2YORK INTERNATIONAL

TABLE OF CONTENTS

GeneralInformation .......................................................................................... 2

Typical Nomenclature ....................................................................................... 3

UnitComponents ............................................................................................. 4

CompressorComponents................................................................................. 5

OperationalLimitations..................................................................................... 6

Physical Data .................................................................................................. 8

Dimensions ...................................................................................................... 10

Electrical Data ................................................................................................. 12

Installation........................................................................................................ 16

WeightDistribution and IsolatorLocations........................................................ 18

WiringDiagrams .............................................................................................. 20

UnitControlsandOperation ............................................................................. 31

Display Keys.................................................................................................... 34

Status Key....................................................................................................... 39

Entry Key......................................................................................................... 42

ProgramKey.................................................................................................... 43

Clock Keys ...................................................................................................... 47

SelectionofReturnor Leaving Chilled Liquid .................................................... 50

Setpoints Keys ................................................................................................ 51

System Safeties .............................................................................................. 61

Print Keys........................................................................................................ 67

Unit On / Off Switch ......................................................................................... 74

CompressorCapacityControl........................................................................... 80

System Startup Checklist ................................................................................ 81

PreventativeMaintenance................................................................................. 86

Options ............................................................................................................ 88

TroubleshootingChart ...................................................................................... 106

TemperatureConversionTables ........................................................................ 110

GENERAL INFORMATION

GENERALDESCRIPTION

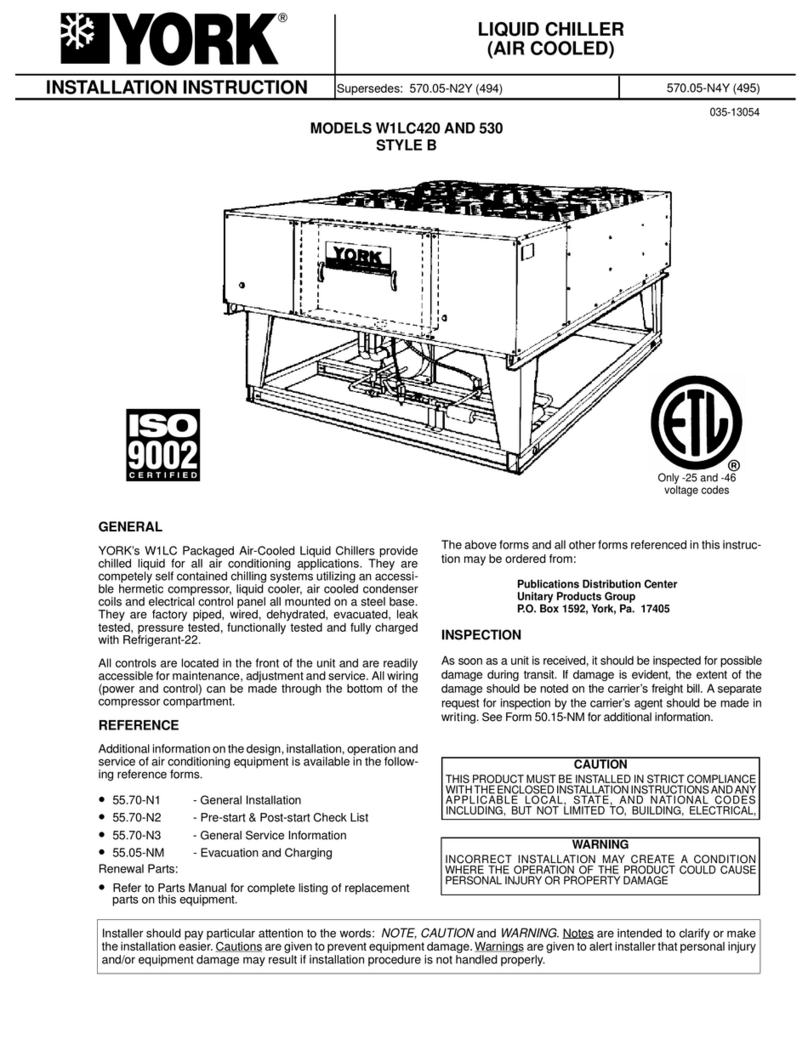

These packaged liquid chillers are completely self-

containedoutdoorunitsshippedready for final job instal-

lationrequiring onlyliquid connections,power and con-

trol wiring. They are designed primarily for central sta-

tion air conditioning applications with normal installa-

tions being on roof-tops or on ground level beside the

building.

CODESTATUS

Theunitsaredesignedin accordance with UL(200,230,

460-3-60),N.E.C., ASHRAE/ANSI STANDARD 15, and

ASME Codes.