BlueBox niji User manual

User Manual

niji

1

www.BlueBoxOptics.com V2.4

niji

Table of Contents

1Preface 4

1.1 Warnings 4

1.2 Emissions Certificate 4

1.3 Safety Certification 5

1.4 Static Sensitivity 5

1.5 Technical Support 5

2Introduction 6

2.1 Preventative Inspection 6

2.2 Minimum Computer Requirements 6

3System Set-Up and Operating Instruction 7

3.1 Unpacking and Inspection 7

3.2 Software 7

3.3 Driver Setup (USB control only) 7

3.4 Software Setup 7

3.5 Hardware Placement and Ventilation 7

3.6 Hardware Set-Up 8

3.7 Connect to the niji 9

3.8 Software Control 10

3.9 Constant Optical Power Mode 12

3.10 Compatible Mode 14

3.11 TTL Setup from Software 15

3.12 Presets 18

3.13 Software Dual Operation Mode 19

3.14 Internal Temperature 20

4General Use 21

4.1 Hardware Operation 21

4.2 Channel Output Settings 21

4.3 Light Guide Adapter and Interlock 21

4.4 Lid Removal and Interlock 21

5Removable Filters 22

6Module Operation 25

6.1 Module Installation 26

2

www.BlueBoxOptics.com V2.4

niji

7Optics 27

8Serial Command Control 27

8.1 Communication 28

8.2 Channel Level Command String 28

8.3 Channel Level Set: Example 28

8.4 Channel On/Off 29

8.5 Channel Active Set: Example 29

8.6 Channel Identification 29

8.7TTL Command String 29

8.8 TTL Set: Example 29

9Technical Specifications 30

9.1 External Power Supply 30

9.2Typical Wavelengths and Relative Power emission 30

9.3 Classification 30

3

www.BlueBoxOptics.com V2.4

niji

List of Figures

Figure 1: Front View Panel ......................................................................................................8

Figure 2: Rear View Panel.......................................................................................................9

Figure 3: Lockout Screen Examples.....................................................................................10

Figure 4: Lights OFF - All Channels OFF ...............................................................................11

Figure 5: Lights ON- All Channels On ..................................................................................11

Figure 6: Channel 5 Wavelength Select.............................................................................12

Figure 7: Rear view of TTL Connector..................................................................................16

Figure 8: TTL Mode Active.....................................................................................................17

Figure 9: Preset Options ........................................................................................................18

Figure 10: Preset Loaded ......................................................................................................19

Figure 11: Internal Temperature Display.............................................................................20

Figure 12: niji Filter Paddle ....................................................................................................22

Figure 13: Filter Positioning....................................................................................................23

Figure 14: A Filter and Filter Paddle.....................................................................................24

Figure 15: Green/Amber Channel Filter and Filter Paddle ..............................................24

Figure 16: niji Unit without Modules .....................................................................................25

Figure 17: niji Unit with all Modules ......................................................................................27

Figure 18: RS232 Communication Interface ......................................................................28

Figure 19: Port Setup..............................................................................................................28

List of Tables

Table 1: Light Source Controls .............................................................................................10

Table 2: TTL Configuration.....................................................................................................16

Table 3: 15 Way TTL Connector Pinout ...............................................................................16

4

www.BlueBoxOptics.com V2.4

niji

1Preface

1.1 Warnings

Do not use this equipment without first consulting the operating manual.

To avoid risk of electric shock, this equipment must only be connected to a

mains supply with protective earth.

Only the external power supply provided may be used.

Do not use this equipment should there be any visible damage to cables

and/or connectors.

Electrical installations used in the same environment as this equipment must

comply with the applicable IEC standards.

Do not look directly into the light output.

Ensure that the output end of the light guide is safely directed into an

enclosed optical path.

Do not drop this equipment.

Modification of this equipment will invalidate the warranty and may render

the unit inoperable.

Switch off the unit when not in use.

Do not allow liquids to enter the housing.

Do not cover air vents.

