BOXER BM 100 User manual

Identification Data

Description

1. Technical Specifications......................1

2. Location of Parts.................................2

3. How to Ride Motorcycle.....................9

4. Safe Riding Tips..................................10

5. Daily Safety Checks............................ 11

6. Running In Instruction......................... 12

7. Periodic Maintenance Information............13

8. Periodic Maintenance & Lubrication........ 15

9. Periodic Part Replacement Schedule...... 17

10. Pre Delivery Inspection............................ 18

11. Applicable to Periodic Services.............. 19

12. Non-use Maintenance.............................. 20

Notice: The description and illustration in this booklet are not to be taken as binding on the

manufacturers. The essential features of the type described and illustrated herein remaining

unaltered. Bajaj Auto Limited reserves the right to carry out at any moment without being

obliged to bring this booklet upto-date. Modifications on the vehicle, parts or accessories

as may be convenient and necessary.

Safety and Warning information :

Warning : This indicates that a potential hazard or injury to you or other persons & to the

vehicle can happen if advice provided is not followed

Caution : This indicates that a potential hazard that could result in vehicle damage. Follow

the Advice provided with the caution.

2

1

Engine : 4 stroke, Single cyl.

Air cooled, SI Engine.

Bore x Stroke : 53.0 mm x 45.0 mm

Engine Displacement : 99.27 cc

Compression Ratio : 9.5 : 1

Idling Speed : 1300 + 100 rpm

Max. Net Power : 6.03kW (8.2Ps) at 7500

rpm

Max. Net Torque : 8.05 Nm at 4500 rpm

Ignition System : Digital CDI with twin

map ignition

Spark Plug : Mico UR3AC,

Champion PRZ9HC

Spark Plug Gap : 0.6 to 0.7 mm

Lubrication : Wet sump, Forced.

Transmission : 4 speed constant mesh.

Brake Front / Rear : Mech. expanding shoe.

Fuel Tank Capacity :

Full : 9.3 litres

Reserve : 2.2 litres

Usable Reserve : 1.2 litres

Tyre Size :

Front : 2.75 x 17

Rear : 3.00 x 17

Tyre Pressure :

Front : 1.75kg / cm2 (24.5 PSI)

Rear (solo) : 2 kg / cm2 (28 PSI)

Rear (pillion) : 2.50 kg / cm2 (36 PSI)

Dimensions :

Length : 1970 mm

Width : 770 mm

Height : 1065 mm

Wheel base : 1235 mm

Min. Turning radius : 1900 mm

Ground clearance : 150 mm (Min.)

Electrical System : 12 Volts AC + DC

Head Lamp : 35/35 W

Position Pilot Lamp : 3W

Stop Lamp/Tail Lamp : 21 W / 5 W

Turn Signal Lamp : 10 W

Neutral Indicator Lamp : 3 W

Hi Beam Indicator Lamp : 3 W

Turn Pilot Indicator Lamp : 3 W

Speedometer Lamp : 3 W (2 Nos.)

Horn : 12 V DC

Battery : 12 V-2.5 Ah

Vehicle Kerb Weight : 109 kg.

Gross Vehicle Weight : 239 kg.

Max. Speed : 90 km/hr.

(single rider 68 kg)

0

Climbing ability : 25% (14 ) max.

Note : All dimensions are under UNLADEN

condition. Above information is subject to

change.

Technical Specifications Location of Parts

Clutch Lever

Fuel Tank Rear Shock

Absorber

Grab

Handle

Pillion

Foot Rest

Side Stand

Center

Stand

Gear

Change Lever

Front Fork

4

3

Location of Parts

1. Mirror - LH/RH

2. Control Switch LH

3. Speedo Console

4. Control Switch RH

5. Throttle Grip

6. Indicators LH/RH

7. Fuel Tank Cap

12341

6 6

7

5

The Frame and Engine serial numbers are

used to register the motorcycle. They are

the unique alpha-numeric codes to identify

your particular vehicle from others of the

same model and type.

Engine Number

Frame Number

Location of Parts

1. Turn Signal Indicator (LH & RH) : When

turn signal switch is turned to Left or Right,

Turn pilot indicator will flash with engine

running.

2. Speedometer : The Speedometer pointer

shows the speed of vehicle.

3. Odometer : The Odometer shows the total

distance that the vehicle has accumulated.

