Bomm STATIX DP User manual

MCH_HQ00

5

STATIX R DP

Crucibles: 350, 600 or 1000 cc

This instruction manual is an integral part of the machine supply

and should accompany it whenever it is moved.

The manual must be carefully kept for the duration of the

machine's life and must in all cases be available for at least 10

years, it must therefore be kept in a known location and made

available to all the personnel concerned.

Do not connect the machine or put it into operation until this

manual has been read.

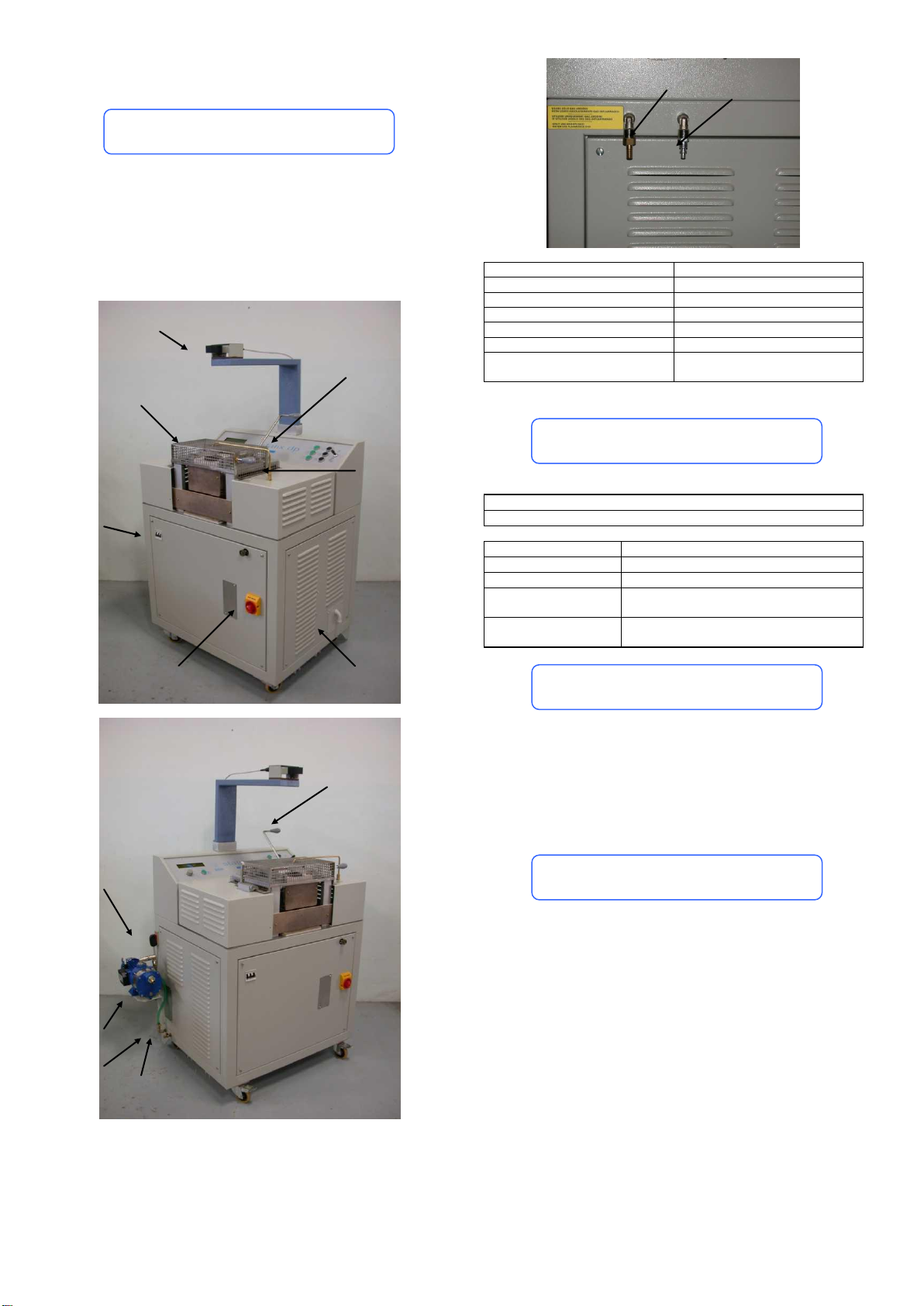

Pict.1

1 Optical reader

8 Water pump socket

2 Crucible lock lever

9 Water inlet pipe connection

3 Main switch

10 Water outlet pipe connection

4 Argon pipe

11 Water pump support

5 Casting area protection grid

12 Crucible tilting lever

6 Circuit breaker

13 Compressed air inlet

7 Power supply covering

panel

14 Argon gas inlet

STATIX F DP is avabile in the following versions:

380V 50-60Hz

Power

15kW

Depth

94 cm

Width

112 cm+ 20 cm for water pump

Height

117 cm + 34 cm of the optical reader

support

Controllable

temperature range:

800 1999°C

STATIX R DP is an electronic casting machine for alloys used in

jewellery technology field. Its aim is to melt by induction the alloy

placed in a special crucible. Once liquid the alloy can be poured

into the mold tilting the crucible by means of a special lever.

Any use other than the one described above is to be considered

improper and releases the manufacturer from all liability for

damage of any type and nullifies tha warranty rights on the

equipment itself.

The machine must be used by adult and suitably trained

personnel.

Given the weight of the machine, it must only ever be moved

with an appropriate trolley or on its wheels.

Never horizontally tilt the machine when moving or

transporting it. The machine must always rest on its feet.

If the machine needs to be moved after it has been installed,

always firstly empty the water from the tank.

Wear the dark glasses supplied. The light emitted from the

metal being cast could damage your sight.

Always use the relevant grips for removing the crucible.

Make sure that the electrical system has a ground fault

interrupter.

INTRODUCTION

SPECIFICHE TECNICHE