Do not stand the device on its side, upside down or on its rear side.

High power UV (HPUV) mainframe is NOT backwards compatible with the

standard UV module. This module should not be fitted and may damage

the module and mainframe.

1.2 Emissions Certificate

This equipment has been tested and found to comply with the limits of EMC directive

2004/108/EC. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses and emits radio frequency which may cause harmful

interference to radio communications if not installed and used in accordance with

the instruction manual.

5

www.BlueBoxOptics.com V2.4

niji

1.3 Safety Certification

CE Declaration of Conformity

EMC Directive 2014/30/EC

Low Voltage Directive 2014/35/EC

RoHS Directive 2011-65-EU

UL, CSA and TUV Certified power supply

IEC/EN 62471, Photobiological Safety of Lamps and Lamp Systems

WEEE - Under the WEEE directive the niji should be disposed of at recycling facilities

where these exist. Registration WEE/BU4061XA.

1.4 Static Sensitivity

Appropriate precautions should be taken to prevent damage from static electricity

discharge.

1.5 Technical Support

For technical support and advice, please contact Bluebox Optics Ltd.

This equipment contains no user serviceable parts. For any maintenance or for any

concerns regarding function, please notify your supplier or Bluebox Optics Ltd at the

point of contact below.

Bluebox Optics Ltd.

Unit 9,

Avro Court, Ermine Business Park,

Huntingdon,

Cambridgeshire,

UK,

PE29 6XS

Tel: +44 (0) 1480 272 557

6

www.BlueBoxOptics.com V2.4

niji

2Introduction

Bluebox Optics are proud to present the niji light engine, a modular system providing

up to seven spectrally discrete light outputs. All outputs are controlled via our software,

designed and developed for maximum efficiency and ease of use. The unit can also

be controlled via 3rd party interface using the command protocols provided. The

supplied software controls light source selection, on/off switching, TTL configuration

and output intensity. The output level can be set with a sliding graphic controlled by

mouse, keyboard, touch screen (when using a windows tablet PC) or any

combination of the above. Preset values can be saved and loaded at any time to

ensure a smooth and accurate setup.

With all modules in position, the niji comprises seven discrete solid state light sources

whose outputs are defined by user-exchangeable filters. All modules are optimised

during the manufacturing process to ensure the highest quality and precision. Light

output can be coupled into a liquid light guide (LLG).

The niji system also comprises a TTL port whereby a TTL signal can trigger light output

switching on/off.

The niji multi-wavelength light engine is Mercury free and has been designed for use

in a laboratory environment. The intended user will have basic lab experience and an

understanding of good working practice as a minimum. The equipment’s primary

function is to provide a defined set of wavelengths for fluorescence microscopy and

for contrast illumination. Each channel of the niji is discrete and can be controlled

independently.

2.1 Preventative Inspection

Visually inspect the equipment before each use, paying attention to the cables and

connectors. In the event of any cable damage, please notify the equipment supplier

and do not use the equipment.

Although the niji does not need regular servicing, care should be taken to ensure the

air filters are clean and dust free. These can be replaced if required, please contact

your distributor or Bluebox Optics.

2.2 Minimum Computer Requirements

Windows PC or Tablet with 1 x USB 2.0 Port

USB cable (A-B) or RS232 cable

MCP2221 Windows Driver –supplied with equipment

7

www.BlueBoxOptics.com V2.4

niji

3System Set-Up and Operating Instruction

3.1 Unpacking and Inspection

The system comprises the following:

niji Unit

Filter paddles

Power Supply

Power Cable

USB or RS232 Cable

USB stick with Software and user manual

Interlock keys

3mm Hex Key for fastening Liquid light guide

1.5mm Hex Key for filter paddle grub screw

Optional accessories

oLiquid Light guide

oMicroscope Collimator

oCollimator adapter rings

oTTL BNC breakout cable

Any inconsistencies or damage should be reported to your supplier immediately.

Carefully remove all packing material and check that the above system components

are present and undamaged. Any screws that have loosened in transit should be re-

secured with the appropriate tool.