4. Hi beam Indicator : When Headlight is

‘ON’ and Hi beam is selected with engine

running, Hi beam indicator will be lit.

N

5. Neutral Indicator :

When the transmission is in Neutral and

Ignition switch ‘ON’, with engine running

the Neutral indicator is lit.

6. Ignition Switch : Key operated switch

for Ignition ‘ON’/‘OFF’.

OFF : Ignition OFF.

ON : Ignition ON.

Ignition ON & OFF :

OFF ON

6

5

Location of Parts

Steering Lock ON & OFF :

To Lock the Steering : To lock the steering,

turn the handle bar to the left. Turn the key to

“LOCK” position and remove the key.

To Lock the Steering : To lock the steering,

insert the key in steering lock & turn it

anticlockwise to “ON”.

To Unlock the Steering : To unlock the

steering, insert the key in steering lock & turn

it clockwise to “OFF”.

Key : A common key is used for Steering

lock, Ignition lock, Fuel tank cap and Side

cover lock.

Fuel Tank Cap

•To open the fuel tank cap, insert the key

in the lock and turn it clockwise and lift

fuel tank cap.

•‘Fuel Tank Cap’ is locked when pushed

back into the place.

Fuel Tap

Fuel tap lever has following positions.

ON : When fuel level is above Reserve

position.

RES : When fuel level is below Reserve

position.

OFF : When fuel supply is to be cut off.

