Booth EXL95H User manual

1

Product Manual

EXL95H/96H

Chiller/Cooler Carbonator

3B7961-OR

2

Contents

Section

Page

Section

Page

Introduction & Specification

2-3

Fault Finding

16-17

Model Numbering, Installation &

Commissioning

4-6

Replacement Parts

18-21

Wiring Schematics & Water

Circuits

7 -15

Removal, transportation

and Disposal

22

Introduction

The EXL95H & EXL96H units are med/high capacity chillers incorporating soda recirculation which

include an option of a cold carbonator incorporating soda recirculation. It is designed in a modular fashion

to cover a range of control options, with a single mechanical thermostat, or a choice of two digital

thermostats which are specified at time of order. They also have the capacity to incorporate up to 6 syrup

cooling coils.

The wiring schematics included in the following pages reflect this modularity:

Safety

The EXL95H/96H models use a R290 (Care 40, Propane) refrigerant. Below are some safety points

which the end user must adopt to mitigate the risk of unsafe conditions arising.

Service must only be carried out by a suitably qualified refrigeration engineer.

The unit must be isolated from the electricity supply before removal of the covers.

Do not damage the refrigeration circuit.

Ventilation openings must be clear of obstructions.

There must be a gap of at least 100mm between the appliance and a wall or other restriction.

Where electrical components are replaced, the new component must be of the same type.

Operate the unit within (ambient) operating temperatures; 10⁰C to 32⁰C.

Introduction and Specification

3

Specification

Dimensions

780mm(W)

Compressor

Cubigel

455mm(D) (EXL95H)

NPY12LAb (EXL95H)

512mm(D) (EXL96H)

NLY12RAa (EXL96H)

520mm(H)

This product contains Propane Refrigerant gas with a

GWP of 3 in a hermetically sealed system

Dry Weight

EXL95HX –49Kg

EXL95HC - 59Kg

Refrigerant

R290, 105g (EXL95H)

EXL96HX –55Kg

R290, 80g (EXL96H)

