BMC GW024 User manual

Page 1 of 48

NOTE: Models covered by this installation manual are NOT for use as

pool heaters or in marine applications.

MIS-3159

Earth Loop Fluid Temperatures 25° – 110°F

Ground Water Temperatures 45° – 75°

Manual: 2100-583G

Supersedes: 2100-583F

Date: 5-17-18

BMC, Inc.

Bryan, Ohio 43506

INSTALLATION INSTRUCTIONS

WATER-TO-WATER

GEOTHERMAL HEAT PUMP

Models:

GW024 GW036 GW048 GW060 GW070

Manual 2100-583G

Page 2 of 48

CONTENTS

Getting Other Informations and Publications......... 3

General Information

Water Source Nomenclature..................................... 4

Application and Location

General ................................................................. 7

Shipping Damage ..................................................... 7

Application ................................................................ 7

Location ................................................................. 7

Unit Stacking............................................................. 7

Additional Consideration ........................................... 7

Required Steps after Final Placement ...................... 7

ANSI Z535.5 Denitions............................................ 8

Power & Control Wiring

High Voltage Line Supply.......................................... 9

Low Voltage Control Wires........................................ 9

Control Wiring ......................................................... 11

Relocatable Control Panel...................................... 10

Wiring - Low Voltage

Dual Primary & Low Voltage Connections

............ 12

P

iping Access to Unit

Loop, Load & Desuperheater Connections............. 13

Load Side

Water Connections

Sizing Buffer Tanks for Zoned Systems .................. 14

Ground Loop (Earth

Coupled Water Loop App.)

Circulation System Design...................................... 16

Ground Water (

Well System App.)

Water Connections.................................................. 18

Well Pump Sizing............................................18 & 19

System Start Up Procedure for Ground Water App. ...

20

Water Corrosion...................................................... 20

Remedies of Water Problems ................................. 21

Lake & Pond Installations ....................................... 22

Desuperheater (Potable Hot Water Assist)

Description .............................................................. 23

Location ............................................................... 23

Electrical Connection .............................................. 23

Installation Procedure - General ............................. 23

Operation of Heat Recovery Unit ............................ 24

Start Up & Check Out ............................................. 24

Maintenance ........................................................... 24

Control Board Sequence of Operation.................... 28

Sequence of Operation

Part Load Cooling ................................................... 29

Full Load Cooling .................................................... 29

Part Load Heating ................................................... 29

Full Load Heating.................................................... 29

Geothermal Logic Control ....................................... 29

High & Low Pressure Switch................................... 30

Flow Switch............................................................. 30

Over/Under Voltage Protection ............................... 30

Intelligent Reset ...................................................... 30

Alarm Output........................................................... 30

Pressure Service Ports ........................................... 30

Checking Refrigerant Quantity................................ 30

Refrigerant Charge

General ............................................................... 31

R-410A & Topping Off System Charge ................... 31

Safety Practices ...................................................... 31

Troubleshooting

Table ............................................................... 45

Service

Hints, Unbrazing System Components & Compressor

Solenoid ............................................................... 46

Ground Source HP Perf. Report

& Checklist - Perform. Unit............................ 47 & 48

Figures

Figure 1 Unit Dimensions ....................................... 6

Figure 2 Wire Routing to Control Panel.................. 9

Figure 3 Changing Water Entrance Location ....... 10

Figure 4

Control Wiring (Control Panel & Conduits).. 11

Figure 5 Typical Load Side Hydronic System....... 15

Figure 6 Circulator System Design....................... 16

Figure 7A Circulation System Design ..................... 17

Figure 7B Model DORFC-1 Flow Center ................ 17

Figure 7C Model DORFC-2 Flow Center ................ 17

Figure 8 Water Connection Components ............. 19

Figure 9 Water Coil Cleaning ............................... 21

Figure 10 Desuperheater Wiring Diagram.............. 25

Figure 11 One-Tank Desuperheater System.......... 26

Figure 12 Two-Tank Desuperheater System .......... 27

Figure 13 Inlet & Outlet Thermistor Temp Curves .. 28

Figure 14 System Component Locations ............... 32

Figure 15 Electrical Control Locations.................... 32

Figure 16 Cooling Cycle Diagram .......................... 33

Figure 17 Heating Cycle Diagram .......................... 34

Figures 18-22 Pressure Tables ...........................35-44

Tables

Table 1 Rated Flow Rates for Various Fluids........ 4

Table 2 Electrical Specications ........................... 5

Table 3 Source Side Water Coil Pressure Drops ... 5

Table 4 Operating Voltage Range....................... 12

Table

Low Voltage Connections for DDC Controls

. 12

Manual 2100-583G

Page 3 of 48

GETTING OTHER INFORMATION AND PUBLICATIONS

These publications can help you install the air

conditioner or heat pump. You can usually nd these

at your local library or purchase them directly from the

publisher. Be sure to consult current edition of each

standard.

National Electrical Code .......................ANSI/NFPA 70

Standard for the Installation...............ANSI/NFPA 90A

of Air Conditioning and Ventilating Systems

Standard for Warm Air .......................ANSI/NFPA 90B

Heating and Air Conditioning Systems

Load Calculation for Residential ...... ACCA Manual J

Winter and Summer Air Conditioning

Duct Design for Residential..............ACCA Manual D

Winter and Summer Air Conditioning and Equipment

Selection

Closed-Loop/Ground Source Heat Pump ........IGSHPA

Systems Installation Guide

Grouting Procedures for Ground-Source .........IGSHPA

Heat Pump Systems

Soil and Rock Classication for ......................IGSHPA

the Design of Ground-Coupled Heat Pump Systems

Ground Source Installation Standards .............IGSHPA

Closed-Loop Geothermal Systems ..................IGSHPA

– Slinky Installation Guide

Radiant Systems Design .........................................RPA

...........................................................................IAMPO

..............................................................................ASSE

FOR MORE INFORMATION, CONTACT

THESE PUBLISHERS:

ACCA Air Conditioning Contractors of America

1712 New Hampshire Avenue

Washington, DC 20009

Telephone: (202) 483-9370

Fax: (202) 234-4721

ANSI American National Standards Institute

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900

Fax: (212) 302-1286

ASHRAE American Society of Heating Refrigerating,

and Air Conditioning Engineers, Inc.

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400

Fax: (404) 321-5478

NFPA National Fire Protection Association

Batterymarch Park

P.O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555

Fax: (617) 984-7057

IGSHPA International Ground Source

Heat Pump Association

490 Cordell South

Stillwater, OK 74078-8018

Radiant Professionals Association

www.radiantprofessionalsalliance.org

IAPMO

www.iampo.org

American Society of Sanitary Engineering

www.asse-plumbing.org

World of Plumbing Council

www.worldplumbing.org

EPA WaterSense Partner

www.epa.gov/watersense

American Society of Mechanical Engineers

www.asme.org

NSF International

www.nsf.org

United Association (Union of Plumbers, Fitters,

Welders & HVAC Service Techs.

