1

Installation and Maintenance Manual

Version : 10//28/2011

Issue : THT-100-IMM-USA REV A6

TABLE OF CONTENTS

GENERAL INFORMATION................................................................................................... 3

1 Introduction................................................................................................................... 3

1.1

COPYRIGHT................................................................................................................................ 3

1.2

LIABILITY.................................................................................................................................... 3

1.3

PRODUCT MODIFICATIONS........................................................................................................... 3

1.4

PRODUCT OPTIONS..................................................................................................................... 4

1.5

ABBREVIATIONS.......................................................................................................................... 4

1.6

SYMBOLS ................................................................................................................................... 4

2 Product Safety............................................................................................................... 4

2.1

INSTALLATION AND MAINTENANCE SAFETY ................................................................................... 4

2.2

OPERATIONAL SAFETY................................................................................................................ 5

3 Product description ...................................................................................................... 6

3.1

GENERAL ................................................................................................................................... 6

3.2

SHIELD OPTIONS ........................................................................................................................ 7

3.3

BARRIER ASSEMBLY OPTIONS..................................................................................................... 8

3.4

CEILING PLATE........................................................................................................................... 8

3.5

ROTOR ARM OPTIONS ................................................................................................................ 9

3.6

ROTOR INFILL COVERS (OPTION) .............................................................................................. 10

3.7

TOP CHANEL COVER OPTIONS .................................................................................................. 10

3.8

CONTROL SYSTEM.................................................................................................................... 12

3.9

SPEED CONTROL UNIT .............................................................................................................. 13

4 Operating concept ...................................................................................................... 14

4.1

OPERATING FUNCTIONS ............................................................................................................ 14

4.2

ACCESS CONTROL SYSTEM (ACS)............................................................................................. 15

4.3

SECURITY ................................................................................................................................ 15

