BOXER AGRI WLF 1300 User manual

FLAIL MOWER

WLF 1300 ● WLF 1700

USER MANUAL

P. de Heus en Zonen Greup B.V.

Stougjesdijk 153

3271 KB Mijnsheerenland

The Netherlands

Tel: +31 (0) 18 66 12 333

E-mail: info@boxeragri.nl

FLAIL MOWER | User manual February 2021

ENG | ENGLISH

TRANSLATION OF THE ORIGINAL MANUAL

CONTENTS

February 2021FLAIL MOWER | User manual

1. INTRODUCTION .......................................................................................................................... 4

2. SAFETY ....................................................................................................................................... 5

2.1 Safety at all times ................................................................................................................................. 5

2.2 Symbols ................................................................................................................................................ 6

2.3 Safety Labels......................................................................................................................................... 8

3. ASSEMBLY AND SET-UP .............................................................................................................. 9

4. OPERATION .............................................................................................................................. 10

5. ADJUSTMENTS ......................................................................................................................... 11

6. MAINTENANCE ......................................................................................................................... 12

7. SPECIFICATIONS AND CAPACITIES ............................................................................................. 14

8. TROUBLESHOOTING ................................................................................................................. 15

9. BOLT TORQUE .......................................................................................................................... 16

10. WLF FLAIL MOWER ASSEMBLY ................................................................................................. 17

11. SHAFT COUPLE ......................................................................................................................... 21

12. OIL PIPE ASSEMBLING .............................................................................................................. 22

13. CE DECLARATION OF CONFORMITY .......................................................................................... 23

Page 4/23

FLAIL MOWER | User manual February 2021

1. INTRODUCTION

BoxerAgri welcomes you to the growing family of new product owners. This implement has been designed with care

and built by skilled workers using quality materials. Proper assembly, maintenance, and safe operating practices will

help you get years of satisfactory use from the machine.

Application

The Flail Mowers are designed for Category 1 - three point hitch or Quick-Hitch System mounting. These Fixed Bar

Flail Mowers are ideal for ripping, leveling, finish grading, and backfilling applications at feedlots, outdoor arenas,

building sites, and maintenance operations on farm and ranch lanes or roadways.

Using This Manual

• This Operator’s Manual is designed to help familiarize you with safety, assembly, operation, adjustments,

troubleshooting, and maintenance. Read this manual and follow the recommendations to help ensure safe and

efficient operation.

• The information contained within this manual was current at the time of printing. Some parts may change

slightly to assure you of the best performance.

• To order a new Operator’s or Parts Manual contact your authorized dealer. Manuals can also be printed from

the BoxerAgri Service & Support Center by your dealer.

Terminology

“Right” or “Left” as used in this manual is determined by facing the direction the machine will operate while in use

unless otherwise stated.

Definitions

Note: A special point of information that the operator must be aware of before continuing.

Important: A special point of information related to its preceding topic. The intention is that this information should

be read and noted before continuing.

Owner Assistance

The Warranty Registration card should be filled out by the dealer at the time of purchase. This information is

necessary to provide you with quality customer service. If customer service or repair parts are required contact a

dealer. A dealer has trained personnel, repair parts and equipment needed to service the machine.

The parts on your machine have been specially designed and should only be replaced with genuine parts.

Serial Number Plate

For prompt service always use the serial number and model number when ordering parts from your dealer. Be sure

to include your serial and model numbers in correspondence also.

Page 5/23

February 2021FLAIL MOWER | User manual

2. SAFETY

2.1 Safety at all times

Thoroughly read and understand the instructions given in this manual before operation. Refer to the “Safety Decal”,

read all instructions noted on them.

Do not allow anyone to operate this equipment who has not fully read and comprehended this manual and who has

not been properly trained in the safe operation of the equipment.

• Operator should be familiar with all functions of the unit.

• Operate implement from the driver’s seat only.

• Make sure all guards and shields are in place and secured before operating the implement.

• Do not leave tractor or implement unattended with engine running.

• Dismounting from a moving tractor could cause serious injury or death.

• Do not stand between tractor and implement during hitching.

• Keep hands, feet, and clothing away from power-driven parts.

• Wear snug fitting clothing to avoid entanglement with moving parts.

• Watch out for wires, trees, etc., when raising implement. Make sure all persons are clear of working area.

• Turning tractor too tight may cause implement to ride up on wheels. This could result in injury or equipment

damage.

Look For The Safety Alert Symbol

The SAFETY ALERT SYMBOL indicates there is a potential hazard to personal safety involved and extra safety

precaution must be taken. When you see this symbol, be alert and carefully read the message that follows it. In

addition to design and configuration of equipment, hazard control and accident prevention are dependent upon the

awareness, concern, prudence and proper training of personnel involved in the operation, transport, maintenance

and storage of equipment.

Page 6/23

FLAIL MOWER | User manual February 2021

2.2 Symbols

This booklet contains three "safety graphic symbols" which highlight the relevant danger levels or important

information:

WARNING

It draws the operator's attention to situations which can jeopardize people's safety.

CAUTION

It draws the attention to situations which jeopardize the machine efficiency but not people's safety.

IMPORTANT

It highlights general information which does not endanger people's safety or the efficiency of the parts.

For your protection

Thoroughly read and understand the “safety label” section, read all instructions noted on them.

Shutdown and storage

• Lower machine to ground, put tractor in park, turn off engine, and remove the ignition key.

• Detach and store implements in a area where children normally do not play. Secure implement by using blocks

and supports.