www.ua.org

Manual 2100-583G

Page 4 of 48

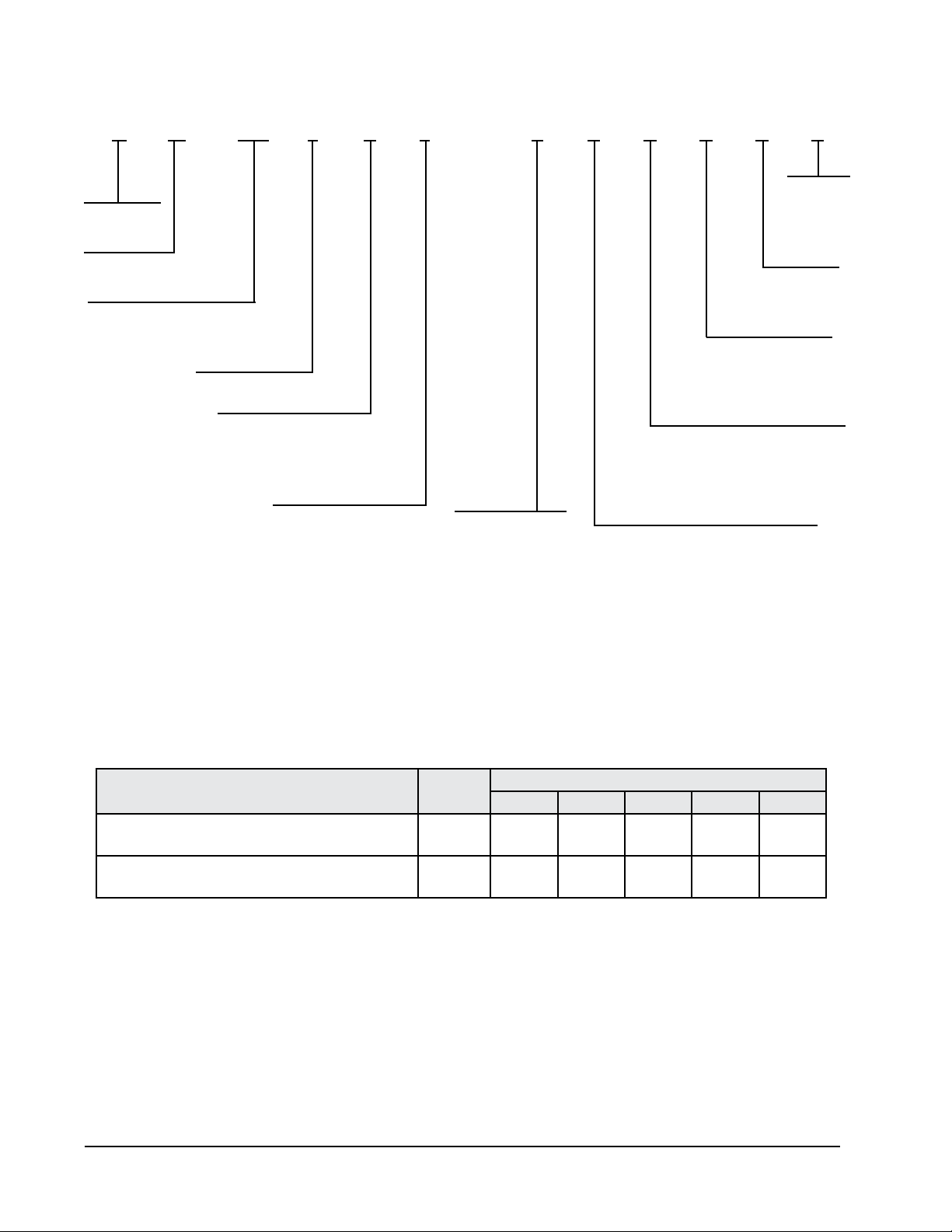

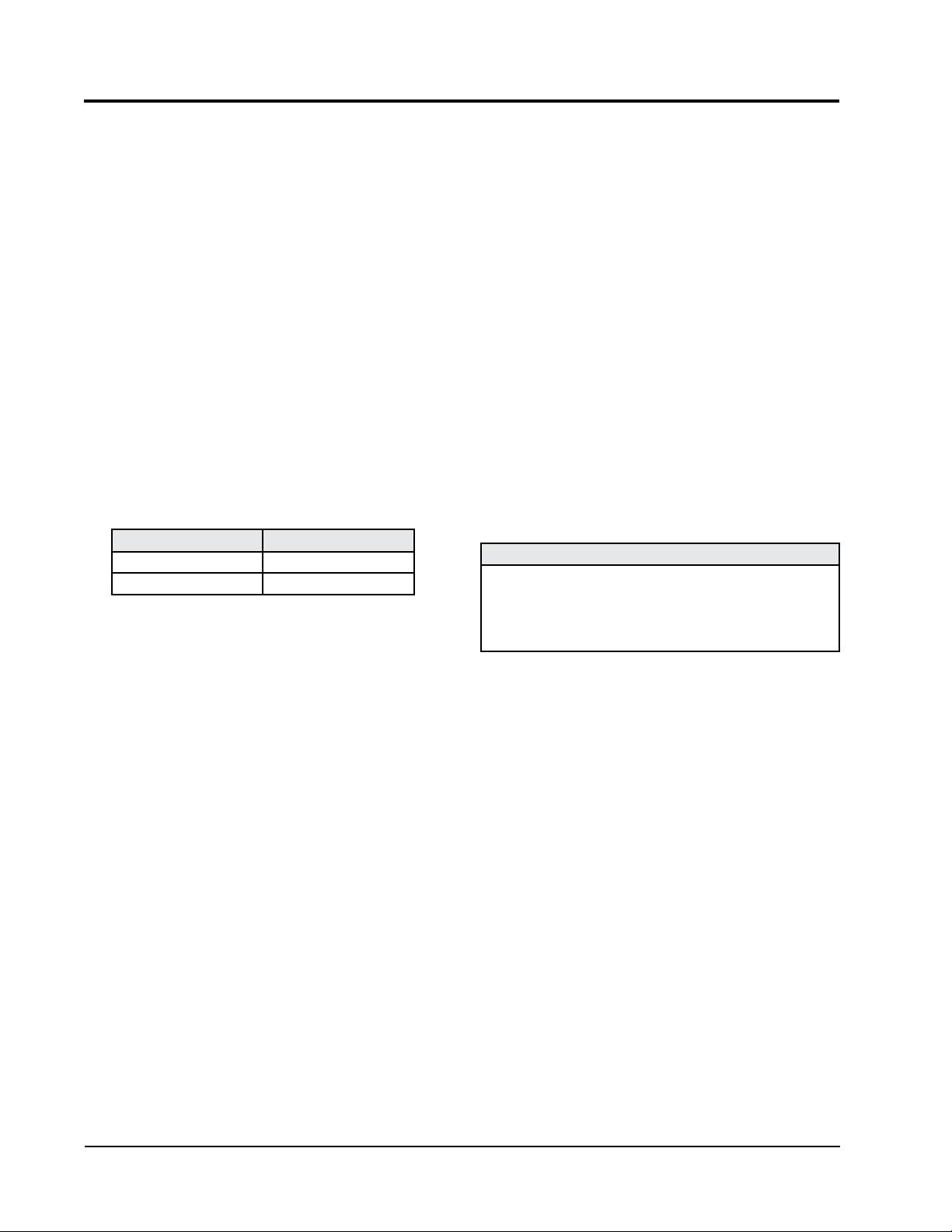

GEO WATER-TO-WATER HEAT PUMP MODEL NUMBER NOMENCLATURE

TABLE 1

RATED FLOW RATES FOR VARIOUS FLUIDS

APPLICATION SOURCE MODEL

GW024 GW036 GW048 GW060 GW070

Ground Loop (15% Methanol, Propylene, Glycol, etc. Loop

Load

7

7

9

9

11

11

13

13

15

16

Ground Water Loop

Load

7

7

9

9

11

11

13

13

15

16

G W 048 1 S 1 —A X R C C X

No. of Compressors

Compressor Type

S = Step Capacity

Water-to-Water

Geothermal

Options

X = None

Voltage

A = 230/208-60-1

Capacity MBTUH

024

036

048

060

070

Revision Level

Hot Water Generator Option

X = No HWG

1 = HWG & Pump

Reversible Option

H = Heating Only (Phase 2 Release)

R = Reversible (Phase 1 Release)

Source Coax

C = Copper (closed loop)

N = Cupronickel (open loop)

Load Coax

C = Copper

Loop circulating pumps – Source & Load are eld-installed external of the GSH unit for ease of installation, maintenance and service.

Manual 2100-583G

Page 5 of 48

TABLE 2

ELECTRICAL SPECIFICATIONS

TABLE 3

SOURCE SIDE WATER COIL PRESSURE DROPS

(Based upon 15% Methanol in Heating Mode @ 50°F)

+75°C copper wire ++ HACR type circuit breaker

MODEL GW024 GW036 GW048 GW060 GW070

Electrical Ratings (Volts/Hz/Phase) 208/230-60-1

Operating Voltage Range 253-197 VAC

Minimum Circuit Ampacity 16.9 21.4 28.8 36.1 39.4

+Field Wire Size 10 8 6 6 6

Ground Wire Size 12 12 10 10 10

++Delay Fuse of Circuit Breaker Max. 25 35 50 60 60

COMPRESSOR

Volts 208/230-60-1

Rated Load Amps (230/208) 8.2 / 9.2 12.2 / 14.0 17.6 / 20.3 21.8 / 24.1 29 / 32

Branch Circuit Selection Current 11.7 15.3 21.2 27.1 29.7

Locked Rotor Amps (230/208) 58.3 83.0 104.0 152.9 179.2

Flow Center (Based upon DORFC-2)

Volts 208/230-60-1

Amps 2.14

Desuperheat Pump Motor

Volts 208/230-60-1

Amps 0.15

Model

GPM

GW024 GW036 GW048 GW060 GW070

PSID Ft. Hd. PSID Ft. Hd. PSID Ft. Hd. PSID Ft. Hd. PSID Ft. Hd.