EXL96HC - 65Kg

Rated Current

EXL95HX –3.1A

Wet Weight

EXL95HX –81.5Kg

EXL95HC –4.0A

EXL95HC –91.5Kg

EXL96HX –4.9A

EXL96HX –87.5Kg

EXL96HC –6.0A

EXL96HC –97.5Kg

Fuse Rating

10A

Supply

230Vac/50Hz

CO2 Pressure

4 bar

Rated Input

EXL95HX –690W

Climatic Class

N

EXL95HC - 848W

Nominal ice bank

9kg

EXL96HX –935W

Potable water inlet pressure

1 bar min

EXL96HC - 1136W

4 bar max

Introduction and Specification

4

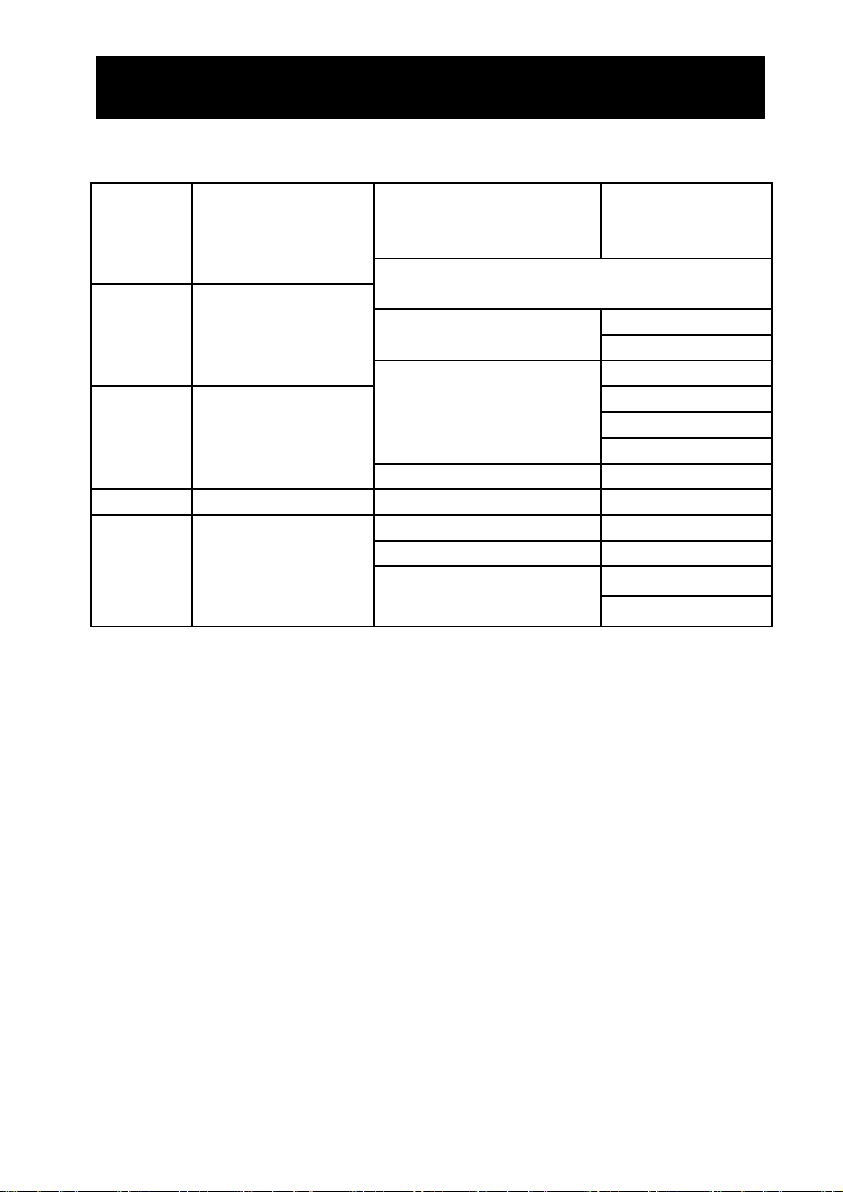

Unit Number

(W)

(X)

(Y)

(Z)

Key:

(W)

Base Type

(X)

Deck Option

(Y)

Control Option

(Z)

Coil Option

Reference

Part No

Description

(W)

Base Type

EXL95H

EXL95H

Intergral Base Unit

EXL96H

EXL96H

Split Base Unit

(X)

Deck option

CRV

1A6587

Carbonator Deck + Rotary Vane Pump

C

1A6615

Carbonator Deck + GPR10-15 Pump

CMD

1A6672

Carbonator Deck + Mag Drive Pump

XRV

1A6591

Non-Carbonator Deck + Rotary Vane Pump

X

1A6614

Non-Carbonator Deck + GPR10-15 Pump

XMD

1A6673

Non-Carbonator Deck + Mag Drive Pump

(Y)

Control Type

Z

1A6543

DFx Digital Control

A

1A6544

Eliwell Digital Control

B

1A6545

EXL95H Mechanical Control

1A6712

EXL96H Mechanical Control

(Z)

Coils

0

1A6671

0 Coil Pack

6

1A6670

6 Coil Pack

Model Numbering, Installation and Commissioning

5

Installation and Commissioning

The unit must be installed by a competent person, on a firm level surface capable of supporting the

weight of the machine when the bath is filled, and all connections made. Please ensure that the unit is

positioned at least 100mm from any other surfaces, as it is important that the ventilation openings in the

machine are not blocked and allow the free movement of air for both the carbonator & non-carbonator

version. Inadequate ventilation will shorten the life of the fridge system.

Locate a container beneath the bath overflow to prevent any water spillage as ice is formed in the bath,

and fill the bath with cold water until it comes out of the overflow.

For the EXL95H/96H Carbonator Deck

Turn off the soda recirc pump and disable the can fill circuit by means of the 2 switches located on the

front of the unit. Important: Great caremust be taken on commissioning the machine when power

is applied to the unit. Power may now be applied to the machine to allow the fridge to form an ice bank

while the rest of the system is installed.

Connect the water inlet to a potable water supply, connect the soda recirc lines to the bulkhead

connectors, and then connect the CO2 inlet but do not turn on just yet.

Turn on the water supply and turn on the can fill circuit (black switch). Allow the can to carb can to fill

with water. The can fill pump will switch off once the can is full, this should take between 5-10 seconds.

Installation & Commissioning

6

Turn on the CO2 and purge the carbonator vessel by lifting the ring lever of the pressure relief valve on

top of the can, and let gas flow for up to 5 seconds.

Switch on the soda recirc pump (green switch) ensuring that the water supply is on. The rest of the circuit

should now be primed and as much air as possible removed from the circuit. The lifespan of the recirc

pump will be shortened if it is allowed to run dry for prolonged periods.

To achieve optimum carbonation, all air must be purged from the pipework, carbonator can, and the

soda recirc circuit. All air from the circuit will tend to be pumped back to the can, so it is suggested that

this be vented regularly while the circuit is being primed.

Optimum carbonation will only be achieved once the fridge has achieved normal working temperature

and there is ice present in the bath. It is also advisable to initially pull off approx. 1ltr –2litres of

carbonated water per dispense point to allow the carbonated water to circulate round the system.