3.2 Software

The niji PC application allows the user to control each individual channel, software is

provided with each unit and written exclusively for Bluebox Optics.

3.3 Driver Setup (USB control only)

The drivers for this unit will compile automatically when running Windows 10. Any

previous version of Windows will require a manual driver install.

The required driver is the MCP2221 Windows Driver from microchip. Once installed the

equipment should be connected to a free USB port.

A driver is not required for RS232 control unless using a USB serial dongle. Refer to the

operation manual for the dongle.

3.4 Software Setup

The niji software is a self-contained executable and does not require installation. A

copy should be made and transferred to the control PC to allow the software to

operate.

3.5 Hardware Placement and Ventilation

Place the equipment on a clean, clear and even surface, ensuring reasonable free

space for rear and underside ventilation. Air intake vents are located on the underside

8

www.BlueBoxOptics.com V2.4

niji

of the equipment and these should remain free from obstruction. A low dust

environment with allow longer usage before the air filters need to be serviced. Any

significant reduction in air flow may damage this equipment which will impact on its

performance and functionality. Internal temperature probes are installed to monitor

the equipment temperature and this data is displayed via the software interface.

3.6 Hardware Set-Up

Connect the liquid light guide (LLG) to the device via the input port at the front of the

unit (Figure 1).

Connect the equipment to mains power using the power supply provided and

connect one end of the USB cable (A-B) to the USB port on the device, and the other

to the computer (Figure 2).

Keep trailing cables tidy to minimise the risk of tripping

Figure 1: Front View Panel

9

www.BlueBoxOptics.com V2.4

niji

Figure 2: Rear View Panel

3.7 Connect to the niji

Ensure that the niji is connected to the PC via the USB-B cable supplied. The niji should

be connected to mains power via the power supply provided and switched on at the

power supply unit and at the rear of the unit (Figure 2). The power LED indicator at the

front of the niji will show one of the following conditions:

Green

The unit is ready for use.

No Colour/Off

Press and hold the small blue power button at the front of the

unit for 5 seconds. The channel LEDs will run through a short start

up sequence before the power indicator changes to a

constant green.

Red (Flashing)

One or more of the built-in safety Lockout requires action –

please see below.

The niji has several built-in safety conditions which must be satisfied before any light is

emitted. When the power indicator at the front of the unit flashes red, the following

actions should be taken:

Ensure that the key provided has been inserted into the keyhole at the rear of

the unit and turned 90° counter-clockwise.

Ensure that the lid to the unit is closed.

Ensure that a light guide has been inserted into the designated light guide input

at the front of the unit

Once the niji unit is connected, launch the software application. The software will

attempt to seek the correct com port for the niji (See Figure 3). If this is unsuccessful, it

will display an “Awaiting Connection” status until a connection is established.

Once a connection has been established, the software is now ready to use and all

possible outputs will be displayed along with a slider control for channel setup and

configuration (Figure 4, Figure 5). Those not fitted will remain greyed out.

10

www.BlueBoxOptics.com V2.4

niji

Failure to adhere to all the safety conditions during operation will initiate lockout

mode. In lockout mode, no light will be emitted and the power indicator will flash red.

Should any combination of lockout conditions occur during operation then the

lockout warning in Figure 3 will be displayed in the software.

Figure 3: Lockout Screen Examples

3.8 Software Control

The very top of the software window shows the light status. This will read either “LIGHTS

ON” or “LIGHTS OFF”. The “LIGHTS OFF” status will only occur if all channels are turned

off as they are in Figure 4. When a single or multiple channels are switched on, the

status will change to “LIGHTS ON”. This is an integral safety feature by design.

