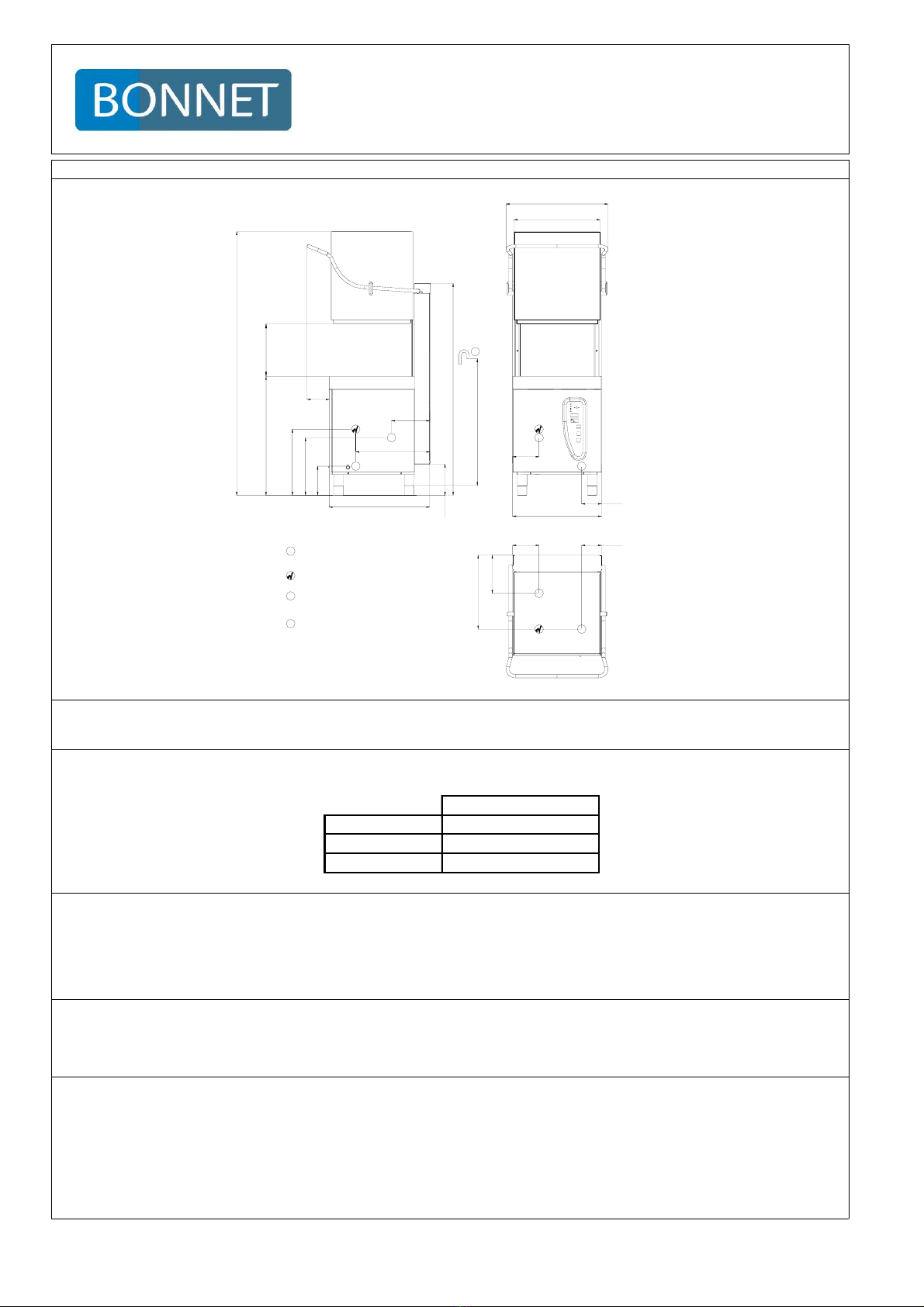

DISHWASHER INO 81 Code NU271706-02/04

Chap. 2 – Page 3

2.4 CONNECTION

Electrical connection

* Electrical connection

Before connecting the dishwasher, make sure that the voltage and frequency of the electrical network

correspond to those indicated on the manufacturer’s nameplate fitted on the dishwasher.

Before connecting to the electrical network, make sure that the supply line is not switched on.

Efficient earthing, imposed by the preventive standards in force, is a safety measure for the

operator and the dishwasher.

It is necessary to verify this basic principle. In case of doubt, a careful check of the installation must be

made by the qualified personnel who have been called in to connect the machine to the network.