For the EXL95H/EXL96H Non-Carbonator Deck

Connect the ‘still water in’coil to a potable water supply, connect the recirc lines to the bulkhead

connector and the ‘recirc in’ coil.

Connect your supply of soda water to the ‘soda in’ coil.

Power may now be applied to the machine to allow the fridge to form an ice bank.

Installation & Commissioning

7

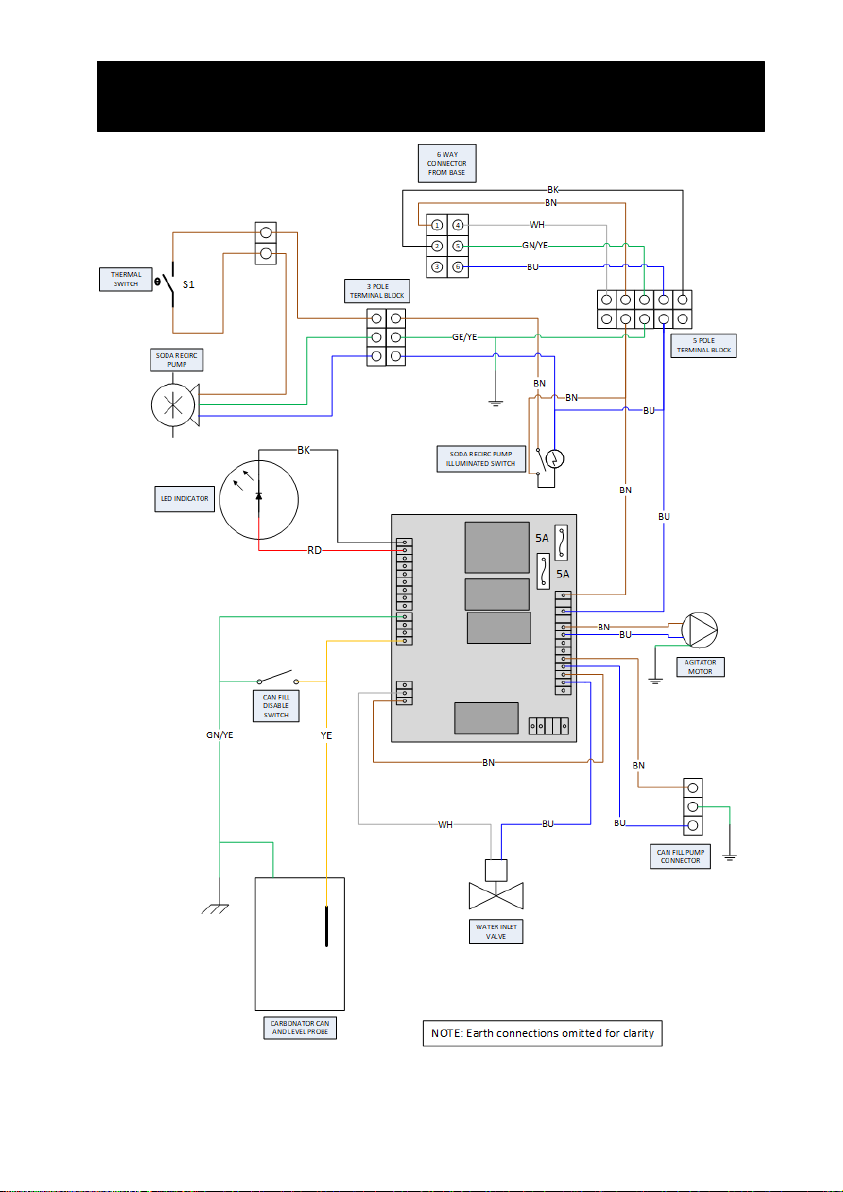

Schematics –EXL95H Base Wiring

1

2

3

4

5

6

G/Y

BR

COMPRESSOR

FAN OR

GLYCOL PUMP

BU

BU

BU

BR

WH

WH

WH

BU

BU

CONTROL

MODULE

IEC TO DECK

1

2

3

BNBU

BU

BN

BN

GN/YE

YE

BK