Fuel Tank

Cap Fuel Tap

OFF

ON

RES

Location of Parts

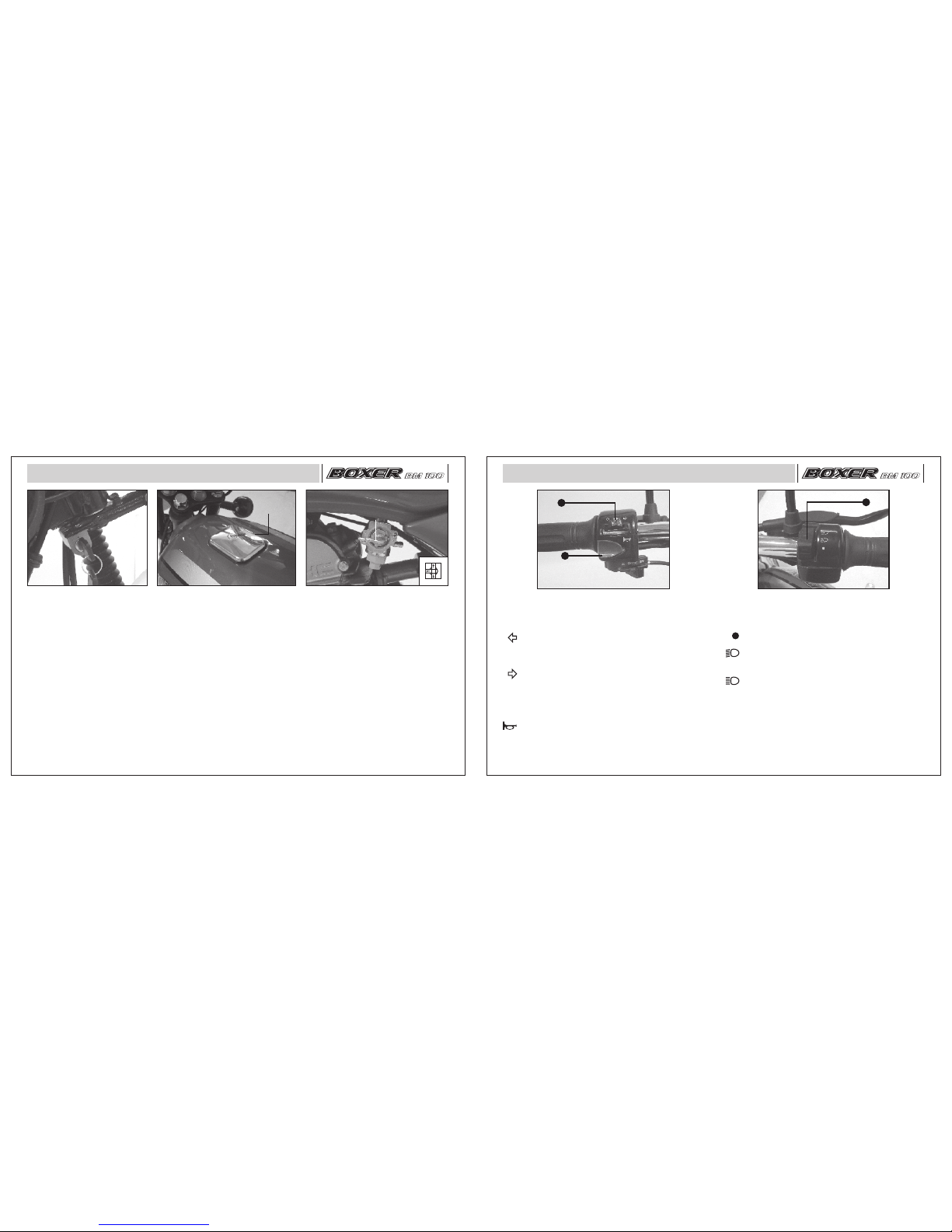

A. Turn Signal Switch :

: When the turn signal switch is turned to

Left the Left side Front and Rear turn

signal flash ‘ON’ and ‘OFF’.

: When the turn signal switch is turned to

Right the Right side Front and Rear

turn signal flash ‘ON’ and ‘OFF’.

B. Horn Button :

: Press horn button for sounding horn.

A. Head Light Switch : It has 3 positions.

:All lamps 'OFF'.

:With engine running, Low beam, Tail

lamp and Meter lamps ‘ON’.

:With engine running, High beam, Tail

lamp and Meter lamps ‘ON’.

A

Right Handle Bar Switches

B

A

Left Handle Bar Switches

87

Location of Parts

SIDE

COVER LH

A

B

C

SIDE

COVER RH

D

B

A

Removal Of Side Cover LH and RH

• Insert the key into cover lock (C) & turn

the key clockwise & pull ‘Side cover’ LH

out from bottom.

• Pull ‘Side cover’ from (A) to release Lug

provided on ‘Side cover’ from hole

provided on ‘Frame’.

• Slide the ‘Side Cover’ forward (towards the

engine) from location (B) to release slot

provided on front side of ‘Side cover’ from

bracket with rubber cap provided on ‘Fuel

Tank’. Take out ‘Side cover’.

• Similarly ‘Side cover’ RH can be removed

after removing screw (D).

Caution : Remove cover as described

above, otherwise the lugs may break.

Fitment Of Side Cover LH and RH

• Match slot (B) provided on front side of

‘Side Cover’ with bracket provided on

‘Fuel Tank’ and slide ‘Side cover’

backward (towards Tail lamp).

• Match Lug (A) provided on rear side of

‘Side cover’ with hole provided on

‘Frame’ and press ‘Side cover’ inside.

• Match the lock plate of ‘Side cover’

properly with bracket on ‘Chassis’ and

Lock. (For ‘Side cover’ LH).

• For ‘Side cov e r’ RH adopt same

procedure and fit the screw (D) properly.

Caution : Fit cover as described above to

ensure proper fitment.

Location of Parts

FRONT

BRAKE

ADJUSTER

Front Brake Adjustment

For safe riding, the brakes must always be

maintained in perfect condition. Brake is

properly adjusted if

• The wheel rotates freely when the

control lever is in the resting position.

• The braking action starts after Front

brake lever is pressed by 2-3 mm.

These conditions are obtained by adjusting

the cables by means of adjuster shown in

the figure and minor play adjustments can

be done by adjuster provided near front

brake lever.

Rear Brake

Rear brake is properly adjusted if

• The wheel rotates freely when the brake

pedal is in the resting position.

• The braking action starts after Brake

pedal is pressed by 20-30 mm.

These conditions are obtained by adjusting

the cables by means of adjuster shown in

the figure.

Warning :

Brakes are items of personal safety and

hence must be maintained in perfect

condition.

Adjustment

REAR

BRAKE

ADJUSTER

This manual suits for next models

1

Table of contents

Other BOXER Motorcycle manuals

Popular Motorcycle manuals by other brands

MV Agusta

MV Agusta Brutale 675 Workshop manual

APRILIA

APRILIA RSV MILLE - PART 1 1999 User manual content

Royal Enfield

Royal Enfield Himalayan 2018 owner's manual

SSR Motorsports

SSR Motorsports Lazer5 owner's manual

MOTO GUZZI

MOTO GUZZI 2005 Griso 1100 Use and maintenance book

KTM

KTM 85 SX 19/16 owner's manual