Bombardier-Rotax 462 User manual

·

.

OPERATOR

'

S

MANUAL

TYPE 462 ENGINES

EQU

I

PPED

WI

T

H

BOSCH CONTACT BREAKER

IGNITION SYSTEM AND

BING

CARBU

R

ErOR

Edition

0

4

BOMB

A

R

DIER-ROTAX

G

M

BH

MOTORENFABR

IK

A-4623

Gunsk

i

rchen

-

Au

s

tr

ia

Telefon

:

(07246)

27

1-

0

·

,

Tele

x:

255

46

brg

k a

Telegrammadresse:

Bom

b

rotax

G

un

skirc

h

en

1

988

FORHISTORICALREFERENCEPURPOSESONLY:THISINFORMATIONMAYBEOUTDATED!

,

'.

,"

~,

.1

'Q

'"..

'"

..

I

r

..

t,

'I

.-

•

•.

~

l'

:.

.

.( ,\,

,,.

.

'.

'I i

I

1

.I

.

.

-

.~

',

..

'"

'"

..

•

•

"

f,

,

.

,;

~

..

.

.

,

""

.,

"

•

.I.,

t'

r

-,

.

'I

...

•

•

,

.

~

"

;

I

"

•

.•

.-

•..

,

"

A.

•

r

.

'

.

"

I

..,

(

.

:.

~

"

·4

'':

••

'

..

'I

i

:r

J.

t

"

..

,..

.

..

.

.

.

'i

•

f

t'

"':

~.

•

"

"',.-.

"

..

,

..

.

.

"

f

!'~

~

.

""

.

,

,_:-

.•

r

..

,\.,

".

;

.

''',

: ,

I

rt

I

.

(

J

.

"

h

"

.'

,.

.;

..-

,

r

'

-

.•.

.-

c

"

FORHISTORICALREFERENCEPURPOSESONLY:THISINFORMATIONMAYBEOUTDATED!

-

1

-

Table

of

Contents

Page

2

3

4

6

7

8

9

10

11

.

.

12

13

14

16

18

20

21

22

Fuel/Fuel Oil

Mixture

Break-in

Procedure

Rotary

Valve

Adjustment

/

Carburetor

Starting

the

engine

/

Spark

Plug

Ingition

Unit

Adjustment

of

I

gnition

Timing

/

Pole Shoe

Gap

Wiring

Diagram

Ignition

Damping

Box

/

Wiring

Diagram

for

mounting

ignition

damping

box 866 572

Lighting

Circuit

Wiring

Diagrams

for

rectifier-regulator

866 080

Wiring Diagrams

for

rectifier

-

regulator

264

870

Rewind

Starter

/

Changing

the

starter

rope

Decarbonizing

/

Main

Torquing

Specifications

Fault-Tracing

-

Schedule

Liquid

-

Cooling System

Gear for

rotary

valve

and

liquid-cooling

pum

p

Mounting-,

Maintenance-

and

Safety

Instructi

on

s

for

UL

-

prop

gear

on

ROTAX

engine

types

377

-

447

-

503

-

462

-

532

24

Service Information

type

462

UL

-

Rotary

Val

v

e

Adjustment

25

Technical

Data

FORHISTORICALREFERENCEPURPOSESONLY:THISINFORMATIONMAYBEOUTDATED!

-

2

-

GENERAL

The

ROTAX engine

is

a

liquid-cooled

2-stro~~

engine.

Careful

and

extensively

tested~design and rugged

construction

as

well

as

.

the

use

of

.

high quality

parts

warrant

maximum reliability

and

durability. With proper maintenance and

care

and

with

the

use

of

suitable

fuel

and oil

the

engine

wilL

give

you

trouble-free

service for

many

years.

'_

,

The

ROTAX

design

~ncorporates

the

latest

technical

develop-

ments.

In

order

to

take advantage of

future

developm.ents

we

reserve

the

right

to

make modificat~ons

in

the

ROTAX

design

.without

notice.

FUEL

As

fuel

for

engine

type

462

UL

regular

gasoline, leaded

or

unleaded,

octane

number

not

below

RON

90

(or

MON

83)

is

prescribed.