RD

LED

INDICATOR

NOTE: Earth connections omitted for clarity

BN

BU

BN

BU

GN/

YE

BN

BU

BN

to

CAN FILL PUMP

CONNECTOR

IEC FROM

BASE

TERMINAL

BLOCK

SODA RECIRC PUMP

THERMAL TRIP

SODA RECIRC PUMP

ILLUMINATED SWITCH

SODA RECIRC

PUMP

WATER INLET

VALVE

CARBONATOR CAN

AND LEVEL PROBE

GN/

YE

BN

BU

AGITATOR

MOTOR

5A

5A

8

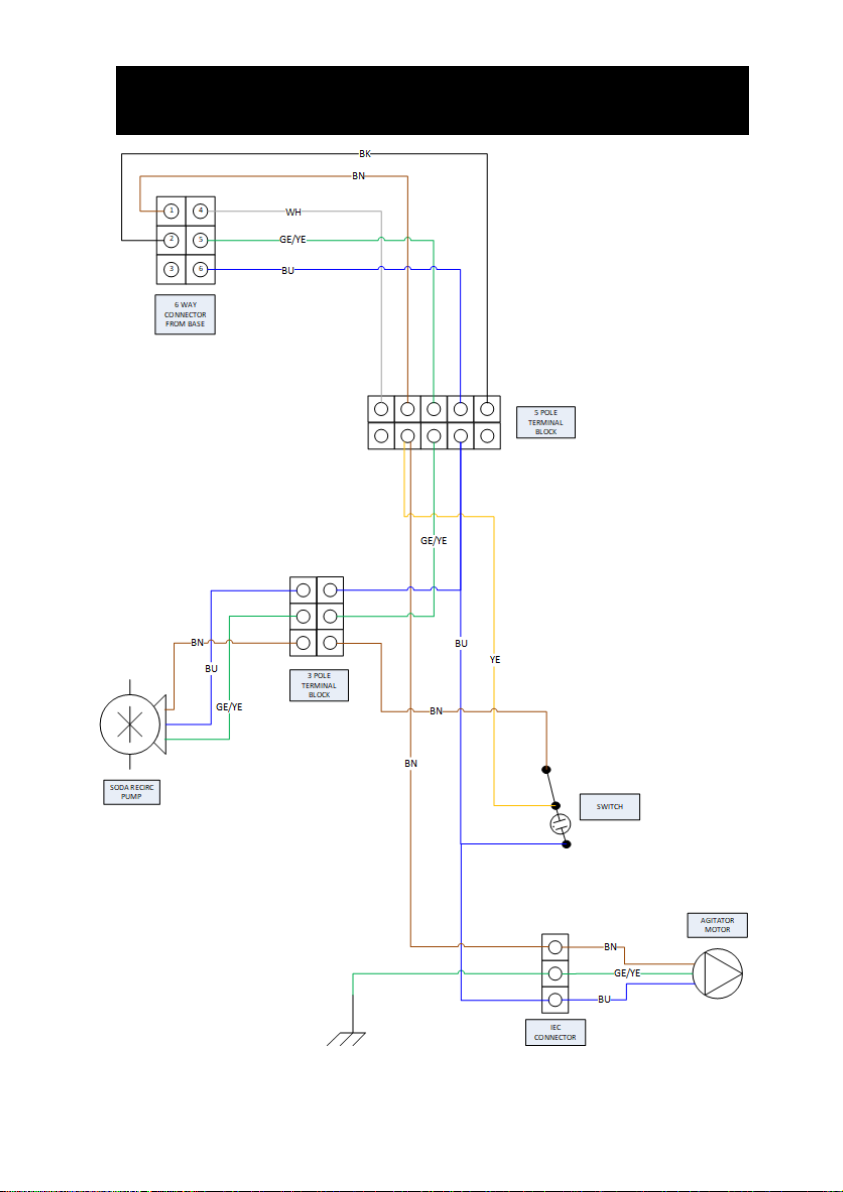

Schematics –EXL96H Base Wiring

1

2

3

4

5

6

G/Y

BR

COMPRESSOR

FAN OR

GLYCOL PUMP

BU

BU

BU

BR

WH

WH

WH

BU

BU

CONTROL

MODULE

IEC TO DECK

1

2

3

BNBU

BU

BN

BN

GN/YE

YE

BK

RD

LED