4 .93 2.15

5 1.55 3.58 1.57 3.62

6 2.17 5.01 2.19 5.05 1.63 3.75

7 2.79 6.44 2.81 6.48 2.21 5.10

8 3.48 8.03 3.56 8.21 2.80 6.45 1.76 4.06

9 4.17 9.62 4.31 9.94 3.38 7.80 2.20 5.08

10 0 5.18 11.95 4.12 9.49 2.64 6.09 2.6 6.07

11 6.05 13.96 4.85 11.19 3.08 7.11 3.1 7.17

12 5.70 13.15 3.58 8.25 3.6 8.28

13 6.55 15.11 4.07 9.39 4.1 9.39

14 4.63 10.67 4.6 10.58

15 5.18 11.95 5.1 11.77

16 5.74 13.23 5.7 13.12

17 6.3 14.46

18 6.9 15.81

Manual 2100-583G

Page 6 of 48

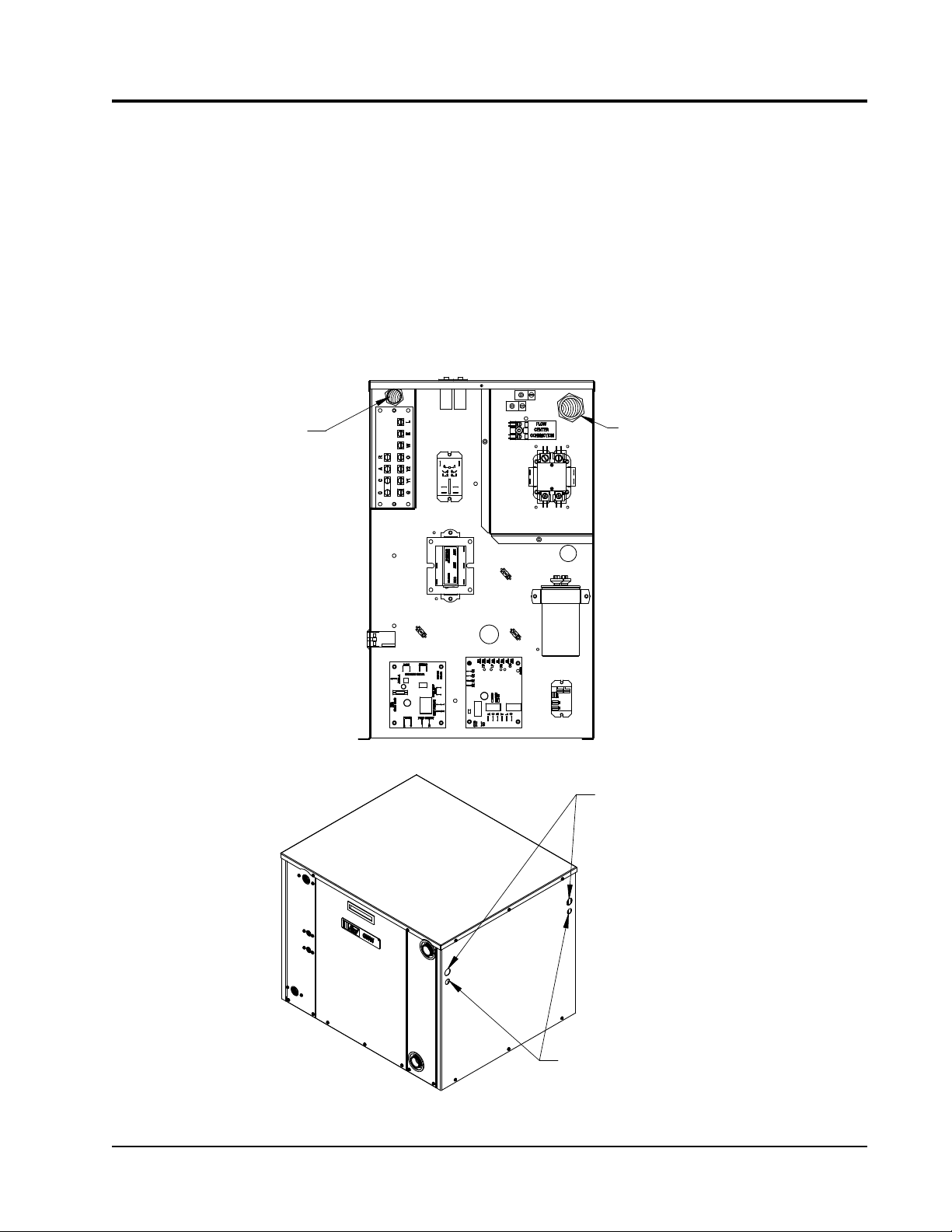

DSH INLET

SOURCE OUTLET

SIDE

LOAD OUTLET

DSH OUTLET

LOAD INLET

FRONT

SOURCE INLET

TOP

B D

26 5/16"

2 13/16"

11 5/8"

14 5/8"

A

C

33 3/8"

2 13/16"

E

5 5/8"

F

MIS-3160

UNIT A B C D E F

GW024 19 1/2" 3 1/2" 5 3/8" 5 1/2" 19 7/16" 3 9/16"

GW036 19 1/2" 3 1/2" 5 3/8" 5 1/2" 19 7/16" 3 1/2"

GW048 20 5/16" 3 1/2" 5 5/16" 5 7/16" 20 5/16" 3 11/16"

GW060 21 3/8" 2 3/4" 5 1/4" 5 1/8" 21 3/8" 3"

GW070 24 1/8" 2 3/4" 5 1/8" 5" 24 1/16" 2 5/8"

HIGH VOLTAGE

ENTRANCES

LOW VOLTAGE

ENTRANCES

19.044

1.357

19.044

20.763

1.357

20.763

28.296

FIGURE 1 – UNIT DIMENSIONS

Manual 2100-583G

Page 7 of 48

APPLICATION AND LOCATION

GENERAL

Each unit is shipped internally wired, requiring both ground-

source and load-side water piping, aquastat wiring, 230/208

volt AC power wiring, and optional desuperheater piping.

The equipment covered in this manual is to be installed by

trained, experienced service and installation technicians.

These instructions and any instructions packaged with any

separate equipment required to make up the entire heat

pump system should be carefully read before beginning

the installation. Note particularly any tags and/or labels

attached to the equipment.

While these instructions are intended as a general

recommended guide, they do not in any way supercede any

national and/or local codes. Authorities having jurisdiction

should be consulted before the installation is made.

SHIPPING DAMAGE

Upon receipt of the equipment, the carton should be checked

for external signs of shipping damage. If damage is found,

the receiving party must contact the last carrier immediately,

preferably in writing, requesting inspection by the carrier’s

agent.

APPLICATION

Capacity of the unit for a proposed installation should be

based on heat loss calculations made in accordance with

methods of the Air Conditioning Contractors of America.

The piping systems should be installed in accordance all

local, state, and federal requirements, and to the references

included on Page 3 of this document.

LOCATION

The unit may be installed in a basement, closet, or utility

room provided adequate service access is ensured, and

equipment will not freeze.

These units are not approved for outdoor installation

and therefore must be installed inside structure being

conditioned. Do not locate in areas subject to freezing in

the winter, or subject to sweating in the summer.

Prior to setting the unit, consider ease of piping and electrical

connections for the unit. Also for units which will be used

with a desuperheater, consider the proximity of the unit to

the water heater or storage tank. Place the unit on a solid

base, preferably concrete, to minimize undesirable noise and

vibration. DO NOT elevate the base pan on rubber or cork

vibration eliminator pads as this will permit the unit base to

act like a drum, transmitting objectionable noise.

UNIT STACKING

The GW-Series products are designed to allow them to

be stacked up to three units high to lower the amount of

installed square footage requirements. Included with unit

are tie plates to secure the units together once they are

stacked. Remove, then replace the bottom three (3) screws

from bottom sides of the upper unit, and the top of the

lower unit to apply the tie plate. NOTE: The tie plates

are secured to the front of the control panel cover for

shipment.

ADDITIONAL CONSIDERATION

As an additional measure of safety in regard to the structure,

consider installing a drain pan with an alarm switch

underneath this water-bearing equipment.

REQUIRED STEPS AFTER FINAL

PLACEMENT

The compressor is secured to the unit base for shipping.

Although the unit will perform as designed with the

compressor secured in place, there may be noticeable

additional noise and vibration. To obtain the lowest noise

and vibration levels, remove the compressor shipping

brackets after the unit is in its nal operating location.

To gain access to the compressor shipping brackets, remove

both the front and rear service panels. The brackets have

“hot pink” labels and are located on the compressor double

isolation base at the front and rear of the compressor. The

brackets are secured to the unit base with two (2) screws,

and secured to the isolation plate with a ¼" nut. Remove

and dispose of the two (2) screws and brackets. Reinstall

¼" nut once bracket is removed.

NOTE: MODELS COVERED BY THIS INSTALLATION MANUAL ARE NOT FOR USE AS A

POOL HEATER OR IN MARINE APPLICATIONS

Manual 2100-583G

Page 8 of 48

ALL GEOTHERMAL EQUIPMENT IS DESIGNED FOR

INDOOR INSTALLATION ONLY. DO NOT INSTALL OR

STORE UNIT IN A CORROSIVE ENVIRONMENT OR IN

A LOCATION WHERE TEMPERATURE AND HUMIDITY

ARE SUBJECT TO EXTREMES. EQUIPMENT IS NOT

CERTIFIED FOR OUTDOOR APPLICATIONS. SUCH

INSTALLATION WILL VOID ALL WARRANTIES.

FAILURE TO FOLLOW THIS CAUTION MAY RESULT

IN PERSONAL INJURY. USE CARE AND WEAR

APPROPRIATE PROTECTIVE CLOTHING, SAFETY

GLASSES AND PROTECTIVE GLOVES WHEN

SERVICING UNIT AND HANDLING PARTS.

BEFORE DRILLING OR DRIVING ANY SCREWS INTO

CABINET, CHECK TO ENSURE SCREW WILL NOT HIT

ANY INTERNAL PARTS, REFRIGERANT LINES, WATER

LINES, OR ELECTRICAL WIRES/COMPONENTS.

ANSI Z535.5 Denitions:

• DANGER (color RED): Indicate[s] a hazardous situation

which, if not avoided, will result in death or serious injury.

The signal word “DANGER” is to be limited to the most

extreme situations. DANGER [signs] should not be used

for property damage hazards unless personal injury risk

appropriate to these levels is also involved.

• WARNING (color ORANGE): Indicate[s] a hazardous

situation which, if not avoided, could result in death or

serious injury. WARNING [signs] should not be used

for property damage hazards unless personal injury risk

appropriate to this level is also involved.

• CAUTION (color YELLOW): Indicate[s] a hazardous

situation which, if not avoided, could result in minor or

moderate injury. CAUTION [signs] without a safety alert

symbol may be used to alert against unsafe practices that

can result in property damage only.

• NOTICE (color BLUE): [this header is] preferred to

address practices not related to personal injury. The safety

alert symbol shall not be used with this signal word. As an

alternative to “NOTICE” the word “CAUTION” without the

safety alert symbol may be used to indicate a message not

related to personal injury.

Manual 2100-583G

Page 9 of 48

MIS-3161

3/4" CONDUIT CONNECTION TO

INTERNAL CONTROL PANEL FOR

LINE POWER, AND FLOW CENTER

1/2" PLASTIC CONDUIT

CONNECTION TO LOW VOLTAGE

TERMINAL STRIP

WIRE ROUTING TO CONTROL PANEL

CENTER POWER

LIQUID-TITE CONDUIT FOR

POWER ENTRANCE & FLOW

ENTRANCE POINTS FOR 3/4"

ENTRANCE POINTS FOR 1/2"

PLASTIC CONDUIT FOR

CONTROL WIRING TO AQUA-STAT

FIGURE 2

WIRE ROUTING TO CONTROL PANEL

POWER & CONTROL WIRING

HIGH VOLTAGE LINE SUPPLY

Supplied with the unit is an adequate length of ¾" liquid-tite

conduit and ttings to run internally within the sheet metal

chassis from the control panel to one of four (4) 1⅛" holes

in the chassis sides (front/rear corners) for line voltage wires

to be ran through. See Figures 2 & 4.