PURPOSE OF THE EQUIPMENT

PRECAUTIONS

TECHNICAL SPECIFICATIONS

1

3

6

7

2

5

12

4

14

13

10

9

11

8

MCH_HQ00

6

The machine is supplied in a wooden crate on a platform, proceed

ad follows to remove the packaging.

Cut the straps.

Remove the metal staples from the top of the crate and

remove the lid.

Remove the box of accessories and the electronic tube box

that are visible as soon as the crate is opened.

Remove the metal staples from the base of the crate.

Remove the side panels of the crate putting them upwards.

Remove the platform and stand the machine on the floor.

The machine must be placed in a dry and dust free premises, far

from boilers or flask furnaces, especially if they are gas-fired with

less than perfect draft.

.

Prepare a power lead consisting of three phase wires plus one for

ground connection. The cables must be of adequate cross-section

for the machine’s consumption requirement. Other user equipment

must not be connected on the machine line.

The machine must be connected to a socket suitable for the

power output and voltage as indicated on the rating and must be

grounded.

Power lead connection

1. Remove the terminal protection panel (7, pict.1) on the right

side of the machine.

2. Provide the ends of the cables with eyelets.

3. Loosen the nuts positioned on the line filters.

4. Insert the eyelets of the three phase cables on the screws

positioned above the line filters and the grounding connection

cable on the screw marked PE.

5. Secure the cables by means of the special nut.

Fitting the water pump

1. Unscrew the two bolts on the frame and use them to fix the

bracket supporting the water pump (11, pict. 1).

2. Pour water into the suction pipe while holding it upwards until

you see the water flow out of the outlet pipe, then place the

suction pipe into the tank and the outlet pipe into the water

inlet connector of the machine (9, pict. 1)

3. Connect a side of a pipe to the water outlet connector (10,

pict.1) and put the other side into the tank.

Fitting the tipping lever

Fit the tipping lever as shown in pict. 2.

Pict. 2

Fitting the optical reader

The optical reader is mounted on its support arm.

Fix the arm in the position illustrated in pict. 1 by means of the two

screws.

