The time-tested Intimidator platform has a new brother—the Vice. Beginning in

2000 with the release of the Classic Intimidator, Bob Long set the bar high with the

rst marker to feature breakbeam anti-chop eyes, dual regulation, an integrated

drop forward, two piece barrel, and gradient anodizing in several patterns in one

marker—in one affordable package.

Although this marker was relatively under the radar of the paintball community, Bob

Long Technologies set the paintball world on re in 2001 with the release of the

Ground Zero Intimidator—the smallest, fastest, and most consistent marker to hit

the scene. Featuring a 45 frame, the new Torpedo™ regulator, and faster electron-

ics—and a smaller, sportier feel.

In 2002, Bob Long expanded upon the Intimidator line with the release of more

models, extensive milling and upgraded electronics; featuring the world’s most ag-

gressive marker programming at the time. Three years later, Bob Long rocked the

tournament on its heels again with the Alias Intimidator—bringing Intimidator speed

and reliability to a smaller scale.

Finally, in the Intimdator’s last stand before the release of the Vice, the Generation

Five brought efciency and speed to a whole new level. And new for 2008, the Vice

aims to surpass all expectations, and set the bar notches higher—in a true Bob

Long fashion.

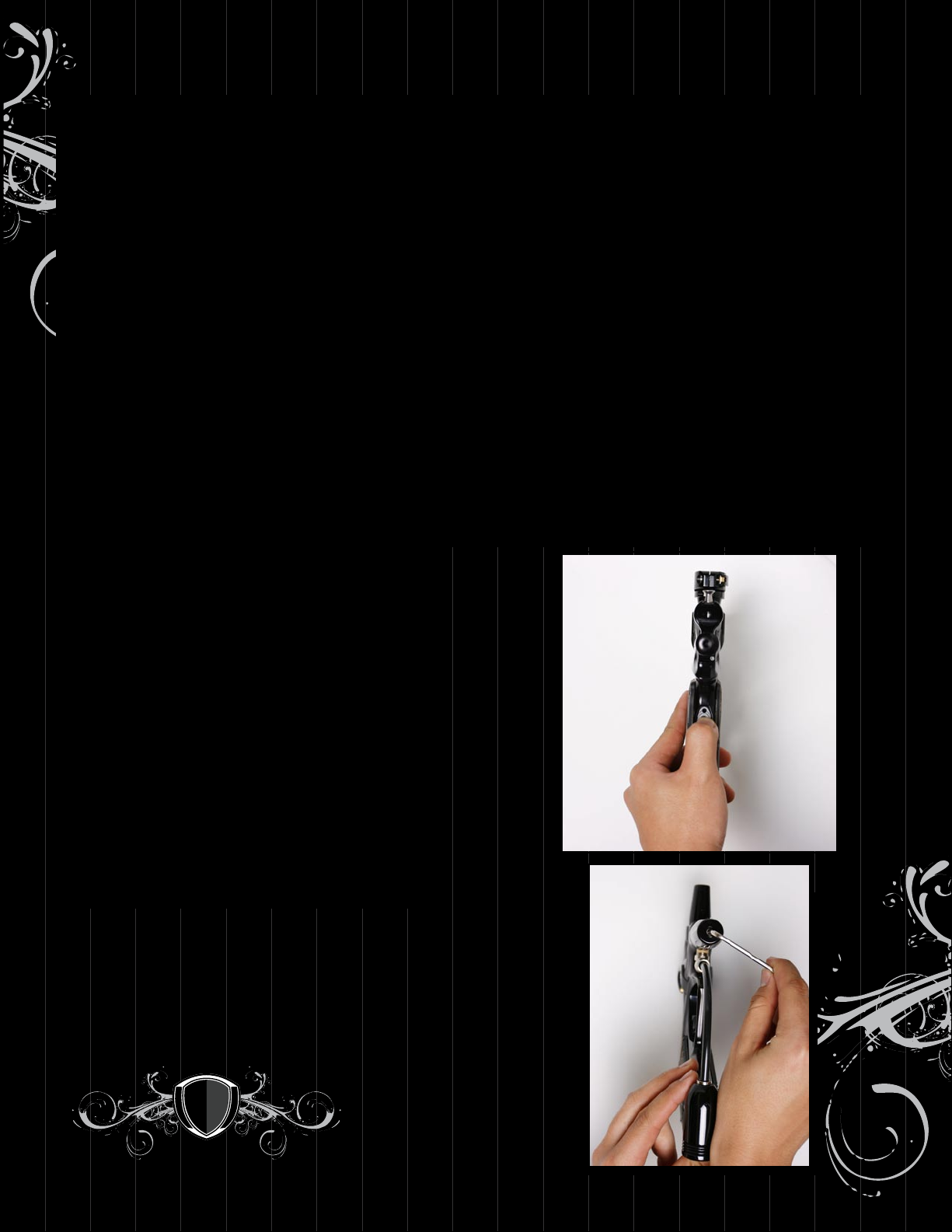

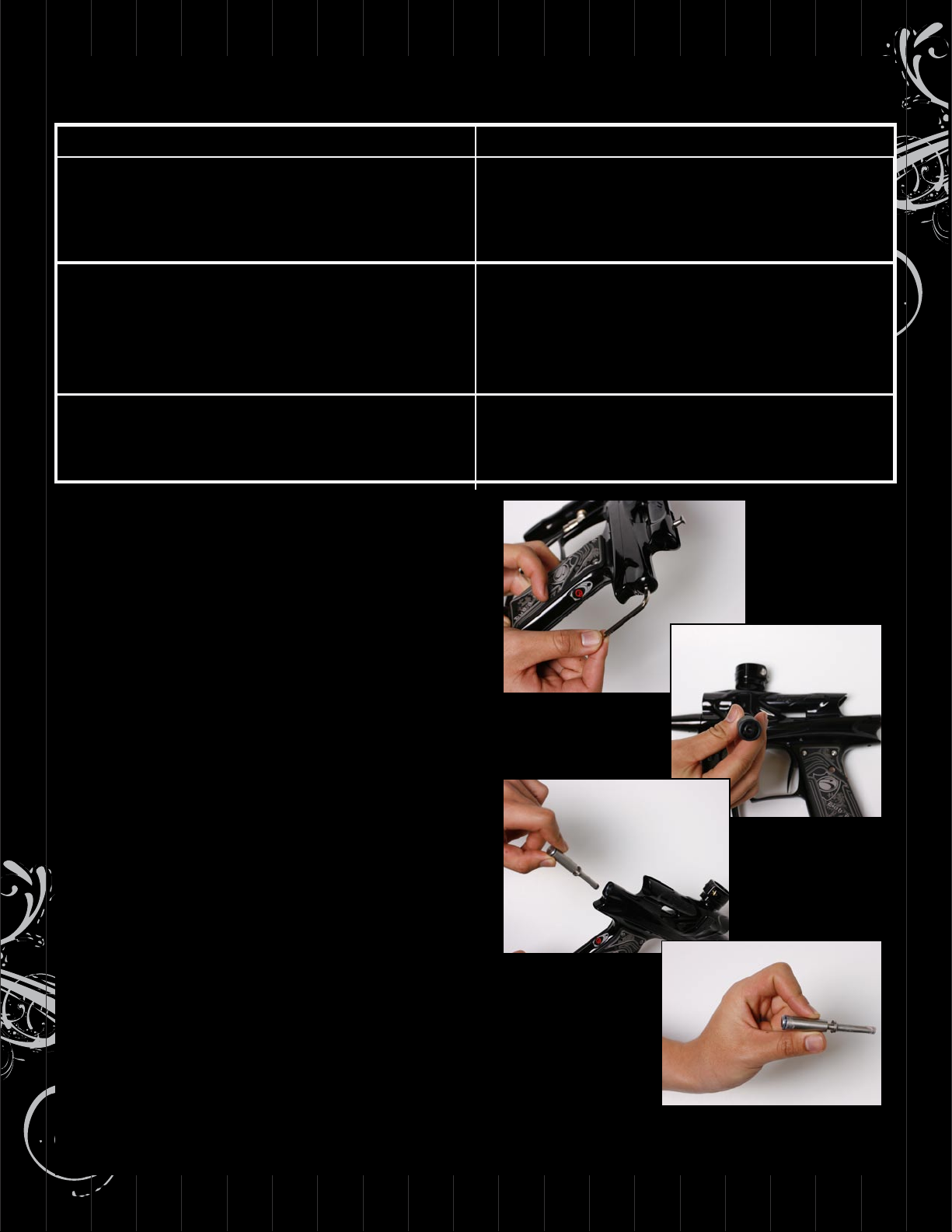

The Vice marker represents the newest addition to the stable of cutting edge Bob

Long products. Featuring the absolute newest and greatest features a marker can

offer, the Vice serves as the latest issue of the acclaimed Intimidator series. The

Vice incorporates the winning features of the timeless Intimidator with the demands

of the modern player. The Vice is smaller, faster, stronger and lighter than any of its

predecessors—and more affordable. Utilizing the patented 4C Quad optoelectronic

system, the Vice combines the blazing electronic speed of the Marq series with the

utterly efcient stacked-tube poppet design of the Intimidator.

5

www.BobLongDirect.com