Use safety lights and devices

• Slow moving tractors, self-propelled equipment, and towed implements can create a hazard when driven on

public roads. They are difficult to see, especially at night.

• Flashing warning lights and turn signals are recommended whenever driving on public roads. Use lights and

devices provided with implement.

Transport machinery safely

• Comply with state and local laws.

• Maximum transport speed for implement is 20 mph. Do not exceed. Never travel at a speed which does not

allow adequate control of steering and stopping. Some rough terrain require a slower speed.

• Sudden braking can cause a towed load to swerve and upset. Reduce speed if towed load is not equipped with

brakes.

• Use the following maximum speed - tow load weight ratios as a guideline:

- 20 mph when weight is less than or equal to the weight of tractor.

- 10 mph when weight is double the weight of tractor.

Page 7/23

February 2021FLAIL MOWER | User manual

IMPORTANT

Do not tow a load that is more than double the weight of tractor.

Keep riders off machinery

• Riders obstruct of operator’s view, they could be struck by foreign objects or thrown from the machine.

• Never allow children to operate equipment.

Practice safe maintenance

• Understand procedure before doing work. Use proper tools and equipment. refer to Operator’s Manual for

additional information.

• Work in a clean dry area.

• Lower the implement to the ground, put tractor in park, turn off engine, and remove key before performing

maintenance.

• Allow implement to cool completely.

• Do not grease or oil implement while it is operation.

• Inspect all parts. Make sure parts are in good condition and installed properly.

• Remove buildup of grease, oil or debris.

• Remove all tools and unused parts from implement before operation.

Prepare for emergencies

• Be prepared if a fire starts.

• Keep a fist aid kit and fire extinguisher handy.

• Keep emergency numbers for doctor, ambulance, hospital and fire department near phone.

Wear protective equipment

• Protective clothing and equipment should be worn.

• Wear clothing and equipment appropriate for the job. Avoid loose fitting clothing.

• Prolonged exposure to loud noise can cause hearing impairment or hearing loss. Wear suitable hearing

protection such as earmuffs or earplugs.

• Operating equipment safely requires the full attention of the operator. Avoid wearing radio headphones while

operating machinery.

Avoid high pressure fluids hazard

• Escaping fluid under pressure can penetrate the skin causing serious injury.

• Avoid the hazard by relieving pressure before disconnecting hydraulic lines.

• Use a piece of paper or cardboard, not body parts, to check for suspected leaks. Wear protective gloves and

safety glasses or goggles when working with hydraulic systems.

• If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be treated within a few

hours or gangrene may result.

Page 8/23

FLAIL MOWER | User manual February 2021

2.3 Safety Labels

Your Flail Mower comes equipped with all safety labels in place. They were designed to help you safely operate your

implement. Read and follow their directions.

1. Keep all safety labels clean and legible.

2. Replace all damaged or missing labels. To order new labels go to your nearest dealer or visit www.boxeragri.nl.

3. Some new equipment installed during repair requires safety labels to be affixed to the replaced component as

specified by BoxerAgri. When ordering new components make sure the correct safety labels are included in the

request.

4. Refer to this section for proper label placement.

To install new labels:

1. Clean the area the label is to be placed.

2. Spray soapy water on the surface where the label is to be placed.

3. Peel backing from label. Press firmly onto the surface.

4. Squeeze out air bubbles with the edge of a credit card.

Page 9/23

February 2021FLAIL MOWER | User manual

3. ASSEMBLY AND SET-UP

Tractor Requirements

This hydraulic mower is designed for front use and equipped with a quick hitch hook. The oil flow should not exceed

45ltr/min and 160bar.

Assembly

Refer to the parts illustration.

Tractor & wheel loader Hook-Up

1. Be certain that tractor draw bar will not interfere. Move draw bar ahead or remove if required. Draw bar should

also be checked for clearance when unit is being raised for the first time.

2. Connect the quick hitch from the wheel loader into the hook of the mower.

3. The mower should be run with the back 15 degrees lower than the front.

Driveline Installation

1. Connect the oil lines to the tractor /wheel loader.

2. Connect the IN on the hydraulic pressure line and the OUT on the hydraulic return line.

3. Check the rotation direction of the mower.

CAUTION

Tractor PTO shield and all mower guards must be in place at all times during operation!

Model Working

width

Recommended power

(hp)

Oil

(ltr)

Category Weight

(kg)

Cutting

blade

WLF 1300 130 33 - 50 40 - 45 W. 320 22

WLF 1700 170 33 - 50 40 - 45 W. 353 28

Page 10/23

FLAIL MOWER | User manual February 2021

4. OPERATION

Transporting

NOTE: Always disengage PTO before raising mower to transport position.

1. When raising the mower to transport position, be sure that driveline does not contact tractor or mower. Adjust

and set the tractor’s 3-point hitch lift height so that the driveline does not contact mower deck in the fully

raised position.

2. Be sure to reduce tractor ground speed when turning, leaving enough clearance so that the mower does not

contact obstacles such as buildings, trees or fences.

3. Select a safe ground travel speed when transporting from one area to another. When traveling on roadways,

transport in such a way that faster moving vehicles may pass safely.

4. When traveling over rough or hilly terrain, shift tractor to a lower gear.

CAUTION

When traveling on public roads, whether at night or during the day, use accessory lights and devices for adequate

warning to operators of other vehicles. Comply with all Federal, State, and local laws.