Additionally the dishwasher has to be included in an equipotential system where the connection is

made by means of a screw marked by the symbol Ø. The equipotential conductor must have a

10mm² cross section.

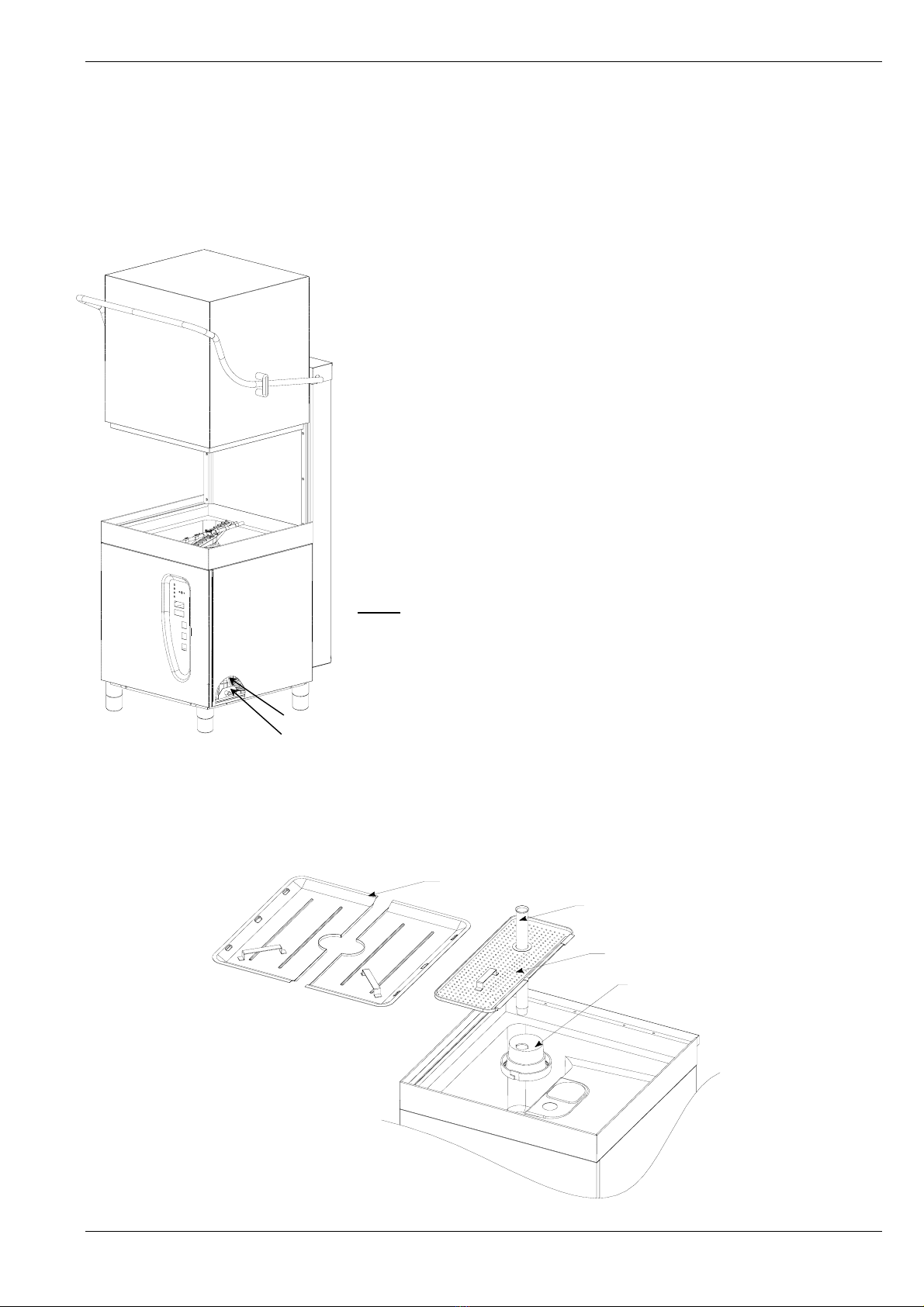

The equipotential stud is located behind the dishwasher on the bottom right side.

Connect the dishwasher according to the type of voltage required; refer to the firm plate (located on the

bottom right of the right side trimming) to check of the voltage type of the dishwasher.

Your dishwasher is delivered with a 2 metres long cable; the dishwater may be connected to :

- 400 V3N~50 Hz

- 230 V3~50 Hz

The supply cable can only be replaced by a cable having the same section of the HO7RN.F type.