LOW VOLTAGE CONTROL WIRES

Supplied with the unit is an adequate length of ½" plastic

conduit and ttings to run internally within the sheet metal

chassis from the low voltage box to one of four (4) ⅞" holes

in the chassis sides (front/rear corners) for thermostat wires

to be ran through. See Figures 2 & 4.

Manual 2100-583G

Page 10 of 48

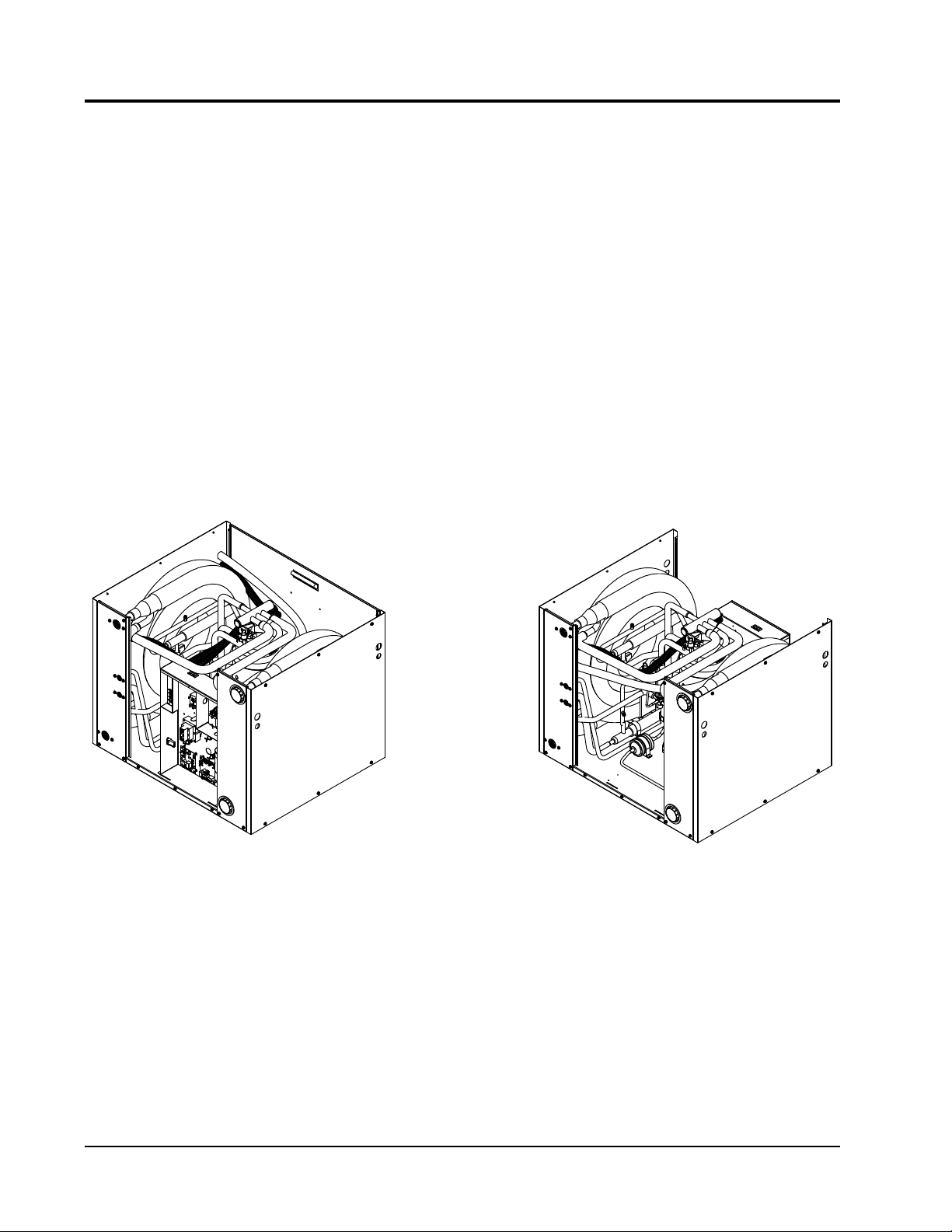

MIS-3163

FRONT - AS SHIPPED LOCATION

CONTROL PANEL LOCATIONS

OPTIONAL REAR LOCATION

FIGURE 3

CHANGING WATER ENTRANCE LOCATION (FRONT TO REAR)

BY RELOCATING CONTROL PANEL

RELOCATABLE CONTROL PANEL

The control panel of the GW-Series products can be

relocated to best suit the installation. It is factory shipped

where the control panel is located on the same side of the

unit the water connections are located. NOTE: the control

panel can be moved to the rear of the unit opposite to

where the water connections are located. See Figure 3.

1. Remove both front and rear service panels.

2. Remove control panel cover.

3. Remove four (4) screws securing control panel to

unit base.

4. Lift and turn control panel sideways guiding it

along the right side of the compressor toward the

rear of the unit.

5. Re-secure to unit base at new location.

Manual 2100-583G

Page 11 of 48

CONTROL PANEL

CONDUITS

MIS-3162

FIGURE 4

WIRE ENTRANCE CONDUITS

POWER & CONTROL WIRING

The GW-Series Geothermal Water-to-Water Heat Pumps

contain 2-stage compressors. This will need to be thought

through in planning and ordering the Aquastat control.

The two-stage compressor will not necessarily affect

the net water temperature, but can give great benet of

reducing the required number of compressor cycles,

especially under lower-load conditions.

In selecting the Aquastat, and depending upon the

particular installation, there are different ways to utilize

this.

1. Select an Aquastat with an outdoor temperature

sensor, and program the Aquastat to only energize

the “Y2” signal when outdoor temperatures fall

below a certain level.

2. Program a length of time to offset Stage #2 being

energized following Stage #1 call. This will

increase system run time/thermal consistency, and

minimize the start/stop cycles on the compressor,

and minimize short cycling.

3. Program the Aquastat to only energize “Y2” when

temperature of water cannot be held or increased

with only “Y1” energized (only bring on “Y2” with

further temperature fall).

4. A jumper can be installed from “Y1” to “Y2”

changing the system to a single stage system.

However, this is not recommended for longevity of

equipment service life or energy efciency.

TABLE 4

OPERATING VOLTAGE RANGE

TAP RANGE

240V 253 - 216

208V 220 - 187

LOW VOLTAGE CONNECTIONS FOR DDC CONTROLS

Heating Part Load Energize

“Y1”

Heating Full Load Energize

“Y1”, “Y2”

Cooling Part Load Energize

“Y1”, “O”

Cooling Full Load Energize

“Y1”, “Y2”, “O”

Manual 2100-583G

Page 12 of 48

NOTE: The voltage should be measured at the eld power

connection point in the unit, and while the unit is operating at full

load (maximum amperage operating conditions).

WIRING – LOW VOLTAGE WIRING

UNIT MAIN POWER WIRING

This equipment requires a nominal 208/230-60-1 power

supply for proper operation. Line voltage connections are

made at the compressor contactor as noted by the wiring

diagram. Unit main power will route into the control

panel to the contactor through the supplied 3/4" Liquid

Tite conduit from one of the four (4) selectable electrical

entrance points.

230/208, 1-PHASE & 3-PHASE

EQUIPMENT DUAL PRIMARY VOLTAGE

TRANSFORMERS

All Equipment leaves the factory wired on 240 Volt

transformer tap. For 208 Volt operation, reconnect from

240 Volt to 208 Volt tap. The acceptable operating voltage

range for the 240V and 208V transformer taps are as noted

in Table 4.

For low voltage connections between the Aquastat and

the geothermal heat pump, a low voltage terminal strip is

factory mounted in the heat pump.

LOW VOLTAGE CONNECTIONS

These units use a grounded 24V AC low voltage circuit.

“R” terminal is 24 VAC hot.

“C” terminal is 24 VAC grounded.

“Y1” terminal is the compressor part load input.

“Y2” terminal is the compressor full load input (“Y1”

must also be energized along with “Y2”).

“O” terminal is the reversing valve input. The reversing

valve must be energized for cooling mode.

“A” terminal is 24 VAC output to external ow center

control, or to source water solenoid coil.

“L” terminal is compressor lockout output. This

terminal is activated on a high pressure, low pressure, or

ow switch trip on the Geothermal Logic Control. This

is a 24 VAC output.

Manual 2100-583G

Page 13 of 48

NOTE: All double o-ring ttings require “hand

tightening only”. Do not use a wrench or pliers as

retainer nut can be damaged with excessive force.

NOTE: Apply provided petroleum jelly to o-rings to

prevent damage and to aid in insertion.