INDICATOR

NOTE: Earth connections omitted for clarity

BN

BU

BN

BU

GN/

YE

BN

BU

BN

to

CAN FILL PUMP

CONNECTOR

IEC FROM

BASE

TERMINAL

BLOCK

SODA RECIRC PUMP

THERMAL TRIP

SODA RECIRC PUMP

ILLUMINATED SWITCH

SODA RECIRC

PUMP

WATER INLET

VALVE

CARBONATOR CAN

AND LEVEL PROBE

GN/

YE

BN

BU

AGITATOR

MOTOR

5A

5A

9

Schematics –EXL95H/96H GPR10-15 Pump Carb Deck Wiring

10

Schematics –EXL95H/96H RV/Mag Drive Pump Carb Deck Wiring

11

Schematics –EXL95H/96H GRP10-15 Non Carb Deck Wiring

12

Schematics –EXL95H/96H RV/MAG Drive Non Carb Deck Wiring

13

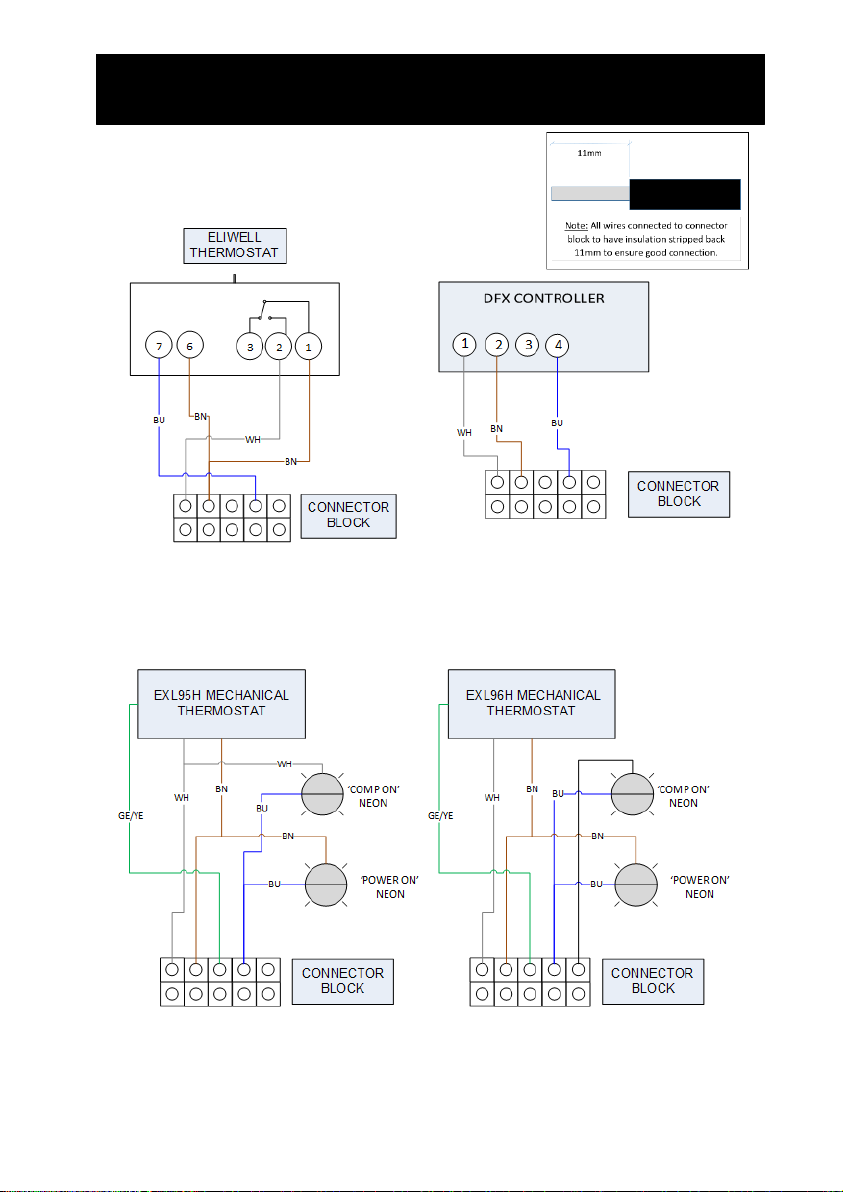

Schematics –Module wiring

14

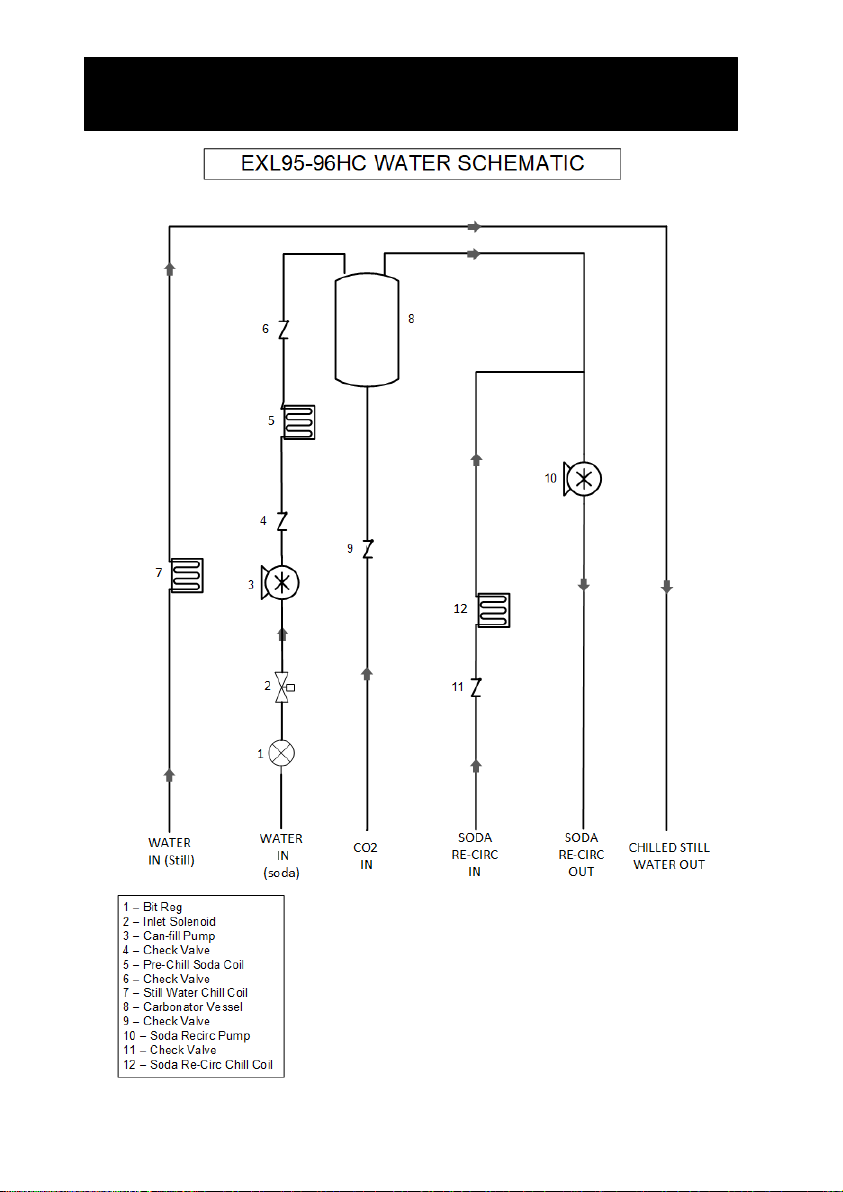

Schematics –EXL95H/96H Carb Deck Water Circuit

15

Schematics –EXL95H/96H Non Carb Deck Water Circuit

16

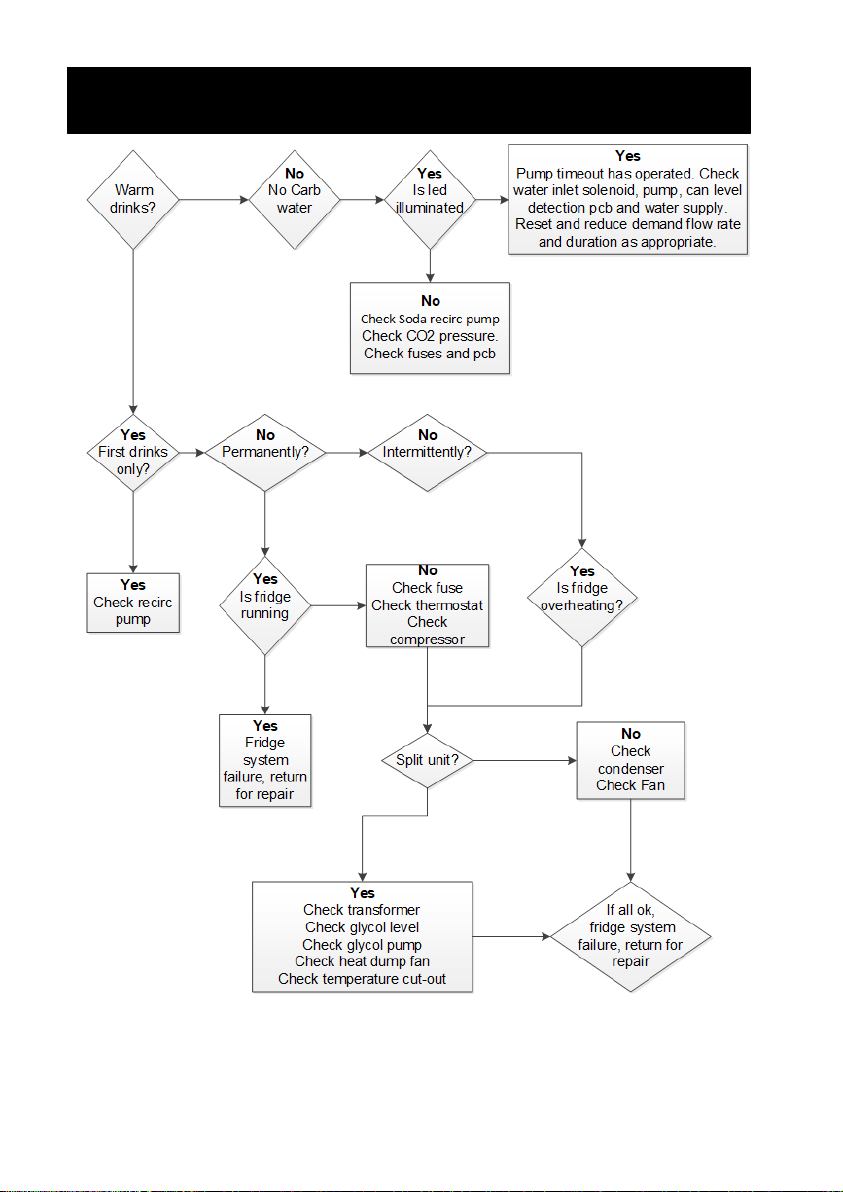

Fault Finding –EXL95H/96H Carb Deck

17

Fault Finding –EXL95H/96H Non Carb Deck

18

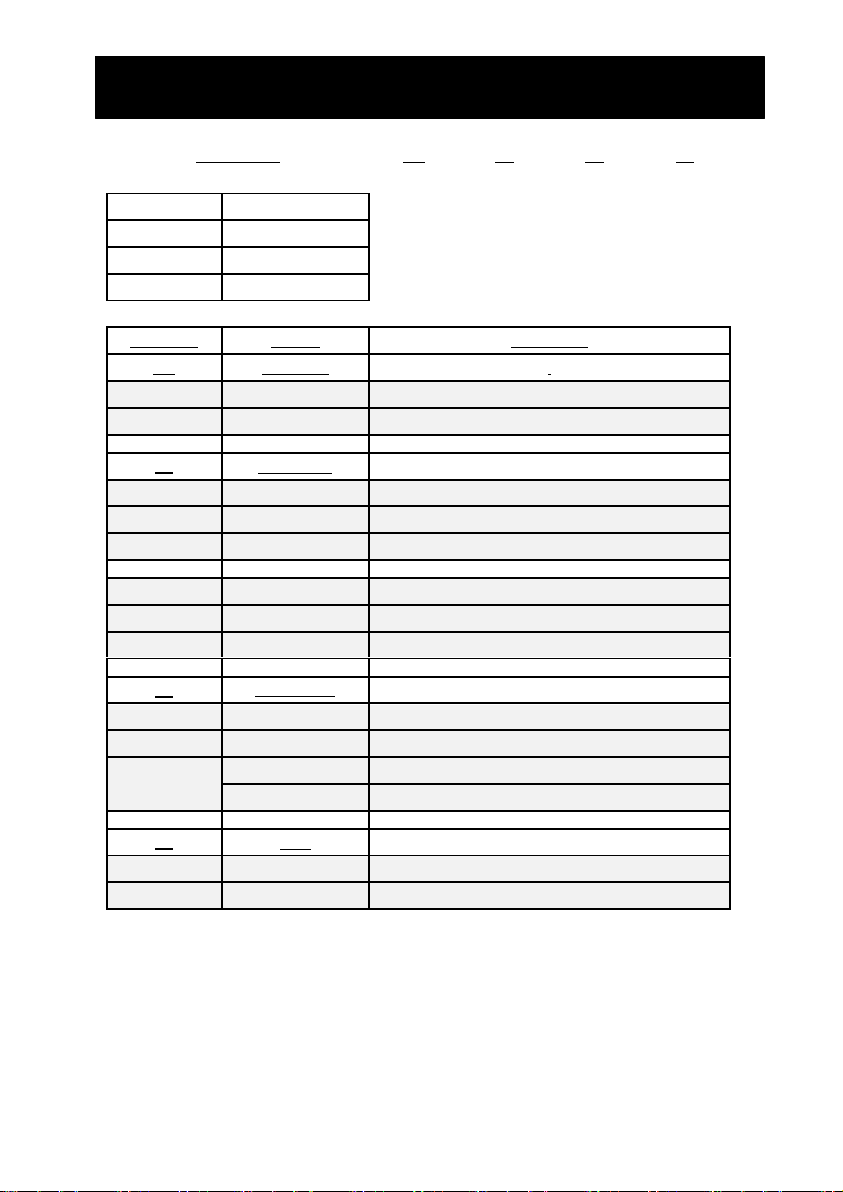

Item No

Description

Part No

1

PCB

1A5417

2

Soda recirc pump GPR10-15

1A6677

Soda recirc pump RV Motor Only

1A5368

Soda recirc pump RV Pump Head Only

1A5907

Soda recirc pump Mag Drive

3B7844

3