See Table 1 for all available light source control commands:

Action

Response

Right mouse click over a channel

Channel On/Off

Select the “Off” button

Channel On

Select the “On” button

Channel Off

Mouse scroll up/down within the enabled channel

Intensity up/down

respectively

Channel slider up/down for enabled channels

Intensity up/down

respectively

Arrow keys on keyboard up/down

Intensity up/down

respectively

Arrow keys on screen up/down

Intensity up/down

respectively

Overtype numerical values in the intensity selector

Intensity up/down

LIGHTS ON

All Channels On

LIGHTS OFF

All Channels Off

Table 1: Light Source Controls

11

www.BlueBoxOptics.com V2.4

niji

When the channel has been switched on, the “Off” button changes to “On” and the

column of colour will change from dark to bright. It is possible to adjust the light

intensity while in the “Off” mode however, the channel will not switch on unless a

“channel on”action is taken. This is an inherent safety feature. Figure 4 and Figure 5

demonstrate the difference in the software display when all channels are off and on

respectively.

Figure 4: Lights OFF - All Channels OFF

Figure 5: Lights ON- All Channels On

Seven channels are available. Channel 5 delivers highly broadband light and as

standard, is configured in the broadest band and referred to as Amber. As an option,

the emission can be restricted to the green band by changing the LED filter. Selecting

either “Amber” or “Green” tells the software which filter has been used to configure

the LED and this change will be reflected in the colour of channel 5 as displayed in

the software (See Figure 6): Selecting Green or Amber in the software does not

change the filter or spectral output of the LED. This is a manual process and must be

12

www.BlueBoxOptics.com V2.4

niji

completed by the end user. See section 5, “Filter Removal”, for further details on

manual filter removal.

Figure 6: Channel 5 Wavelength Select

3.9 Constant Optical Power Mode

The niji has a constant optical power mode which increases the light power stability

of each channel for more precise illumination. It is primarily design for medium to low

optical power applciations. This can be enabled in the “Configuration” window.

In Constant Optical Power mode, the niji can be controlled using the sliders etc as it

would normally be used but the user will be will be restricted to 80% optical power,

allowing the device some overhead for power conpensation. It is programed to

record the optical power at the level set and hold the LED stabily at this power level.

NOTE: In constant optical power mode the niji will only allow one channel to be

illuminated at a time to restrict photodiode crosstalk between channels.

13

www.BlueBoxOptics.com V2.4

niji

14

www.BlueBoxOptics.com V2.4

niji

3.10 Compatible Mode

The niji is compatible and programmable with many microscope systems. Custom

configuration including intial power on settings can be achieved using the XML

configuration file. If you wish to use the niji in compatible mode or with a custom

configuration, please contact Bluebox Optics or your local distributor.

15

www.BlueBoxOptics.com V2.4

niji

3.11 TTL Setup from Software

The 15 way TTL interface on the rear of the unit can be used to trigger from 1 to 7

channels independently and simultaneously.

To choose which channels you wish to control remotely, you will need to ensure that

the relevant pins on the 15 pin connector are connected to a suitable signal

generator and to the 15 way TTL interface at the rear of the niji. A BNC breakout cable

is available from Bluebox Optics.

TTL settings can be found in the “Configuration” tab on the niji software. There are two

ways to activate TTL mode. With the physical connections completed, either check

the “TTL Light Control” in the niji software (Figure 10), or send a serial command (page

27).

Active High or Active Low

TTL triggering can be configured in “Active High”or “Active Low”mode (see Table 2

below). “Active High” mode turns the specified channels “on”when a 5V logic level

is applied to a channel pin (Table 3) and “off” when a 0V logic level is applied. An

“Active Low” configuration turns the specified channels “on” when 0V is applied and

“off” when 5V is applied. The level of emission of each channel is set either through

the niji software or through serial commands.

Those channels that are not connected to the TTL interface will remain in their “on” or

“off” state independent of the emission status of any TTL controlled channels.

Example: Setting the blue channel to deliver 50% max emission when TTL is at 5V using

the software interface.