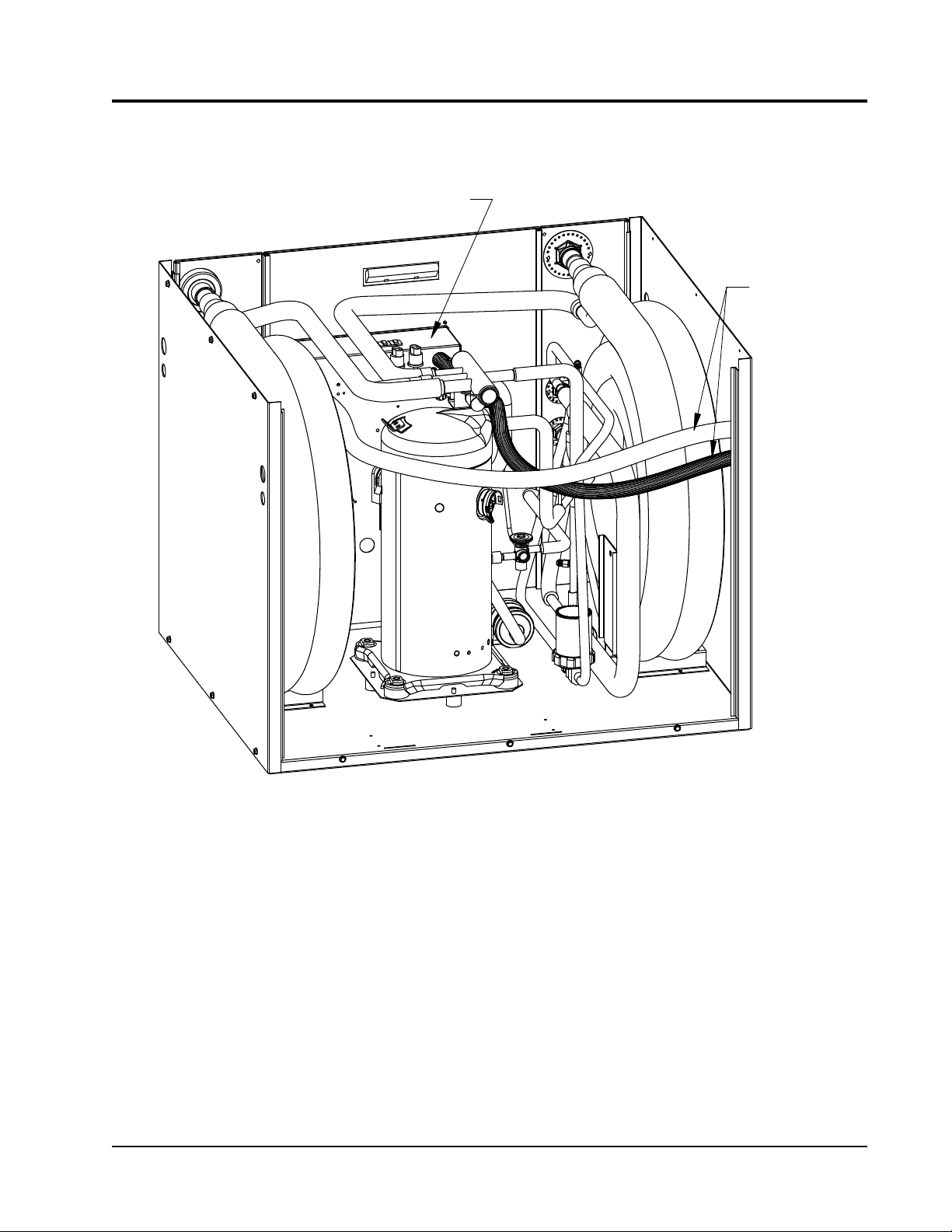

PIPING ACCESS TO UNIT

Water Piping to and from the unit enters the unit cabinet on

either the front or rear-side through the ability to relocate the

control panel. See Figure 3 of the cabinet.

LOOP CONNECTIONS are a special double o-ring tting

with a retainer nut that secures it in place. (It is the same

style of tting used for the ow center connection on ground

loop applications.)

Various ttings are available so you may then connect to the

unit with various materials and methods. These methods

include 1" barbed tting (straight and 90°), 1" MPT (straight

and 90°), and 1¼" hot fusion tting (straight only). See

Product Specication Sheet.

LOAD CONNECTIONS are standard 1" Female Pipe

Thread allowing for any standard 1" Male Pipe Threaded

ttings to be utilized to make the connection.

DESUPERHEATER CONNECTIONS are standard ½"

Female Pipe Thread allowing for any standard ½" Male Pipe

Threaded ttings to be utilized to make the connection.

t x Qheatsource

v =

500 x T

10 x 50,000

v = = 50 gallons

500 x (120-100)

Manual 2100-583G

Page 14 of 48

LOAD SIDE WATER CONNECTIONS

The use of a buffer tank is highly recommended on the

load side of the GW-Series Water-to-Water heat pumps.

If heat pump sizing at all the various conditions is not

perfectly matched to the load, you are likely to short cycle

the refrigerant system on high or low pressure controls.

Buffer tanks provide thermal mass that allows the rate of

generation by the heat source to be signicantly different

from the rate of dissipation by the distribution system. They

are an essential component in any hydronic system that uses

a low thermal mass on/off heat source in combination with a

multiple-zone application.

SIZING BUFFER TANKS FOR ZONED

SYSTEMS

The required volume of a buffer tank depends on the rate of

heat input and release, as well as the allowed temperature

rise of the tank from when the heat source is turned on, to

when it is turned off. The greater the tanks volume, and the

wide the operating temperature differential, the longer the

heat source cycle length.

The following fomula can be used to calculate the volume

necessary when given a specied minimum heat source on-

time, tank operating differential, and rate of heat transfer:

Where:

v = required volume of the buffer tank (gallons)

t = desired duration of the heat source’s “on cycle”

(minutes)

Qheatsource = heat output rate of the heat source (Btu/h)

Qload = rate of heat extraction from the tank (Btu/h)

DT = temperature rise of the tank from when the heat source

is turned on to when it is turned off (°F).

For example, assume it’s desired that a heat pump operates

with a minimum compressor on-cycle duration of 10

minutes. The heat pump, when on, supplies 50,000 Btu/h.

The compressor turns on when the buffer tank drops to

100°F, and off when the tank reaches 120°F. What is the

necessary buffer tank volume to accomplish this?

If a tank larger than the minimum required volume is used,

the on-cycle length could be increased, or the temperature

differential setpoint could be reduced

The wider the temperature differential, and the greater the

volume of the tank, the longer the heat source on-cycle will

be.

Manual 2100-583G

Page 15 of 48

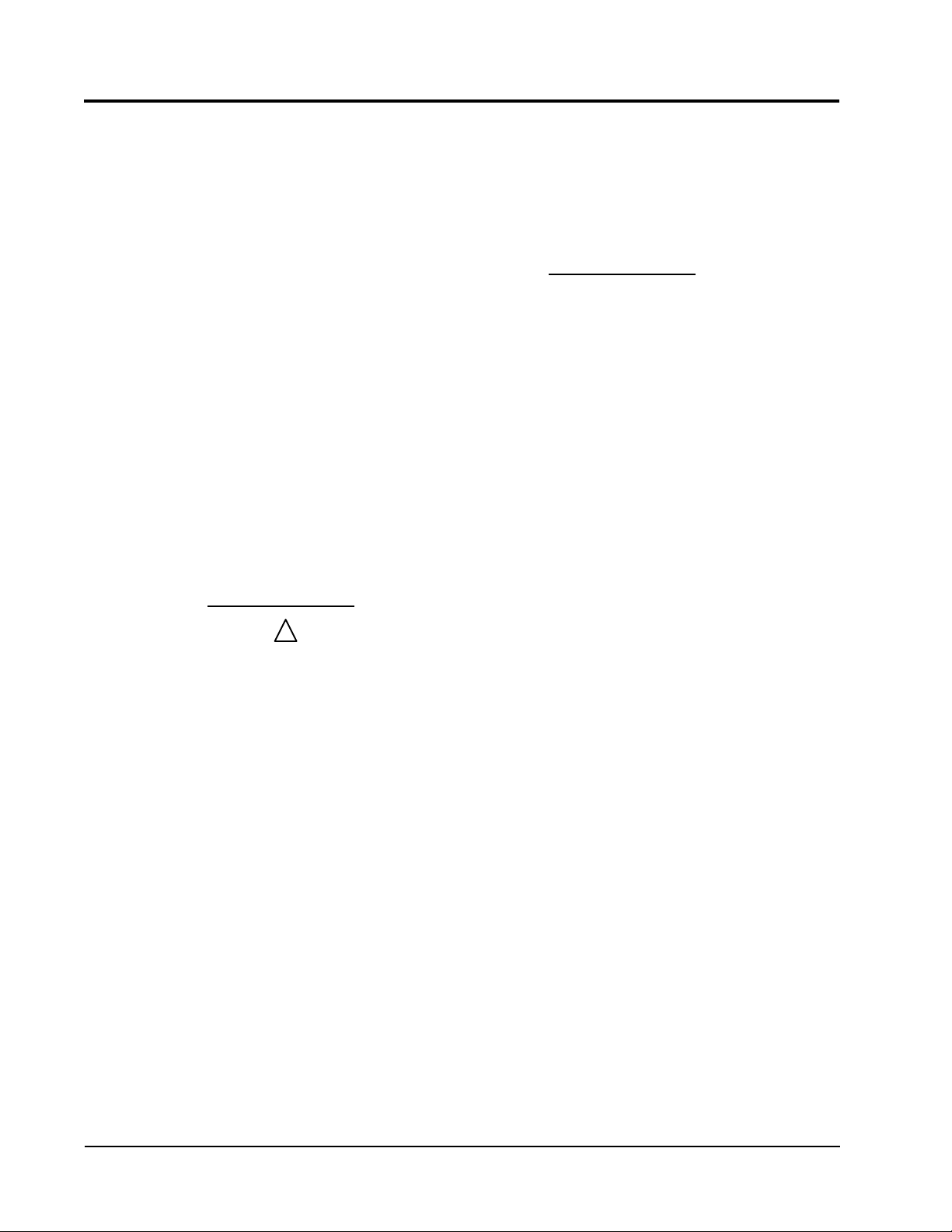

MAKE-UP-WATER

MIS-3164 A

HYDRONIC AIR HANDLER

AUTO AIR

RETURN

HEADER

PURGE

VALVES

ZONE

HEADER

VALVES

SUPPLY

BUFFER TANK

TEMPERATURE

ZONES

SENSOR

AQUA STAT

OUTDOOR

TO/FROM OTHER

TEMPERATURE

SEPARATOR

CIRCULATOR

SENSOR

AIR

CIRCULATOR

PURGE

VALVE

VALVE

PURGE

TANK

GEOTHERMAL HEAT PUMP

EXPANSION

PURGE

PRESSURE REDUCING

VALVE W/BACKFLOW

PREVENTER

NOTE: REQUIRES

PRESSURE/TEMPERATURE RELIEF

VALVE WITH TYPICAL 30 PSIG

SETPOINT. (MAY VARY BY LOCAL

CODE. CONSULT LOCAL CODES FOR

INSTALL REQUIREMENTS.)

