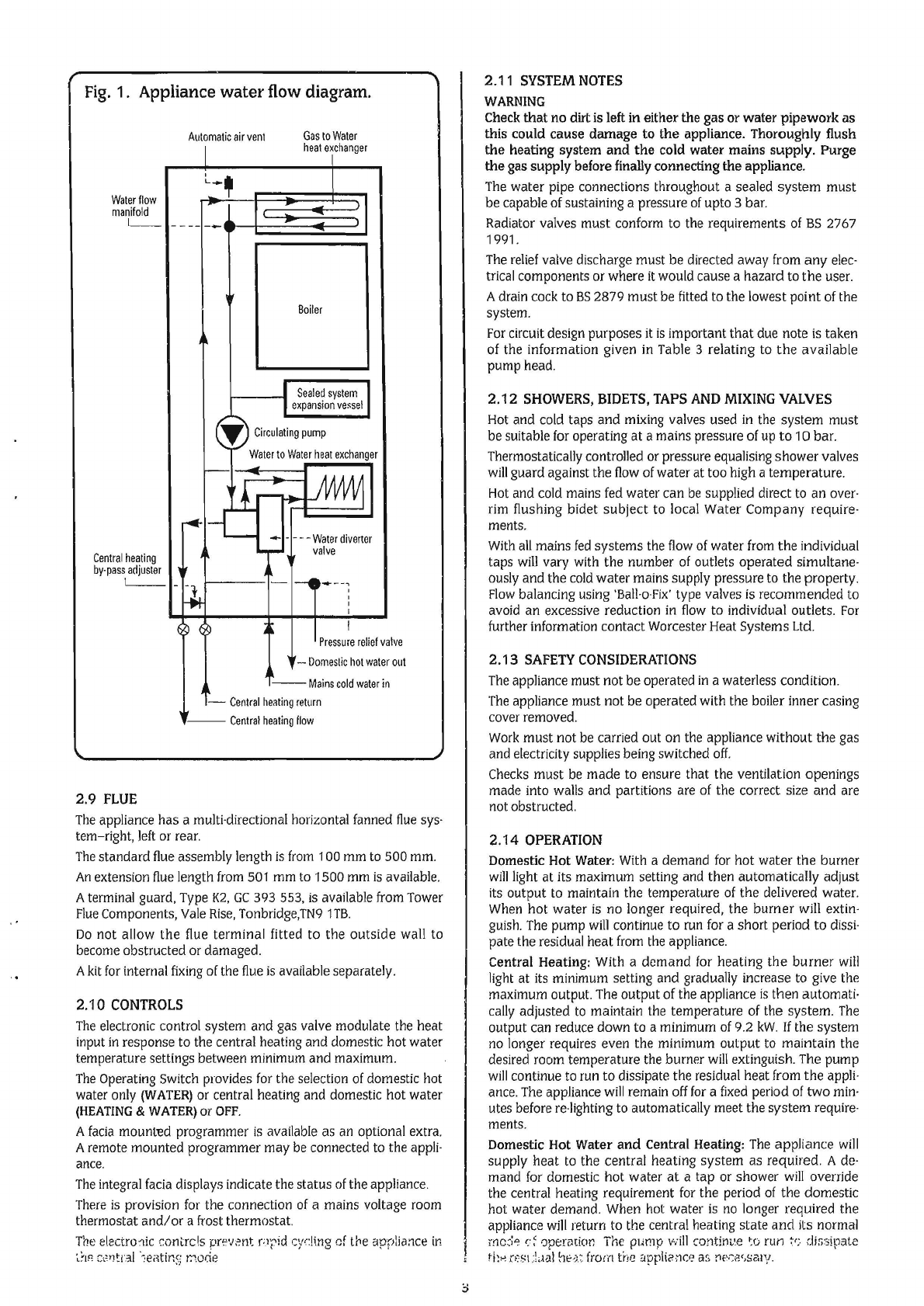

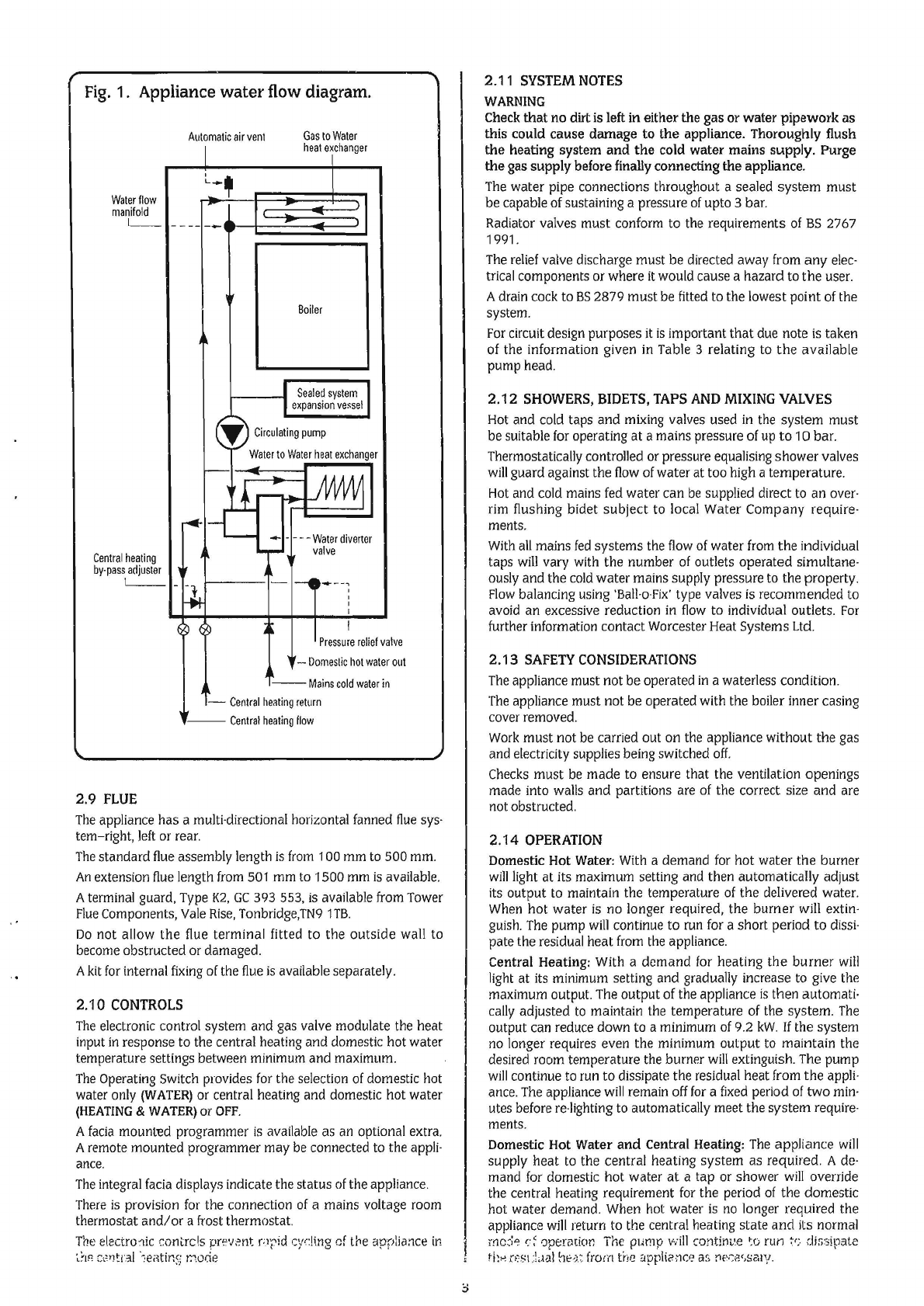

Fig.

1. Appliance

water

flow diagram.

Waterflow

manifold

I__

Central

heating

by-pass

adjuster

L__

Automatic

air

vent

Gas

to

Water

I h h

eat

axe

anger

~a-·

~

----

--

Boiler

J

Sealed

system

expansion

vessel

~

Circulating

pump

Water

to

Water

heat

exchanger

-

'l!..---

JVvV\1

~

1-c

--

---Waterdivertor

,__

valve

' -

1--0---~

-

-,.

f-*

'

'

I

o

c9

I

Pressure

relief

val

ve

-

Domestic

hot

water

out

I'

__

Mains

cold

water

in

-

Central

heating

retmn

--

Central

heatin

flow

2.9

FLUE

The

appliance has a multi-directional horizontal fanned

flue

sys-

tem-right,

left

or

rear.

The

standard

flue

assembly length

is

from

1

00

mm

to

500

mm.

An

extension

flue

length

from

501

mm

to

1500

mm

is

available.

Aterminal guard,

Type

K2,

GC

393

553,

is

available

from

Tower

Flue

Components,

Vale

Rise,

Tonbridge,TN9

1

TB.

Do

not

al.low

the

flue

terminal fitted to the outside wall to

become

obstructed or damaged.