Premium

gasoline

can

be

used,

too.

If

possible,

leaded

fuel

should

be used.

When

using

unleaded

fuel.

only

use

fuels

'

o~

recognized

brands.

When

lead

in

fuel

is

omitted,

alcohol (methanoL ethanoL isobutanol

etc

.

)

is

added

to

avoid

knocking. Due

to

the

water

absorption

of

the

highly

hygros~.o.pical

alcohols. the fuel

quality

cannot

be

maintained

over

a

long

period.

Further

the

alcohol

additive

causes

leaner

fu

~

air

mixture

(because

of

oxygene

in

alcohol)

resulting

in

general

i

)r

/

higher

engine temperatures.

A

higher

percentage

of

alcohol increases the

risk

of

vapour

lock due

to

higher

vapour

pressure

of

alcohol.

The

alcohol

percentage

must

not

exceed

10

%.

FUEL

-

OIL

-

MIXTURE

The

.

ROTAX

engine

is

operated

by

a

mixture of standard

grade

gasoline

and

-

Super

2-stroke

oil

the oil

lubricating

the

moving

engine

parts.

'

Mixing ratio

fuel

be

respected. oil

is 50

:

1;

this

mixing ratio

has

to

Too

much

oil

will

cause

carbon

deposits

on

the

spark

plug,

on

the

piston,

in

the

cylinder

ports

and in

the muffler

and

will

cause

problems.

In

addition,

the

piston ringsmay

stick.

I

f

too

little

oil

is

used_ lubrication

will

be

insufficien

t

,

the

pistons

will seize

and

the

bearings will

be

damaged.

FORHISTORICALREFERENCEPURPOSESONLY:THISINFORMATIONMAYBEOUTDATED!

-

3

_

-

BREAK-IN

PROCEDURE

The

break-in

has

to

be

perfor~ed with

the

engine

in

the

nir-

frame,

loaded

with

the

propeller. Tishten

the

plane

t

.

o

the

gr-ound

and run the

engine

ac

cording

to the follmdng graph:

Engine

rop

.m·l

.:x

1000

Full

10 15

sec sec

20 30

sec

sec

j

2

min

min

2

min

1

-

-

----- ---

-

_-

--- ---- r--

-

-

-

.--

;

-

1

,-

1

5

5

5

5

5

5

5

5

5

-

_

_

_.

i..

1

1

1

1

.,

1

1

1

2

·1

...

tl

I

I

•

,

-'

I I

-

I

•

1

T I

.

5,5

5

4,,5

4

3,,5

3

'r

2

"

o

10

20

30

40

50

60

Time

(min)

After

this

procedure

the

idle

has to

be

adjusted.

Then

sh

o

rt

take-offs

can be

conducted

.

.

FORHISTORICALREFERENCEPURPOSESONLY:THISINFORMATIONMAYBEOUTDATED!

Rotary

Valve Adjustment

Installation:

To

correctly install

the

rotary valve disc proceed

as

follows:

-

Turning

crankshaft counter-clockwise

(drive

pulley

side),

bring

.

magneto

side

piston

to

Top

Dead Center using

a

T.D.C

o

gauge.

-

.

-

Position

the

rotary valve disc on

gear

to

have edges

as

close

as

possible

to

the

marks.

NOTE:

The

rotary valve disc

is

asymmetrical, therefore,

at

assembly

try

positioning each

side of

disc on gear

to

de:termine

best

installation position.

See

also page

no.

24

CARBURETOR

The

BING

carburetor

is

a

piston

type

carburetor with

float

chamber

.

The

carburetor

can

be

adjusted

by

jets

and

adjusting

screws.

Changing of jets should

only

be

done

by

a

specialist

or

after consulting

the

engine manufacturer.

The air

-

fuel

mixture

at

idle

speed

is

adjusted

by

the

air

adjusting

screw

(see

ill. no.

28).

The

idle

r.p.m.

is

adjusted

by

the

carburetor piston adjust-

ment

screw

(ill.

no.

30).

Note:

The

carburetor

must

be

in

an

exact right

angle

position

i

n

relation

to

the

crankshaft

in

both views

from

top

and

from

the

intake

side

to

ensure

an

equal

mixture

distri-

bution

to

both

cylinders.