Connect the external socket that comes out of the back of the

optical reader.

Compressed air connection

Connect the machine to the external air compressor troughout the

suitable fitting (13, pict.1). For a correct driving of the heating coil

set the air pressure output at 6 bar minimum.

Pict. 3

1. Display

2. Encoder (by rotating it, it is possible to change the casting

parameter selected

3. Parameter selector (when pressed it changes the casting

parameter to be set: setpoint and casting power)

4. On button

5. Off button

6. Generator ON button

7. Generator OFF button

8. Casting ON button

9. Casting OFF button

10. Coil UP/DOWN lever (lever in up position = coil up, lever in

down position = coil down)

The display shown the following indications:

POWER SUPPLY

UNPACKING

POSITIONING

ACTIVATION

CONTROL PANEL

The machine must be earthed by law.

It must be installed by a qualified electrician capable of

checking that it is earthed.

The manufacturer declines all responsibility

for any damage or injury caused by failure

to comply with this requirement.

1

2

3

4

6

8

5

9

7

10

MCH_HQ00

7

P = XXX

PH = 0000

TEMP= 0850

T = 0900

P = 01250

ISW = 00.00

VTEST

TN = 040

TI = 060

OFF STOP

PHLIM

CR1

P

Casting power setted (min 260 –max 440)

T

Temperature to be reached

TEMP

Metal temperature measured

PH

Power output (min 260 –max 440)

P

Power output on the crucible ( kW)

ISW

Current measured on the power circuits

VTEST

This sign appears only when the machine si not heating. It

disappears when the casting is in ON.

TN

Power mosfet temperature (°C)

TI

Water cooling temperature (°C)

This symbol indicates that the machine is heating.

OFF

Generator status (OFF = not powered, ON= powered)

STOP

Heating status (STOP = not active, START = active)

PHLIM

It appears sometimes during the heating. Not relevant

CR1

It appears if the coil is down or if the casting protection

grid is open. When CR1 is present is not possible to start

casting

It is possible to set the parameters as below:

1. For changing the casting power press the parameters

selection button (3, pict.3) until the “>” symbol is visible near

to the P parameter:

P >XXX

PH = 0000

TEMP= 0850

T = 0900

P = 01250

ISW = 00.00

VTEST

TN = 040

TI = 060

OFF STOP

PHERR

CR1

or until the symbol is near to the T parameter to set the

casting temperature.

2. Rotate the encoder (2, pict.3) to change the parameter value.

Working parameters could be changed also when the casting is

ON: they are immediately executed.

1. Place the main switch (3, pict.1) at the position ON.

2. Turn on the automatic safety cut-out (6, pict.1).

3. Press the ON button (4, pict.3)

4. Set the working parameters as indicated in previous section.

5. Press the ON generator button (6, pict. 3): the OFF indication

on the display will disappear and it will be shown ON.

6. Put the crucible into its hole. Put the metal inside the crucible.

7. Lock the crucible with the crucible lock lever (2, pict.1)

8. Close the cating area protection grid (5, pict. 1)

9. Put the coil lever (10, pict.3) in up position: the casting coil will

rise up. If the coil doesn’t move, please check that the

machine is connected to the external compressed air supply.

10. Press the casting on button (8, pict.3) for start the casting.

Now the machine will start heating until the metal reach the

temperature setted. On the display the TEMP parameter will

shown the temperature of the metal.

When the metal is ready to be casted:

a. open the casting area protection grid (5, pict.1): casting

will be immediately stopped.

b. put the coil lever (10, pict.3) in down position.

c. Hold the crucible tipping lever (12, pict.1), pull with it the

crucible support, and after rotate the lever to pour the

crucible.

To stop in any moment the casting you can operate in one of the

following ways:

a. Open the casting area protection grid (5, pict.1)

b. Put the coil lever in down position (10, pict.3)

c. Press the casting OFF button (9, pict.3)

d. Press the generator OFF button (7, pict.3)

In all these situations the haeting will be stopped (STOP indication

on the display) and, except the (c) case, it will be also deactivated

the generator (OFF on display). To restart casting repeat the

wroking procedure from item (5).

