Borg & Overstrom u1 Instruction sheet

Other manuals for u1

5

Table of contents

Other Borg & Overstrom Chiller manuals

Popular Chiller manuals by other brands

aquatherm

aquatherm AT-5000 Installation, use & care manual

SMC Networks

SMC Networks HRZ001-L Operation manual

York

York YCAS Series Installation operation & maintenance

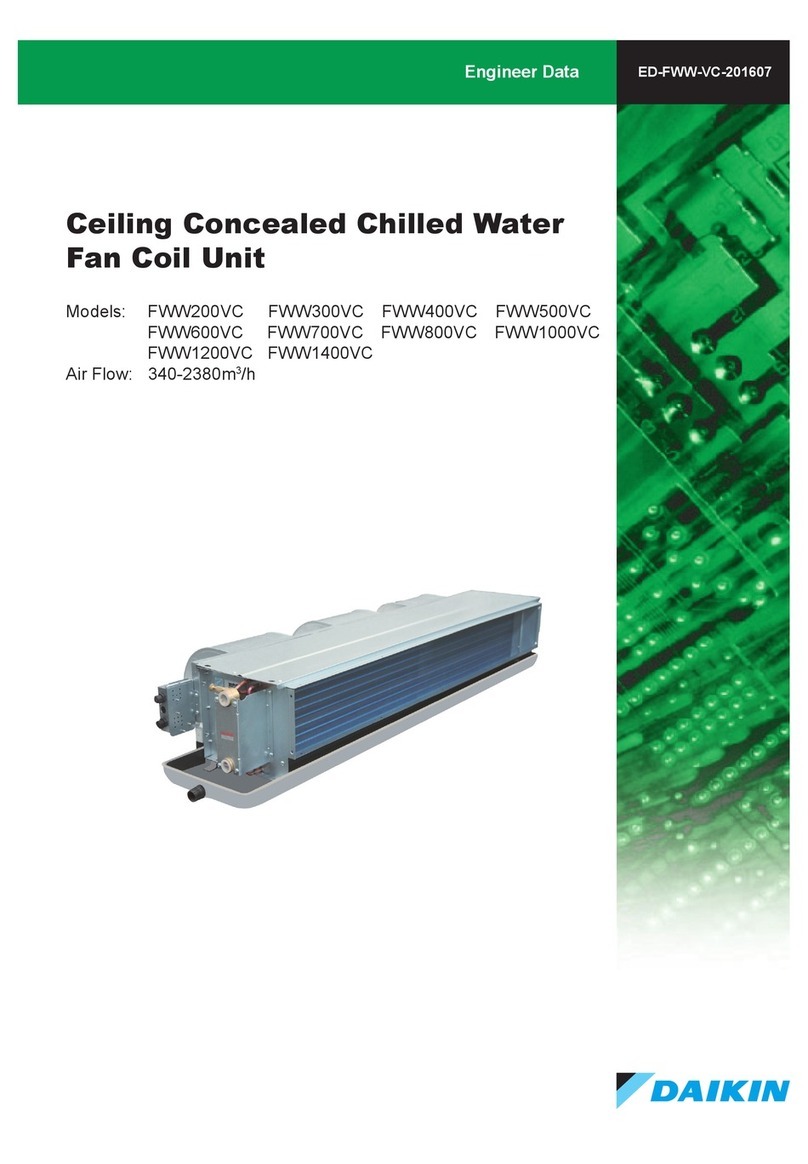

Dakin

Dakin FWW200VC manual

Carrier

Carrier 30GX080-265 user manual

AIRTAK

AIRTAK C-25 through C-8000 Installation, operation and maintenance instructions

Perlick

Perlick FR48 SS Installation & operation manual

Trane

Trane 4TXCB004DS3HCC Installer's guide

Daikin

Daikin Hydrocube EWLP012KAW1N Operation manual

McQuay

McQuay AGR 055AS Installation, operation and maintenance manual

Emerson

Emerson InSinkErator NeoChiller CWT150 Installation, care & use

Diamond

Diamond CBT101/NT INSTRUCTIONS FOR THE INSTALLATION, USE AND MAINTENANCE

Daikin

Daikin EWAQ016BAW Installation and operation manual

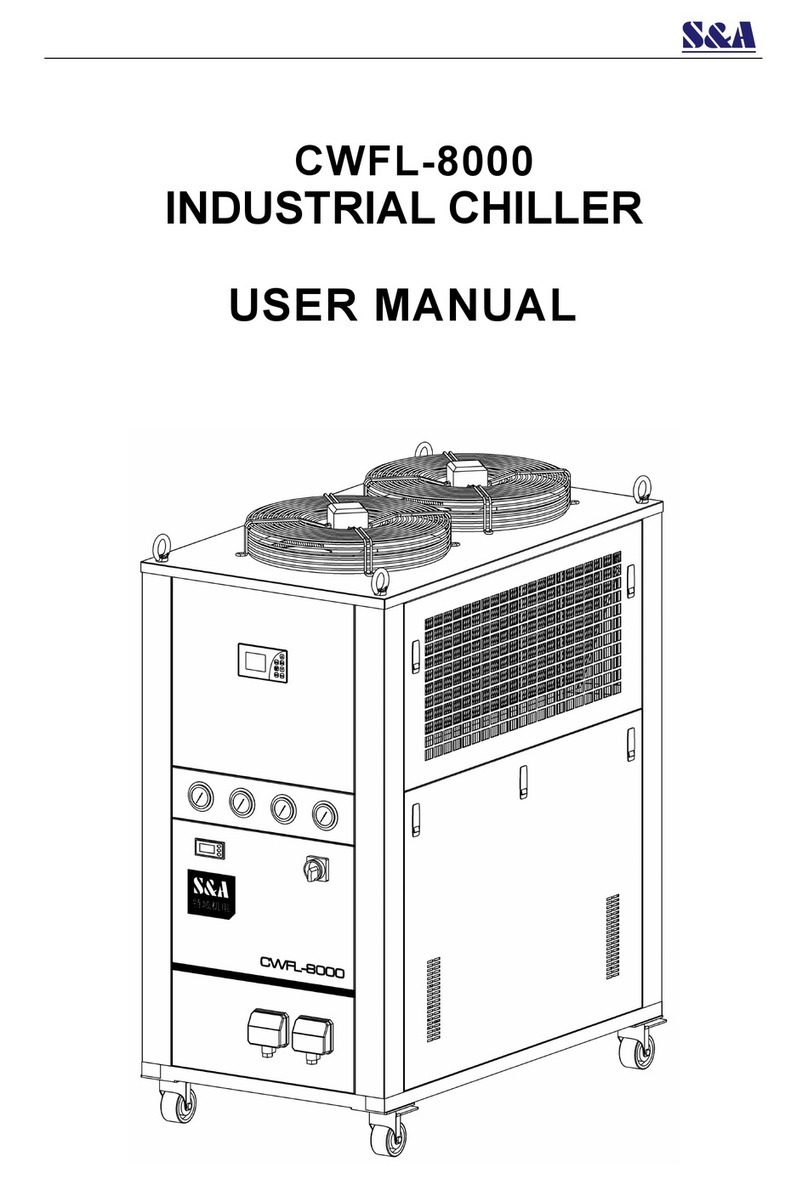

S&A

S&A CWFL-8000 Series user manual

Clint

Clint idroinverter CHA/IK Series INSTALLATION, USE AND MANTEINANCE MANUAL

Carrier

Carrier AquaEdge 23XRV installation instructions

iCool

iCool TurboCool Installation & operation manual

Trane

Trane AquaStream CGWN 205 Installation operation & maintenance