Mowing Instructions

1. Clear area to be mowed of objects and debris that might be picked up and thrown by the mower blades.

2. Grass is best cut when it is dry. Mowing wet grass can cause plugging resulting in grass clumps behind the

mower.

3. Grass should be mowed frequently as shorter clippings deteriorate faster.

4. If mowing extremely tall grass, it is best to raise cutting height and mow the area, then lower cutting height and

mow a second time at the desired height.

Operating Instructions

Proper servicing and adjustments are the key to the long life of any machine. With careful and systematic

inspection of the mower, costly maintenance, time and repair can be avoided.

Before beginning to mow, the following inspection should be performed:

1. Check oil level in gearbox.

2. Check that all plugs in gearbox have been replaced and tightened properly.

3. Be sure all mower knives, bolts and nuts are tight.

4. Be certain all guards and shields are in place and secure.

5. Grease driveline shaft and all other grease fittings.

6. Clear area to be mowed of rocks, branches and other foreign objects.

7. Lower mower to ground. Set tractor throttle at approximately 1/4 open. Engage PTO to start blades rotating.

8. Operate with 540 rpm PTO tractor.

9. At first begin mowing at a slow forward speed and shift up until the desired speed is achieved - maintaining 540

PTO rpm.

10. Mower knives will cut better at a faster blade speed than at reduced throttle.

11. After mowing the first 50 feet, stop and check to see that the mower is adjusted properly.

12. Do not make sharp turns or attempt to back up while mower is on the ground.

13. Do not engage PTO with mower in the fully raised position. Do not engage PTO at full throttle.

Page 11/23

February 2021FLAIL MOWER | User manual

5. ADJUSTMENTS

Leveling the Mower

NOTE: Tractor and mower should be on level ground.

Leveling can be adjusted at the tractor’s 3-point arms and center link.

Cutting Height Adjustment

The machines cutting height depends upon the position of the rear roller.

1. Remove the bolts that fix the roller on both sides.

2. Lift or lower both sides of roller in equal measurements.

3. Replace bolts and re-tighten.

3-Point Hitch Adjustments

The 3-point hitch system on this mower has been designed for front to back flotation when mowing on uneven

terrain. Adjust tractor’s top center link to place the upper hitch pin vertically above or slightly behind the lower hitch

pins. The mower should be run with the back 15 degrees lower than the front.

The hitch can also be adjusted from side to side by turning the adjustment handle. Turn handle until you have

achieved your desired location.

CAUTION

Engage parking brake, shut off tractor, remove key and disengage PTO before making any height adjustments!

Belt Tension

CAUTION

Belt drive system under spring tension; use care to avoid bodily harm!

The Belt tension should be checked after the first 20 hours of use. And then every 40 hours of use.

1. Tension on the belt can be adjusted with the belt tension bolt. Turn the bolt until desired tension is achieved.

When the belt has the correct tension the gearbox should be adjusted so that the gearbox extension is running

straight (parallel) with the flail mower. Loosen bolts at the bottom of the gearbox and move gearbox until

gearbox extension is running straight.

2. Excessive tension on the belt may lead to premature failure of belt and drive components.

CAUTION

Excessive tension on the belt may lead to premature failure of belt and drive components. Excessive tension on the

belt may also lead to a safety hazard to the operator or bystanders.

Page 12/23

FLAIL MOWER | User manual February 2021

6. MAINTENANCE

Maintenance

Proper servicing and adjustment is the key to the long life of any farm implement. With careful and systematic

inspection, you can avoid costly maintenance, time and repair.

CAUTION

For safety reasons, each maintenance operation must be performed with tractor PTO disengaged, mower lowered

completely to ground and tractor engine shut off with ignition key removed.

After using the mower for several hours, check all bolts to be sure they are tight and check drive belt tension.

Replace any worn, damaged or illegible safety decals by obtaining new decals from dealer.

Knife Replacement

IMPORTANT

Make sure that the knife is the same length as the others on the mower. This will keep the rotor rotation balanced.

1. Remove bolt and nut.

2. Remove old knife.

3. Install new knife and existing bolt.

4. Secure with nut.

V-Belt Installation

CAUTION

Belt drive system under spring tension; use care to avoid bodily harm!

1. Remove belt guard fender and belt cover.

2. Disengage belt tension by loosening belt tension bolt until belt can be removed.

3. With tension relieved from belt remove old belt from pulleys.

4. Tighten belt tension bolt.

5. Reinstall belt guard and belt guard fender.

Storage

At the end of the working season or when the mower will not be used for a long period, it is good practice to clean

off any dirt or grease that may have accumulated on the mower and any of moving parts.