1. Connect pins 6,7,8,10 to the ground pin of your TTL generator

2. Connect pin 12 to the 0-5VDC output of your TTL generator

3. Set the emission level of the blue channel to 50% using the software interface

4. Activate the TTL Light Control by ticking the box on the software (Figure 8).

5. Select Active High Input from the drop down menu (Figure 8).

6. Select “100k Pull Up Enabled” (Figure 8).

When the TTL output is at 5V, the blue channel will emit 50% of maximum output power,

and 0% when the TTL is at 0V. To increase or decrease the level of output emission of

the channel, simply adjust the output whilst in TTL mode, and the channel output will

change to the new setting in the next on/off cycle.

In this example, those channels that are not connected to the TTL interface will remain

in their current “on” or “off” state independent of the TTL and emission status of the

blue channel.

16

www.BlueBoxOptics.com V2.4

niji

100k Pull Up Enabled vs 100k Pull Down Enabled

Enabling the 100k Pull Up/Down feature allows multiple channels to be set to emit

synchronously and independently of the state of a switched TTL channel.

In “Active High” mode and with the “100k Pull Up Resistor”enabled, all channels will

be in an “on” state, and only the TTL triggered channels will be controlled by the TTL

interface. In this mode, only those channels which are tied to ground are in the “off”

state.

With the 100k Pull Down resistor activated, all channels will be in an “on” state, and

only the TTL triggered channels will be controlled by the TTL interface. In this mode,

only those channels which are tied to 5V are in the “off” state.

Active

High

Active

Low

100k

Pull Up

100k Pull

Down

5V

GND

Function

•

-

•

-

ON

OFF

TTL and static channel control1

•

-

-

•

ON

OFF

TTL Active Only

-

•

•

-

OFF

ON

TTL Active Only

-

•

-

•

OFF

ON

TTL and static channel control2

Table 2: TTL Configuration

Pin Number

Description

Channel

Electrical

1

Red

6

Vmax = 5.0V

2

Green/Amber

5

3

Cyan

4

4, 5, 9, 14

Not Used

-

-

6,7,8,10

Ground

-

-

11

Royal Blue

2

Vmax = 5.0V

12

Blue

3

13

Ultra Violet

1

15

Far Red

7

Table 3: 15 Way TTL Connector Pinout

Figure 7: Rear view of TTL Connector

1

In this mode, any unwanted channels must be tied to GND to turn the channel OFF.

2

In this mode, any unwanted channels must be tied to 5V to turn the channel OFF.

17

www.BlueBoxOptics.com V2.4

niji

Figure 8: TTL Mode Active

18

www.BlueBoxOptics.com V2.4

niji

3.12 Presets

After setting the channels, the set values and channel status (ON-OFF) can be saved

to a preset found in the “Configuration” tab. This allows multiple users to save their

individual configurations. Up to 10 preset configurations can be saved and recalled

at any time however, an unlimited number of preset files can be saved if needed, see

Figure 91.

Figure 9: Preset Options

To save a preset, select your chosen preset identification name by right clicking your

mouse in the preset box and typing over one of the 10 preset numbers. Hit “Enter” on

the keyboard to save the preset name and return to the main screen. Once satisfied

with your preset configuration click “Save Presets” which will prompt you to choose a

19

www.BlueBoxOptics.com V2.4

niji

file name and save location for this preset file. This allows for unlimited saving of presets

under unique file names/locations. The preset function retains the channel on/off and

channel intensity values from the save point.

To load a preset, select “Load Preset” and select your chosen preset file from your

specified location. The “Active Preset” box will then display your chosen preset

filename and preset identification name. Figure 10 shows preset filename as “Test

Presets” and preset identification name as “Test Preset ”.

Figure 10: Preset Loaded

3.13 Software Dual Operation Mode

The niji can receive and send commands to multiple sources via the separate

hardware connection ports (USB and RS232). For example, with the niji software

running on a windows desktop and a windows tablet, both devices can control and

monitor the current level settings. If a level is changed on one software instance the

other instance of the software will mirror the change.

3.14 Using the niji with Micromanager

The niji has a native Micromanager adapter which is available by downloading the

nightly release. If running the niji with Micromanager using the RS232 connection, the

baud rate should be set to 57600 using an XML configuration file. Please contact

Bluebox Optics or your local distributor for more information.