Take

care that

end

of

both

ventilation

tubes

(ill. no.

31)

are

protected

from

FORHISTORICALREFERENCEPURPOSESONLY:THISINFORMATIONMAYBEOUTDATED!

·

.

I

,

.

,

.

.

BING-Carburetor

40~

T

~

41

42

43

-

5

-

-

44

~---29

~30

21

24

25

5

0-

4

9-

FORHISTORICALREFERENCEPURPOSESONLY:THISINFORMATIONMAYBEOUTDATED!

6

-

STARTING

THE ENGINE

On

cold

engine

use

choke.

Don't

set

throttle

.

Start

the

engine.

After

the

first

ignitions

open

throttle

and shortly

after

close

choke

.

Attention:

Throttle

opening

reduces

the

effect

of

,the

choke.

If

the

engine

is

started

too

long

with

the

'

choke,

,

the

engine

gets

flooded with

fuel.

If

this

.

nappens ;

the

_

_

apar-k

v

p.Lug

s

have

to

be

unscrewed,

cleaned,

dried

and

the

engine has

to

be

started

(cranked

through)

several

times.

If

the engine still

does not

start,

see

chapter

"Fault

Tracing

Schedule".

SPARK

PLUG

If

the

engine

fails

to

start

or

operates

only on

one

cylinder,

_

it

should be

checked whether

the

ignition wiring

is

disconnected

from the

spark plug protectors

or

from

the

spark

plugs.

Then

the

condition

of

the

spark

plugs has

to be checked (bridged

between

the

electrodes,

oily,

sooty

etc.).

If

the

spark

plug

heat

range

and the

carburetor calibration

are

correct,

the spark

plugs look brownish.

'

With

too

high heat

range

(cold

plug)

and

too

rich carburetor

<

,

calibration they look

black

and

sooty.

With

too

low

heat range

(hot

plug)

or

too

lean

,

carburetor

calibration the spark

plugs

are

burnt white

and

the

electrodes

are

covered

with melt

drops.

ATTENTION:'

Heavy

oil

deposits

on the

electrodes

and

insulator

cause

engine

troubles and

have

to

be

removed

regularly

(every

10

hours).

FORHISTORICALREFERENCEPURPOSESONLY:THISINFORMATIONMAYBEOUTDATED!

,

,

'

-

-

7

-

If

even

after

cleaninc

or

chaneing

the

spark

p~ug

there

is

no

spark, the

spark

plug protector

and

the

ignition

cables

and

finally the

ignition

unit

should

be

checked.

IGNITION

UNIT

,The

ROTAX

engine

is

equipped

with

a

BOSCH

magneto generator

12V

l~OW

producing

the

current

necessary

for the

spark.

The

ignition

unit

has

been

set

most

carefully

and

precisely

by

the

factory.

Make

no

changes

unless

absolutely

nec

es

sary

,'

In

case of

troubles

observe

the

following:

If

the

ignition

fails

intermittently

or

if

there

are

other

troubles

that

are

due

to

neither

spark

plug

nor

jets

nor

carburetor~

the

contact

breakers may

be the cause.

Contacts

must

be

clean

and

must

not

be burnt.

With

new

engines

the

cam-follower

of the

contact

breaker

must still adjust

it-

self

.

Re-setting

of

contacts

may therefore

be

necessary

'

after

some

time.

The

breaker contacts

are

accessible

after

remo~al

of

the

rewind

starter and

the

starting

pulley. The

magneto

housing

need

not

be

removed.

To

check

whether

the

ignition

timing

is

correct

there

is

an

arrow

on

the

crank~ase.

Further

there

is

a

mark

on

'

the

magneto

housing.

At

the

moment

of

ignition

(i.e.

~hen

br

e

aker

contacts

open~

check

with

test

lamp~

buzzer

etc.~

cori

~e

c

t

ed

to

'

shorting

cable

of

the

respective cylinder

and

to

mass),the

mark

on

the

magneto housing must correspond with

the

arrow

on

the

crankcase.

FORHISTORICALREFERENCEPURPOSESONLY:THISINFORMATIONMAYBEOUTDATED!