1. Clean as necessary.

2. Check knives for wear and replace if necessary.

3. Inspect mower for loose, damaged or worn parts and adjust or replace as needed.

4. Store unit inside if possible for longer life.

5. Repaint parts where paint is worn or scratched to prevent rust.

6. Replace all damaged or missing decals.

Page 13/23

February 2021FLAIL MOWER | User manual

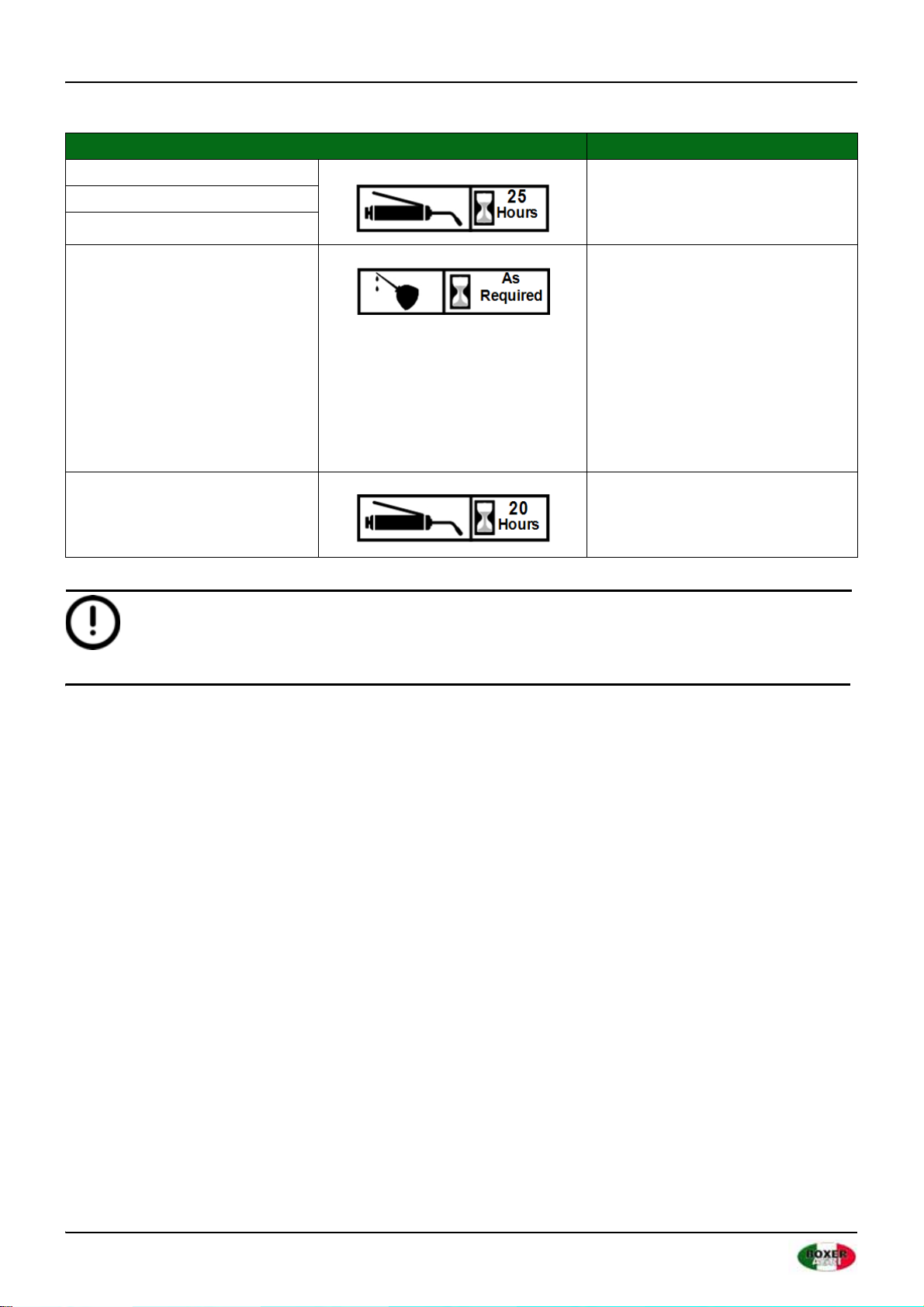

Lubrication

IMPORTANT

Mower should be level when checking oil in gearbox!

