Bolens 225 Guide

Other Bolens Snow Blower manuals

Bolens

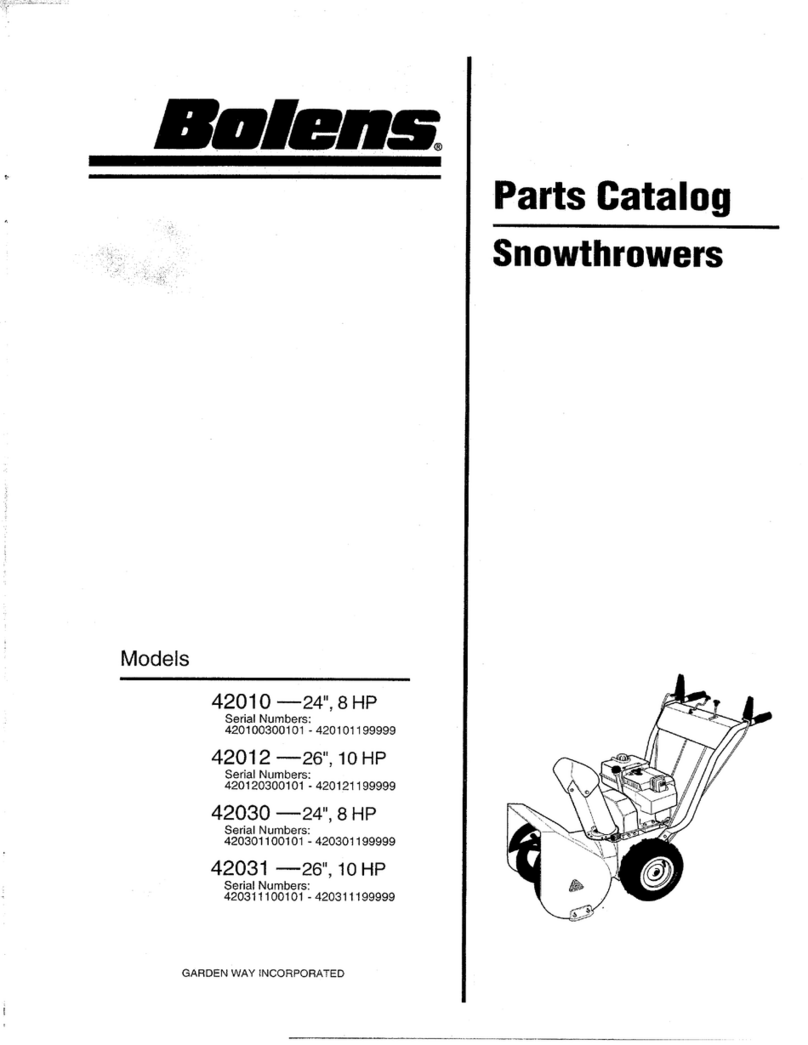

Bolens 42010 Instruction Manual

Bolens

Bolens 1026 Owner's manual

Bolens

Bolens 500 User manual

Bolens

Bolens 824A Owner's manual

Bolens

Bolens 31AE6GKF500 User manual

Bolens

Bolens 2N1 User manual

Bolens

Bolens 18148-01 Installation guide

Bolens

Bolens 772C0774 MTD User manual

Bolens

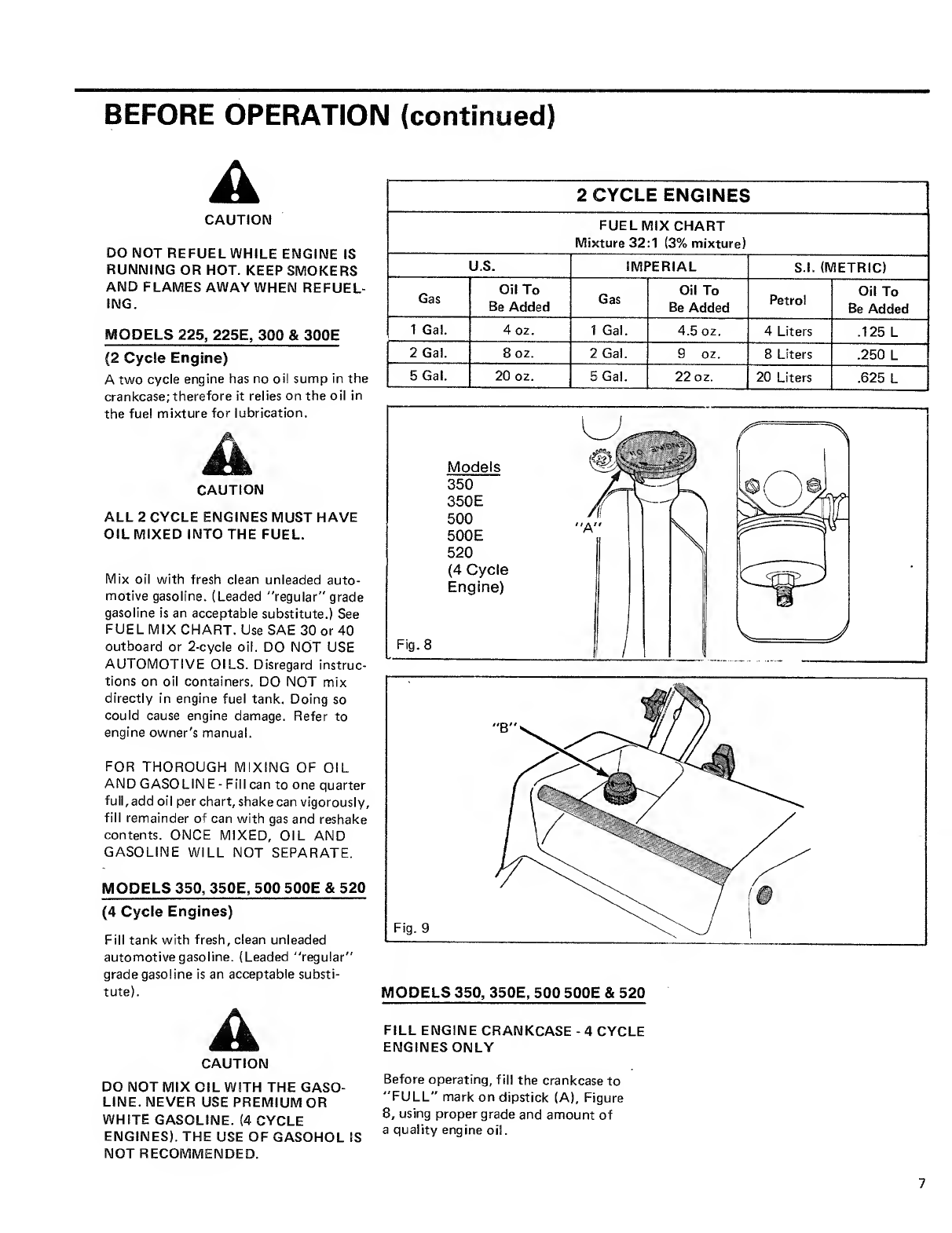

Bolens 225 Guide

Bolens

Bolens SNOW THROWER 42028 Instruction Manual