NOTE: NEVER SWITCH OFF THE MACHINE (by pressing OFF

button (5, pict.3) or by puttin in OFF position the automatic safety

cutout (6, pict1) or the main swicth (3, pict.1)) WHEN THE COIL

IS UP AND WITH A WARM CRUCIBLE INSIDE. Risk to damage

the heating coil.

The reader is pre-set for all types of alloy. It is only necessary

to move a switch on the reader itself when the alloy has a very

high platinum content.When you wish to melt these types of

alloy slightly unscrew the four screws holding the cover. Move

the switch as shown in figure 6.

Always check that the mirror and the lens of the reader is

completely clean. The mirror is easy to get at. The lens is in a

horizontal position towards the instrument (fig. 6).

Fig. 6

Do not tamper with the two screws under the temperature

setter display.

Use very clean metal making sure that the recast heads are

sanded properly in such a way that all traces of coating that

could cause porosity are removed. Do not melt metals

covered in oil or grease etc.

Never leave the hot crucible in the heating coil of a machine

that is completely off and, generally, whenever water is not

circulating (lack of water, no power).

While melting inside the heating coil is under way, a high

frequency current flows through the metal.

Under no circumstances touch the coil or metal with hands or

metallic objects since you would risk getting a shock that while

not being dangerous is unpleasant.

Note:only use ceramic stirring rods to mix the metal while it is

melting.

WORKING PROCEDURE

WARNINGS

PARAMETERS SETTINGS

WARNINGS

MCH_HQ00

8

ALLOY

MELTING

TEMPERATURE

FLASK

CASTING

TEMPERATURE

SILVER FINE

961

427

SILVER (STERLING)

893

427

GOLD 10 K YELLOW

907

510

GOLD 14 K YELLOW

879

482

GOLD 18 K YELLOW

927

482

GOLD 10 K WHITE

1052

538

GOLD 14 K WHITE

996

510

GOLD 18 K WHITE

943

482

BERYLIUM COPPER

982

427

PLATINUM

1773

871

HERCULOY

927

482

BRON-WHITE

843

482

SILICON BRONZE

971

482

REYART

927

482

Note

1. Casting temperature should be approximately 40 - 70°C above

melting temperature.

2. Melting temperature will vary slightly according to the alloy

used.

3. Flask temperature will vary depending on the quantity of

casting.

4. Pure silver melts at 961°C.

5. Pure gold melts at 1063°C.

The device is guaranteed for 12 months.

The warranty is cancelled in cases of improper use, tampering or

the use of non-original spare parts.

The warranty is automatically cancelled in the event that crucibles

that are not of our production are used on the device.

Failure to return the Warranty Card, implies the immediate

cancellation of the same.

The warranty does not cover labour or transport charges that

are always and in all circumstances to be borne by the

purchaser.

WARRANTY

CASTING TEMPERATURE CHART

WARRANTY

This manual suits for next models

2

Popular Test Equipment manuals by other brands

Alcohawk

Alcohawk AT7000 Operation manual

R&S

R&S RTO6 Getting started

Agilent Technologies

Agilent Technologies 54622A user guide

Frye

Frye FONIX FA10 manual

The Diagnostic Box

The Diagnostic Box TDB760 operating manual

MAHA Maschinenbau Haldenwang

MAHA Maschinenbau Haldenwang MPP 2140 Original operating instructions

Schumacher Electric

Schumacher Electric PTI100 owner's manual

Tektronix

Tektronix SC 501 instruction manual

Rohde & Schwarz

Rohde & Schwarz RTM2032 user manual

MULTI MEASURING INSTRUMENTS CO.,LTD.

MULTI MEASURING INSTRUMENTS CO.,LTD. MIS-2D instruction manual

Hioki

Hioki 3554 instruction manual

Sealey

Sealey Auto Service Line VS2030 instructions