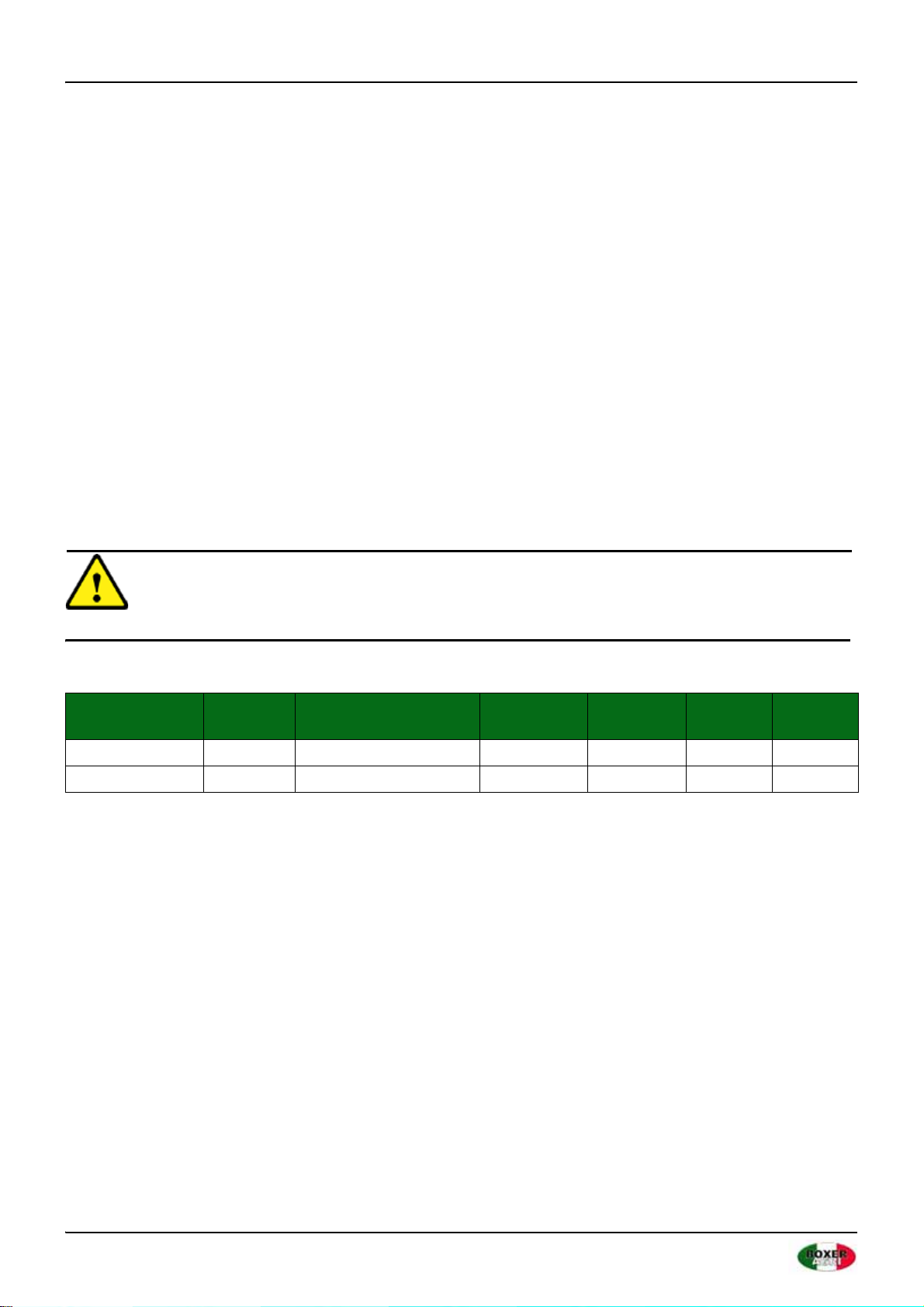

Type of Lubrication

Driveline Shaft U-Joints

Multi-purpose Grease

Roller Bearing (Both Ends)

Cutter Rotor Bearing (Both Ends)

Gearbox

Check oil level in gearbox by

removing the plug located on the

right hand side. Oil should be level

with bottom of plug hole. Add oil if

necessary by removing top fill plug

and side plug. Add oil until it flows

from side plug hole. Do not overfill!

SAE 90W Gear Lube

Driveline Profiles Multi-purpose Grease

Page 14/23

FLAIL MOWER | User manual February 2021

7. SPECIFICATIONS AND CAPACITIES

MODEL WLF1300 WLF1700

Structure weight 320Kg 353Kg

Cutting width 1300mm 1700mm

Hydraulic Flow 42L/min-45Lmin, 180Bar 42L/min-45L/min, 180Bar

Hammer No. 22pcs 28 pcs

Mounting Type Euro Hitch Euro Hitch

Hydraulic Couples need 3 line, oil-in, oil-out, drain port

Page 15/23

February 2021FLAIL MOWER | User manual

8. TROUBLESHOOTING

CAUTION

Do not try to clean rear discharge area when mower is running. Bodily harm may occur!

Problem Solution

Belt slipping

Unplug and clean mower deck.

Remove belt guard shields and clean sheaves.

Replace belt.

Patches of uncut grass

Mow at full throttle (540 PTO rpm), check PTO speed and tractor engine.

Shift transmission to a lower gear.

Tighten belts.

Replace missing knives.

Excessive vibration

Replace knives.

Replace drive belt.

Replace pulleys or align.

Remove belt guard shields & clean debris from belt area & sheaves.

Gearbox noisy Check lubricant level.

Knives scalping grass

Raise cutting height by adjusting roller.

Change mowing pattern.

Reduce speed turns

Uneven cut

Shift to a lower gear.

Level mower.

Replace missing knives.

Tractor loaded down by mower

Mow at full throttle (540 PTO rpm).

Shift to a lower gear.

Clean mower.

Page 16/23

FLAIL MOWER | User manual February 2021

9. BOLT TORQUE

The tables shown below give correct torque values for various bolts and cap screws. Tighten all bolts to the torques

specified unless otherwise noted. Check tightness of bolts periodically, using bolt torque chart as a guide. Replace

hardware with the same strength bolt.

Torque figures indicated above are valid for non-greased or non-oiled threads and heads otherwise specified.

Therefore, do not grease or oil bolts or cap screws unless otherwise specified in this manual. When using locking

elements, increase torque values by 5%.