-'8

-

ADJUSTMENT

OF

IGNITION

TIMING

The

igriition

timing

is

~djusted after loosening

the

fixing

screw

G

next

to

the

adjusting groove

H

(see

wiring

diagram),

.

so

that

the

contact breaker

starts

opening when

the

piston

is

{

~'

.

.

-

"~'

(1

0)

-

-

'

.

.

_

.

.

:

;

"

:

·

-:

,

:

-~~

~

·:

r

:

~

:

·'-

-

-

-

-

-"

~

-

~

~(

.

;

{

,

i~

~

t:iS

~

n

·

.

,

,

1

.

,86

.

mm

;

8

_

_

.

be

.

.:t.:

.

o:;I;'J;L

_

'l'

•

.

D.

_

O

.

•

.-

,

,

--

-,

_

-

..

_

..

.

.

_

_

i

.

:

'

"

1

1

Che

.

ck

with

test lamp or

'

buzzer

as

described

before.

When

cranking

the

engine,

the

breaker contacts

must

open

0,30

~

0,40

mm

(0,012

7

0,015

in).

If

this

is

not the case,

turn

the

stator

plate

and repeat

the

above procedure.

POLE

SHOE

GAP

When

correct

timing

is

achieved, check pole

shoe

break-away

gap.

The gap

must

be

within

13

to

17

mm

or

0,51

to

0.

9

7

in.

(see

illustration)

when

the

mark

on

flywheel corresponds

w~th

mark

on fan

housing.

If

the

~reak-away

gap

is

out

of

tolerance,

the

flywheel

may

have

turned

on the crankshaft.

Remove

flywheel

and inspect

taper

and

key.

Repair

if

necessary.

pole

Q)

.

,

,

cardboard

strip

magnet

FORHISTORICALREFERENCEPURPOSESONLY:THISINFORMATIONMAYBEOUTDATED!

-

9

-

"

Timing

adjustment

and

repair

of

ignition

units

should

best

be

left

to

a

skilled

mechanic.

Improper handling

can easily

cause

more

troubles

with

such

delicate

parts.

WIRING

DIAGRAf1

Particular

care

has

to

be

taken

that

the

ignition

generator

'

cables

(J)

and

the

mass

cables

(M)

be

correctly connected

to

the

ignition

coils

(A),

see

illustration.

(Power

Take

Off)

N

damping

<

box

o

N

PTO

.

/

MAG

A

ignition

coils

H

adjusting

groove

B

generator

coil

(bottom)

J

generator

cables

lighting

coil

30W

(top)

K

shorting

cables

'

C

lighting

coil

110\-1

.

L

lighting

cables

D

condenser

M

,

mass cables

E

contact

breaker

lever

N

ignition

cables

F

breaker

contacts

0

spark plug

protectors

G

fixing screw

To

cut

off

the

ignition,

the

2

shorting

cables

K

have

to

be

'

connected

together

and/or

to

ground.

FORHISTORICALREFERENCEPURPOSESONLY:THISINFORMATIONMAYBEOUTDATED!

IGNITION

DAMPING

BOX

.

- 10 -

To

prevent

piston

failures

caused

by

glowinG

of

deposits

on

spark

plugs

(due

to

certain

fuel additives)

it

is

necessary

.

:

a)

to

clean

the spark

plugs

every

approx.

10

hours of

opera-

tion

or

to

replace

them,

b)

An

ignition damping

box,

part

no.

866

572, i

'

a

mounted

on

the

engine

to

reduce

the

spark

energy

and

the

glowing

of

the

spark plug

deposits.

WIRING

DIAGRAM

FOR

MOUNTING

IGNITION

DAMPING BOX

866

572

-

red cable

to

magneto

side

ignition

~oil,

connection

1

-

black

cable

to

p.t.o.

side ignition

coil,

connection

15

I

p.t.o

•

.

side

ignition

coil

damping

box

866

.572

I

red

black

mag.

side

ignition

coil

Damping box

check

a)

precaution

check:

Connect

damping box

with

reversed

polarity.

There must

be

£2

spark

on

both plugs

when

cranking

the

engine.