4.4

OPTIONAL AND CONFIGURATION FEATURES ............................................................................... 16

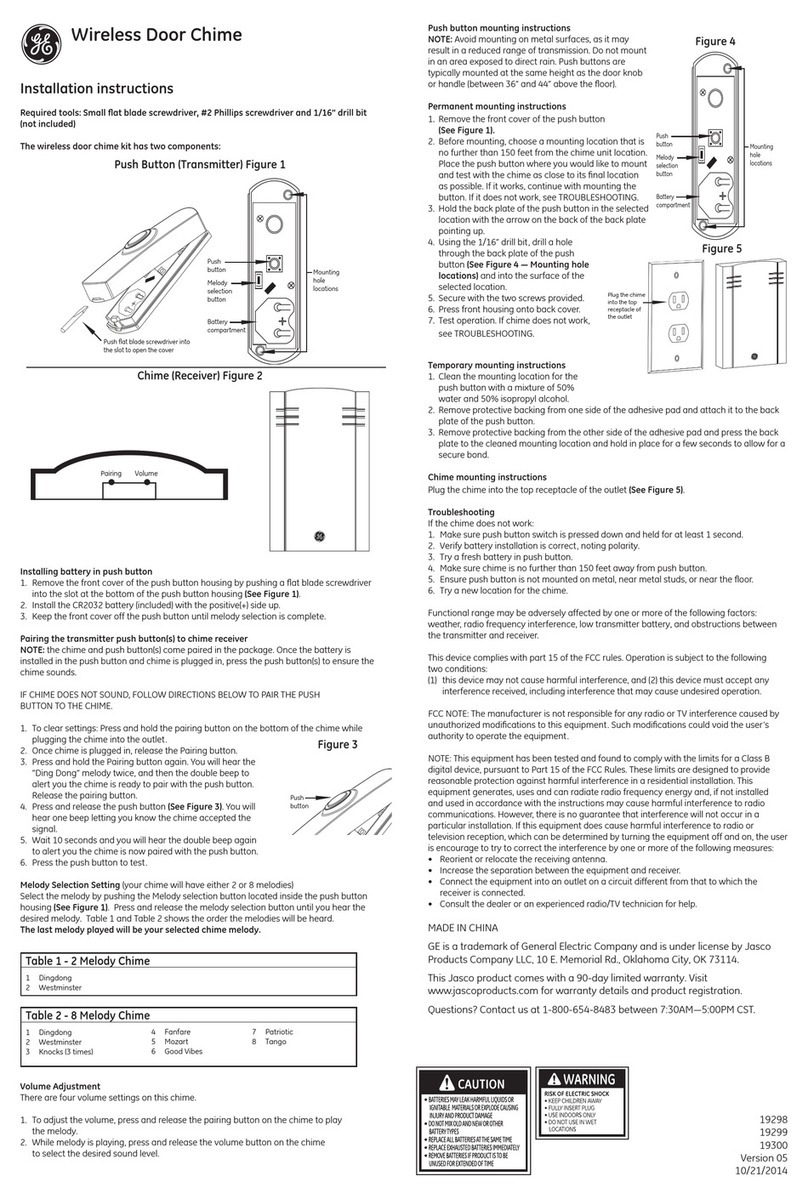

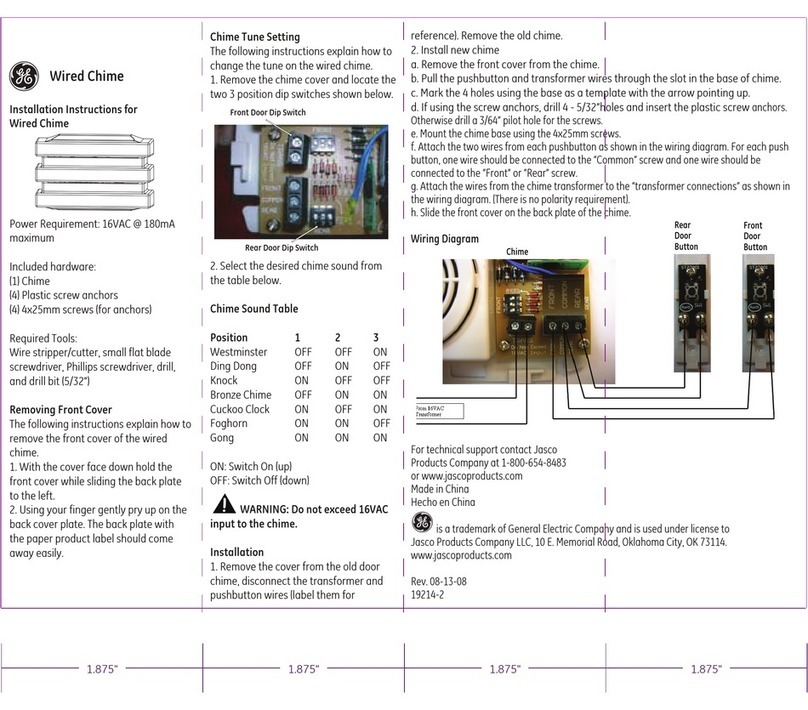

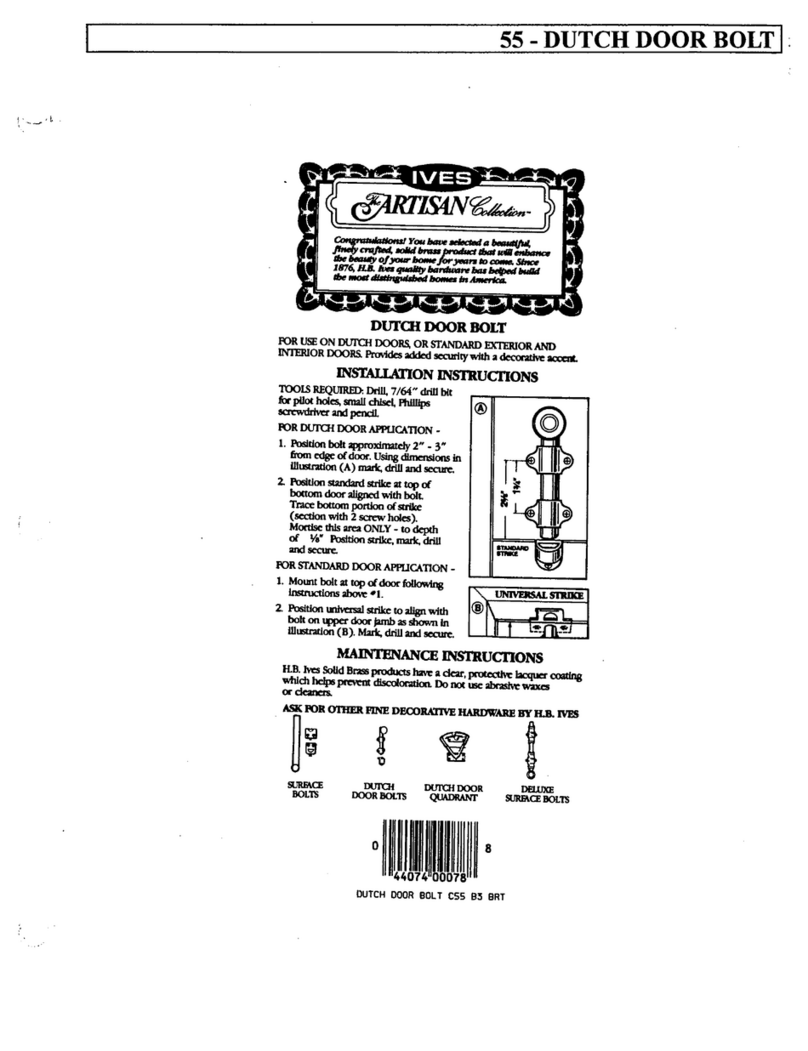

INSTALLATION .................................................................................................................. 19