ENGLISH TORQUE SPECIFICATIONS

SAE 2 SAE 5 SAE 8

Bolt Diameter N.m lb-ft N.mt lb-ft N.m lb-ft

1/4” 8 6 12 9 17 12

5/16” 13 10 25 19 36 27

3/8” 27 20 45 33 63 45

7/16” 41 30 72 53 100 75

1/2” 61 45 110 80 155 115

9/16” 95 60 155 115 200 165

5/8” 128 95 215 160 305 220

3/4” 225 165 390 290 540 400

7/8” 230 170 570 420 880 650

METRIC TORQUE SPECIFICATIONS

8.8 10.9

Bolt Diameter N.m lb-ft N.m lb-ft

M3 0.5 0.4 1.8 1.3

M4 3 2.2 4.5 3.3

M5 6497

M6 10 7 15 11

M8 25 18 35 26

M10 503770 52

M12 90 66 125 92

M14 140 103 200 148

M16 225 166 310 229

M20 435 321 610 450

M24 750 553 1050 744

M30 1495 1103 2100 1550

M36 2600 1917 3675 2710

Page 17/23

February 2021FLAIL MOWER | User manual

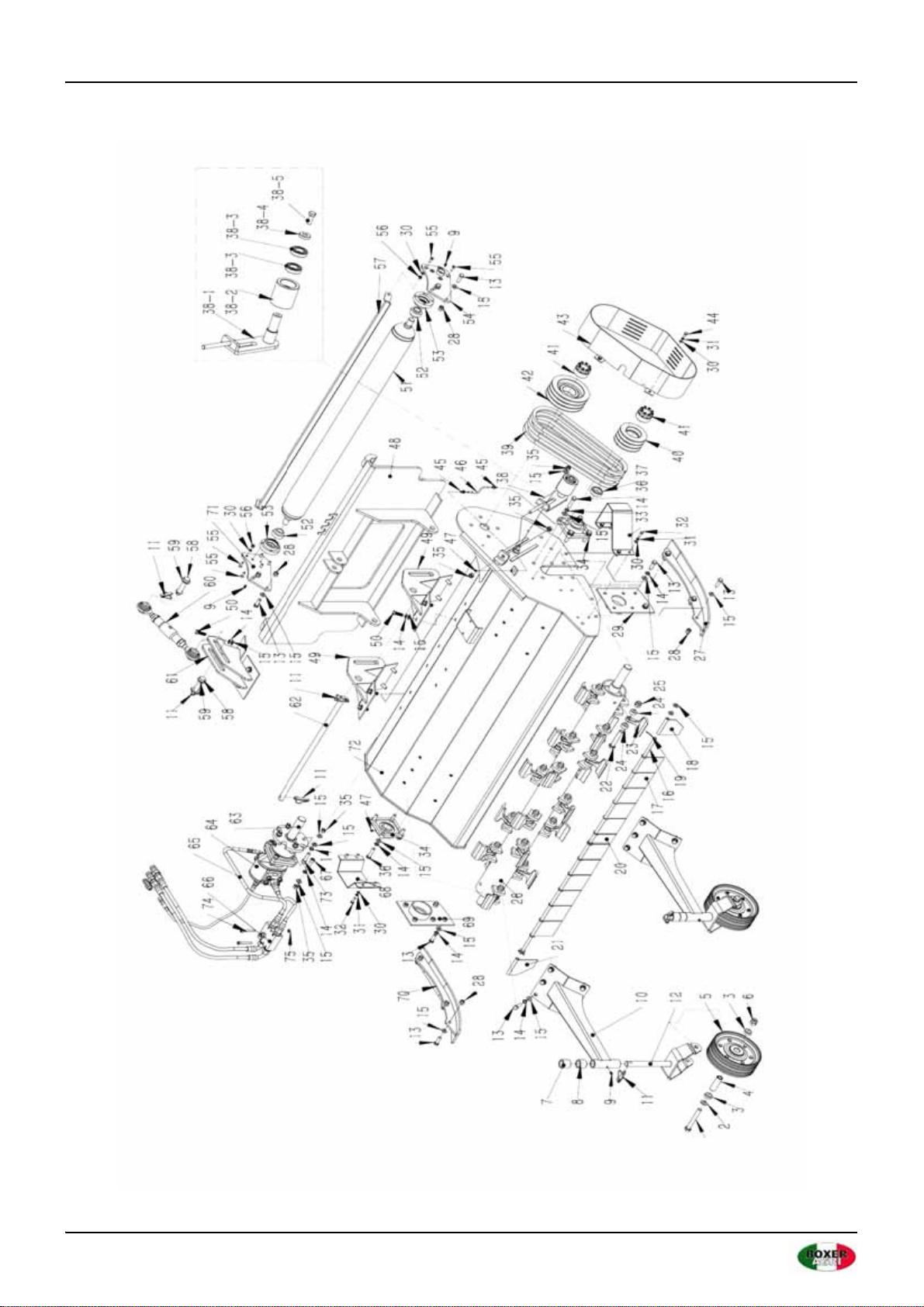

10. WLF FLAIL MOWER ASSEMBLY

Page 18/23

FLAIL MOWER | User manual February 2021

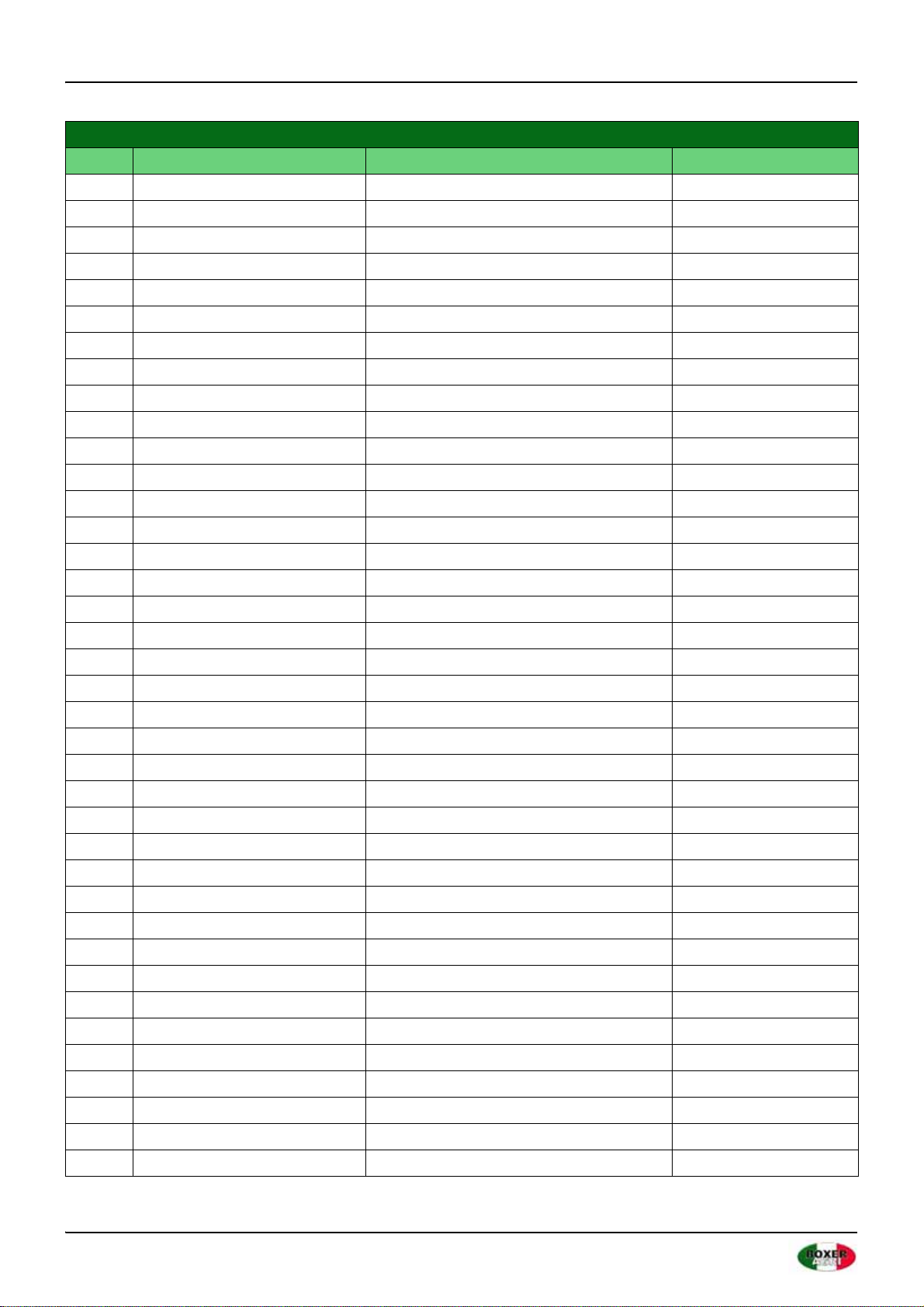

WLF FLAIL MOWER ASSEMBLY

No. Part No. Description Quantity

1 GB/T 5782 Bolt M16*120 2

2 GB/T 97.1 Washer 16 4

3 LM180.27 Bushing 4

4 LM180.25 Bushing for wheel 2

5 LM180.10 Wheel Φ220*75 2

6 GB/T 6182 Lock nut M16 2

7 WLF130.4 Adjust bushing 02 2

8 WLF130.3 Adjust bushing 01 2

9 JB / T 7940.1-1995 Grease nipple M8*1 4

10 WLF130.2 Wheel arm weldment 2

11 DIN 11023 Lock pin Φ11*40 6

12 WLF130.1 Wheel fork weldment 2