FIGURE 5

A TYPICAL LOAD SIDE HYDRONIC SYSTEM

Manual 2100-583G

Page 16 of 48

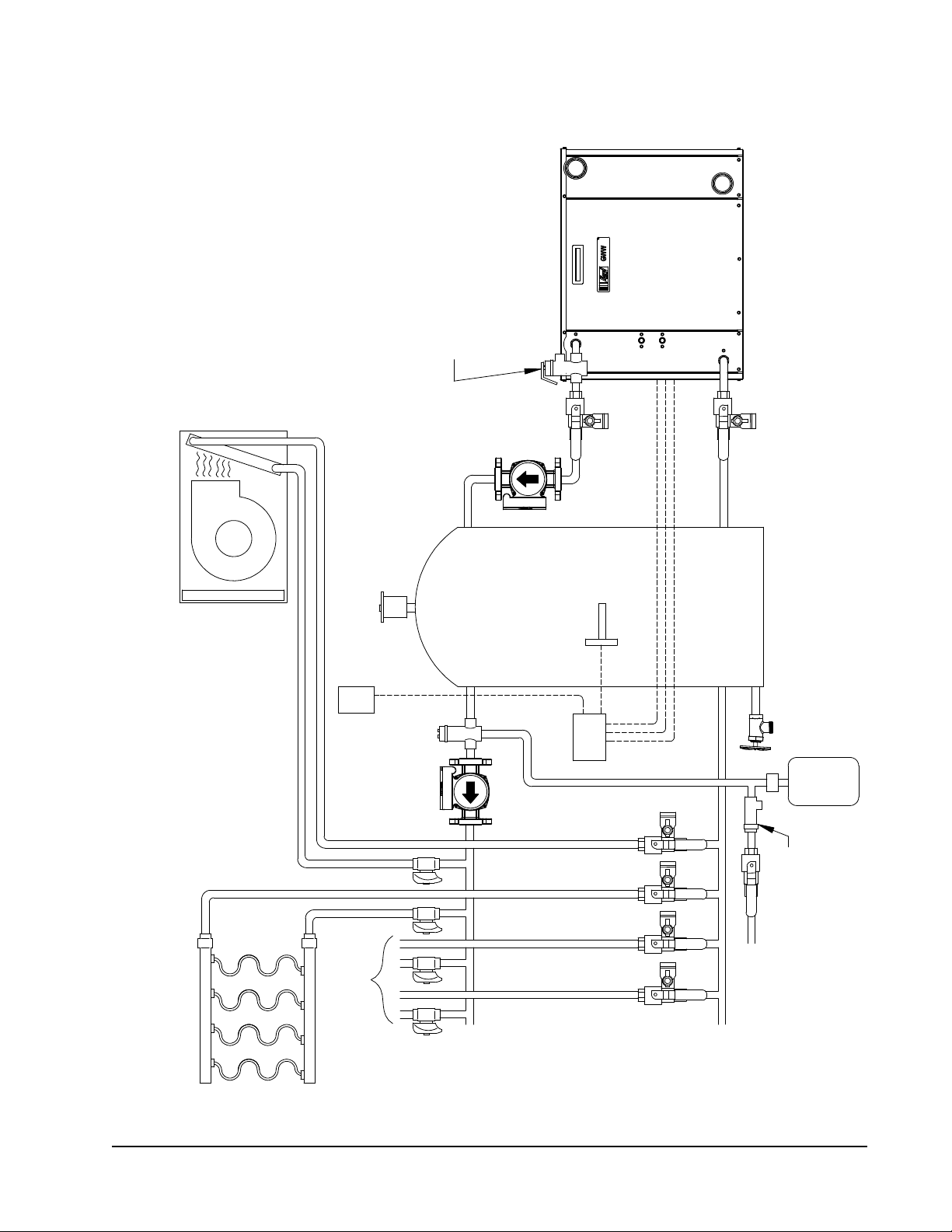

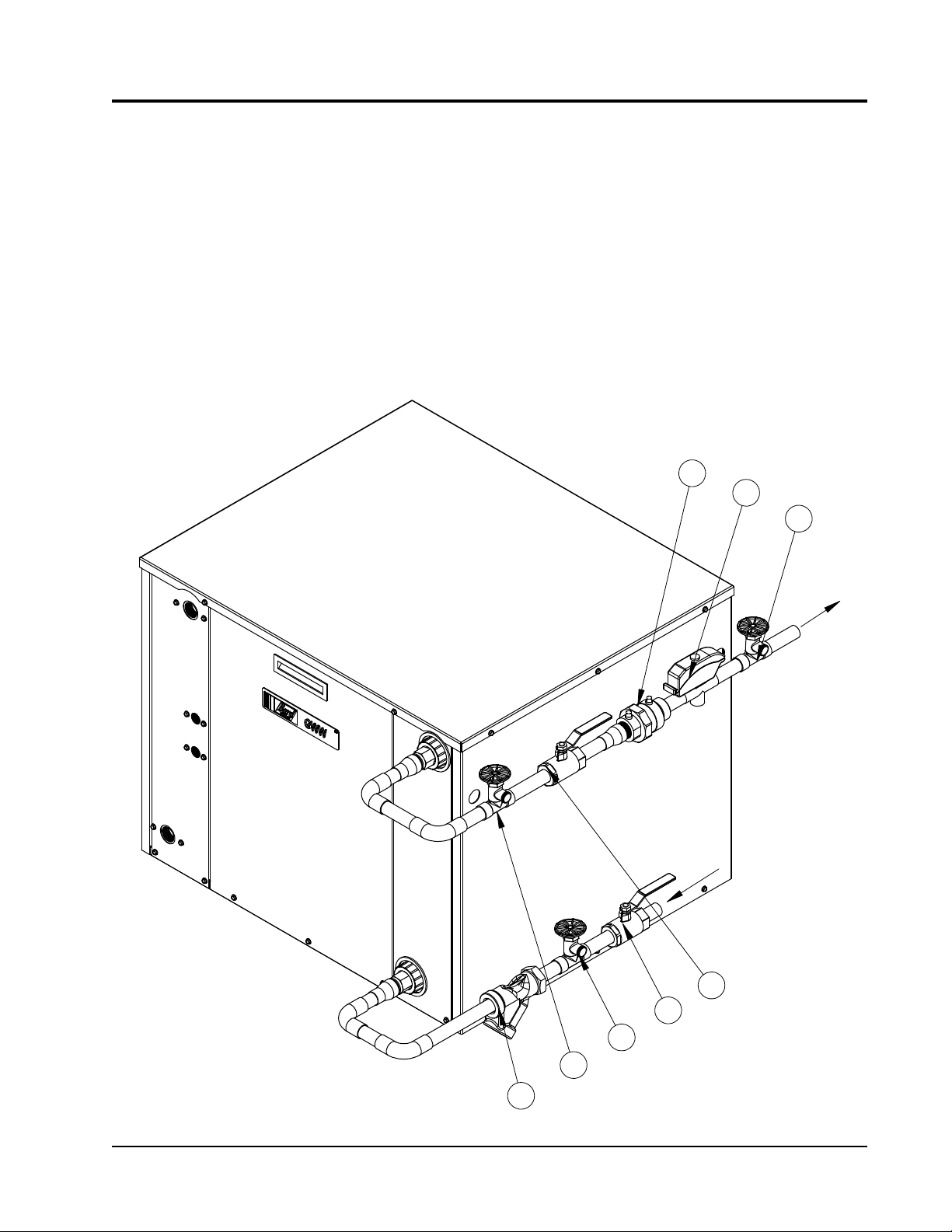

MIS-3165

BRASS ADAPTERS

PUMP MODULE

WATER IN

HOSE CLAMPS

STRAIGHT BARBED

WATER OUT

PIPE FROM

GOUND LOOP

GROUND LOOP

OPTIONAL VISUAL

PIPE TO

NOTE: IF USED SUPPORT

WITH A FIELD FABRICATED

WALL BRACKET

1" FLEXIBLE HOSE

FLOW METER

NOTE: APPLY PETROLEUM

JELLY TO O-RINGS TO PREVENT

DAMAGE AND AID ININSERTION

FIGURE 6

CIRCULATOR SYSTEM DESIGN

GROUND LOOP (EARTH COUPLED WATER LOOP APPLICATIONS)

NOTE: Unit shipped from factory with 75 PSIG low

pressure switch wired into control circuit and must be

rewired to 55 PSIG low pressure switch for ground

loop applications. This unit is designed to work on earth

coupled water loop systems, however, these systems operate

at entering water (without antifreeze) temperature with

pressures well below the pressures normally experienced in

water well systems.

THE CIRCULATION SYSTEM DESIGN

Equipment room piping design is based on years of

experience with earth coupled heat pump systems. The

design eliminates most causes of system failure.

The heat pump itself is rarely the cause. Most problems

occur because designers and installers forget that a ground

loop “earth coupled” heat pump system is NOT like a

household plumbing system.