If

there

is

still

a

spark,

the

damping

~ox

is

defective.

b)

in

case

of

ignition

troubles

(no

spark):

Disconnect

damping

'

box,

if

there

is"

:

now

a

spark.

!h~_£Q11Q~!ug_~rrQr:§Q~££~§_§r~_2Q§§!Q1~l

1)

Damping

box

defect

or

reverse

connected

(see

a)

~)

Pole-ring

break-away

gap

out

of

tolerance

(defective

Woodruff-key

or

w~ong

armature

plate adjustment

'

>

(see

page

8)

FORHISTORICALREFERENCEPURPOSESONLY:THISINFORMATIONMAYBEOUTDATED!

-

11

-

LIGHTING

CIRCUIT

The

BOSCH magneto

generator

produces,

apart

from

the

'

electric

current

required

for

the

~gnition, 12V

l~OW

alternating

current

which

can

be

directly

used

for feeding lights

and/or

other

users

that

can

be

operated

with alternating

current.

To

avoid

the

voltage

to

rise

above

permissible

levels,

either

users

amounting

to

1QO

watts

have to

be

connected, or

a

vol-

tage

regulator

has

to be used.

To

operate

u,sers

requiring

direct

current

(e.g.

battery),

a

rectifier-regulator

is

required.

A

rectifier-regulator,

part

no.

866

080,

is available.

For

feeding

lights

only,

this

rectifier-regulator

can

also

be

used

without

battery.

In

this

case the

regulated

RMS

voltage

will

be

between

11

and

12

Volts

as

long

as

a

minimum

load

of

1

amp

is

provided.

In case

of

a

battery

it

has

to be

capable

to

absorb

approx.

1

amp.

minimum

continuous

charging

load,

even

with

full

battery

(suggested

min.

battery

capacity:

9

amp.h).

Regulated

voltage

is

13.5

to

lQ.5

volts.

FORHISTORICALREFERENCEPURPOSESONLY:THISINFORMATIONMAYBEOUTDATED!

.

.

'

-

12

-

in

a

circuit

without battery

WIRING-DIAGRAM

FOR

RECTIFIER-REGULATOR

866

080

red

yel

black

866 080

yel

green/black consumer

min.

1A

·

in

conjunction

~

a

battery

WIRING

DIAGRAM

FOR

RECTIFIER-REGULATOR

866 080

green

fuse

16A

yel red

1

866

I

;

-

080

-

yel

con-

green/black

12

V

sumer

-

_J_

-

WIRING

DIAGRAM FOR ELECTRIC

STARTER

green

yel

red

fuse

16A

08d

I

black

yel

green/black

>'0

Cd

--+--,,>,..r-,'a:

88

~

~

QI

.

.,

88a

~

.

....

III

85

86

"

starter

button~

1.

0----"

FORHISTORICALREFERENCEPURPOSESONLY:THISINFORMATIONMAYBEOUTDATED!

13

-

WIRING DIAGRAM

FOR

RECTIFIER-REGULATOR

264

870,

(not

limited

to

minimum

of

1

Ampere

consumption)

WIRING DIAGRAM

FOR

RECTIFIER-regulator_264

870

in

a

circuit

without battery

not

connected

0:0:

WO

•....•

1-

u..~

•...

.

•

_J

1-::>

U (!)

I

ww

'=t.

black

typical

use:

lights

or

other

resistiv

consumers

(only)

12V

WIRING

DIAGRAM

FOR

RECTIFIER-regulator

264

870

(in

conjunction

with

a

condensor

2000

~F)

.

..

not

connected

condensor_

2000

lJF

-!-

typical

use:

instruments,

lights

or

any

other consumers

CD

12V

WIRING

DIAGRAM

FOR RECTIFIER-REGULATOR

2

64 8

70

in

conjunction

with

a

battery

not

connected

typical

use:

electric

starter

or

any

other

consumers

.

.

~

.

>-:;;:

;

'" \0 '

41'"

:

•..

.

•.

•

>

:

]~

1.

.

starter

-J:..

I

swi

tch

..::c..~

1.

n

FORHISTORICALREFERENCEPURPOSESONLY:THISINFORMATIONMAYBEOUTDATED!