13 GB/T 70.1 Bolt M12*35 28

14 GB/T 93 Spring washer 12 42

15 GB/T 97.1 Washer 12 75

16 WLF130.6 Bar for fender 1

17 EFGC175.24A Fender 95 11

18 EFGC175.24B Fender 95 1

19 GB/T 91 Cotter pin 3.2*22 2

20 EFGC175.24C Fender 24 1

21 EFGC175.24D Fender 95 1

22 GB/T 5785 Bolt M16*1.5*90 22

23 EF100.00.102B Hammer 350g 22

24 EFGC175.28 Bushing for hammer seat 44

25 GB/T 889.2 Locking nut M16*1.5 22

26 WLF130.13 Flail rotor weldment 1

27 WLF130.8 Skid Left 1

28 GB/T 6182 Locking nut M12 10

29 WLF130.12 Cover weldment Left 1

30 GB/T 97.1 Washer 8 13

31 GB/T 93 Spring washer 8 11

32 GB/T 70.1 Bolt M8X25 8

33 WLF130.9 Protection plate 01 1

34 GB/T 7810 Bearing UCFU207 2

35 GB/T 6170 Nut M12 11

36 GB/T 70.1 Bolt M12*50 8

37 WLF130.26 Bushing 1

38 WLF130.24 Tension roller assemble 1

Page 19/23

February 2021FLAIL MOWER | User manual

38-1 WLF130.24.1 Tension plate weldment 1

38-2 WLF130.24-2 Tension Roller 1

38-3 GB/T 276 Bearing 6005-Z 2

38-4 WLF130.24-3 Washer 1

38-5 GB/T 5783 Bolt M12*30 1

39 GB/T 11544 V-belt SPB1036 3

40 EFGC155.27 Small pulley 1

41 JB/T 11544 Power Lock REACH 04 Type 35X60 2

42 EFGC155.31 Big pulley 1

43 WLF130.23 Pulley cover 1

44 GB/T 70.1 Bolt M8*16 3

45 M6X1-6X4 Lock nut connector 2

46 WLF130.25 Pipe for grease Φ6*Φ4 1