Most household water systems have more than enough

water pressure either from the well pump or the municipal

water system to overcome the pressure of head loss in ½

inch or ¾ inch household plumbing. A closed loop earth

coupled heat pump system however, is separated from the

pressure of the household supply and relies on a small, low

wattage pump to circulate the water and antifreeze solution

through the earth coupled heat pump and equipment room

components.

The small circulator keeps the operating costs of the system

to a minimum. However, the performance of the circulator

MUST be closely matched with the pressure head loss of the

entire system in order to provide the required ow through

the heat pump. Insufcient ow through the heat exchanger

is one of the most common causes of system failure. Proper

system piping design and circulator selection will eliminate

the problem.

Manual 2100-583G

Page 17 of 48

10

120

110

100

90

80

70

60

50

40

30

20

0

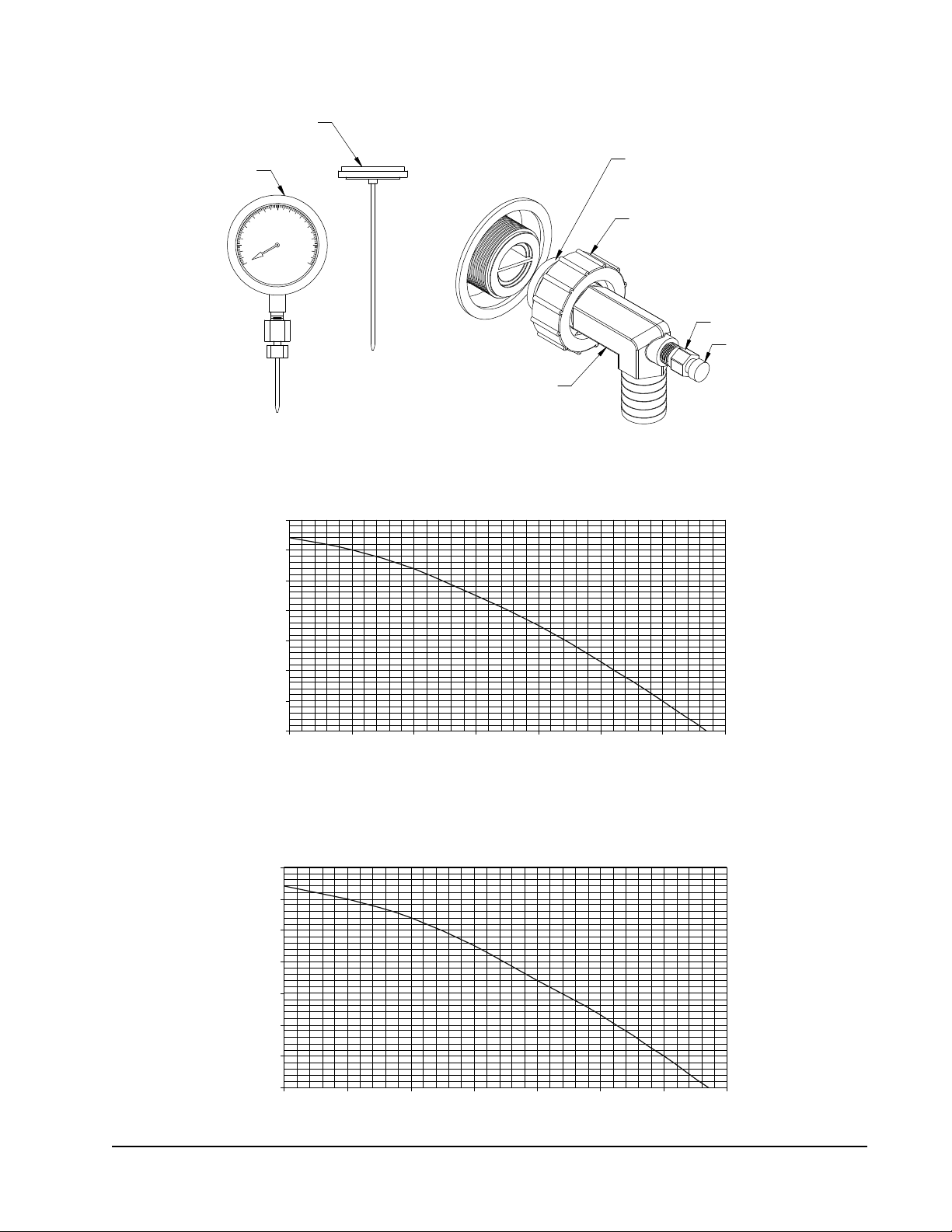

Retaining cap, hand tighten only

Pete's test plug

Test plug cap

Barbed 90° adapter

MIS-2622 A

NOTE: Slide retaining cap back to expose

double o-rings. Apply petroleum jelly to o-rings

to prevent damage and aid in insertion

with guage adaptor

Dial face pressure guage

Thermometer

Manual 2100-545

Page 18 of 38

0

10

20

30

40

50

60

70

0 5 10 15 20 25 30 35

Flow (GPM)

Head (Feet)

FIGURE 9

PERFORMANCE MODEL DORFC-2 FLOW CENTER

0

5

10

15

20

25

30

35

0 5 10 15 20 25 30 35

Flow (GPM)

Head (Feet)

FIGURE 8

PERFORMANCE MODEL DORFC-1 FLOW CENTER

FIGURE 7

10

120

110

100

90

80

70

60

50

40

30

20

0

Retaining cap, hand tighten only

Pete's test plug

Test plug cap

Barbed 90° adapter

MIS-2622 A

NOTE: Slide retaining cap back to expose

double o-rings. Apply petroleum jelly to o-rings

to prevent damage and aid in insertion

with guage adaptor

Dial face pressure guage

Thermometer

P/T

Manual 2100-545

Page 18 of 38

0

10

20

30

40

50

60

70

0 5 10 15 20 25 30 35

Flow (GPM)

Head (Feet)

FIGURE 9

PERFORMANCE MODEL DORFC-2 FLOW CENTER

0

5

10

15

20

25

30

35

0 5 10 15 20 25 30 35

Flow (GPM)

Head (Feet)

FIGURE 8

PERFORMANCE MODEL DORFC-1 FLOW CENTER

FIGURE 7

10

120

110

100

90

80

70

60

50

40

30

20

0

Retaining cap, hand tighten only

Pete's test plug

Test plug cap

Barbed 90° adapter

MIS-2622 A

NOTE: Slide retaining cap back to expose

double o-rings. Apply petroleum jelly to o-rings

to prevent damage and aid in insertion

with guage adaptor

Dial face pressure guage

Thermometer

P/T

FIGURE 7A

FIGURE 7B

PERFORMANCE MODEL DORFC-1 FLOW CENTER

FIGURE 7C

PERFORMANCE MODEL DORFC-2 FLOW CENTER

Manual 2100-583G

Page 18 of 48

NOTE: It is highly recommended on ground water

systems (pump & dump) that a cupronickel coaxial coil

is utilized on the source side of the system. Not doing

so, may void the product warranty due to aggressive/

corrosive/highly oxygenated water attacking the copper

coaxial water coil.

NOTE: Unit shipped from factory with 75 PSIG low

pressure switch wired into control circuit for ground

water applications.

WATER CONNECTIONS

It is very important that an adequate supply of clean,

non-corrosive water at the proper pressure be provided

before installation is made. Insufcient water, in the

heating mode for example, will cause the low pressure

switch to trip, shutting down the heat pump. In assessing

the capacity of the water system, it is advisable that the

complete water system be evaluated to prevent possible

lack of water or water pressure at various household

xtures whenever the heat pump turns on. All plumbing

to and from the unit is to be installed in accordance with

local plumbing codes. The use of plastic pipe, where

pemissible, is recommended to prevent electrolytic

corrosion of the water pipe. Because of the relatively cold

temperatures encountered with well water, it is strongly

recommended that the water lines connecting the unit be

insulated to prevent water droplets from condensing on the

pipe surface.