14

-

.

.

'

REWIND

STARTER

Pull

starter

grip

out

slowly

until resistance

is

felt,

then

pullout

vigorously

but

not

fully

up

to the

end.

As

far

as

possible

pull

in

the

direction

the

rope

comes

out

of

the

sheave.

By

a

rewind

spring

the

starter

grip

returns

to

its

original position. Don't

let

the

starter

grip

fly

.

b~ck.

Do

not

operate

the

engine

if

the

rewind

starter

is

defective.

r~~@~~.,

9

7 5

;;

8

6

3

CHANGING

THE

STARTER

ROPE

(The

numbers

stated

in

brackets

refer

to

the

illustration)

First

remove

snap

ring

(9),

loop

spring

(8),

circlip

(7),

pawl

lock

(6)

and

the

pawl

(5).

'

r

o

ol

.

s:

.

.

.

Snap

ring

tongs

screwdriver

FORHISTORICALREFERENCEPURPOSESONLY:THISINFORMATIONMAYBEOUTDATED!

.

.•

.15

-

,

,'

"

"

Pullout

the

starter

rope

fully

to

the

end,

hold

starter

" '

housing

(1)

and

rope sheave

(3)

together

in

their

position.

"

'

There

is

an

opening

in

the

rope

'

sheave. The

key

'

c

Larnp

:

(~

)

r

•

visible

in the

opening

has to

be

pushed

out in

the

opposite

sense

of

the

pulling

direction

~

Pull

the

'

rope

out

'

or

the

rope

sheave.

~hen

insert

the

new

starter

rope

into

the

rope

sheave,

mount

the

'

key clamp

in

the

same

position

aS

'

it

was

'

before

and remount

the

parts

5"

6,

'

1"

8

and'

9

~

.

'

Caution!

'

Do

not

remove spring

container

'

(2)

;

this

might

,

cause

injuries!

FORHISTORICALREFERENCEPURPOSESONLY:THISINFORMATIONMAYBEOUTDATED!

-

16

-

DECARBONIZING

After

approx.

50

hours

of

J.lse

the

combustion

chamber

should

be

de-carbonized.

To

do

so:

Remove

cylinder

head.

Hold

cylinders

in

place

by

suitable

means.

Using

a

scraper,

the

carbon

scales

on

the

combustion chamber

of·

the

cylinder

head

and

on

the

top

of

the

piston

should

be

removed.

Piston

at

top

dead

center

•

.

MAIN

TORQUING

SPECIFICATIONS

Nm

in.lb

Cylinder

head

nuts

M8

18

·

24

160

210

,-

,

,

Crankcase

screws

M6

8

·

10 70

·

88

H8

18

·

24

160

+

210

14agneto

housing

nut

(1-122

x

1,5)

80

+

90

710

.:.

800

·

Crankcase

nuts

(or

-screws)

Ml0

36

·

40

320

·

354

Exhaust manifold screws

M8

18

+

24

160

·

210

FORHISTORICALREFERENCEPURPOSESONLY:THISINFORMATIONMAYBEOUTDATED!

•

FORHISTORICALREFERENCEPURPOSESONLY:THISINFORMATIONMAYBEOUTDATED!

-

18

-

FAULT-TRACING

SCHEDULE

Open

the

fuel cock Probable

fault

~

no

•

..

..

Does

gasoline

reach

1

.

Gasoline

tank empty

""

the

carburetor?

2.

Blockage

in

tank

cap

yles

3.

Blockage

in fuel

cock

4

.

Blockage

in

fuel

line

5

.

Needle

valve blocked

Does

gasoline

reach

the

engine?

no

1.

Blockage

in

carburetor

yes

-~

yes

•...

Does

the

carburetor

.

..-

1

.

Float

stuck

keep

flooding?

2.

Float

leaks

I

3.

Needle

valve

does

not

no

seat

properly

Has

the

engine

become

wet

with

fuel?

yes

1.

Too

much

use

of

I

starter

2~

Faulty

ignition

system

3.

Incorrect

fuel

~ixture

no

~

Is

there

a

spark

at

the

no

<,

;,;-

1

.