Water Inlet Solenoid

3B3641

4

Can fill pump motor only

3B3136

5

Can fill pump head assembly

3B6321

6

Agitator

3B3333

1

2

3

6

5

4

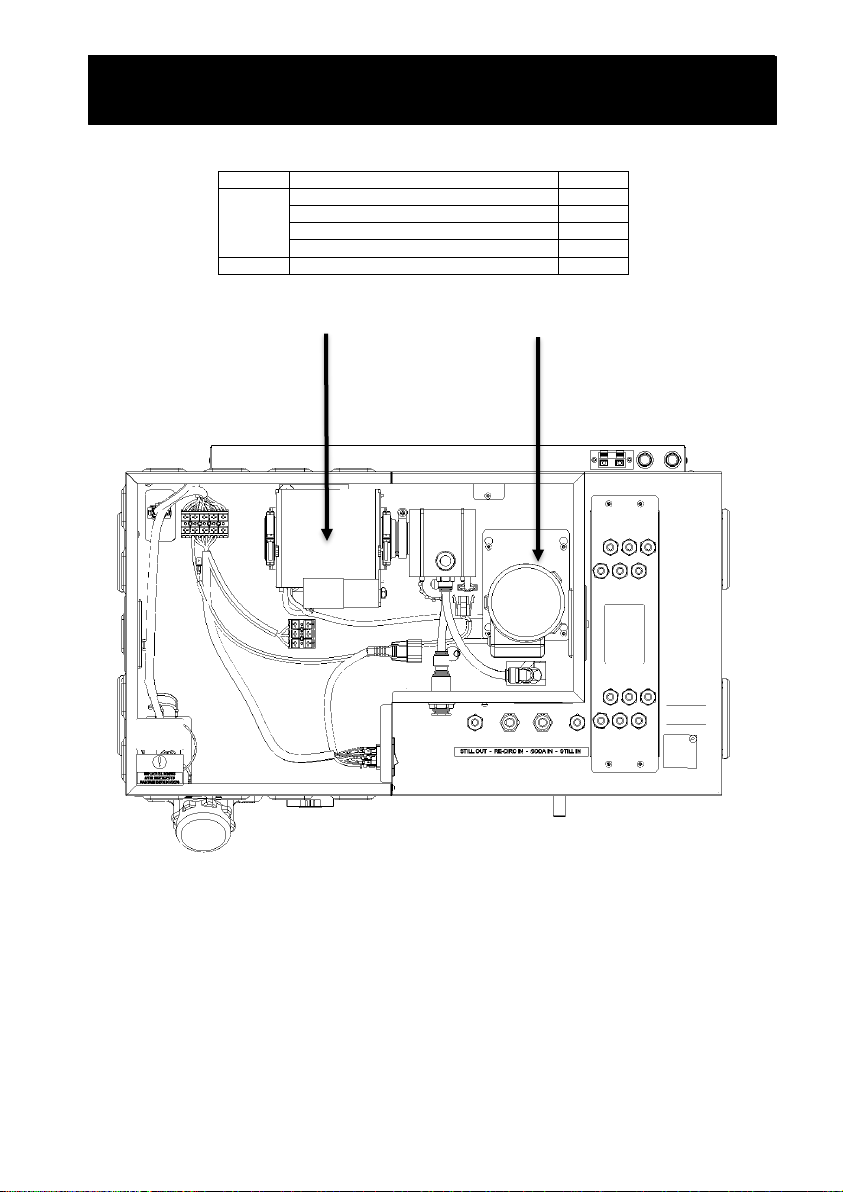

Replacement Parts –EXL95H/96H Carb Deck

19

Item No

Description

Part No

1

Soda recirc pump GPR10-15

1A6677

Soda recirc pump RV Motor Only

1A5368

Soda recirc pump RV Pump Head Only

1A5907

Soda recirc pump Mag Drive

3B7844

2

Agitator

3B3333

Replacement Parts –EXL65H Carb Deck

1

2

Replacement Parts –EXL55H Non Carb Deck

Replacement Parts –EXL95H/96H Non Carb Deck

20

Item No

Description

Part No

1

Condenser Fan Motor

CPART0045S

Control Modules

Mechanical Thermostat

Eliwell Control

Eliwell 1.5m Probe

DFx Control

1A6636

3B3472

3B4341

1A5625

1

Replacement Parts –EXL95H Base

This manual suits for next models

1

Popular Chiller manuals by other brands

Carrier

Carrier Aquaforce 30XA Series Operation instructions

Carrier

Carrier AquaEdge 19DV series Controls operation and troubleshooting

York

York YR owner's manual

Johnson Controls

Johnson Controls York YKEP Series manual

York

York YCAL0065 user manual

Trane

Trane Agility HDWA Installation, operation and maintenance