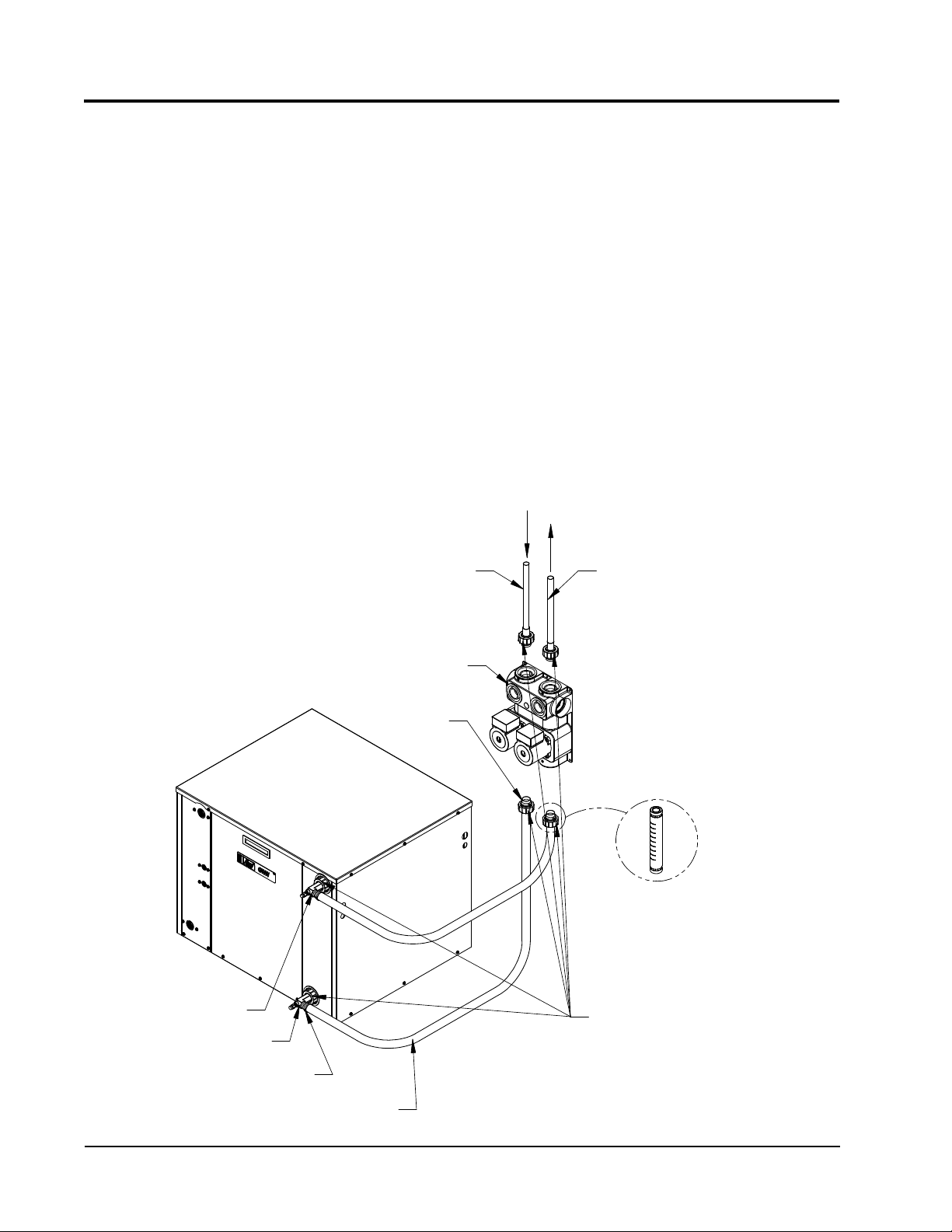

Refer to piping, Figure 8. Slow open/close Electrically

Actuated Valve with End Switch (2), 24V, provides on/off

control of the water ow to the unit. Refer to the wiring

diagram for correct hookup of the valve solenoid coil.

Constant Flow Valve (3) provides correct ow of water

to the unit regardless of variations in water pressure.

Observe the water ow direction indicated by the arrow on

the side of the valve body.

Strainer (8) installed upstream of water coil inlet to

collect foreign material which would clog the ow valve

orice.

The gure shows the use of shutoff valves (4) and (5), on

the in and out water lines to permit isoation of the unit

from the plumbing system should future service work

require this. Globe valves should not be used as shutof

valves because of the excessive pressure drop inherent in

the valve design. Instead, use either gate or ball valves as

shutoffs, so as to minimize pressure drop.

Hose bib (6) and (7), and tees should be included to permit

acid cleaning the refrigerant-to-water coil should such

cleaning be required. See WATER CORROSION.

Hose bib (1) provides access to the system to check water

ow through the constant ow valve to ensure adequate

water ow through the unit. A water meter is used to

check the water ow rate.

WELL PUMP SIZING

Strictly speaking, sizing the well pump is the

responsibility of the well drilling contractor. It is

important, however, the HVAC contractor be familiar with

the factors that determine what size pump will be required.

Rule of thumb estimates will invariably lead to under or

oversized well pumps. Undersizing the pump will result

in inadequate water to the whole plumbing system, but

with especially bad results to the heat pump - NO HEAT/

NO COOL calls will result. Oversized pumps will short

cycle and could cause premature pump motor or switch

failures.

The well pump must be capable of supplying enough

water and at an adequate pressure to meet competing

demands of water xtures. The well pump must be sized

in such a way that three requirements are met:

1. Adequate ow rate in GPM.

2. Adequate pressure at the xture.

3. Able to meet established ow rates and pressures

from the depth of the well-feet of lift.

GROUND WATER (WELL SYSTEM APPLICATIONS)

Manual 2100-583G

Page 19 of 48

6

1

2

3

4

5

7

8MIS-3166

FIGURE 8

WATER CONNECTION COMPONENTS

The pressure requirements put on the pump are directly

affected by the diameter of pipe being used, as well as the

water ow rate through the pipe. The worksheet included

in Manual 2100-078 should guarantee the well pump has

enough capacity. It should also ensure that the piping is

not undersized, which would create too much pressure due

to friction loss. High pressure losses due to undersized

pipe will reduce efciency and require larger pumps and

could also create water noise problems.

GROUND WATER (WELL SYSTEM APPLICATIONS)

Manual 2100-583G

Page 20 of 48

SYSTEM START UP PROCEDURE FOR

GROUND WATER APPLICATIONS

1. Be sure main power to the unit is OFF at disconnect.

2. Set thermostat system switch to OFF.

3. Move main power disconnect to ON. Except as

required for safety while servicing – DO NOT

OPEN THE UNIT DISCONNECT SWITCH.

4. Fully open the manual inlet & outlet valves, and

manually open water solenoid valve on the source side.

5. Check water ow.

a. Connect a water ow meter to the drain cock

between the constant ow valve and the solenoid valve.

b. Check the water ow rate through the constant ow

valve and the solenoid valve. Run a hose from the

ow meter to a drain or sink. Open the drain cock.

c. When water ow is okay, close the drain cock and

remove the water ow meter. The unit is now ready

to start.

6. Start the unit in heating mode by switching on the

Aquastat.

a. Make sure the water solenoid valve actuated/

opened.

7. Check the system refrigerant pressures against the

refrigerant pressure table located on the backside

of the system service door at the corresponding

source and load ow rates and enetering water

temperatures. If the refrigerant pressures do not

match, check for water ow issues, and then a

refrigeration system problem.

8. Switch the Aquastat/thermostat to cooling mode

and again verify water solenoid actuation, and

refrigerant pressures.

NOTE: If a charge problem is determined (high or low):

A. Check for possible refrigerant loss.

B. Reclaim all remaining refrigerant.

C. Evacuate unit down to 29" of vacuum.

D.

Recharge unit with refrigerant by weight to the serial

plate, as this is the only way to ensure proper charge.

WATER CORROSION

Two concerns will immediately come to light when

considering a water source heat pump, whether for ground

water or for a ground loop application: Will there be enough

water? And, how will the water quality affect the system?

Water quantity is an important consideration and one which

is easily determined. The well driller must perform a pump

down test on the well according to methods described

by the National Well Water Association. This test, if

performed correctly, will provide information on the rate

of ow and on the capacity of the well. It is important to

consider the overall capacity of the well when thinking

about a water source heat pump because the heat pump

may be required to run for extended periods of time.

The second concern, about water quality, is equally

important. Generally speaking, if the water is not offensive

for drinking purposes, it should pose no problem for

the heat pump. The well driller or local water softening

company can perform tests which will determine the

chemical properties of the water.

Water quality problems will show up in the heat pump in

one or more of the following ways:

• Decrease in water ow through the unit.

• Decreased heat transfer of the water coil (entering to

leaving water temperature difference is less).

There are four main water qualtiy problems associated with

ground water. These are:

1. Biological Growth This is the growth of microscopic

organisms in the water and will show up as a slimy deposit

throughout the water system. Shock treatment of the well

is usually required and this is best left to the well driller.

The treatment consists of injecting chlorine into the well

casing and ushing the system until all growth is removed.

2. Suspended Particles in the Water Filtering will

usually remove most suspended particles (ne sand, small

gravel) from the water. The problem with suspended

particles in the water is it will erode metal parts, pumps,

heat transfer coils, etc. As long as the lter is cleaned and

periodically maintained, suspended particles should pose

no serious problem. Consult with your well driller.

3. Corrosion of Metal Corrosion of metal parts results

from either highly corrosive water (acid water, generally

not the case with ground water), or galvanic reaction

between dissimilar metals in the presence of water. By

using plastic plumbing or dielectric unions, galvanic

reaction is eliminated. The use of corrosion resistant

materials such as a Cupronickel Water Coil through the

water system will reduce corrosion problems signicantly.

4. Scale Formation Of all the water problems, the

formation of scale by ground water is by far the most

common. Usually due to the formation of calcium

carbonate, but magnesium carbonate or calcium sulfate

may also be present. Carbon dioxide gas (CO2), the

carbonate of calcium and magnesium carbonate, is very

soluble in water. It will remain dissoved in the water

until some outside factor upsets the balance. This outside

inuence may be a large change in water temperature or

pressure. When this happens, enough carbon dioxide gas

combines with the dissolved calcium or magnesium in

the water and falls out of solution until a new balance is

reached. The change in temperature that this heat pump

produces is usually not high enough to cause the dissoved

gas to fall out of solution. Likewise, if pressure drops

are kept to a reasonable level, no precipitation of carbon

dioxide should occur.

GROUND WATER (WELL SYSTEM APPLICATIONS)

This manual suits for next models

4

Table of contents

Other BMC Heat Pump manuals

Popular Heat Pump manuals by other brands

Whirlpool

Whirlpool W2H3 installation instructions

Viessmann

Viessmann Vitovalor PT2 operating instructions

York

York YZF installation manual

Daikin

Daikin RQYQ140-180PY1 Service manual

ratiotherm

ratiotherm WP Max-Air Technical document

ClimateMaster

ClimateMaster Trilogy VE Series Installation, operation & maintenance instructions

Daikin

Daikin Altherma 3 R F User reference guide

Airwell

Airwell XDA user manual

Ecotec

Ecotec EAS SERIES Installation & user manual

Carrier

Carrier 50TCQD17-D24 Service and maintenance instructions

Daikin

Daikin Altherma 3 H HT EPRA18DAW1 Installer's reference guide

Trane

Trane FLEX HP HT Installation operation & maintenance