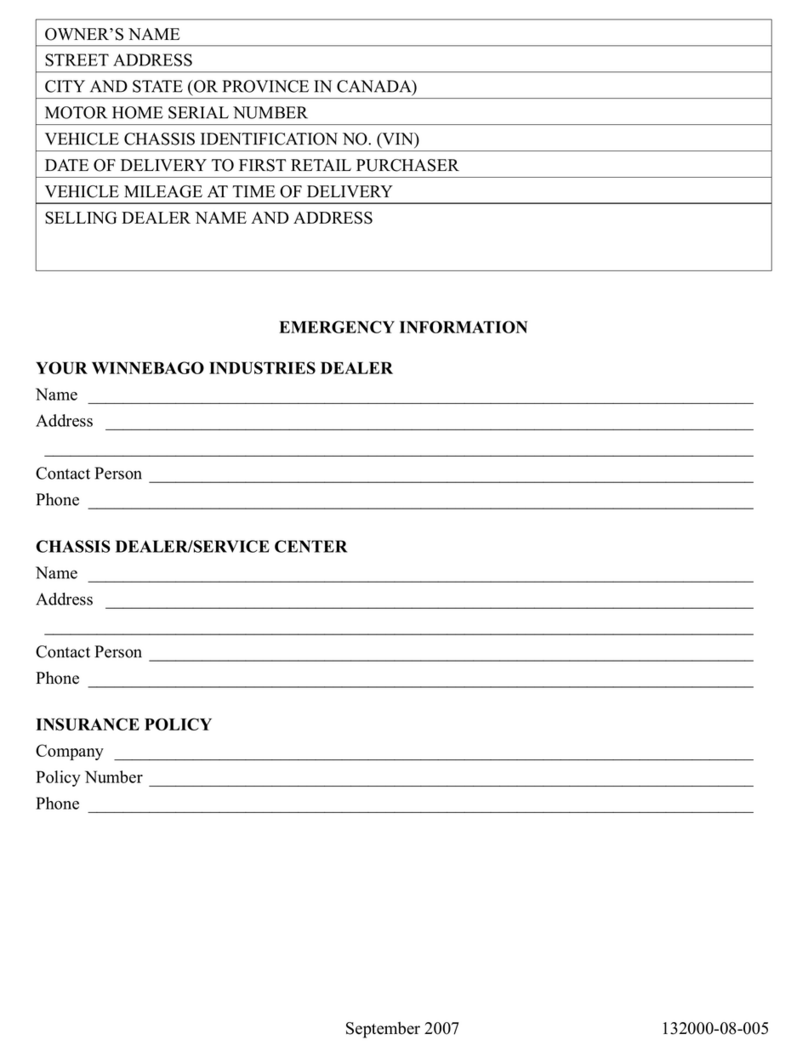

Whomay make a claim under the Warranty?

Whoever owns the Wanderlodge • during the Warranty

Period may make a claim. In other words, the Warranty is

transferred automatically when the Wander lodge'"'is trans-

ferred.

What must the owner do to have defects repaired unde r

the Warranty?

You should promptly take your Wanderlodge e to the dealer

who sold it toyou or to the nearest Wanderlodgee dealer. (You

may obtain the name and address of the nearest dealer by

writing or calling us at the address and number set forth

below.) In the event there is some geographic or mechanica l

reason you cannot get to a Wanderlodge'!>dealer, you may

(with our approval) use any qi.pable and reputable repair fa.

cility. The dealer will make any needed repairs (or arrange

for them to be made) within a reasonable time after you de-

liver the vehicle to him. Youmust take the vehicle tothe deal-

er promptly after discovering the defect and, in any event,

within the Warranty Period.

You are responsible for properly operating, maintain ing

and caring for your Wanderlodge t in accordance with the in-

struct ions contai ned in your Owner's Manual.

You are responsible for keeping maintenance records,since

in some instances, it may be necessary for you to show that

proper maint ena nce hasbeen performed.

Where does the Warranty apply?

This Warranty applies to those Wanderlodges~ which are

legally registered and normally operated in the United States

or Canada. ·

What if a Warranty matter is not handled to the owne r's

satisfaction?

Let the dealer know ifyou are not happy with his treatment

of your claim. If you believe he hasn't treated you right, let

us know the details. Write directly tothe top:

General Manager

Blue Bird Wanderlodge

One Wanderlodge Way

Fort Valley,Georgia 31030

Whatdoes this Warranty not cover?

The preceding paragraphs describe everything that is

covered bythis Warranty.

Anything else isnot covered. Without limiting this general

state ment about what is not covered, we point out as exam-

ples that telephone calls, lossof time, commercial loss,incon-

venience, and loss ofuse ofthe vehicle, hotel or motel accomo-

dations, whether in the field or at the factory are not covered.

Similarly, equipment we do not manufacture or supply is not

covered, and material separately warranted by other man-

ufacturers is not covered. Nor does this Warranty cover any

part of the vehicle which fails or malfunctions as a result of

work by anyone besides us. Normal deterioration ofpaint and

trim from weather and exposure (and damage to paint and

trim after you accept delivery of the Wanderlodge-9)are not

covered.

Is there anything else important in this Warranty?

YES . ANY IMPLIF,I) WARRANTIES. INCLUDING THO SE OF MER-

CHANTARll ,ITY OR FITNESS, ARE LIMITED TO THE WARRANTY PERIOD

OF THI S WR\ITF,N WARRANTY. AND WE WlLL NOT BE LIABLE FOR INCI-

DENTAi. OR CONS EQUENTIAi. DAMAGES RESULTING FROM BREACH

OF THIS WRIITF.N WARRANTY OR ANY LMPLIED WARRANTY . Some

states do not allow limitation s on how long an implied war-

ranty will last, or the exclusion or limitation ofincidental or

consequent ial damages , so the above limitation s or exclu-

sions may not applytoyou.

This Warranty gives you specific legal rights and you may

also have other rights which vary from state to state.

Any lawsuit forbreach ofthis Warranty must be filedwith-

in one year ofbreach.

No one, includin g the dealer, is aut horized to modify this

Warranty or to make any other warranty on our behalf.There

is no other express warranty on this vehicle. To the extent al-

lowed by law, Georgia Law governs this Warranty and rights

arising hereunder .

BLUE BIRD WANDERLODGE • ONE WANDERLODGE WAY• FORTV ALLEY,GEORGIA,31030 • l912l825-2021