Table of contents

Popular Engine manuals by other brands

SOMFY

SOMFY Sonesse 50 PA installation guide

Tecumseh

Tecumseh Power OV195EA Operator's manual

LIMBACH

LIMBACH L 2000 EA Operating and maintenance manual

Grundfos

Grundfos RADIOMODULE 2G4 Installation and operating instructions

Assun

Assun AM-CL2232MAN Series product manual

Agri-Fab

Agri-Fab MOW-N-VAC 501887 owner's manual

Motori Minarelli

Motori Minarelli am6 user manual

Mercury

Mercury 4.3 TKS series Operation & maintenance manual

Mitsubishi Heavy Industries

Mitsubishi Heavy Industries SA Operation & maintenance manual

brel-motors

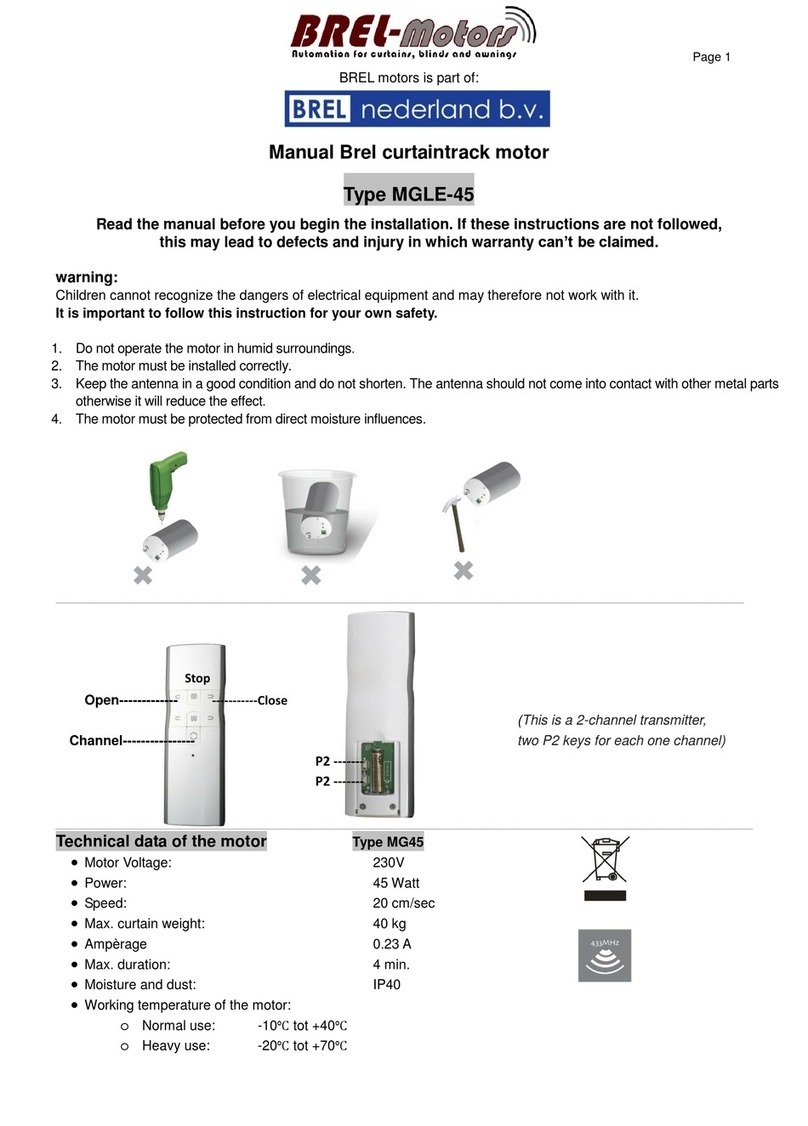

brel-motors MGLE-45 manual

elero

elero JAR quick start guide

Zenoah

Zenoah G231PUM Owner's service manual