Poor contact

between

spark

plug

protector? ignition

coil and

i~nition

,

cable

2.

Ignition

cable

broken

or

yes

short-circuiting

I

3.

Faulty ignition

coil

Change

e

spar

p

ug

,It

Is

the

engine

difficult

yes

....

1.

Faulty

ignition timing

,

/

to

start?

2.

Float

needle

does

not seat

I

properly

3

.

Air

cleaner blocked

no

4

.

Fault

in

carburetor

5

.

Defective

spar

k

plug

I

yes

I------~

1.

Electrode

gap

too

large

2.

Bridging

between

electrodes

3.

Insulator

broken

or

wet

4.

Spark

plug

oily

th

k

1

Is

there

a

spark

at

the

spark

plug?

no

FORHISTORICALREFERENCEPURPOSESONLY:THISINFORMATIONMAYBEOUTDATED!

Other manuals for 462

1

Table of contents

Other Bombardier-Rotax Engine manuals

Popular Engine manuals by other brands

YASKAWA

YASKAWA SGMAS user manual

Hacker

Hacker SKALAR 8 manual

SOMFY

SOMFY Movelite WireFree RTS instructions

Grundfos

Grundfos MGE Service Kit Instructions

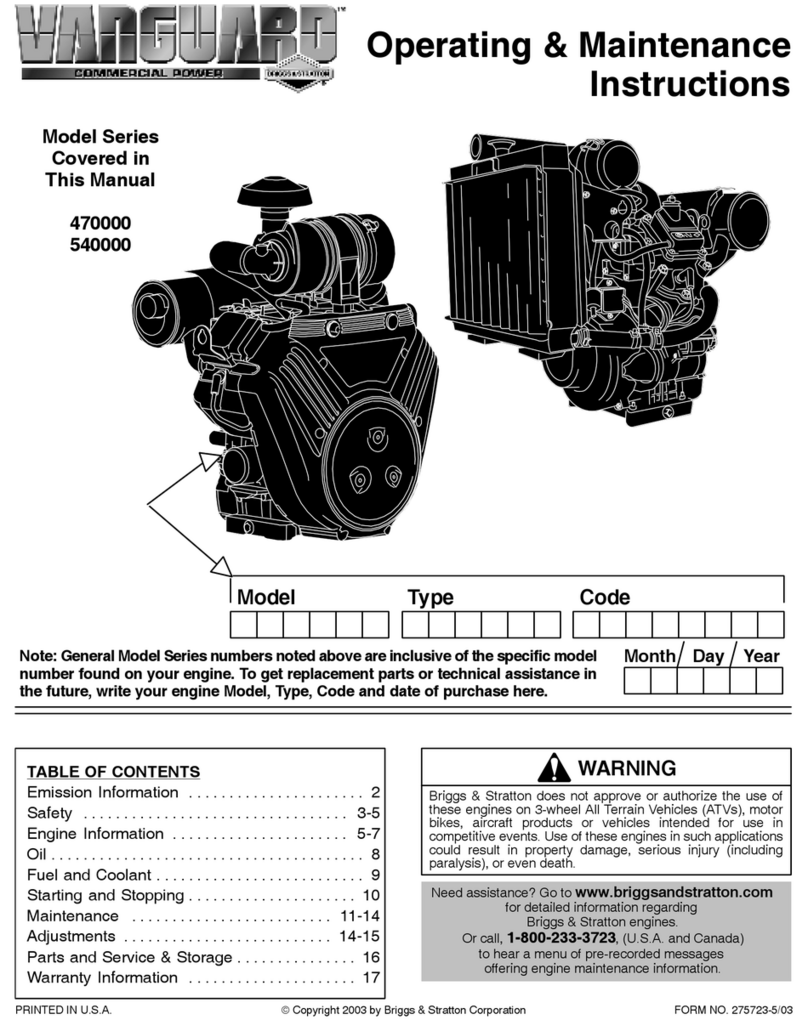

Briggs & Stratton

Briggs & Stratton Vanguard 470000 Series Operating & maintenance instructions

Sonex Aircraft

Sonex Aircraft Aerovee 2.1 Assembly and installation