Allow for an omnipolar separation device homologated for personal safety, (with an opening

distance between contacts of at least 3mm).

THE INSTALLATION MUST BE COMPLIANT WITH THE NFC 15100 STANDARD.

Hydraulic connection

Before connecting the dishwasher, make sure that a valve has been inserted between the water supply

network and the dishwasher so as to be able to shut off supply whenever needed or in case of repair.

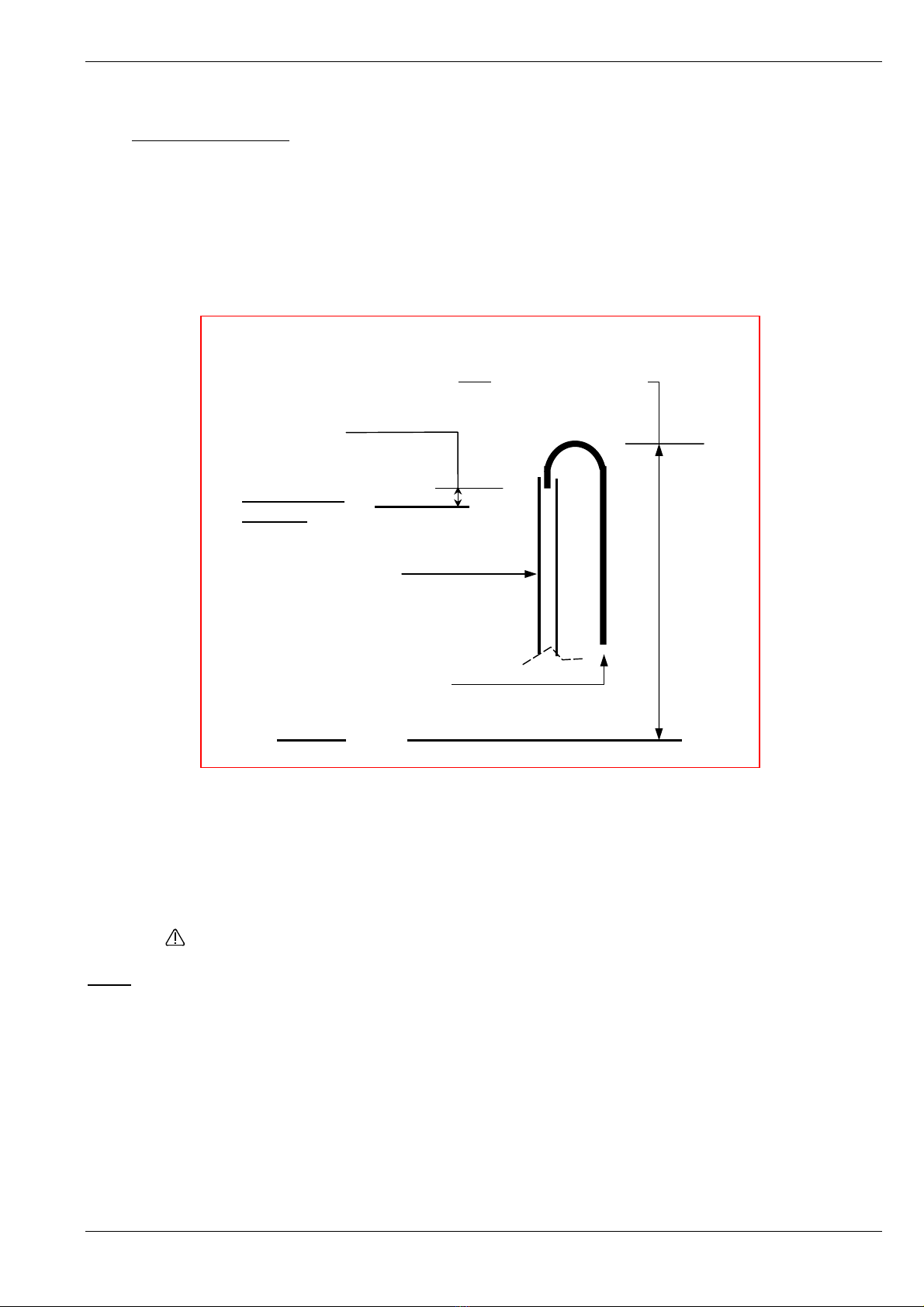

The minimum supply pressure measured at the water inlet to the dishwasher on final rinsing (rate

pressure), even when other taps are open on the same line, must correspond to the chart of technical

characteristics Chap. 1 - 1.