47 JB/T 7940.1 Grease nipple M6*1 2

48 WLFEH.0 Mount connector euro hitch 1

49 WLF130.29 Low linkage weldment 2

50 GB/T 70.1 Bolt M12*35 8

51 WLF130.16 Rear Roller 1

52 UC205 Bearing UC205 2

53 EFGC175.19 Bearing seat 2

54 WLF130.145 Left connection plate for roller 1

55 GB/T 70.3 Nut bolt M8*25 10

56 GB/T 6182 Nut M8 2

57 WLF130.17 Scriper 1

58 WLF130.22 Pin for top linkage 2

59 GB/T 97.1 Washer 16 3

60 WLF130.19 Adjust link rod 1

61 WLF130.18 Top linkage weldment 1

62 WLF130.21 Pin for down linkage 1

63 WLF130.30 Shaft coupling 1

64 CM-WLF Gear motor 1

65 WLF130.27 Oil pipe assembling 1

66 WLF130.28 Checking valve and priority valve 1

67 GB/T 70.1 Head screw M12*50 4

68 WLF130.10 Protection plate 02 1

69 WLF130.11 Cover weldment Right 1

70 WLF130.7 Skids Right 1

71 WLF130.14 Right connection plate for roller 1

72 WLF130.5 Mower deck weldment 1

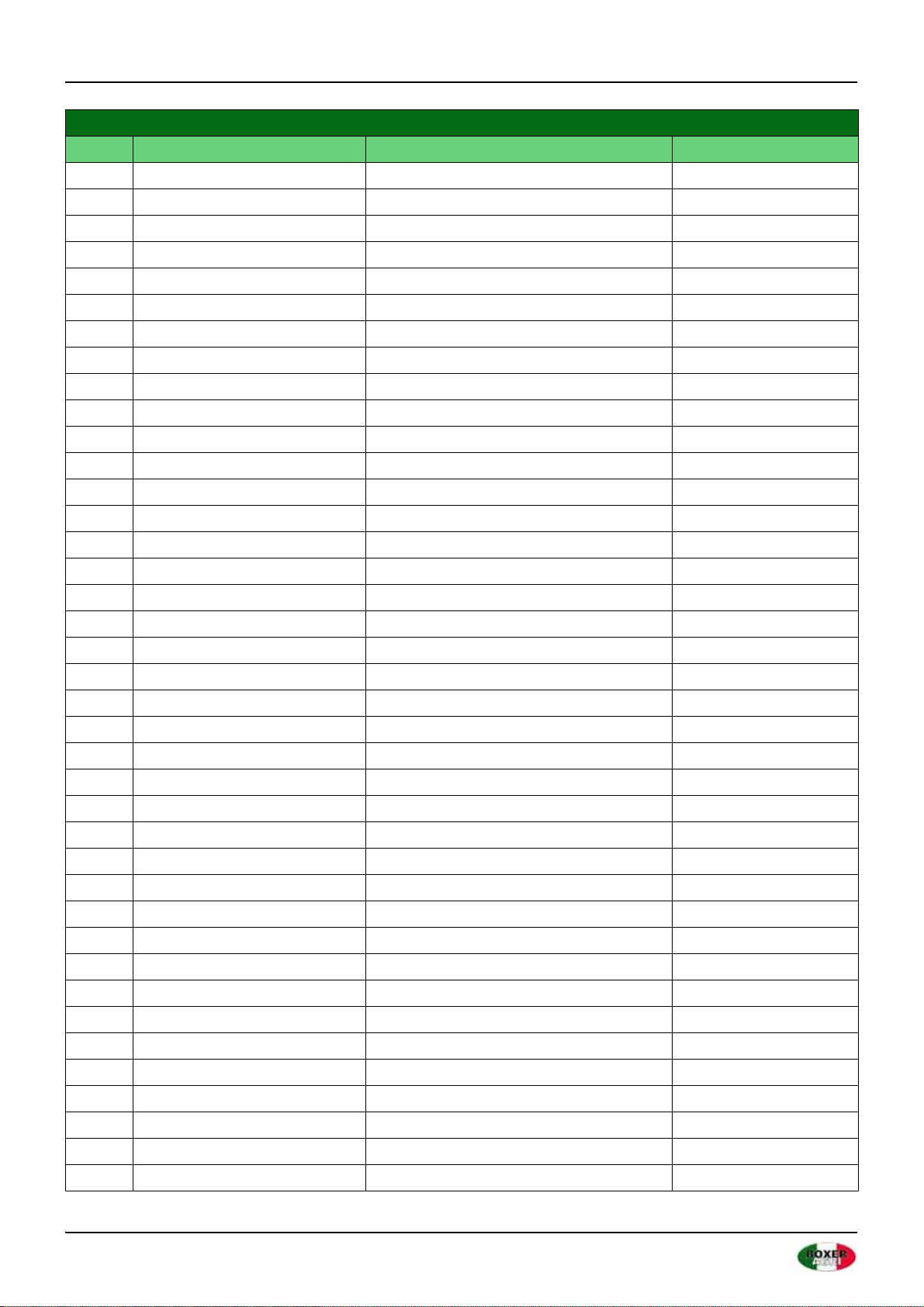

WLF FLAIL MOWER ASSEMBLY

No. Part No. Description Quantity

Page 20/23

FLAIL MOWER | User manual February 2021

73 GB/T 70.1 Head screw M12*45 4

74 GB/T 70.1 Bolt M8*60 2

75 GB/T 6170 Nut M8 2

WLF FLAIL MOWER ASSEMBLY

No. Part No. Description Quantity

This manual suits for next models

1

Table of contents

Other BOXER AGRI Lawn Mower manuals