5 Installation procedure................................................................................................. 19

5.1

PACKAGING AND CRATING......................................................................................................... 19

5.2

TOOL AND MANPOWER LIST ...................................................................................................... 20

5.3

BOLT TORQUE SPECIFICATIONS ................................................................................................ 20

5.4

ANCHOR TECHNIQUES .............................................................................................................. 20

5.5

ANCHOR LOCATIONS................................................................................................................. 21

5.6

FLOOR LAYOUT......................................................................................................................... 22

5.7

MECHANICAL ASSEMBLY ........................................................................................................... 23

5.8

ELECTRICAL INSTALLATION........................................................................................................ 30

5.9

MAIN CONTROL BOX................................................................................................................. 31

5.10

CONFIGURATION....................................................................................................................... 34

5.11

GENERAL ................................................................................................................................. 35

5.12

TIME OUT RELAY ADJUSTMENT ................................................................................................. 35

5.13

SPEED CONTROL ADJUSTMENT (OPTIONAL) .............................................................................. 35

6 Parts Overview ............................................................................................................ 36

6.1

THT100- EXPLODED VIEW ....................................................................................................... 36

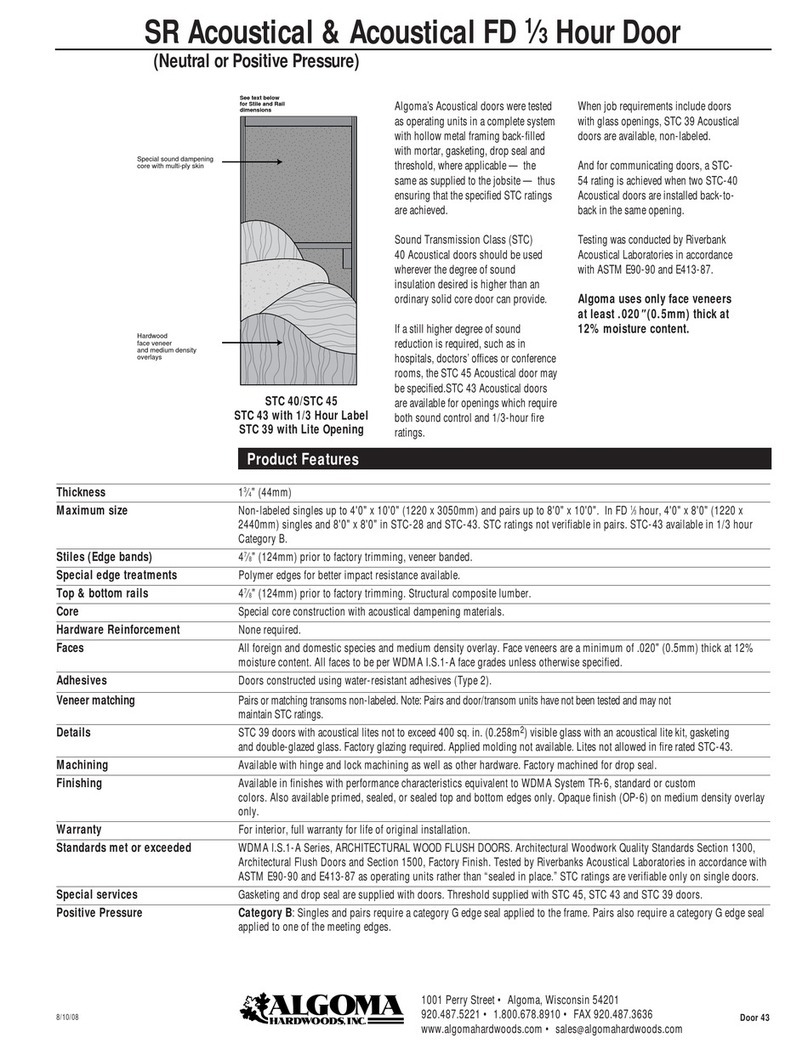

Safety INSPECTIONS and MAINTENANCE ...................................................................... 37

7 Safety Inspections ...................................................................................................... 37

7.1

DAILY INSPECTION.................................................................................................................... 37

8 Maintenance ................................................................................................................ 37

8.1

WEEKLY CLEANING................................................................................................................... 37

8.2

SEMI-ANNUAL PLANNED MAINTENANCE ..................................................................................... 37

8.3

MAINTENANCE CHECKLIST......................................................................................................... 39

9 Troubleshooting.......................................................................................................... 40