A

kit

for

internal

fixing

of

the

flue

is

available separately.

2.1

0

CONTROLS

The

electronic control system and gas valve modulate the heat

input

in

response to the central heating and domestic hot water

temperature settings between minimum and maximum.

The

Operating

Switch

provides

for

the selection

of

domestic hot

water

only

(WATER)

or central heating and domestic hot water

(HEATING

&

WATER)

or

OFF.

A

facia

mounted programmer

is

available as

an

optional extra.

Aremote mounted programmer may

be

connected

to

the

appli-

ance.

The

integral

facia

displays indicate the status

of

the appliance.

There

is

provision

for

the connection

of

a mains voltage

room

thermostat

and/

or a frost thermostat.

The

electro'lic contrcls

prfv~~nt

nrid

cyr:!ing

cf the

applia:1ce

in

·,~IR

Cc'YJ~t.:tl

·,ei{tir.5.i

/.!.ode

2_11

SYSTEM

NOTES

WARNING

Check

that no dirt

is

left in either the gas or water pipework as

this could cause damage to the appliance. Thoroughly flush

the heating system and

the

cold water mains supply. Purge

the gas supply before finally connecting the appliance.

The

water pipe connections throughout a sealed system must

be capable

of

sustaining a pressure

of

upto 3 bar.

Radiator valves must conform to the requirements

of

BS

2767

1991.

The

relief

valve discharge must be directed away

from

any

elec·

trical

components or where

it

would cause a hazard

to

the user.

Adrain

cock

to

BS

2879 must

be

fitted

to

the lowest point

of

the

system.

For

circuit design purposes

it

is

important that due note

is

taken

of

the information given

in

Table 3 relating

to

the available

pump head.

2.12

SHOWERS,

BIDETS,

TAPS

AND

MIXING

VALVES

Hot

and

cold

taps and

mixing

valves used

in

the

system must

be suitable

for

operating at a mains pressure

of

up

to

10 bar.

Thermostatically controlled

or

pressure equalising shower valves

will

guard against the

flow

of

water at too high a temperature.

Hot

and

cold

mains

fed

water can

be

supplied direct

to

an over·

rim

flushing bidet subject to local Water Company require-

ments.

With

all

mains

fed

systems the

flow

of

water

from

the individual

taps

will

vary with the number

of

outlets operated simultane-

ously and the

cold

water mains supply pressure

to

the property.

Flow

balancing using

'Ball-o-Fix'

type valves

is

recommended to

avoid an excessive reduction

in

flow

to individual outlets.

For

further information contact Worcester Heat Systems

Ltd.

2.13

SAFETY

CONSIDERATIONS

The

appliance must not be operated

in

a waterless condition.

The

appliance must not

be

operated with the boiler inner casing

cover removed.

Work

must not

be

carried out

on

the appliance without the gas

and electricity supplies being switched

off.

Checks

must

be

made to ensure that the ventilation openings

made into

walls

and partitions are

of

the correct

size

and are

not obstructed.

2.14

OPERATION

Domestic Hot Water:

With

a demand

for

hot water the burner

will

light

at its maximum setting and then automatically adjust

its output

to

maintain the temperature

of

the delivered water.

When

hot water

is

no

longer required, the burner

will

extin·

guish.

The

pump

will

continue to

run

for

a short period to

dissi-

pate the residual heat

from

the

appliance.

Central Heating: With a demand

for

heating the burner

will

light

at its minimum setting and gradually increase

to

give

the

maximum output.

The

output of the appliance

is

then automati·

cally

adjusted

to

maintain the temperature

of

the system.

The

output can reduce down to a minimum

of

9.2

kW.

If

the system

no

longer requires even the minimum output

to

maintain the

desired room temperature the burner

will

extinguish.

The

pump

will

continue to run to dissipate the residual heat

from

the appli·

ance.

The

appliance

will

remain

off

for

a

fixed

period

of

two

min·

utes before

re-lighting

to

automatically meet the system require·

ments.

Domestic Hot Water

and

Central Heating:

The

appliance

will

supply heat

to

the central heating system as required. A

de·

mand

for

domestic hot water

at

a tap

or

shower

will

override

the central heating requirement

for

the period

of

the domestic

hot water demand.

When

hot

water

is

no

longer required the

appliance

will

return

to

the central heating state and its normal

mc3~

('~

0pennior.

The

pump will

continv.e

~o

run

~r:.

dissipate

ti:.;

r•'SLLBll'lr:J:

from

the

applii?.no~

as

ne·~B',scuv.